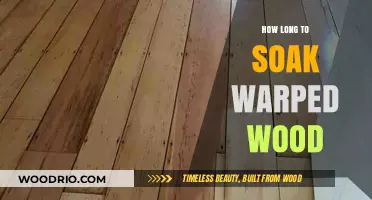

Soaking wood in linseed oil is a popular method for enhancing its natural beauty, durability, and resistance to moisture. The duration of soaking depends on the type of wood, its porosity, and the desired finish. Generally, softwoods like pine may only require a few hours to absorb the oil, while denser hardwoods such as oak or walnut could benefit from soaking for 24 to 48 hours. It’s essential to monitor the process, as over-soaking can lead to a greasy or sticky surface. After soaking, excess oil should be wiped off, and the wood allowed to cure for several days to achieve a smooth, protective finish. Always test a small area first to ensure the desired result.

| Characteristics | Values |

|---|---|

| Recommended Soaking Time | 15–30 minutes for initial coat; 24 hours for deep penetration |

| Type of Linseed Oil | Raw linseed oil (boiled linseed oil dries faster but is less penetrative) |

| Wood Type | Hardwoods (e.g., oak, maple) absorb slower than softwoods (e.g., pine) |

| Temperature | Warmer temperatures (20–25°C / 68–77°F) speed up absorption |

| Humidity | Lower humidity reduces drying time; higher humidity slows it down |

| Number of Coats | 2–3 coats recommended, allowing 24 hours between coats |

| Excess Removal | Wipe off excess oil after 15–30 minutes to prevent sticky surface |

| Drying Time Between Coats | 24 hours for raw linseed oil; 4–6 hours for boiled linseed oil |

| Full Cure Time | 7–14 days for raw linseed oil; 3–5 days for boiled linseed oil |

| Ventilation | Work in a well-ventilated area to avoid fumes |

| Protection Level | Provides moderate water resistance and enhances wood grain |

| Maintenance | Reapply every 1–2 years depending on exposure and wear |

| Environmental Impact | Natural and eco-friendly, but raw linseed oil can be flammable |

| Alternative Oils | Tung oil, Danish oil, or walnut oil for faster drying or different finishes |

Explore related products

What You'll Learn

Optimal Soaking Time for Hardwoods

Hardwoods, with their dense grain structure, demand a more deliberate approach when soaking in linseed oil. Unlike softer woods, which readily absorb oil, hardwoods require a balance between penetration and surface treatment. The optimal soaking time hinges on achieving this equilibrium, ensuring the oil enhances the wood's natural beauty without leaving it greasy or prone to residue.

Generally, hardwoods benefit from a shorter initial soak of 15-30 minutes. This allows the oil to penetrate the surface layer, enriching the color and providing a baseline protection. After this initial soak, wipe off any excess oil with a clean cloth to prevent buildup. For deeper penetration, consider a second application after 24 hours, allowing the wood to fully absorb the oil over a 48-hour period.

The type of linseed oil also plays a crucial role. Raw linseed oil, being slower to dry, is ideal for hardwoods as it gives the wood ample time to absorb the oil. Boiled linseed oil, with its added dryers, can lead to a quicker surface cure but may not penetrate as deeply. For hardwoods, prioritize raw linseed oil and avoid the temptation to accelerate the process with heat, as this can compromise the oil's effectiveness and the wood's integrity.

A practical tip for hardwoods is to test a small, inconspicuous area before treating the entire surface. This allows you to gauge the wood's absorption rate and the desired finish. If the wood feels tacky after 24 hours, it may need more time to absorb the oil. Conversely, if it appears dry, a second application might be necessary. Patience is key; rushing the process can lead to an uneven finish or insufficient protection.

In conclusion, the optimal soaking time for hardwoods in linseed oil is a nuanced process. Start with a 15-30 minute initial soak, followed by a thorough wipe-down. Allow 24-48 hours for full absorption, and consider a second application if needed. Using raw linseed oil and testing a small area beforehand ensures a professional, long-lasting finish that highlights the wood's natural grain and beauty.

