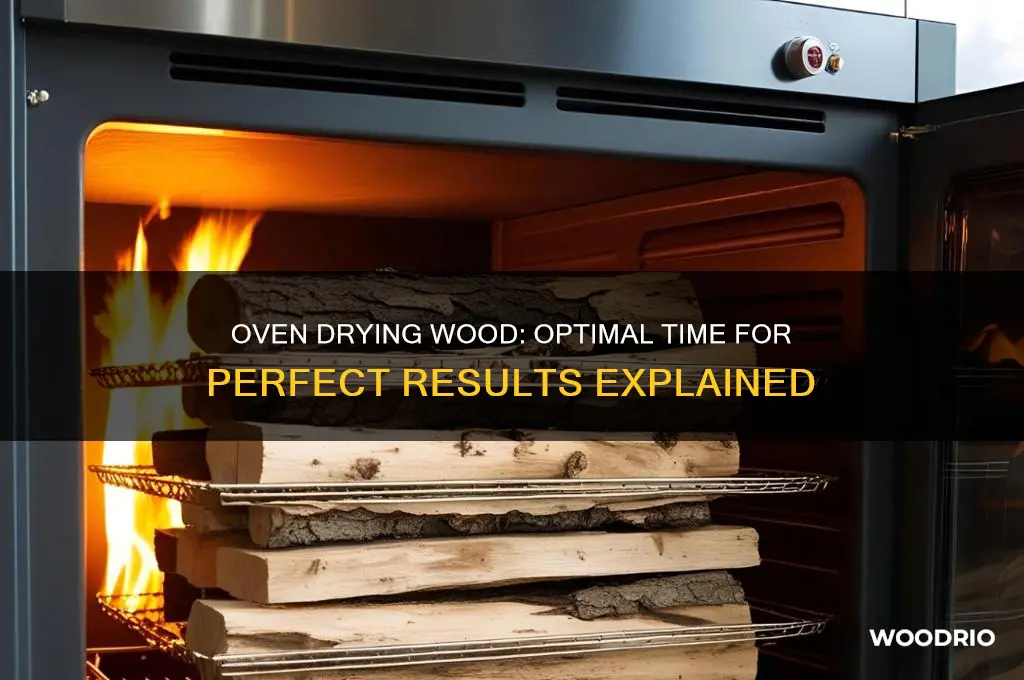

Drying wood in an oven is a method often used by woodworkers and hobbyists to expedite the moisture removal process, which is crucial for projects requiring stable, dimensionally consistent wood. Typically, this technique involves setting the oven to a low temperature, around 170°F to 200°F (77°C to 93°C), and placing the wood inside for several hours, depending on its thickness and initial moisture content. Thinner pieces may dry in as little as 2 to 4 hours, while thicker sections could take 6 to 8 hours or more. However, this method requires careful monitoring to avoid overheating, which can cause the wood to crack, warp, or even ignite. It’s also essential to ensure proper ventilation and use oven-safe materials to prevent damage to the appliance. While oven-drying is faster than air-drying, it’s best suited for small pieces and should be approached with caution to achieve optimal results.

| Characteristics | Values |

|---|---|

| Optimal Oven Temperature | 150°F to 200°F (65°C to 93°C) |

| Drying Time per 1/4 inch Thickness | 1 hour (e.g., 1-inch thick wood = 4 hours) |

| Preparation Required | Wood should be cut to size and lightly sanded before drying |

| Moisture Content Reduction | Reduces moisture from 20-30% to 8-12% |

| Wood Type Suitability | Best for small pieces like craft wood, not large lumber |

| Oven Type | Conventional oven (avoid convection ovens for uneven drying) |

| Safety Precautions | Monitor closely to prevent fire; ensure proper ventilation |

| Post-Drying Cooling | Allow wood to cool in the oven for 1-2 hours before removing |

| Maximum Wood Thickness | Up to 2 inches (thicker pieces may require longer drying times) |

| Energy Efficiency | Not energy-efficient for large quantities; best for small projects |

| Alternative Methods | Air drying or kiln drying recommended for larger/commercial projects |

Explore related products

What You'll Learn

- Optimal Oven Temperature: Ideal heat settings for drying wood efficiently without causing damage

- Wood Thickness Impact: How thickness affects drying time in an oven

- Safety Precautions: Essential steps to prevent fire or oven damage during drying

- Drying Time Estimates: General timeframes for different wood types and sizes

- Post-Drying Treatment: Proper handling and storage after oven drying

Optimal Oven Temperature: Ideal heat settings for drying wood efficiently without causing damage

Drying wood in an oven requires precision to balance efficiency and preservation. The optimal temperature range falls between 140°F and 160°F (60°C and 71°C). At this level, moisture evaporates steadily without causing internal stress or surface cracking. Higher temperatures, such as 200°F (93°C) or above, accelerate drying but risk scorching or warping the wood, particularly in thinner pieces. Lower temperatures, below 120°F (49°C), may not provide enough energy to effectively drive out moisture, prolonging the process unnecessarily. This range ensures the wood dries uniformly while retaining its structural integrity.

