Installing a wood fence is a popular choice for homeowners due to its aesthetic appeal and durability, but the time required for installation can vary significantly based on several factors. On average, a professional crew can complete the installation of a standard wood fence in one to three days for a typical residential property, assuming favorable weather conditions and no unforeseen obstacles. However, DIY installations may take longer, ranging from a few days to a week or more, depending on the installer's experience, the complexity of the terrain, and the size of the area to be fenced. Additional factors such as obtaining permits, preparing the ground, and staining or sealing the wood can also extend the timeline. Proper planning and understanding these variables are essential for setting realistic expectations and ensuring a successful fence installation.

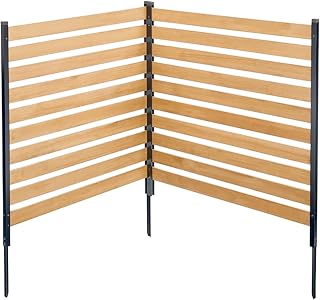

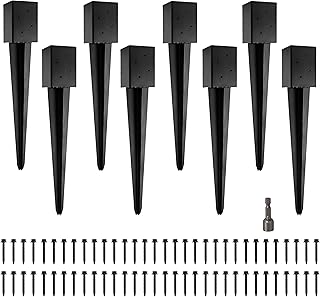

Explore related products

What You'll Learn

Planning and Preparation

Before you swing a hammer, meticulous planning and preparation are the bedrock of a successful wood fence installation. This phase, often overlooked, can significantly impact the project's timeline and overall quality. A well-planned approach not only ensures a smoother installation process but also helps in avoiding costly mistakes and delays.

Assessing the Terrain and Materials

Begin by evaluating your property’s terrain. Sloped or uneven ground may require additional labor and materials, extending installation time by 20–30%. Measure the perimeter accurately, accounting for gates and corners, and calculate the amount of wood, posts, and hardware needed. For instance, a standard 6-foot privacy fence uses approximately 2–3 wooden boards per linear foot. Factor in a 10% buffer for waste or errors. Research local building codes and HOA regulations early to avoid last-minute redesigns, which can add weeks to your timeline.

Securing Permits and Utilities

One of the most time-consuming aspects of preparation is obtaining necessary permits. Depending on your location, this process can take 2–6 weeks. Contact your local municipality to understand permit requirements and fees. Equally critical is calling 811 to have underground utilities marked. Striking a water or gas line not only halts progress but can incur fines and repairs, adding days or even weeks to your project. Schedule these steps at least a month before your intended start date.

Tool and Team Coordination

A well-equipped team can install a wood fence at a rate of 10–20 linear feet per day, depending on complexity. Ensure you have the right tools: post-hole diggers, power augers, levels, and saws. Renting specialized equipment like an auger can save hours of manual labor. If hiring professionals, book them 4–6 weeks in advance, especially during peak seasons like spring and summer. DIYers should allocate 2–3 weekends for a 100-foot fence, factoring in weather delays and learning curves.

Material Acclimation and Layout

Wood expands and contracts with moisture, so store materials on-site for 2–3 days before installation to acclimate to local humidity. Pre-staining or sealing boards can add a day but saves future maintenance. Mark the fence line with string and stakes, ensuring alignment with property boundaries. Use a laser level for precision, especially on slopes. This step, though detail-oriented, prevents costly realignment later and ensures a professional finish.

By investing time in planning and preparation, you set the stage for a streamlined installation. While this phase may extend the overall timeline by 2–4 weeks, it mitigates risks, reduces stress, and ensures a durable, aesthetically pleasing fence. Think of it as laying the foundation for a project that will stand the test of time.

Exploring Muir Woods: Main Trail Length and Hiking Tips

You may want to see also

Explore related products

Gathering Materials and Tools

Before you swing a hammer, success hinges on meticulous preparation. A wood fence installation is a symphony of materials and tools, each playing a critical role. Skipping this step risks delays, frustration, and costly mistakes.

