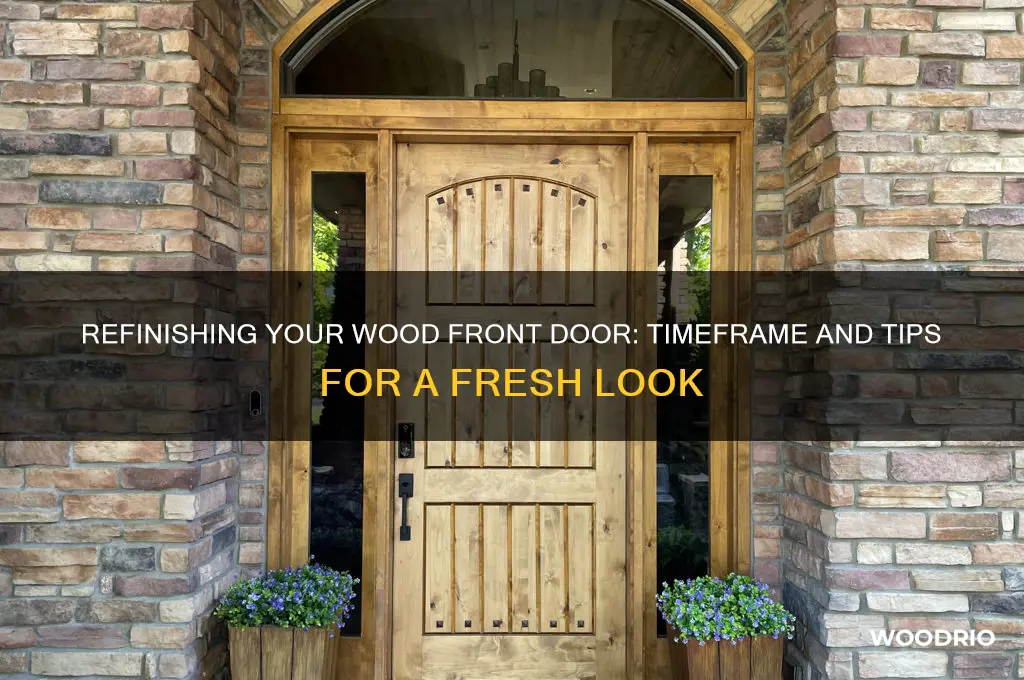

Refinishing a wood front door is a rewarding project that can restore its beauty, protect it from the elements, and extend its lifespan. The time required to complete this task varies depending on factors such as the door's condition, the extent of repairs needed, the type of finish used, and your level of experience. On average, refinishing a wood front door can take anywhere from a weekend to several days. Preparation, including sanding, stripping old paint or varnish, and repairing any damage, typically consumes the most time. Applying new stain or paint and allowing it to dry properly also adds to the timeline. With proper planning and the right tools, you can achieve professional results and give your front door a fresh, polished look.

| Characteristics | Values |

|---|---|

| Average Time to Refinish | 6-8 hours (spread over 2-3 days due to drying times) |

| Preparation Time | 1-2 hours (sanding, cleaning, removing hardware) |

| Sanding Time | 1-2 hours (depends on door condition and sanding method) |

| Staining/Painting Time | 1-2 hours (per coat, 2-3 coats recommended) |

| Drying Time Between Coats | 2-4 hours (varies by product and humidity) |

| Final Drying/Curing Time | 24-48 hours (before reinstalling hardware or using the door) |

| Complexity of Door Design | Adds 1-3 hours (intricate details or panels require more time) |

| Professional vs. DIY | DIY: 6-8 hours total; Professional: 4-6 hours (faster with expertise) |

| Weather Impact | High humidity/cold temps can add 2-4 hours to drying time |

| Stripping Old Finish (if needed) | 1-3 hours (chemical stripper application and removal) |

| Total Project Duration | 2-3 days (including drying and curing time) |

Explore related products

What You'll Learn

Preparation time for sanding and stripping old finishes

The preparation phase for sanding and stripping old finishes from a wood front door is often the most time-consuming step in the refinishing process. On average, this stage can take anywhere from 4 to 12 hours, depending on the door’s size, the condition of the existing finish, and the tools you use. For example, a standard 36-inch wide by 80-inch tall door with multiple layers of peeling paint or varnish will require significantly more effort than one with a single, well-maintained coat. Always factor in drying time for chemical strippers, which can add 30 minutes to 2 hours per application, depending on the product.