Wood Glue Paper Mache Drying Time: A Comprehensive Guide

You may want to see also

Explore related products

Softwood Linseed Oil Absorption Rate

Softwoods, such as pine, cedar, and spruce, are known for their porous and less dense structure compared to hardwoods. This characteristic significantly influences their linseed oil absorption rate, making them ideal candidates for oil treatments but requiring careful consideration of application time. When applying linseed oil to softwoods, the initial absorption is rapid, often within the first 15 to 30 minutes. However, full penetration and curing can take anywhere from 24 to 48 hours, depending on factors like wood moisture content, temperature, and humidity. For optimal results, apply a thin, even coat and allow the wood to absorb the oil completely before adding additional layers.

The absorption rate of linseed oil in softwoods is not uniform across all species. For instance, pine, with its open grain, tends to absorb oil more quickly than cedar, which has natural oils that can slow down the process. To test absorption, apply a small amount of oil to an inconspicuous area and observe how long it takes to dry. If the oil remains tacky after an hour, the wood may be saturated, and further application should be delayed. Conversely, if the oil is fully absorbed within 30 minutes, a second coat can be applied to enhance protection and appearance.

Temperature and humidity play critical roles in the absorption and curing process. In warmer, drier conditions (above 70°F and below 50% humidity), linseed oil will penetrate and cure faster. Conversely, cooler or more humid environments can slow absorption and extend curing time to several days. To expedite the process, ensure the wood is dry before application and consider using boiled linseed oil, which contains metallic dryers that accelerate curing. Avoid applying oil in direct sunlight, as this can cause uneven drying and surface imperfections.

For projects requiring deep penetration, such as outdoor furniture or decking, multiple thin coats are more effective than a single heavy application. Allow at least 24 hours between coats to ensure each layer is fully absorbed. Over-application can lead to a gummy surface that never fully cures. If this occurs, lightly sand the surface to remove excess oil and reapply a thin coat. For maintenance, reapply linseed oil annually or when the wood begins to look dry, ensuring long-term protection and a natural finish.

Understanding the absorption rate of linseed oil in softwoods is key to achieving a durable and aesthetically pleasing result. By considering wood type, environmental conditions, and application techniques, you can maximize the benefits of this natural treatment. Patience is paramount—rushing the process can compromise the finish, while proper timing ensures a beautiful, long-lasting outcome. Whether restoring antique furniture or protecting outdoor structures, mastering this technique will elevate your woodworking projects.

Perfecting Wood Staining: Rit Dye Application Time for Optimal Results

You may want to see also

Explore related products

Factors Affecting Soaking Duration

The duration required to soak wood in linseed oil isn’t one-size-fits-all. Wood density plays a critical role—hardwoods like oak or maple absorb oil more slowly than softwoods like pine or cedar. For dense hardwoods, plan on at least 24 hours of initial soaking, while softwoods may only need 6–12 hours. Always test a small area first to gauge absorption rates and adjust timing accordingly.

Temperature and humidity significantly influence soaking time. Linseed oil penetrates wood faster in warmer conditions—ideally between 70°F and 80°F (21°C–27°C). In cooler environments, extend the soaking period by 50% or use a heat source like a hairdryer to expedite absorption. High humidity can slow drying, so ensure proper ventilation during and after application.

The desired finish depth also dictates soaking duration. For a light, surface-level treatment, a single 2–4 hour soak may suffice. Deeper penetration, ideal for outdoor furniture or cutting boards, requires multiple applications with 24-hour intervals between coats. Wipe off excess oil after each soak to prevent sticky buildup and allow the wood to breathe.

Boiled linseed oil, which contains metallic dryers, cures faster than raw linseed oil but may alter the wood’s natural color. If using raw linseed oil, expect longer soaking and drying times—up to 72 hours for full absorption. Always apply thin, even coats to avoid saturation and ensure a smooth, durable finish.

Finally, the wood’s condition matters. New, untreated wood absorbs oil more readily than aged or previously finished surfaces. Sanding rough or sealed wood before soaking removes barriers and promotes even absorption. For reclaimed or weathered wood, pre-treat with a wood cleaner to open pores and enhance oil penetration. Tailor your approach to the wood’s history for optimal results.

How Long Does a Face Cord of Wood Typically Last?

You may want to see also

Explore related products

Quick vs. Deep Soaking Methods

Soaking wood in linseed oil is a balancing act between time and effect. Quick soaking, typically 1-2 hours, offers a surface-level treatment ideal for projects needing immediate protection or a subtle, natural finish. This method involves brushing on a generous coat of raw linseed oil, allowing it to penetrate briefly, then wiping off the excess. It’s perfect for indoor furniture, cutting boards, or decorative pieces where deep saturation isn’t necessary. The result is a matte, slightly enhanced grain that resists moisture without altering the wood’s texture significantly.