To implement this method, preheat the oven to 150°F (65°C) and place the wood on a wire rack to allow air circulation. Avoid overcrowding the oven, as this restricts airflow and leads to uneven drying. For thicker pieces, such as 1-inch planks, plan for 3 to 4 hours of drying time, checking every hour after the first two hours. Thinner pieces, like ¼-inch slices, may dry in 1 to 2 hours. Always monitor the wood closely, as oven temperatures can vary, and adjustments may be necessary to prevent overheating.

A comparative analysis reveals why this temperature range outperforms alternatives. While air-drying is gentler, it can take weeks or months, making it impractical for small projects. Kiln drying, though faster, often exceeds 180°F (82°C), which can compromise the wood’s natural properties. The oven method at 140°F to 160°F strikes a balance, offering speed without the risks associated with higher heat. It’s particularly useful for hobbyists or small-scale projects where precision and time efficiency are critical.

Practical tips enhance the process further. First, ensure the wood is properly prepared by cutting it to the desired size and sanding rough edges before drying. Second, lightly mist the wood with water if it’s already partially dried to prevent it from becoming too brittle in the oven. Finally, after drying, let the wood cool gradually in the oven with the door ajar to minimize shock. This method, when executed with care, yields wood that’s ready for carving, turning, or crafting without the long wait of traditional drying methods.

Discovering the World's Longest Wooden Footbridge: A Marvel of Engineering

You may want to see also

Explore related products

Wood Thickness Impact: How thickness affects drying time in an oven

The thickness of wood is a critical factor in determining how long it will take to dry in an oven. Thinner pieces, such as 1/4-inch slices, can dry in as little as 2 to 4 hours at a low temperature (150°F to 200°F). In contrast, thicker pieces, like 1-inch boards, may require 8 to 12 hours or more under the same conditions. This disparity arises because moisture must travel a greater distance to escape from thicker wood, slowing the drying process. Understanding this relationship allows for better planning and energy efficiency when drying wood in an oven.

To illustrate, consider a comparative experiment: two pieces of the same wood species, one 1/2-inch thick and the other 1-inch thick, are placed in an oven at 170°F. The thinner piece reaches a moisture content of 10% (ideal for most woodworking) in approximately 4 hours, while the thicker piece takes nearly double the time, around 7 to 8 hours. This example highlights the exponential increase in drying time with thickness, emphasizing the need to adjust oven duration based on wood dimensions.

When drying wood in an oven, it’s essential to monitor progress to avoid overheating or cracking. For thicker pieces, a gradual approach is recommended: start at a lower temperature (150°F) for the first few hours, then increase to 180°F to expedite moisture removal without causing stress. Thinner pieces can typically handle a consistent 170°F to 200°F throughout the process. Always use a moisture meter to check progress, aiming for 8% to 12% moisture content for most applications.

A practical tip for managing thickness variations is to cut thicker wood into more uniform pieces before drying. For example, a 2-inch slab can be split into 1-inch boards, reducing drying time from 24+ hours to 8–12 hours. Alternatively, stacking thinner pieces together in the oven can optimize space and energy use, provided adequate airflow is maintained between them. This approach balances efficiency with the need for thorough drying.

In conclusion, wood thickness directly influences oven drying time, with thicker pieces requiring significantly more time and careful temperature management. By understanding this relationship and applying practical strategies, such as adjusting temperature, monitoring moisture levels, and preprocessing thicker wood, you can achieve consistent and efficient drying results. This knowledge not only saves time and energy but also ensures the wood’s structural integrity for future use.

Wood Hardener Drying Time: Quick Guide to Curing Process

You may want to see also

Explore related products

Safety Precautions: Essential steps to prevent fire or oven damage during drying

Drying wood in an oven can be an efficient method, but it demands meticulous attention to safety to prevent fire hazards and oven damage. The process involves high temperatures and flammable materials, making it a delicate balance between utility and risk. Understanding the essential precautions is not just recommended—it’s critical.

Step-by-Step Safety Measures:

- Pre-Dry Wood Selection: Choose only small, thin pieces of wood (e.g., slices or shavings) and ensure they are free from moisture, sap, or resin. Thick or resinous woods like pine or cedar are high-risk and should be avoided.

- Oven Preparation: Remove all flammable items, such as oven liners or food residue. Set the oven to its lowest temperature (140°F to 170°F) to minimize ignition risk.

- Ventilation and Monitoring: Crack the oven door slightly to allow moisture to escape and prevent steam buildup. Stay within sight of the oven at all times—unattended drying is a recipe for disaster.

Critical Cautions:

Avoid exceeding 200°F, as higher temperatures dramatically increase fire risk. Never use a gas oven for this purpose, as the open flame poses an immediate danger. If smoke or a burning smell occurs, turn off the oven immediately and allow it to cool before investigating.