Analyzing the tools at your disposal can drastically reduce preparation time. A power sander equipped with 60-grit sandpaper can strip a door in half the time it takes to do it by hand, but it requires careful handling to avoid gouging the wood. Chemical strippers, while effective, demand safety precautions—wear gloves, goggles, and work in a well-ventilated area. For intricate carvings or recessed panels, a detail sander or wire brush may be necessary, adding 1–2 hours to the process. Pro tip: Test a small area first to gauge how the wood responds to your chosen method.

Comparing DIY methods to professional services highlights the trade-off between cost and time. Hiring a pro can cut preparation time to 2–3 hours, as they use industrial-grade tools and techniques. However, this option can cost $200–$500, whereas DIY materials (sandpaper, stripper, brushes) typically run $50–$100. If your door has sentimental value or intricate details, investing time in careful preparation ensures a better finish. Conversely, if time is your primary constraint, outsourcing might be the smarter choice.

Descriptive details matter when planning your timeline. Imagine a door with decades-old paint that cracks like dried mud—this will require multiple rounds of stripping and scraping. Conversely, a door with a single layer of weathered varnish might yield to sanding in just one session. Always inspect the door closely: look for raised grain, deep scratches, or stubborn stains that could complicate the process. Practical tip: Use a putty knife to gently scrape a small section and assess how easily the finish lifts.

Instructively, breaking the preparation into steps can make the task feel less daunting. Start by removing hardware (knobs, knockers, hinges) to avoid damage. Next, apply a chemical stripper in thin, even coats, allowing it to sit until the finish bubbles. Scrape off the softened material with a plastic scraper, then sand the surface smooth with progressively finer grits (80, 120, 220). Finally, wipe the door with a tack cloth to remove dust before proceeding to staining or painting. Caution: Never use steel wool on wood that will be stained, as it can leave rust marks.

Optimal Timing for Sealing Your Wooden Deck: Expert Tips and Advice

You may want to see also

Explore related products

$99.99 $114.21

Drying duration for wood after cleaning and treatment

Wood absorbs moisture differently depending on its density, grain pattern, and existing finish. After cleaning and treatment, softwoods like pine may dry within 24–48 hours under ideal conditions (low humidity, good airflow), while hardwoods like oak or mahogany can take 72 hours or longer. Always test a small area first to gauge drying time, as over-saturation or uneven application can prolong the process.

Steps to Optimize Drying:

- Wipe Excess Moisture: After cleaning or applying treatment, use a lint-free cloth to remove any standing liquid. This prevents warping or raised grain.

- Temperature Control: Aim for a consistent room temperature of 65–75°F (18–24°C). Avoid direct heat sources like radiators or hair dryers, as they can cause cracking.

- Humidity Management: Use a dehumidifier if indoor humidity exceeds 50%. Ideal drying conditions are below 40% humidity.

- Air Circulation: Position a fan to create gentle airflow across the door’s surface, but avoid pointing it directly at one spot to prevent uneven drying.

Cautions to Consider:

- Reapplication Timing: If a second coat of treatment (e.g., stain or sealant) is needed, wait until the first coat is fully dry to the touch and no longer tacky. Rushing this step can lead to bubbling or adhesion issues.

- Environmental Factors: Drying times double or triple in high-humidity climates or during rainy seasons. Plan accordingly, especially for exterior doors.

- Product-Specific Guidelines: Always follow the manufacturer’s drying recommendations for cleaners, stains, or sealants. Some products require 4–6 hours, while others may need 24 hours or more.

Practical Tips for Efficiency:

- Timing Treatments: Schedule cleaning and treatment during dry, mild weather if possible. Early morning or late evening hours often provide optimal conditions.

- Surface Preparation: Lightly sanding the door before treatment can improve absorption and reduce drying time by removing barriers like old finish or dirt.

- Monitoring Progress: Test dryness by pressing a finger gently against the surface. If no indentation remains, the wood is ready for the next step.