Deep soaking, on the other hand, demands patience—often 24 hours or more. This technique involves submerging the wood entirely in a container of linseed oil or repeatedly applying coats until the wood stops absorbing. It’s best suited for outdoor projects like garden furniture, decks, or tools, where durability against weather is critical. The oil penetrates deeply, stabilizing the wood fibers and providing long-lasting protection. However, this method can darken the wood noticeably and requires thorough drying to avoid tackiness.

The choice between quick and deep soaking hinges on the project’s purpose and the wood’s intended use. For instance, a kitchen spoon benefits from a quick soak to maintain its light color and smooth feel, while a wooden planter box requires deep soaking to withstand rain and soil moisture. Always use raw linseed oil for soaking, as boiled linseed oil contains additives that can hinder absorption. After soaking, allow the wood to cure in a well-ventilated area for at least 72 hours to ensure the oil hardens properly.

A practical tip for deep soaking is to warm the oil slightly (not above 100°F) to reduce its viscosity, allowing it to penetrate faster. For quick soaking, use a clean cloth to apply the oil in the direction of the grain, ensuring even coverage. Avoid over-applying, as excess oil can lead to sticky surfaces or uneven drying. Both methods require regular maintenance—reapply oil every 6–12 months for indoor items and every 3–6 months for outdoor pieces exposed to harsh conditions.

Ultimately, the quick vs. deep soaking debate is about prioritizing either speed and subtlety or endurance and depth. Quick soaking is efficient for light protection and aesthetic enhancement, while deep soaking is an investment in longevity, particularly for wood exposed to the elements. Understanding these differences ensures the right approach for each project, maximizing both the beauty and functionality of the wood.

When to Repaint Your Wood House: A Maintenance Timeline Guide

You may want to see also

Explore related products

Preventing Over-Soaking of Wood

Soaking wood in linseed oil is a delicate balance—too little time, and the wood remains unprotected; too long, and you risk over-saturation, leading to a sticky, gummy surface that never fully cures. The key to preventing over-soaking lies in understanding the wood’s porosity and the oil’s absorption rate. Softwoods like pine absorb linseed oil more quickly than hardwoods like oak, meaning they require shorter soaking times. For instance, softwoods typically need no more than 30 minutes to an hour, while hardwoods may benefit from 2–4 hours. Always test a small, inconspicuous area first to gauge absorption.

The method of application also plays a critical role in preventing over-soaking. Instead of submerging the wood entirely in linseed oil, which can lead to excessive absorption, apply the oil generously with a brush or cloth and allow it to penetrate naturally. Wipe off any excess after 10–15 minutes to avoid buildup. This technique ensures the wood absorbs only what it needs, reducing the risk of over-saturation. For larger projects, work in sections to maintain control over the oil’s distribution.

Temperature and humidity are often overlooked factors in the soaking process. Linseed oil dries more slowly in cool, damp conditions, increasing the likelihood of over-soaking. Aim to apply the oil in a warm, dry environment (ideally 70–80°F) to promote proper curing. If working in humid conditions, consider thinning the linseed oil with a solvent like mineral spirits (at a 1:1 ratio) to improve absorption and reduce drying time. This adjustment can prevent the oil from pooling on the surface and causing issues.

Finally, patience is paramount in preventing over-soaking. After the initial application, allow the wood to dry completely before assessing the need for additional coats. Depending on conditions, this can take 24–48 hours. Rushing the process by adding more oil before the first coat cures will exacerbate over-soaking. For best results, apply no more than 2–3 thin coats, allowing ample drying time between each. This approach ensures a durable, non-greasy finish that enhances the wood’s natural beauty without compromising its integrity.

Mastering Smoking: Optimal Soaking Time for Wood Chunks Revealed

You may want to see also

Frequently asked questions

For initial treatment, soak wood in linseed oil for 1 to 2 hours, allowing the oil to penetrate deeply. Wipe off any excess to prevent sticky buildup.

It’s not recommended to leave wood soaking in linseed oil overnight, as prolonged exposure can lead to oversaturation and a greasy surface. Stick to shorter durations and reapply as needed.

Re-soak wood in linseed oil every 6 to 12 months, depending on wear and exposure. Apply for 30 minutes to an hour, wiping off excess for maintenance.