Drying wood in a kiln is a crucial process in woodworking and construction, as it removes moisture to enhance the material's stability, durability, and workability. The duration of kiln-drying wood varies significantly depending on factors such as the wood species, initial moisture content, thickness of the lumber, and the kiln's efficiency. Softwoods like pine typically dry faster, often within 2 to 4 weeks, while hardwoods such as oak or maple may require 4 to 8 weeks or more due to their denser structure. Additionally, the kiln's temperature and humidity settings play a vital role in determining the drying time, with higher temperatures accelerating the process but requiring careful monitoring to avoid defects like warping or cracking. Understanding these variables ensures optimal results, preserving the wood's quality for its intended use.

| Characteristics | Values |

|---|---|

| Drying Time | Varies based on wood type, thickness, and kiln settings. Typically ranges from 2-8 weeks. |

| Temperature Range | 120°F to 200°F (49°C to 93°C), depending on wood species and desired moisture content. |

| Moisture Content Reduction | From 20-30% (green wood) to 6-12% (kiln-dried wood). |

| Wood Types Suitable for Kiln Drying | Hardwoods (oak, maple, walnut), softwoods (pine, cedar), and exotic woods. |

| Kiln Types | Conventional kilns, dehumidification kilns, solar kilns, and vacuum kilns. |

| Energy Consumption | Varies; dehumidification kilns are more energy-efficient than conventional kilns. |

| Cost Factors | Initial kiln setup, energy costs, labor, and maintenance. |

| Benefits | Reduces warping, cracking, and insect infestation; improves dimensional stability and workability. |

| Environmental Impact | Can be minimized with energy-efficient kilns and sustainable wood sourcing. |

| Monitoring Tools | Moisture meters, thermometers, and humidity sensors to track drying progress. |

Explore related products

What You'll Learn

- Drying Time Factors: Wood thickness, kiln temperature, humidity, and species affect drying duration significantly

- Moisture Content Goals: Target moisture levels for specific uses (e.g., furniture, flooring) dictate drying time

- Kiln Types: Conventional, dehumidification, solar, and vacuum kilns vary in drying speed and efficiency

- Wood Species Impact: Hardwoods dry slower than softwoods due to density and resin content

- Monitoring Techniques: Use moisture meters and kiln schedules to ensure optimal drying without defects

Drying Time Factors: Wood thickness, kiln temperature, humidity, and species affect drying duration significantly

Wood thickness is the most straightforward factor influencing drying time in a kiln. Thicker pieces, such as 4/4 (1-inch) or 8/4 (2-inch) lumber, retain moisture deeper within their structure, requiring longer exposure to heat. For instance, a 4/4 hardwood board might dry adequately in 4–6 weeks, while an 8/4 board could demand 8–12 weeks under similar conditions. To expedite the process, some kiln operators use a technique called "S2S drying," where both faces of thicker boards are planed to increase surface area, reducing drying time by up to 20%.

Kiln temperature plays a dual role: it accelerates moisture evaporation but risks damaging the wood if mismanaged. Temperatures typically range from 120°F to 180°F (49°C to 82°C), with lower settings (120°F–140°F) ideal for delicate species like cherry or walnut to prevent checking or warping. Higher temperatures (160°F–180°F) are reserved for denser woods like oak or maple, but even then, gradual increases are critical. A sudden spike can cause case hardening, where the outer layer dries too quickly, trapping moisture inside.

Humidity control is often overlooked but equally vital. Kilns maintain relative humidity (RH) levels to manage the moisture gradient between the wood and the air. During the initial drying phase, RH is kept high (around 90%) to prevent surface checking. As drying progresses, RH is gradually reduced to 60–70%, then to 30–40% in the final stages. This stepwise approach ensures uniform drying without compromising wood integrity. For example, a kiln schedule for oak might start at 140°F and 90% RH, dropping to 160°F and 40% RH over several weeks.

Wood species dictate drying strategies due to inherent density and moisture content. Softwoods like pine dry faster than hardwoods like teak, which have higher natural oils and density. For instance, pine can achieve 12% moisture content in 2–3 weeks, while teak may require 6–8 weeks. Exotic species like ipe or ebony demand even more patience, often needing 10–12 weeks due to their extreme density. Species-specific schedules, often provided by kiln manufacturers, are essential to avoid defects like honeycomb or end splits.

In practice, balancing these factors requires precision and adaptability. A kiln operator might start with a standard schedule but adjust temperature or humidity mid-cycle based on moisture meter readings. For hobbyists, investing in a moisture meter (accurate to ±1%) is invaluable for monitoring progress. Professionals often use vacuum kilns, which reduce boiling point and allow lower temperatures, cutting drying time by 30–50% for thick or dense woods. Whether drying for furniture, flooring, or construction, understanding these variables ensures efficient, defect-free results.

Wood Roach Lifespan: How Long Until They Perish Naturally?

