Transforming trees into wood planks is a multi-step process that varies in duration depending on factors such as tree species, desired plank quality, and the methods used. Typically, the process begins with felling the tree, followed by debarking and cutting the logs into rough dimensions. These logs are then air-dried or kiln-dried to reduce moisture content, which can take weeks to months, depending on the method and wood type. Once dried, the logs are milled into planks using sawmills, a step that can be completed relatively quickly. Finally, the planks may undergo additional processes like planing or sanding to achieve a smooth finish. Overall, the entire process can range from a few weeks to several months, with drying being the most time-consuming stage.

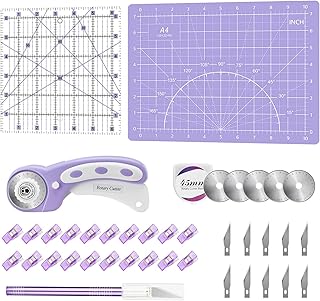

Explore related products

What You'll Learn

- Tree Selection and Felling: Choosing suitable trees, cutting them down safely, and preparing for milling

- Log Preparation: Debarking, cutting logs to length, and storing them for seasoning

- Seasoning Wood: Air-drying or kiln-drying logs to reduce moisture content for stability

- Milling Process: Using sawmills or tools to cut logs into rough planks

- Finishing Planks: Planing, sanding, and smoothing planks for final use or storage

Tree Selection and Felling: Choosing suitable trees, cutting them down safely, and preparing for milling

The journey from tree to plank begins long before the sawmill whirs to life. It starts with a discerning eye in the forest, selecting the right tree for the job. Not all trees are created equal when it comes to lumber. Species, age, and health are critical factors. Hardwoods like oak and maple, prized for their strength and durability, require decades of growth, often 40-60 years, before they reach optimal milling size. Softwoods like pine, used for framing and construction, mature faster, typically within 20-30 years. A seasoned forester can assess a tree’s suitability by examining its straightness, diameter, and absence of defects like rot or excessive branching.

Felling a tree is both art and science, demanding precision and safety. The process begins with planning the fall direction, clearing the area, and using proper tools. A chainsaw with a sharp, well-maintained blade is essential, as dull equipment increases the risk of kickback and uneven cuts. The first cut, the notch, is made on the side facing the intended fall direction, typically at a 60-degree angle. The second cut, the felling cut, is made on the opposite side, stopping just before the notch to create a hinge. This controlled technique ensures the tree falls predictably, minimizing damage to the trunk and surrounding area.

Safety is paramount during felling. Personal protective equipment—helmet, eye protection, ear protection, and chainsaw chaps—is non-negotiable. Never work alone; a spotter can monitor for hazards and assist in emergencies. Be mindful of wind direction and speed, as gusts can alter a tree’s fall path. Additionally, inspect the tree for tension wood or lean, which can cause unpredictable movement. If in doubt, consult a professional arborist or logger.

Once the tree is down, preparation for milling begins. Limbing, the removal of branches, is the first step, streamlining the log for transport and processing. Logs should be cut to lengths suitable for the sawmill, typically 8-16 feet, depending on the equipment and desired plank size. Storing logs properly is crucial; stacking them off the ground and covering them with tarps prevents moisture absorption and insect infestation. For optimal results, logs should be milled within a year of felling to avoid warping or cracking.

The time from tree selection to milling-ready logs varies widely, influenced by factors like tree size, equipment availability, and weather conditions. On average, the process takes 1-3 days for a single tree, including felling, limbing, and preparation. However, this is just the first phase in a much longer journey. From forest to finished plank, the entire process can span weeks or even months, depending on drying and curing times. Yet, the care taken in these initial steps ensures the final product is strong, stable, and ready for use.

Woodley Park to Bethesda Metro Ride Time: Quick Guide

You may want to see also

Explore related products

Log Preparation: Debarking, cutting logs to length, and storing them for seasoning

The journey from tree to plank begins long before the sawmill. Log preparation is a critical, often overlooked phase that directly impacts the quality and longevity of the final wood product. Debarking, cutting logs to length, and proper seasoning are not mere preliminaries—they are essential steps that determine whether the wood will warp, crack, or resist the test of time.

Debarking is the first step in this process, and its importance cannot be overstated. Bark acts as a protective layer for the tree, but it becomes a liability in lumber production. Bark traps moisture, which can lead to fungal growth and insect infestations during storage. Moreover, bark can cause staining and reduce the efficiency of sawing. Mechanical debarkers, which use blunt knives or friction to remove the bark, are commonly employed in commercial operations. For smaller-scale projects, manual debarking with tools like drawknives or bark spuds can be effective, though more labor-intensive. The goal is to remove the bark without damaging the underlying sapwood, ensuring the log remains structurally sound.

Once debarked, logs must be cut to the desired length, a step that requires precision and foresight. The length of the log determines the size of the planks that can be milled from it, so careful planning is essential. For example, if you’re aiming for 8-foot planks, logs should be cut to at least 8 feet 6 inches to account for waste during milling. Chainsaws or portable sawmills are typically used for this task, with accuracy being key to maximizing yield. Improperly cut logs can lead to uneven drying, warping, or reduced lumber quality, so investing time in this step pays dividends later.