Comparative Insight:

While air-drying wood is safer, oven drying offers speed—but at a cost. The controlled environment of a kiln is ideal, but for home use, the oven method requires constant vigilance. Think of it as a high-stakes trade-off: time saved versus heightened risk.

Practical Tips for Success:

Place wood on a wire rack to ensure even drying and air circulation. Limit drying sessions to 1–2 hours, checking every 30 minutes. For thicker pieces, consider pre-drying outdoors before oven use. Always prioritize safety over expediency—a damaged oven or fire hazard is never worth the shortcut.

By adhering to these precautions, you can mitigate risks while achieving the desired results. Remember, the goal is not just to dry wood but to do so without compromising safety or equipment integrity.

Stardew Valley Hardwood Respawn Time: How Long to Wait?

You may want to see also

Explore related products

Drying Time Estimates: General timeframes for different wood types and sizes

Wood density plays a critical role in determining drying time in an oven. Hardwoods like oak or maple, with their tighter grain structure, take significantly longer to dry than softwoods like pine or cedar. For instance, a 1-inch thick piece of oak might require 8–12 hours at 140°F (60°C), while a similarly sized piece of pine could dry in 4–6 hours under the same conditions. This disparity highlights the importance of understanding wood type before setting your timer.

Thickness is another decisive factor. A general rule of thumb is to allow 1 hour of drying time per inch of wood thickness at 140°F (60°F). For example, a 2-inch thick walnut board would need approximately 2 hours, while a 0.5-inch balsa wood piece could be ready in just 30 minutes. However, this is a rough estimate—moisture content, oven consistency, and airflow all influence the actual drying duration.

Moisture content at the start of the process can dramatically alter drying times. Freshly cut "green" wood with 50–100% moisture content will take far longer than air-dried wood with 20–30% moisture. For green wood, pre-drying methods like air drying for several weeks can reduce oven time by half. A moisture meter is a valuable tool here, helping you monitor progress and avoid over-drying, which can lead to cracking or warping.

While time estimates provide a starting point, monitoring the wood’s condition is crucial. Look for signs of dryness such as a lighter color, a matte surface, and a hollow sound when tapped. If the wood feels cool to the touch or shows signs of moisture (e.g., condensation on the oven walls), extend the drying time in 30-minute increments. Always err on the side of caution—underdried wood can lead to mold or structural issues, while overdrying risks damage.

Finally, consider the oven’s limitations. Household ovens often lack consistent airflow and temperature control, making them less ideal for larger or thicker pieces. For projects requiring precision, a dedicated kiln or dehydrator may be more effective. However, for small-scale tasks like drying craft wood or stabilizing small carvings, an oven can suffice with careful monitoring and adherence to these timeframes. Always prioritize safety by ensuring proper ventilation and avoiding flammable finishes or treatments.

Curing Acrylic Paint on Wood Frames: Time and Tips for Durability

You may want to see also

Explore related products

Post-Drying Treatment: Proper handling and storage after oven drying

Once wood is oven-dried, its post-drying treatment is critical to preserving its integrity and preventing moisture reabsorption. Immediate handling is key: allow the wood to cool gradually in a controlled environment, avoiding sudden temperature changes that can cause warping or cracking. Place the wood on a flat, dry surface, ensuring adequate air circulation around each piece. Rushing this step by stacking or moving the wood too soon can negate the benefits of oven drying.

Storage conditions play a pivotal role in maintaining the wood’s dryness. Opt for a climate-controlled space with humidity levels below 50%—ideally between 40–45%. If such an environment isn’t available, use silica gel packets or a dehumidifier to manage moisture. Store the wood horizontally on stickers (small strips of wood) to promote airflow and prevent moisture accumulation. Avoid basements or garages prone to humidity fluctuations unless sealed containers are used.

For long-term storage, consider sealing the wood in airtight containers or wrapping it in breathable materials like burlap or paper. Plastic wrap can trap moisture if the wood isn’t completely dry, leading to mold or mildew. Label containers with the wood type, drying date, and moisture content for future reference. This practice ensures consistency in woodworking projects and helps track the wood’s condition over time.

Inspect stored wood periodically for signs of moisture absorption or damage. If humidity levels rise, re-dry the wood in the oven at a low temperature (140–160°F) for 2–3 hours to restore its dryness. Regular monitoring and proactive adjustments are essential, especially in humid climates or during seasonal changes. Proper post-drying care extends the wood’s usability and protects the investment of time and energy spent drying it.

Woodworking Clamps: Optimal Duration for Glued Wood Joints Explained

You may want to see also

Frequently asked questions

Drying wood in an oven typically takes 2-4 hours at a low temperature (180-200°F or 82-93°C), depending on the thickness and moisture content of the wood.

The ideal temperature range for drying wood in an oven is 180-200°F (82-93°C). Higher temperatures can cause the wood to crack or warp.

Drying wood in an oven is generally safe if done correctly, but prolonged use or high temperatures can potentially damage the oven’s heating elements or interior. Always monitor the process and avoid overheating.