You may want to see also

Explore related products

Moisture Content Goals: Target moisture levels for specific uses (e.g., furniture, flooring) dictate drying time

Wood intended for furniture typically requires a moisture content (MC) of 6% to 8% to prevent warping, cracking, or dimensional instability once in use. Achieving this range in a kiln demands precise control, as hardwoods like oak or maple release moisture at different rates compared to softer woods such as pine. For instance, a 4/4 oak board might take 4 to 6 weeks to reach 8% MC, while a similar thickness of pine could dry to the same level in 2 to 3 weeks. Kiln operators must monitor MC regularly using a pin-type or pinless moisture meter, adjusting temperature and humidity to avoid case-hardening, where the exterior dries too quickly, trapping moisture inside.

Flooring, on the other hand, often targets an MC of 6% to 12%, depending on the installation environment. Wood for humid climates should lean toward the lower end of this range to minimize expansion, while drier regions can tolerate slightly higher MC. Engineered flooring, with its layered construction, requires even stricter control, typically aiming for 6% to 8% MC to ensure adhesive bonds remain intact. Kiln schedules for flooring must balance speed with uniformity, often using lower temperatures and longer drying times to prevent checking or splitting. Pre-drying in a solar kiln or air-drying for several weeks can reduce total kiln time by 20% to 30%, making the process more efficient.

Specialty applications, like musical instruments or boatbuilding, demand even tighter MC tolerances. Guitar makers, for example, often target 5% to 7% MC to ensure tonal stability and structural integrity. This requires slow, low-temperature drying (around 100°F to 120°F) over 8 to 12 weeks, with frequent MC checks to avoid stress cracks. Boatbuilders, meanwhile, aim for 12% to 15% MC to accommodate the wood’s natural movement in wet conditions, using a combination of kiln and air-drying to achieve this balance. In both cases, understanding the wood’s final use is critical to setting the kiln schedule.

To optimize drying time while meeting MC goals, kiln operators should follow a few key practices. First, stack wood with uniform spacing (1–2 inches between boards) to allow air circulation. Second, use a dehumidification kiln for softer woods or thinner stock, which reduces drying time by 30% to 50% compared to conventional methods. Third, employ a moisture content gradient schedule, starting at 120°F and gradually increasing to 160°F as the wood approaches target MC. Finally, always allow for an equilibration period after kiln-drying, storing wood in a controlled environment for 1 to 2 weeks to ensure MC stabilizes before use. These steps ensure the wood not only meets its MC goal but also retains its structural and aesthetic qualities.

Drying Cholla Wood: Timeframe and Tips for Perfect Preservation

You may want to see also

Explore related products

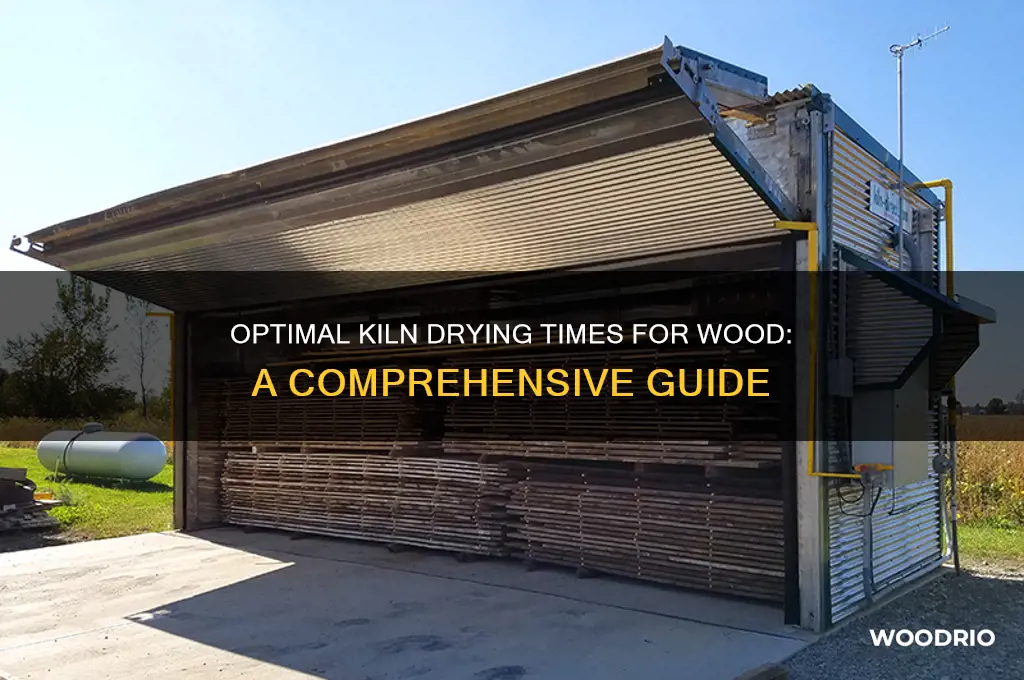

Kiln Types: Conventional, dehumidification, solar, and vacuum kilns vary in drying speed and efficiency

The time wood spends in a kiln depends heavily on the kiln type, each offering distinct advantages and trade-offs in drying speed and efficiency. Conventional kilns, the industry standard, rely on steam or heated air to gradually remove moisture. This method typically takes 4 to 8 weeks for hardwoods and 2 to 4 weeks for softwoods, balancing cost-effectiveness with longer drying times. While reliable, conventional kilns consume significant energy, making them less efficient for smaller operations or environmentally conscious businesses.