Comparative Analysis:

While oil-based treatments penetrate deeper and require longer drying times (up to 72 hours), water-based products dry faster (6–12 hours) but may need multiple coats. Polyurethane sealants typically cure within 24–48 hours but can remain soft for up to a week. Understanding these differences ensures you allocate sufficient time for each stage of refinishing.

Takeaway:

Patience is key when drying wood after cleaning and treatment. Rushing the process risks damaging the door’s integrity or finish. By controlling environmental factors, following product guidelines, and testing for dryness, you can ensure a smooth, durable result that enhances your front door’s appearance and longevity.

Mastering the Flute: Time to Achieve Comfort with Wooden Instruments

You may want to see also

Explore related products

Application and curing time for new stain or paint

The application and curing time for new stain or paint on a wood front door can significantly impact the project's timeline and final appearance. Typically, applying a single coat of stain or paint takes about 30 minutes to an hour, depending on the door's size and the product's viscosity. However, this is just the beginning. Most stains require at least 2-4 hours of drying time between coats, while oil-based paints can take 8-24 hours. Latex paints dry faster, usually within 1-2 hours, but curing—the process of fully hardening—can take up to 30 days for both types. This extended curing period is crucial for durability, especially on a front door exposed to weather and frequent use.

Consider the environmental conditions during application and curing. Ideal temperatures range between 50°F and 85°F (10°C and 29°C) with humidity below 50%. High humidity or cold temperatures can double drying times and lead to uneven finishes. For example, applying stain in 90°F heat with 70% humidity may cause the product to dry too quickly, resulting in lap marks or a blotchy appearance. Conversely, cold temperatures can prevent proper adhesion, leaving the finish susceptible to peeling. Always check the manufacturer’s guidelines for specific product requirements, as some stains or paints may have unique sensitivities.

A common mistake is rushing the process by applying additional coats before the previous one has fully dried. This can lead to bubbling, cracking, or a tacky surface. To avoid this, test the dryness by lightly touching the surface with a finger. If no paint or stain transfers, it’s ready for the next coat. For stains, two coats are usually sufficient, while paint may require 2-3 coats for full coverage. Sanding lightly between coats with 220-grit sandpaper ensures better adhesion and a smoother finish, but allow the dust to settle and wipe the surface clean before proceeding.

For those seeking a professional finish, patience is key. After the final coat, avoid heavy use of the door for at least 48 hours to prevent dents or scratches. If possible, remove the door from its hinges and lay it flat during the drying process to minimize drips and ensure even coverage. Once cured, apply a clear topcoat or sealer to protect the finish from UV rays, moisture, and wear. This additional step adds another 24-48 hours to the project but extends the life of the refinish significantly.

In summary, refinishing a wood front door with stain or paint involves more than just application time. Understanding drying and curing times, environmental factors, and proper techniques ensures a durable and attractive result. Plan for at least 2-3 days for the project, with up to a month for full curing, and always prioritize quality over speed for a finish that stands the test of time.

Wood Conditioner Drying Time: Essential Tips for Perfect Wood Preparation

You may want to see also

Explore related products

Weather conditions impact on refinishing process timeline

Humidity levels dictate drying times for wood refinishing products. Ideal conditions hover between 40-70% relative humidity. Below 40%, solvents evaporate too quickly, leading to uneven absorption and a blotchy finish. Above 70%, drying slows dramatically, extending the curing process by days. For example, a polyurethane coat might dry to the touch in 2 hours at 50% humidity but could take up to 6 hours at 80%.

Temperature extremes disrupt the refinishing timeline. Most wood finishes perform optimally between 65-85°F. Below 50°F, the chemical reactions in stains and sealers slow, causing them to remain tacky or fail to harden completely. Above 90°F, finishes can dry too rapidly, trapping air bubbles or leading to a rough texture. If your front door is exposed to direct sunlight, the surface temperature can spike 10-15°F above ambient air temperature, further accelerating drying and increasing the risk of imperfections.

