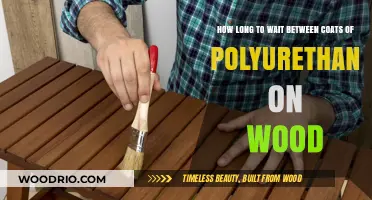

Steaming wood is a crucial process in woodworking, particularly for bending or shaping hardwoods, as it softens the material by breaking down its lignin, making it more pliable without causing damage. The duration required to steam wood varies depending on factors such as the wood species, thickness, and desired flexibility, typically ranging from 30 minutes to several hours. For example, thinner pieces like veneers may only need 30 to 60 minutes, while thicker sections, such as those used for chair legs or boat frames, can require 2 to 4 hours or more. Proper timing ensures the wood is sufficiently softened for bending but not over-steamed, which could weaken its structure. Always consult specific guidelines for the wood type and project requirements to achieve optimal results.

| Characteristics | Values |

|---|---|

| Wood Type | Hardwoods (e.g., oak, maple, walnut) typically require longer steaming times than softwoods (e.g., pine, cedar). |

| Wood Thickness | Thicker pieces require more time: 1-inch thickness ≈ 1-2 hours; 2-inch thickness ≈ 2-4 hours. |

| Steam Temperature | Optimal temperature: 100°C (212°F). Higher temperatures may damage wood fibers. |

| Steaming Time (General) | 30 minutes to 4 hours, depending on wood type and thickness. |

| Steaming Time (Softwoods) | 30 minutes to 2 hours. |

| Steaming Time (Hardwoods) | 1 to 4 hours. |

| Moisture Content Goal | Aim for 20-25% moisture content for optimal bending. |

| Steaming Method | Use a steam box or a sealed container with a steam source. |

| Cooling Process | Cool wood slowly under pressure to retain shape after bending. |

| Safety Precautions | Wear heat-resistant gloves and ensure proper ventilation to avoid steam burns. |

| Environmental Factors | Humidity and ambient temperature can slightly affect steaming time. |

| Re-Steaming | Wood can be re-steamed if it cools too quickly, but avoid over-steaming to prevent weakening. |

Explore related products

What You'll Learn

- Steaming Time by Wood Type: Different woods require varying steaming durations for optimal results

- Desired Bend or Shape: Steaming time depends on the complexity of the desired wood bend

- Wood Thickness Impact: Thicker wood pieces need longer steaming times to become pliable

- Steam Temperature Effects: Higher temperatures can reduce steaming time but risk wood damage

- Cooling and Setting Time: Proper cooling after steaming ensures the wood retains its new shape

Steaming Time by Wood Type: Different woods require varying steaming durations for optimal results

Steaming wood is a precise art, and the duration required varies significantly depending on the wood type. Hardwoods like oak and maple, known for their density, typically demand longer steaming times—often 1 to 2 hours—to achieve the necessary plasticity for bending. Softer woods, such as pine or cedar, are more pliable and usually require only 30 to 45 minutes. This disparity highlights the importance of understanding wood characteristics before applying heat and moisture.

Consider the goal of steaming: to soften the wood fibers without causing damage. For example, walnut, a semi-hardwood, strikes a balance between hardness and flexibility, needing around 45 to 60 minutes of steaming. Oversteaming can lead to brittleness, while understeaming leaves the wood too rigid to bend. Monitoring the wood’s temperature—ideally between 180°F and 212°F (82°C to 100°C)—ensures it reaches the optimal state without overheating.

Practical tips can streamline the process. For instance, pre-soaking dense woods like hickory for 12 to 24 hours before steaming can reduce the required steaming time by up to 30%. Conversely, lightweight woods like balsa should be steamed immediately to avoid waterlogging. Always use a moisture-resistant thermometer to gauge the wood’s internal temperature, as surface readings can be misleading.

Comparing wood types reveals intriguing patterns. Tropical hardwoods like teak or mahogany, prized for their durability, often require steaming times closer to 2 hours due to their high resin content. In contrast, domestic softwoods like spruce or fir, commonly used in furniture making, are ready for bending after just 20 to 30 minutes. These differences underscore the need for tailored approaches based on wood density, grain structure, and intended use.

Finally, experimentation is key. While guidelines provide a starting point, factors like humidity, wood age, and steaming equipment can influence results. For instance, freshly cut green wood may steam faster than seasoned wood, but it’s also more prone to cracking. Keep a log of steaming times and outcomes for different wood types to refine your technique over time. This iterative approach ensures consistent, high-quality results in every project.

Drying Cord Wood: Understanding the Time It Takes to Season Properly

You may want to see also

Explore related products

Desired Bend or Shape: Steaming time depends on the complexity of the desired wood bend

The complexity of the bend you're aiming for directly impacts how long you'll need to steam your wood. A gentle curve for a chair leg requires significantly less time than a tight, intricate twist for a decorative element. Think of it like stretching dough: a simple roll-out takes moments, while shaping a pretzel demands more patience.

