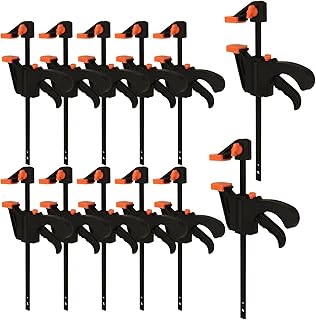

Steam bending wood is a traditional woodworking technique that allows for the creation of curved or shaped pieces by softening the wood fibers with steam and then bending them to the desired form. Once the wood is bent, it must be clamped securely in place to maintain its new shape as it dries and sets. The duration for which the wood needs to remain clamped depends on several factors, including the wood species, thickness, moisture content, and the complexity of the bend. Generally, hardwoods require longer clamping times, often ranging from 24 to 48 hours, while softer woods may only need 12 to 24 hours. Additionally, thicker pieces or tighter bends may necessitate extended clamping periods to ensure the wood retains its shape without springing back. Proper clamping pressure and environmental conditions, such as humidity and temperature, also play a crucial role in achieving a successful bend. Always allow ample time for the wood to stabilize fully before removing the clamps to ensure the bend holds permanently.

| Characteristics | Values |

|---|---|

| Clamping Time for Steam Bent Wood | Varies based on wood species, thickness, and moisture content |

| General Rule | 1 hour per 1/4 inch (6 mm) of wood thickness |

| Minimum Clamping Time | 30 minutes for thin pieces (e.g., 1/8 inch or 3 mm) |

| Maximum Clamping Time | 24 hours or longer for thick pieces (e.g., 1 inch or 25 mm) |

| Wood Species Influence | Hardwoods (e.g., oak, maple) require longer clamping than softwoods |

| Moisture Content | Higher moisture content may require extended clamping time |

| Temperature Consideration | Cooler environments may necessitate longer clamping |

| Humidity Factor | Higher humidity can reduce drying time, shortening clamping duration |

| Form Complexity | Complex bends may require additional clamping time |

| Post-Clamping Drying | Allow wood to air dry completely before use (24–48 hours typically) |

| Safety Precaution | Avoid removing clamps prematurely to prevent spring-back or warping |

Explore related products

What You'll Learn

- Clamp Time Factors: Wood type, moisture, bend severity, and thickness affect required clamp duration

- Checking for Set: Test wood flexibility periodically to ensure it holds shape

- Drying Time: Allow wood to fully dry under clamps for lasting bend retention

- Over-Clamping Risks: Too much pressure or time can crush or warp the wood

- Accelerated Drying: Use heat or fans cautiously to reduce clamp time, monitor closely

Clamp Time Factors: Wood type, moisture, bend severity, and thickness affect required clamp duration

Steam bending wood is an art that hinges on precision, particularly when determining how long to keep the material clamped. The required clamp time isn’t arbitrary—it’s dictated by four critical factors: wood type, moisture content, bend severity, and thickness. Each element interacts dynamically, demanding careful consideration to ensure the wood retains its new shape permanently.

Wood type plays a pivotal role in clamp duration. Hardwoods like oak or maple, with their dense fibers, resist bending and require longer clamping times—often 24 to 48 hours—to set properly. Softer woods like pine or cedar, more pliable by nature, may need only 12 to 24 hours. Tropical woods, such as mahogany, fall in between, typically requiring 18 to 36 hours. Always research the specific wood species to avoid under- or over-clamping, which can lead to springback or over-drying.

Moisture content is equally critical. Steam bending relies on raising the wood’s moisture level to 25–30%, making it more flexible. After bending, the wood must dry gradually while clamped to lock in the shape. If the wood is too wet, clamping for 48–72 hours may be necessary to prevent warping. If slightly damp, 24–48 hours suffices. Always monitor humidity levels during clamping, as dry environments accelerate drying, while humid conditions slow it down.

Bend severity directly impacts clamp time. Sharp bends, where the wood is forced into a tight radius, require longer clamping—up to 72 hours—to counteract the internal stress. Gentle curves, by contrast, may only need 12–24 hours. A practical tip: for severe bends, apply even pressure and check for gaps between the wood and the mold periodically, adjusting clamps as needed to maintain contact.

Thickness is the final determinant. Thicker pieces retain moisture longer and take more time to stabilize. A 1-inch thick board may need 48–72 hours, while a ¼-inch strip could be ready in 12–24 hours. Thicker wood also cools more slowly after steaming, so allow it to acclimate to room temperature before clamping to avoid uneven drying.

