When working with pressure-treated wood, it’s crucial to understand the waiting period before sanding to ensure optimal results and longevity. Pressure-treated wood is chemically treated to resist rot, decay, and insects, but these chemicals need time to fully penetrate and stabilize within the wood fibers. Sanding too soon can release harmful dust and compromise the wood’s protective properties. Generally, it’s recommended to wait at least 48 to 72 hours after installation to allow the wood to dry, but for sanding, a longer wait of 2 to 4 weeks is advised to ensure the chemicals have fully cured. Always wear protective gear when sanding, as the dust from pressure-treated wood can be hazardous.

| Characteristics | Values |

|---|---|

| Recommended Waiting Time | 2-7 days (varies based on moisture content, climate, and wood type) |

| Moisture Content Requirement | Wood should be below 15% moisture content before sanding |

| Climate Influence | Longer drying time in humid climates; shorter in dry, sunny conditions |

| Wood Type Impact | Softwoods (e.g., pine) dry faster than hardwoods |

| Chemical Treatment | Pressure-treated wood contains water-soluble chemicals that need to dry |

| Sanding Risks if Too Soon | Raised grain, uneven surface, or chemical residue exposure |

| Testing Method | Use a moisture meter to ensure wood is sufficiently dry |

| Surface Preparation | Clean debris and allow natural drying before sanding |

| Environmental Factors | Avoid sanding in rainy or high-humidity conditions |

| Post-Sanding Treatment | Apply sealant or stain after sanding for protection |

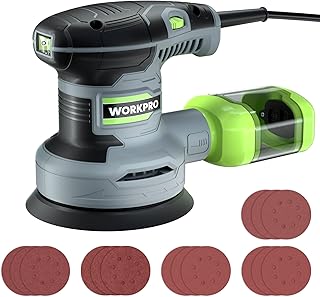

Explore related products

What You'll Learn

- Initial Drying Time: Freshly treated wood needs 2-4 weeks to dry before sanding

- Moisture Content Check: Ensure wood moisture level is below 15% before sanding

- Weather Impact: Humid conditions may require longer waiting periods, up to 6 weeks

- Type of Treatment: Different preservatives affect drying time; check manufacturer guidelines

- Sanding Techniques: Use fine-grit sandpaper to avoid damaging the treated surface

Initial Drying Time: Freshly treated wood needs 2-4 weeks to dry before sanding

Freshly pressure-treated wood is saturated with preservatives, making it too wet for immediate sanding. Attempting to sand before the wood dries can lead to clogged sandpaper, uneven surfaces, and reduced chemical effectiveness. The initial drying period of 2-4 weeks is critical to allow the moisture and treatment chemicals to dissipate, ensuring a smoother sanding process and preserving the wood’s protective qualities.

This waiting period isn’t arbitrary—it’s rooted in the chemistry of pressure treatment. Wood treated with water-based preservatives (like ACQ or CA-B) retains significant moisture post-treatment, which needs time to evaporate. Sanding too early can force chemicals to the surface, creating a gummy residue that hinders adhesion of paints or stains. By waiting 2-4 weeks, you allow the wood to reach a moisture content closer to its equilibrium with the environment, reducing these risks.

Practical tips can optimize this drying phase. Store the wood in a well-ventilated, shaded area to prevent warping or cracking. Avoid stacking boards directly on top of each other; instead, use stickers (spacers) to promote airflow. If you’re in a humid climate, extend the drying time closer to 4 weeks. A simple moisture meter can confirm readiness—aim for a reading below 15% moisture content before sanding.

Comparing this to other wood types highlights its necessity. Untreated lumber may only need a few days to dry, but pressure-treated wood’s chemical composition demands patience. Skipping this step can void warranties on treated wood products and compromise their longevity. Think of it as an investment: 2-4 weeks of waiting now saves years of potential maintenance later.

Instructively, treat this phase as part of the project timeline, not an afterthought. Plan ahead by purchasing wood early or using pre-dried materials if time is a constraint. For larger projects like decks, phase construction to allow boards to dry in place before final sanding and finishing. This approach ensures professional results while respecting the material’s unique properties.

Efficient Wood Stacking: Time to Pile 2 Cords of Firewood

You may want to see also

Explore related products

$19.94

Moisture Content Check: Ensure wood moisture level is below 15% before sanding

Pressure-treated wood, while durable, retains moisture from its treatment process, which can hinder sanding and finishing. Before you even think about sanding, verify the wood’s moisture content. Aim for a level below 15%, as this threshold ensures the wood is dry enough to accept finishes without warping, cracking, or trapping moisture beneath the surface. A moisture meter, available at most hardware stores, is your best tool for this task—simply press it against the wood to get an accurate reading.