Inventory Essentials: The Backbone of Your Fence

Begin with a precise materials list tailored to your fence’s length, height, and style. For a standard 6-foot privacy fence, plan on 8–12 wood posts per 100 feet, 2–3 rails per section, and enough pickets to cover the span (typically 1 per linear foot). Pressure-treated lumber is non-negotiable for posts to combat rot, while cedar or redwood pickets offer durability with natural beauty. Don’t forget hardware: galvanized nails or screws (3-inch for framing, 1.5-inch for pickets), post caps, and concrete for setting posts.

Toolkits: Precision Meets Power

Your arsenal should blend manual precision with power efficiency. A post-hole digger or auger (gas-powered for larger projects) is indispensable for digging holes. A string line and stakes ensure straight lines, while a level guarantees plumb posts. For cutting, a circular saw with a carbide blade or a miter saw streamlines lumber adjustments. Add a rubber mallet for aligning components, a drill for pilot holes, and safety gear—gloves, eye protection, and earpliers when using power tools.

Pro Tip: The Pre-Game Strategy

Order materials with a 10–15% buffer for cuts and mistakes. Schedule deliveries 2–3 days before starting to acclimate wood and avoid delays. Rent specialized tools like augers or cement mixers if buying isn’t feasible. Lay out all components in a staging area to verify quantities and organize workflow.

Cautionary Notes: Avoid Common Pitfalls

Skipping pressure-treated posts for cost savings invites premature decay. Underestimating concrete needs (typically 40–60 lbs per post) weakens foundations. Using rust-prone fasteners accelerates deterioration. Always check local codes for post depth and permit requirements—non-compliance can halt progress mid-project.

Time-Saving Takeaway

Curing Green Wood Spoon Carvings: Timeframe and Best Practices

You may want to see also

Explore related products

$26.99 $30.99

$28.99 $34.63

Setting Fence Posts

Digging holes for the posts is labor-intensive and time-consuming. Each hole should be 2–3 feet deep (or one-third the post’s height) and 3 times the post’s width to accommodate gravel and concrete. For a 4x4 post, this means a 12-inch diameter hole. Using a post-hole digger or power auger speeds up the process, but rocky soil or tree roots can slow progress significantly. Expect to spend 2–4 hours digging holes for a 100-foot fence, depending on soil conditions and tools used.

Pouring concrete is a step that requires careful execution but offers long-term benefits. Start by adding 6 inches of gravel to each hole for drainage, then position the post and brace it plumb. Mix concrete according to package instructions (typically 1 bag per post) and fill the hole to 6 inches below ground level. This ensures proper curing and prevents water pooling. Concrete takes 24–48 hours to set fully, so plan to leave braces in place during this time. Rushing this step risks post misalignment, which can compromise the entire fence.

While setting posts is foundational, it’s also where DIYers often encounter delays. Common mistakes include inadequate hole depth, improper bracing, or uneven spacing. To avoid setbacks, pre-measure and mark post locations with spray paint, and use a level to check alignment before concrete sets. For larger projects, consider renting a two-person auger or hiring help to expedite digging. With proper planning and technique, setting posts for a 100-foot fence can be completed in 6–8 hours, excluding curing time.

Ultimately, setting fence posts is a blend of physical labor and strategic planning. It’s the backbone of your fence’s durability, so invest time upfront to ensure accuracy. While it may seem tedious, the payoff is a sturdy, long-lasting structure that withstands weather and wear. Patience in this phase saves future repairs, making it a cornerstone of successful fence installation.

Teak Wood Durability: How Long Does It Truly Last?

You may want to see also

Explore related products

Attaching Wood Panels

A comparative analysis reveals that attaching panels with screws is more time-consuming than using nails but offers superior strength and stability. Nails can be quicker, especially with pneumatic nail guns, but they may loosen over time due to wood expansion and contraction. For a 100-foot fence with 10 panels, screwing each panel could add 10-20 hours to the project, while nailing might save 5-10 hours. However, the trade-off in durability often justifies the extra time. Additionally, pre-assembled panels can streamline this process, reducing installation time by up to 30%, though they may cost more upfront.