In practice, these factors often overlap. For instance, a thick piece of oak with a severe bend and high moisture content might require the full 72-hour clamp time. Conversely, a thin cedar strip with a gentle curve and moderate moisture could be clamped for just 12 hours. Always err on the side of caution—it’s better to over-clamp slightly than risk springback. Test small samples first to fine-tune your approach, ensuring each project achieves the desired shape with precision.

The Nutcracker Ballet Duration at Wood Theater: What to Expect

You may want to see also

Explore related products

Checking for Set: Test wood flexibility periodically to ensure it holds shape

Steam bending wood is a delicate balance between applying force and allowing the material to relax into its new shape. While clamping time is crucial, the real test of success lies in whether the wood has truly "set" – retained its bent form without springing back. This is where periodic flexibility testing becomes your secret weapon.

Every wood species and bending scenario is unique. A thin strip of oak might set within hours, while a thick walnut curve could require days. Instead of relying solely on time, adopt a proactive approach: gently test the bend's flexibility at regular intervals. Start after the initial cooling period, typically 30 minutes to an hour after removing the wood from the steam source.

Think of it as a gradual release of tension. Apply gentle pressure along the bend, feeling for any resistance or springiness. If the wood readily returns to its original shape, it hasn't set. Reapply clamps and allow more time. If it holds its form with minimal give, you're on the right track.

This method allows you to catch potential issues early. A bend that seems set initially might gradually lose its shape if not given enough time. By testing periodically, you can adjust clamping pressure or extend the clamping time before the wood has a chance to revert completely.

Remember, patience is key. Rushing the process can lead to cracks or warping. Regular flexibility checks ensure you're giving the wood the time it needs to permanently adopt its new, elegant curve.

Treated Wood Chemicals: Lifespan and Long-Term Environmental Impact Explained

You may want to see also

Explore related products

$18.99 $19.99

$17.99 $24.99

Drying Time: Allow wood to fully dry under clamps for lasting bend retention

Steam bending wood is a craft that marries precision with patience, and the drying phase under clamps is where the magic solidifies. The duration required for wood to fully dry in its bent form varies significantly based on factors like wood species, thickness, humidity, and temperature. Hardwoods like oak or maple, for instance, may take 2–3 days to dry under clamps, while softer woods like pine might only need 1–2 days. Thicker pieces, naturally, demand more time—up to a week or longer—to ensure the moisture content stabilizes without reverting to its original shape.

To maximize bend retention, monitor the wood’s moisture level during drying. A moisture meter is an invaluable tool here; aim for a reading that matches the ambient humidity of your workspace, typically around 8–12% moisture content. If the wood feels cool to the touch or appears damp, it’s not ready. Rushing this process risks springback, where the wood reverts partially or fully to its pre-bent state, undoing hours of work.

Environmental control is equally critical. Drying wood in a warm, dry space accelerates the process, but avoid direct heat sources like heaters or sunlight, which can cause uneven drying and warping. A well-ventilated area with consistent airflow is ideal. For larger or more complex bends, consider adding weights or additional clamps to counteract internal stresses as the wood dries, ensuring the bend remains uniform.

Finally, patience is the craftsman’s greatest ally. While it’s tempting to remove clamps early to inspect the bend, premature release can lead to irreversible defects. Think of clamping time as an investment in longevity—the longer you allow the wood to dry undisturbed, the more stable and durable the bend will be. When in doubt, err on the side of caution and add an extra day or two to your drying timeline. The reward is a piece that retains its shape for years, a testament to both the wood’s flexibility and your disciplined approach.

Exploring Winton Woods Trail: Length, Highlights, and Hiking Tips

You may want to see also

Explore related products

$49.99 $69.99

Over-Clamping Risks: Too much pressure or time can crush or warp the wood

Steam bending wood is a delicate balance of art and science, where precision in clamping pressure and duration is critical. Applying too much force or leaving the wood clamped for an excessive period can lead to irreversible damage. The fibers in steam-bent wood are already under stress from the bending process, and over-clamping exacerbates this tension, causing the wood to crush or warp. For instance, hardwoods like oak or maple are more prone to crushing under prolonged pressure, while softer woods like pine may warp if clamped too tightly. Understanding the wood’s properties and adjusting clamping techniques accordingly is essential to avoid these risks.