Skipping this step can lead to costly mistakes. Sanding wood with a moisture content above 15% risks raising the grain excessively, causing uneven surfaces, or even promoting mold growth later. For example, if you’re working on a deck or outdoor furniture, high moisture levels can cause finishes to peel or blister, undoing your hard work. Always test multiple spots on the wood, as moisture distribution can vary, especially in larger pieces.

To expedite drying, store pressure-treated wood in a well-ventilated area, ideally under a covered space to protect it from rain. Stacking wood with spacers between boards allows air to circulate, speeding up evaporation. Depending on climate conditions, this process can take anywhere from a few weeks to several months. In humid environments, consider using a dehumidifier or fans to accelerate drying.

If you’re unsure about the wood’s readiness, err on the side of caution. Waiting a bit longer ensures the wood is fully acclimated, saving you from potential sanding and finishing headaches. Remember, patience now pays off in the longevity and appearance of your project. Always prioritize moisture content over deadlines for the best results.

Seasoning Beech Wood: Optimal Time and Techniques for Perfect Results

You may want to see also

Explore related products

Weather Impact: Humid conditions may require longer waiting periods, up to 6 weeks

Humidity acts as a stubborn gatekeeper, dictating how long you must wait before sanding pressure-treated wood. In dry climates, the wood’s surface moisture evaporates swiftly, often allowing sanding within 2–4 weeks. But in humid environments, where the air is saturated with moisture, this process grinds to a halt. The wood’s chemical preservatives and natural moisture become trapped, unable to escape. Ignoring this reality risks sanding a surface that’s still damp, leading to uneven results, poor adhesion of finishes, and potential long-term damage.

Consider the science behind this delay. Pressure-treated wood is infused with water-based preservatives like alkaline copper quaternary (ACQ) or copper azole, which need time to dry and stabilize. Humidity slows this drying process by reducing the evaporation rate. For instance, in regions with 70% relative humidity or higher, the wood’s moisture content remains elevated, prolonging the wait. A hygrometer can help you monitor indoor conditions, but outdoor projects are at the mercy of weather patterns. If you’re unsure, err on the side of caution and extend the waiting period.

Practical tips can mitigate the impact of humidity. First, choose a well-ventilated area for your wood to dry, ideally under a covered but open space where air circulates freely. Avoid stacking boards directly on top of each other; instead, use stickers (small spacers) to allow airflow between layers. If possible, time your project for the drier months or use a dehumidifier in enclosed spaces. Even with these measures, plan for a 4–6 week wait in humid conditions, testing the wood periodically with a moisture meter to ensure it’s below 15% moisture content before sanding.

Comparing humid and dry climates highlights the stark difference in waiting times. In arid regions like Arizona, where humidity hovers around 20%, pressure-treated wood may be ready for sanding in as little as 10–14 days. Contrast this with Florida’s 80% average humidity, where the same wood could require the full 6 weeks. This disparity underscores the need for localized advice—what works in one climate may fail in another. Always adapt your timeline to your environment, not the other way around.

Finally, patience is your greatest tool when dealing with humid conditions. Rushing the process undermines the wood’s integrity and your project’s longevity. Think of the waiting period as an investment in durability. Sanding too soon not only wastes effort but can also expose fresh wood fibers, making them susceptible to moisture absorption and rot. By respecting the wood’s natural drying curve, you ensure a smooth, stable surface ready for staining, sealing, or painting. In humidity’s slow embrace, time is the craftsman’s ally.

Durability of Wood Docks: Lifespan, Maintenance, and Longevity Factors

You may want to see also

Explore related products

Type of Treatment: Different preservatives affect drying time; check manufacturer guidelines

Pressure-treated wood is infused with preservatives to resist rot, decay, and insect damage, but these chemicals significantly impact drying time. Common treatments like Alkaline Copper Quaternary (ACQ) and Copper Azole (CA-B) require different handling due to their unique chemical compositions. ACQ-treated wood, for instance, often contains copper carbonate and a quaternary ammonium compound, which can leave the surface damp for 2–3 days after treatment. In contrast, CA-B-treated wood, with its copper and tebuconazole mix, may dry within 48 hours under ideal conditions. Knowing the specific preservative used is the first step in determining when to sand, as each type interacts differently with moisture and air.