Seasoning, or drying, is perhaps the most time-consuming yet crucial phase of log preparation. Freshly cut logs contain up to 50% moisture, which must be reduced to 12-15% for stable, usable lumber. Air-drying is the most common method, involving stacking logs in a well-ventilated area with stickers (small pieces of wood) placed between layers to promote airflow. The drying time varies depending on the wood species, log diameter, and climate, but it typically ranges from 6 months to 2 years. For example, softwoods like pine dry faster than hardwoods like oak. Kiln-drying, while faster (taking days to weeks), is more expensive and requires specialized equipment. Properly seasoned wood is lighter, stronger, and less prone to shrinkage or splitting once milled into planks.

In conclusion, log preparation is a meticulous process that demands attention to detail and patience. Debarking, cutting to length, and seasoning are not just steps—they are investments in the quality and durability of the final wood product. Skipping or rushing these stages can lead to subpar lumber, wasted resources, and increased costs. By understanding and respecting these processes, woodworkers and craftsmen can ensure that the planks they produce are not only beautiful but built to last.

Perfect Boston Butt: Wood Pellet Grill Cooking Time Guide

You may want to see also

Explore related products

$386.96

Seasoning Wood: Air-drying or kiln-drying logs to reduce moisture content for stability

Freshly cut timber, often referred to as green wood, contains a significant amount of moisture, typically ranging from 30% to 200% of its dry weight, depending on the species. This moisture must be reduced to 8-12% for most woodworking applications to prevent warping, cracking, and decay. Seasoning wood is the process of removing this excess moisture, and two primary methods dominate: air-drying and kiln-drying. Each method has its advantages, limitations, and ideal use cases, making the choice between them a critical decision in the wood-to-plank transformation.

Air-drying is the traditional, time-honored method of seasoning wood. It involves stacking logs or planks in a well-ventilated area, protected from direct sunlight and rain, and allowing them to dry naturally over time. The process relies on ambient air circulation and temperature fluctuations to gradually reduce moisture content. For softwoods like pine, air-drying can take 6 to 12 months per inch of thickness, while hardwoods such as oak may require 1 to 2 years per inch. Proper stacking is crucial: stickers (small strips of wood) should be placed between layers to promote airflow, and the stack should be elevated to prevent moisture absorption from the ground. While air-drying is cost-effective and environmentally friendly, it is highly dependent on climate conditions and requires ample space.

In contrast, kiln-drying is a faster, more controlled method that uses specialized chambers to regulate temperature, humidity, and airflow. Kiln schedules are tailored to the wood species and thickness, with temperatures typically ranging from 120°F to 180°F (49°C to 82°C). Softwoods can be kiln-dried in 2 to 4 weeks, while hardwoods may take 4 to 8 weeks. This method reduces drying time significantly but requires a substantial investment in equipment and energy. Kiln-dried wood is more consistent in moisture content and less prone to defects, making it ideal for high-quality furniture, flooring, and structural applications. However, improper kiln operation can lead to case-hardening (a hard, dry outer layer with a moist interior) or excessive drying, which weakens the wood.

The choice between air-drying and kiln-drying often boils down to scale, urgency, and budget. Small-scale woodworkers or hobbyists may prefer air-drying for its low cost and simplicity, even if it means waiting months or years for usable planks. Commercial operations, on the other hand, frequently opt for kiln-drying to meet tight production schedules and ensure uniform quality. A hybrid approach, where wood is air-dried to a moderate moisture level and then kiln-finished, can strike a balance between time and expense. Regardless of the method, monitoring moisture content with a reliable moisture meter is essential to determine when the wood is ready for use.

Ultimately, seasoning wood is a delicate balance of patience and precision. Whether through the slow, natural process of air-drying or the rapid, controlled environment of kiln-drying, reducing moisture content is non-negotiable for creating stable, durable wood planks. Each method has its trade-offs, and the best choice depends on the specific needs of the project and the resources available. By understanding these processes, woodworkers can ensure their materials are not only beautiful but also built to last.

Durability of Wood Frame Homes: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Milling Process: Using sawmills or tools to cut logs into rough planks

The milling process transforms raw logs into rough planks, a critical step in woodworking that demands precision and the right tools. Whether using a sawmill or handheld tools, the goal is to maximize yield while minimizing waste. Sawmills, both industrial and portable, offer efficiency and consistency, slicing logs into planks with automated blades. Hand tools, like chainsaws and mills, provide flexibility for smaller operations or remote locations but require more skill and time. The choice of method depends on scale, resources, and desired outcome, but both pathways begin with careful log preparation and end with rough planks ready for further processing.

For those opting for a sawmill, the process starts with debarking and positioning the log on the mill’s bed. Industrial sawmills can process a log into planks in minutes, with some models capable of producing up to 100 board feet per hour. Portable sawmills, while slower, still outperform hand tools, typically yielding 20–50 board feet per hour depending on log size and operator experience. The key advantage of sawmills is their ability to produce uniform thickness and width, essential for structural or furniture-grade lumber. However, they require significant investment and space, making them more suitable for commercial operations.