Understanding this relationship is crucial for achieving successful bends without compromising the wood's integrity.

Let's break it down. For shallow bends, such as those found in traditional Windsor chair spindles, steaming times typically range from 30 to 60 minutes. This allows the wood fibers to relax and become pliable enough for gradual manipulation. Medium bends, like those in curved chair arms or boat ribs, often require 1-2 hours of steaming. The wood needs more time to soften sufficiently for the increased degree of curvature. For extreme bends, such as those in intricate sculptures or tight-radius furniture joints, steaming times can extend to 2-4 hours or even longer.

Here, the wood must become highly pliable, almost to the point of feeling spongy, to accommodate the dramatic shape change.

It's important to note that these are general guidelines, not hard and fast rules. Several factors influence steaming time beyond bend complexity. Wood species plays a significant role, with denser hardwoods like oak requiring longer steaming times than softer woods like pine. Thickness of the wood is another key factor: thicker pieces need more time to heat through and soften evenly. Finally, the steaming method itself matters. A traditional steam box provides consistent, even heat, while makeshift methods may require longer times to achieve the same results.

Regularly checking the wood's flexibility during steaming is essential. Gently bend a test piece to gauge its pliability, ensuring it bends without cracking or splitting.

Remember, steaming wood is both art and science. While understanding the relationship between bend complexity and steaming time is fundamental, it's equally important to develop a feel for the process through practice and observation. Start with simpler bends and gradually work your way up to more challenging shapes, allowing yourself to learn the nuances of this ancient craft. With patience, experimentation, and a keen eye, you'll master the art of steaming wood, transforming rigid planks into graceful curves and captivating forms.

Wood Glue Drying Time: Factors Affecting Cure Speed and Strength

You may want to see also

Explore related products

Wood Thickness Impact: Thicker wood pieces need longer steaming times to become pliable

Steaming wood is a delicate balance of time and temperature, and the thickness of the wood piece is a critical factor in this equation. Thicker wood requires more time to reach the core temperature necessary for the fibers to soften and become pliable. For instance, a 1-inch thick piece of oak might need 30 minutes of steaming, while a 2-inch thick piece could require up to 90 minutes under the same conditions. This relationship is not linear; doubling the thickness does not simply double the steaming time due to the insulating properties of wood and the varying rates of heat penetration.

To effectively steam thicker wood, consider the following steps: first, measure the thickness of your wood piece accurately. Next, consult a steaming time chart or formula specific to the wood species, as different woods have varying densities and moisture contents. For example, a general rule of thumb is to steam wood for 15–20 minutes per inch of thickness, but this can vary. Always start with the minimum recommended time and assess the wood’s pliability before proceeding. If the wood bends without cracking, it’s ready; if not, continue steaming in 10-minute increments.

The science behind this lies in heat transfer and moisture absorption. Thicker wood acts as an insulator, slowing the movement of steam and heat to the center. Additionally, the outer layers of the wood may become saturated with moisture faster, creating a barrier that delays further penetration. This is why thicker pieces not only take longer to steam but also require careful monitoring to avoid over-steaming, which can lead to weakened or damaged wood fibers.

Practical tips for steaming thicker wood include using a steam box with even heat distribution and ensuring the wood is properly sealed to retain moisture. Pre-soaking the wood in water for 24–48 hours can also reduce steaming time by partially hydrating the fibers. However, avoid pre-soaking dense hardwoods like maple or walnut, as they may absorb too much water and become prone to splitting. Always allow the wood to cool slowly after steaming to prevent warping or cracking as it returns to its original shape.

In conclusion, understanding the impact of wood thickness on steaming time is essential for achieving the desired pliability without compromising the wood’s integrity. By combining precise measurements, species-specific guidelines, and practical techniques, woodworkers can effectively steam thicker pieces for bending or shaping. Patience and attention to detail are key, as rushing the process can lead to unsatisfactory results. With the right approach, even the thickest wood can be transformed into beautifully curved or molded pieces.

Seasoning Ash Wood: Optimal Time and Techniques for Perfect Results

You may want to see also

Explore related products

Steam Temperature Effects: Higher temperatures can reduce steaming time but risk wood damage

Steaming wood is a delicate balance between efficiency and preservation. Higher temperatures, typically ranging from 100°C to 120°C (212°F to 248°F), can significantly reduce steaming time—often cutting it in half compared to lower temperatures. For instance, oak might require 6–8 hours at 100°C but only 3–4 hours at 120°C. This efficiency is tempting, especially for large-scale operations, but it comes with a critical caveat: the risk of wood damage increases exponentially with temperature. At 120°C, the wood’s cellular structure can begin to degrade, leading to brittleness or discoloration. Thus, while higher temperatures save time, they demand precision and caution.