Manufacturers provide detailed guidelines tailored to their preservatives, often recommending waiting periods of 72 hours to 2 weeks before sanding. For example, wood treated with Micronized Copper Azole (MCA) may require a full week to dry sufficiently, while Chromated Copper Arsenate (CCA), though less common today, typically needed 4–5 days. These timelines account for factors like humidity, temperature, and wood density. Ignoring these recommendations can lead to sanding issues, such as clogging sandpaper with residual chemicals or damaging the wood’s surface before it’s fully cured. Always consult the treatment tag or product documentation for precise instructions.

The drying process isn’t just about time—it’s about conditions. Preservatives like ACQ and CA-B are water-based, so wood treated with these chemicals will dry faster in warm, dry environments with good airflow. In contrast, oil-based preservatives, though less common, may take longer to cure and require more ventilation to dissipate fumes. Practical tips include storing treated wood in a covered but well-ventilated area, avoiding direct sunlight (which can cause uneven drying), and testing a small area for moisture before sanding. A moisture meter can confirm if the wood’s surface is ready, ideally reading below 15% moisture content.

Comparing treatments highlights why a one-size-fits-all approach fails. For example, while ACQ-treated wood is safe for sanding after 72 hours in dry conditions, CA-B-treated wood may need an extra day or two due to its higher copper content. CCA-treated wood, though largely phased out for residential use, still exists in older structures and requires caution due to its arsenic content. Sanding too soon can release harmful dust, so following guidelines isn’t just about wood quality—it’s about safety. Always wear a respirator and protective gear when working with treated wood, regardless of its age or treatment type.

Ultimately, the type of preservative dictates the waiting period before sanding pressure-treated wood. Manufacturers invest in research to provide accurate timelines, ensuring both the wood’s longevity and your project’s success. Skipping this step or guessing can void warranties, compromise the wood’s protective barrier, or create hazardous conditions. Treat the guidelines as a roadmap, not a suggestion, and plan your project timeline accordingly. Patience in this phase pays off in the form of a smoother, more durable finish that stands the test of time.

Eco-Safe Wood Treatment: Durability and Longevity of Tall Earth Products

You may want to see also

Explore related products

Sanding Techniques: Use fine-grit sandpaper to avoid damaging the treated surface

Pressure-treated wood is a popular choice for outdoor projects due to its durability and resistance to rot and insects. However, its chemical treatment requires careful handling, especially when sanding. The key to preserving the wood's integrity lies in the grit of the sandpaper you choose. Fine-grit sandpaper, typically ranging from 120 to 220 grit, is essential to avoid damaging the treated surface. Coarser grits can scratch the wood, exposing untreated layers and compromising its protective barrier.

When sanding pressure-treated wood, start with a medium grit (120-150) to smooth out rough surfaces or remove mill glaze. Follow this with a finer grit (180-220) to achieve a smooth, even finish. This two-step process ensures you remove imperfections without over-sanding. Always sand in the direction of the wood grain to prevent splintering and maintain a natural appearance. For intricate areas or detailed work, consider using sanding sponges or blocks, which offer better control and conform to the wood's contours.

The choice of fine-grit sandpaper isn’t just about aesthetics—it’s about longevity. Pressure-treated wood relies on its chemical treatment to resist decay, and aggressive sanding can strip away this protective layer. By using finer grits, you minimize the risk of exposing untreated wood fibers, ensuring the treatment remains effective. Additionally, fine-grit sandpaper helps create a smoother surface, which is ideal for painting, staining, or sealing, as it allows finishes to adhere more evenly and last longer.

A practical tip for sanding pressure-treated wood is to wear a dust mask and work in a well-ventilated area, as the sanding process can release fine particles containing chemicals. After sanding, thoroughly clean the surface with a damp cloth to remove any residue before applying finishes. This step ensures better adhesion and a professional-looking result. By prioritizing fine-grit sandpaper and following these techniques, you’ll preserve the wood’s treated surface while achieving a polished, durable finish.

Exploring the Duration of God of the Woods: A Comprehensive Guide

You may want to see also

Frequently asked questions

It’s best to wait at least 48 to 72 hours after installation before sanding pressure-treated wood to allow any excess moisture or chemicals to dry and dissipate.

No, sanding immediately after treatment can release harmful chemicals and may damage the wood. Wait at least 2-4 weeks to ensure the wood is fully cured and safe to sand.

Yes, for outdoor wood, wait 2-4 weeks to allow for proper drying and chemical stabilization. For indoor use, waiting 4-6 weeks is recommended to minimize chemical off-gassing and ensure the wood is fully cured.