Persuasively, investing time in proper panel attachment pays dividends in the long run. A well-attached panel withstands wind, rain, and temperature fluctuations better, reducing maintenance needs. For instance, using a construction adhesive along with screws can further enhance panel stability, adding minimal time (10-15 minutes per panel) but significantly improving resilience. This step is particularly crucial in regions prone to severe weather, where a poorly attached panel could become a hazard.

Descriptively, the process involves positioning the panel against the posts, securing it temporarily with clamps, and then fastening it permanently. Start at the bottom rail, ensuring the panel is flush with the ground or desired height. Work upward, attaching to each rail and post. For fences over 6 feet tall, consider adding diagonal braces for added support. A practical tip: mark panel positions on the posts beforehand to avoid misalignment. This methodical approach ensures each panel is securely attached, contributing to a professional finish.

In conclusion, attaching wood panels demands attention to detail but is manageable with the right tools and techniques. Whether prioritizing speed or durability, the choice of fasteners and methods significantly impacts the outcome. By balancing efficiency with precision, homeowners can achieve a sturdy, attractive fence that stands the test of time.

Charring Wood: Enhancing Durability and Longevity Through Ancient Techniques

You may want to see also

Explore related products

$99.98 $109.98

Finishing and Cleanup

The final stretch of installing a wood fence is where attention to detail separates a professional finish from a makeshift job. After the posts are set and the panels secured, the focus shifts to finishing touches and cleanup, which can take anywhere from 2 to 6 hours, depending on the fence’s length and your meticulousness. This phase isn’t just about aesthetics; it’s about longevity and functionality.

Steps to Perfect Finishing:

- Sand Rough Edges: Use 120-grit sandpaper to smooth any splinters or rough cuts on the wood. Focus on corners, post tops, and gate edges where contact is frequent.

- Apply Stain or Sealant: Choose a wood stain or sealant with UV protection and water resistance. Apply in thin, even coats using a brush or sprayer. Allow 2–4 hours for drying between coats, depending on humidity. For a 100-foot fence, plan for 1–2 gallons of product.

- Inspect Hardware: Tighten all screws, hinges, and latches. Replace any bent or rusted components. Lubricate gate hinges with silicone spray for smooth operation.

Cleanup: Efficiency Meets Safety

Begin by removing excess soil or concrete around posts with a shovel or trowel. Dispose of debris in designated yard waste bags. Sweep or blow sawdust and wood shavings from the area, then rinse the fence with a garden hose to remove dust before staining. For stubborn stains, use a mild detergent solution. Store leftover materials properly—seal paint cans, and keep hardware in a dry container for future repairs.

Comparative Insight: DIY vs. Pro Cleanup

Professionals often use power tools like orbital sanders and airless sprayers to expedite finishing, reducing time by 50%. DIYers, however, can achieve similar results with patience and elbow grease. The key difference lies in post-installation cleanup: pros typically include debris removal in their service, while homeowners must allocate extra time for hauling and disposal.

Takeaway: The Devil’s in the Details

How Long Does Wood Filler Take to Dry? A Quick Guide

You may want to see also

Frequently asked questions

The installation time for a wood fence varies, but it typically takes 1 to 3 days for a standard 150-200 linear foot fence, depending on the complexity and crew size.

Factors include the length of the fence, terrain difficulty, weather conditions, permit requirements, and whether additional features like gates or post caps are included.

DIY installation can take 2 to 5 days for a beginner, depending on the fence size and your skill level. Professional installation is often faster and more efficient.

The type of wood (e.g., cedar, pine) doesn’t significantly affect installation time, but pre-treated or specialty woods may require additional handling or care.

Ground preparation, including marking the area, digging post holes, and setting posts, can take 1 to 2 days, depending on soil conditions and the number of posts needed.