The duration of clamping depends on the wood’s moisture content and thickness, but a general rule is to clamp steam-bent wood for 24 to 48 hours. Exceeding this timeframe, especially with high pressure, can lead to permanent deformation. For example, a 1-inch thick piece of walnut might require closer to 36 hours to set properly, but leaving it clamped for 72 hours could result in flattened or distorted areas. To mitigate this, use a moisture meter to ensure the wood is sufficiently dried before removing clamps, and periodically check for signs of over-compression during the clamping process.

Pressure distribution is another critical factor in preventing over-clamping risks. Uneven clamping can create localized stress points, leading to warping or splitting. Use cauls or padded clamps to distribute pressure evenly across the wood’s surface. For curved bends, consider using flexible clamping strips to maintain consistent contact without overloading specific areas. A practical tip is to start with moderate pressure and gradually increase it over the first few hours, allowing the wood to adjust without sudden stress.

Comparing over-clamping to under-clamping highlights the importance of finding the right balance. While under-clamping may result in springback, over-clamping destroys the wood’s integrity. Think of it as seasoning a dish—too little salt leaves it bland, but too much ruins it entirely. Similarly, clamping steam-bent wood requires careful monitoring to achieve the desired shape without compromising its structure. Regularly inspect the wood for signs of distress, such as visible indentations or uneven drying, and adjust the clamps as needed.

Instructively, here’s a step-by-step approach to avoid over-clamping: First, pre-bend the wood slightly beyond the desired angle to account for springback. Second, apply clamps gradually, starting with light pressure and increasing it incrementally. Third, monitor the wood’s moisture content and adjust clamping time based on its thickness and species. Finally, remove clamps only when the wood is fully dried and stable, typically after 24 to 48 hours. By following these steps, you can preserve the wood’s shape and strength while minimizing the risks of over-clamping.

Understanding Wood Joist Span Lengths for Safe and Effective Construction

You may want to see also

Explore related products

Accelerated Drying: Use heat or fans cautiously to reduce clamp time, monitor closely

Steam-bent wood traditionally requires extended clamping times—often 24 to 48 hours—to ensure the fibers set in their new shape. However, accelerated drying techniques can significantly reduce this timeframe, provided they are applied with precision. Heat and fans are the primary tools for this approach, but their misuse can lead to warping, cracking, or incomplete setting. The key lies in balancing speed with control, ensuring the wood dries uniformly without compromising structural integrity.

Steps to Accelerate Drying:

- Apply Heat Gradually: Use a heat source such as a heat lamp or low-temperature oven (100–120°F) to raise the wood’s temperature. Avoid direct contact with the wood to prevent scorching.

- Introduce Airflow: Position fans to circulate air around the clamped piece, focusing on maintaining consistent airflow rather than high velocity.

- Monitor Moisture Levels: Use a moisture meter to track the wood’s moisture content, aiming for a reduction of 1–2% per hour. Stop acceleration once the wood reaches 12–15% moisture content.

Cautions:

Overheating can cause the wood to dry too quickly, leading to internal stresses and cracks. Similarly, excessive airflow may unevenly dry the surface, creating tension between the outer and inner layers. Always prioritize gradual changes over rapid interventions. For delicate or thin pieces, reduce heat and airflow to half the recommended intensity to avoid damage.

Practical Tips:

- Wrap the wood in a damp cloth before applying heat to slow moisture loss and prevent surface checking.

- Rotate the piece periodically to ensure even drying, especially when using directional heat sources.

- Test the technique on scrap wood first to calibrate your setup and understand its effects.

By carefully integrating heat and airflow, clamp time can be reduced by 30–50%, making accelerated drying a valuable technique for time-sensitive projects. However, success hinges on vigilance and adaptability, as each wood species and project demands unique adjustments.

Chopping Wood: Time Estimates for Efficient Firewood Preparation

You may want to see also

Frequently asked questions

Steam bent wood should typically be left clamped for at least 24 to 48 hours to ensure it fully dries and sets in the desired shape.

Yes, denser hardwoods like oak or maple may require longer clamping times (up to 72 hours), while softer woods like pine may only need 24 hours.

It’s best to wait the full recommended time (24-48 hours) to ensure the wood is fully stabilized, even if it feels dry to the touch.

If clamps are removed too soon, the wood may spring back or lose its shape as it continues to dry and adjust to its new form.

No, additional heat or moisture is not necessary. Allow the wood to air dry naturally while clamped to maintain the bent shape.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)