Direct sunlight and wind act as invisible saboteurs during refinishing. UV rays break down the chemical bonds in finishes, causing discoloration and premature wear. Wind accelerates solvent evaporation, leading to a matte finish instead of the desired satin or gloss. To mitigate these effects, schedule refinishing on a calm, overcast day. If sunlight is unavoidable, work in small sections, keeping the unfinished portions covered with a tarp or cardboard.

Rain and moisture are the arch-nemeses of wood refinishing. Even a light mist can ruin a freshly applied finish, causing it to become cloudy or peel. Check the forecast for at least 48 hours of dry weather before starting. If rain threatens, have a plan to shelter the door immediately. A temporary awning or large tarp can provide protection, but remember that high humidity after rain can still delay curing, adding days to the project timeline.

Seasonal planning can significantly reduce refinishing headaches. Spring and fall offer the most consistent conditions, with moderate temperatures and humidity levels. Avoid summer’s heat and humidity spikes, as well as winter’s cold and unpredictable weather. If refinishing in less-than-ideal seasons, consider using a garage or porch with controlled conditions. For outdoor projects, early morning or late afternoon work sessions take advantage of cooler temperatures and lower UV exposure, helping the finish cure evenly and durably.

Solid Wood Durability: Factors Influencing Collapse Time and Longevity

You may want to see also

Explore related products

$26.99

Tools and techniques to speed up refinishing steps

Refinishing a wood front door can be a time-consuming task, but with the right tools and techniques, you can significantly speed up the process without compromising quality. One of the most effective ways to save time is by using a heat gun instead of a chemical stripper to remove old paint or varnish. A heat gun softens the finish in seconds, allowing you to scrape it off quickly. Pair this with a sharp, carbide-tipped paint scraper for maximum efficiency. This method not only reduces the time spent on stripping but also minimizes the use of harsh chemicals, making it safer and more environmentally friendly.

Another time-saving technique is to invest in a power sander for smoothing the wood surface. Hand sanding is labor-intensive and can take hours, especially for larger doors. A random orbital sander, equipped with 80-grit sandpaper for initial smoothing and 120-grit for finishing, can cut sanding time by more than half. For tight corners and detailed areas, switch to a detail sander or sanding sponges. Always sand in the direction of the wood grain to avoid scratches and ensure a professional finish.

To streamline the staining or painting process, use a paint sprayer instead of brushes or rollers. A handheld HVLP (High Volume Low Pressure) sprayer provides an even coat in a fraction of the time, reducing application time by up to 75%. If you prefer brushing, opt for a high-quality, wide-bristle brush to cover more surface area per stroke. Apply thin, even coats and allow proper drying time between layers to avoid drips and ensure durability. For added efficiency, work in a well-ventilated area with moderate humidity to speed up drying.

Preparation is key to speeding up refinishing steps. Clean the door thoroughly with a degreaser to remove dirt, grease, and grime before starting. Mask off hardware or remove it entirely to avoid unnecessary work. If the door is still in its frame, cover surrounding areas with drop cloths or painter’s tape to protect them from dust and stains. Planning and organizing your workspace can save hours of cleanup and rework, allowing you to focus on the task at hand.

Finally, consider using quick-drying products to accelerate the final stages. Water-based stains and polyurethanes dry faster than oil-based options, often within 2–4 hours, compared to 8–12 hours for traditional finishes. Look for products labeled “fast-drying” or “quick-cure” to minimize downtime between coats. Always follow manufacturer instructions for application and drying times to ensure optimal results. With these tools and techniques, refinishing a wood front door can be completed in as little as a weekend, rather than stretching over several days.

Understanding Face Cord Length: A Comprehensive Guide to Firewood Measurement

You may want to see also

Frequently asked questions

The process usually takes 1-3 days, depending on the door's condition, drying time for products, and weather conditions if done outdoors.

It’s possible for minor touch-ups, but a thorough refinishing, including sanding, staining, and sealing, typically requires at least 24 hours to allow for proper drying between coats.

Yes, humidity and temperature affect drying time. In hot, dry climates, it may dry faster (4-6 hours per coat), while in humid or cold conditions, it can take 8-12 hours or longer.

Refinishing is typically needed every 3-5 years, depending on exposure to weather, sunlight, and wear. Regular maintenance, like cleaning and re-sealing, can extend the time between full refinishes.