Consider the analogy of cooking: just as overboiling ruins a delicate dish, excessive steam heat can compromise wood’s integrity. The optimal temperature range for most hardwoods is 100°C to 110°C (212°F to 230°F), balancing speed and safety. Softwoods, like pine, are even more sensitive and should rarely exceed 95°C (203°F). To mitigate risk, monitor the steam chamber’s temperature with a digital thermometer and avoid sudden spikes. Additionally, pre-soaking the wood in warm water for 30 minutes can reduce the required steaming time, further minimizing exposure to high heat.

A persuasive argument for moderation lies in the long-term value of the wood. While higher temperatures may expedite production, the resulting material may lack durability or aesthetic appeal. For example, steamed wood intended for furniture or musical instruments often requires a flawless finish, which higher temperatures jeopardize. Investing extra hours in lower-temperature steaming ensures the wood retains its natural strength and beauty, ultimately enhancing its market value and longevity.

Comparatively, lower temperatures (90°C to 100°C) are ideal for beginners or small-scale projects. They provide a forgiving margin of error, allowing for experimentation without costly mistakes. Advanced users, however, might opt for higher temperatures when working with dense, hard-to-bend species like hickory or walnut. In such cases, incremental adjustments—increasing temperature by 5°C at a time—can help identify the wood’s tolerance threshold. Always prioritize quality over speed, as damaged wood is irreversible.

In practice, the key to successful steaming lies in understanding the wood’s characteristics and the project’s requirements. For bending tight radii or intricate shapes, higher temperatures might be necessary, but only with vigilant monitoring. Conversely, simpler bends or decorative pieces benefit from lower temperatures and longer durations. Always test a sample piece before committing to the entire batch. By respecting the wood’s limits and adapting the temperature accordingly, craftsmen can achieve both efficiency and excellence.

Standard Wood Mop Handle Length: A Comprehensive Guide for Buyers

You may want to see also

Explore related products

Cooling and Setting Time: Proper cooling after steaming ensures the wood retains its new shape

Steaming wood is a transformative process, but the magic doesn't end when the heat is turned off. The cooling phase is a critical, often overlooked step that determines whether your wood retains its new shape or reverts to its original form. Think of it as the setting time for a freshly molded sculpture—rush it, and you risk losing the intricate details you worked so hard to achieve.

The Science Behind Cooling:

When wood is steamed, its cellulose fibers soften, allowing it to bend and reshape. However, these fibers need time to realign and stabilize in their new position. Rapid cooling can cause internal stress, leading to warping, cracking, or springback. The ideal cooling process involves a gradual temperature reduction, typically over several hours, depending on the wood species and thickness. For example, a 2-inch thick piece of oak might require 6–8 hours to cool properly, while a thinner piece of pine could take as little as 2–3 hours.

Practical Steps for Effective Cooling:

- Controlled Environment: After steaming, remove the wood from the steam source and place it in a dry, room-temperature area. Avoid drafts or direct sunlight, as uneven cooling can lead to defects.

- Clamp and Secure: Use clamps or weights to hold the wood in its desired shape during cooling. This prevents movement and ensures the fibers set correctly.

- Monitor Humidity: Wood cools best in a humidity-controlled environment. Aim for 40–60% relative humidity to avoid moisture absorption or excessive drying.

Cautions and Common Mistakes:

One of the most common errors is removing clamps too soon. Even if the wood feels cool to the touch, its core may still be stabilizing. Another mistake is exposing the wood to extreme temperature changes, such as moving it from a hot steam chamber to a cold garage. This thermal shock can cause irreversible damage. Always err on the side of patience—it’s better to overestimate cooling time than to risk ruining your project.

The Takeaway:

Cooling is not a passive step but an active part of the wood-steaming process. By treating it with the same care and precision as steaming itself, you ensure that your wood retains its new shape permanently. Remember, the goal is not just to reshape the wood but to create a lasting transformation that honors both the material and your craftsmanship.

Seasoning Oak Wood: Timeframe and Best Practices for Optimal Results

You may want to see also

Frequently asked questions

The steaming time for wood varies depending on the species and thickness, but it generally ranges from 1 to 6 hours.

Yes, harder woods like oak or maple may require longer steaming times (3–6 hours), while softer woods like pine or cedar may only need 1–2 hours.

Yes, thinner wood pieces (e.g., 1/4 inch or less) can steam in as little as 30 minutes to 1 hour, while thicker pieces (e.g., 2 inches or more) may take several hours.

Yes, over-steaming can cause wood to become brittle or discolored. It’s important to monitor the process and follow recommended times for the specific wood species.