Hand milling, on the other hand, is accessible and affordable but labor-intensive. Using a chainsaw mill, for instance, involves clamping the log securely and making repeated cuts along its length. This method can take 1–2 hours per log, depending on size and skill level. The result is often rougher planks with more variability in thickness, but this can be desirable for rustic projects or custom work. To improve efficiency, ensure your chainsaw is sharp and use a guide system for straighter cuts. Safety is paramount; always wear protective gear and work with a partner when handling large logs.

Regardless of method, the milling process requires attention to detail. Proper log orientation, such as cutting along the grain to avoid warping, is crucial. Additionally, consider the moisture content of the wood; freshly cut logs (green wood) will shrink as they dry, so plan for this when determining plank dimensions. For best results, allow rough planks to air-dry for 6–12 months before further processing, or use a kiln for faster drying. This step ensures stability and reduces the risk of cracking or twisting in the final product.

In conclusion, the milling process is a blend of art and science, where the right tools and techniques can significantly impact efficiency and quality. Whether using a sawmill for speed and precision or hand tools for flexibility, the goal remains the same: to transform raw logs into usable planks. By understanding the strengths and limitations of each method, woodworkers can choose the approach that best fits their needs, ensuring a steady supply of material for their projects. With practice and patience, even beginners can master this essential step in the journey from tree to timber.

Titebond Wood Glue Clamp Time: How Long Before It's Secure?

You may want to see also

Explore related products

$8.95 $19.75

Finishing Planks: Planing, sanding, and smoothing planks for final use or storage

The final stage of transforming rough-cut planks into usable wood is a meticulous process that demands attention to detail. Planing, sanding, and smoothing are essential steps to ensure the wood is ready for its intended purpose, whether it's for construction, furniture making, or crafting. This finishing process can significantly impact the overall quality and longevity of the wood, making it a critical phase in wood plank production.

The Art of Planing: Achieving Uniformity

Planing is the initial step in refining the surface of a plank. Using a hand plane or a mechanical planer, the goal is to remove imperfections, such as rough spots, splinters, and uneven surfaces. For optimal results, start with a coarse blade angle (around 25-30 degrees) to quickly remove material, then switch to a finer angle (35-40 degrees) for a smoother finish. A well-planed plank should have a consistent thickness and a flat surface, typically achieving a deviation of less than 1/32 inch across its length. This step is crucial for ensuring the wood fits seamlessly in joinery and construction projects.

Sanding: The Key to a Silky Smooth Finish

After planing, sanding takes center stage to refine the surface further. Begin with a coarse-grit sandpaper (80-100 grit) to remove any remaining planer marks and imperfections. Progressively move to finer grits (150, 220, and finally 320 grit) to achieve a smooth, almost glass-like surface. For large planks, a belt sander or orbital sander can save time, but hand sanding with a sanding block ensures precision, especially along edges and corners. Always sand in the direction of the wood grain to avoid scratches and maintain the wood’s natural beauty.

Smoothing for Longevity and Aesthetics

The final smoothing process often involves techniques like scraping or using a cabinet scraper to eliminate any last traces of roughness. For added protection and enhanced appearance, apply a wood conditioner before staining or sealing. This step ensures even absorption of finishes and highlights the wood’s natural grain. When storing planks, ensure they are completely dry and sealed to prevent warping or cracking. Stack them on stickers (small strips of wood) in a well-ventilated area to allow air circulation.

Time Investment: Balancing Speed and Quality

The time required for finishing planks varies depending on the wood species, plank size, and desired finish quality. Planing a single plank can take 10-30 minutes, while sanding may require 20-60 minutes per plank, depending on the grit progression. For a batch of 10 planks, expect to dedicate 5-10 hours for a professional-grade finish. While it’s tempting to rush, investing time in this stage ensures the wood’s durability and aesthetic appeal, ultimately saving time and resources in the long run.

Practical Tips for Efficiency

To streamline the finishing process, organize your workspace with all tools and materials within reach. Use a dust collection system to maintain a clean environment and protect your lungs. For large projects, consider renting industrial-grade planers and sanders to expedite the process. Finally, always test your finishing techniques on a scrap piece of wood to ensure the desired outcome before applying them to your final planks. With patience and precision, the finished planks will not only meet but exceed expectations.

Autoclaving Wood Chips: Optimal Sterilization Time for Effective Results

You may want to see also

Frequently asked questions

The time to cut down a tree and process it into planks varies, but it typically takes 1-3 days for a single tree, depending on the tree size, equipment used, and milling efficiency.

Factors include tree size, wood type, moisture content, milling equipment, and whether the wood needs to dry before planking. Drying alone can take weeks to months.

While cutting and milling can be done quickly, freshly cut wood (green wood) is often too wet for immediate use. It needs to air-dry or kiln-dry, which can take 6 months to 2 years, depending on the method and wood type.