Dehumidification kilns, on the other hand, use a dehumidifier to condense moisture from the air, maintaining lower temperatures that reduce the risk of wood defects like warping or cracking. This process is 20–30% faster than conventional methods, often drying wood in 1 to 3 weeks, depending on thickness and species. Ideal for hobbyists or small-scale producers, these kilns are energy-efficient but require a higher initial investment. For example, a 1-inch thick board of oak might dry in 10–14 days, compared to 3 weeks in a conventional kiln.

Solar kilns leverage renewable energy, using sunlight to heat air that circulates through the wood stack. While environmentally friendly and low-cost to operate, they are highly dependent on weather conditions, making drying times unpredictable. A solar kiln might take 2 to 6 weeks for softwoods and 4 to 8 weeks for hardwoods, but only under optimal sunlight. This method is best suited for regions with consistent sunshine and operators willing to monitor conditions closely.

Vacuum kilns operate by reducing air pressure, lowering the boiling point of water and accelerating moisture evaporation. This process is 50–70% faster than conventional methods, drying wood in days rather than weeks. For instance, a 2-inch thick maple board can dry in 3–5 days, compared to 4–6 weeks in a conventional kiln. However, vacuum kilns are expensive to purchase and maintain, limiting their use to high-volume or specialty wood producers. Their precision also minimizes defects, making them ideal for high-value timber.

Choosing the right kiln type hinges on balancing speed, efficiency, and cost. Conventional kilns suit large-scale operations prioritizing affordability, while dehumidification kilns offer a faster, energy-efficient alternative for smaller setups. Solar kilns appeal to eco-conscious users with patience for variability, and vacuum kilns cater to those needing rapid, defect-free drying despite higher costs. Each kiln type reshapes the timeline for wood drying, tailoring the process to specific needs and constraints.

Durability of Wooden Conservatories: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Wood Species Impact: Hardwoods dry slower than softwoods due to density and resin content

The drying time of wood in a kiln is not a one-size-fits-all process. A critical factor dictating this duration is the wood species, with hardwoods and softwoods exhibiting distinct behaviors. Hardwoods, known for their denser cellular structure and higher resin content, inherently dry at a slower pace compared to their softwood counterparts. This phenomenon is not merely a trivial detail but a pivotal consideration for woodworkers, manufacturers, and kiln operators aiming for optimal drying efficiency and wood quality.

Consider the cellular anatomy of hardwoods and softwoods. Hardwoods, such as oak and maple, possess a more compact arrangement of cells, which restricts moisture movement. This density, while contributing to their strength and durability, also means that water molecules have a more arduous journey to escape. Softwoods, like pine and cedar, have larger, more open cells that facilitate quicker moisture evacuation. Additionally, the resin content in hardwoods acts as a natural barrier, further impeding the drying process. For instance, a 1-inch thick board of white oak might require 2-3 times longer in the kiln compared to a similarly sized piece of Douglas fir.

From a practical standpoint, understanding these differences is essential for scheduling kiln operations and managing expectations. Kiln operators often categorize wood species into drying classes, with hardwoods typically falling into the slower-drying categories. For example, a kiln schedule for red oak might involve a gradual temperature increase over 4-6 weeks, starting at 120°F and peaking at 180°F, with careful monitoring to prevent checking or warping. In contrast, a softwood like spruce might complete its drying cycle in just 2-3 weeks under similar conditions.

The implications of these drying disparities extend beyond the kiln. Woodworkers must account for the residual stress and moisture content differences when crafting furniture or structures. Hardwoods, despite their slower drying, often yield more stable and dimensionally consistent results, making them ideal for high-end applications. Softwoods, while quicker to dry, may require additional stabilization techniques to mitigate shrinkage and distortion. For DIY enthusiasts, selecting the right wood species and understanding its drying characteristics can mean the difference between a successful project and a warped disappointment.

In conclusion, the impact of wood species on drying time is a nuanced yet critical aspect of kiln operation. Hardwoods’ density and resin content necessitate longer, more controlled drying processes, while softwoods benefit from their more open cellular structure. By tailoring kiln schedules to these inherent properties, operators can optimize efficiency, reduce defects, and produce wood that meets the demands of various applications. Whether you’re a professional or a hobbyist, recognizing these species-specific behaviors ensures better outcomes and a deeper appreciation for the craft.

Termite Damage Timeline: How Quickly Can They Destroy Wood?

You may want to see also

Explore related products

$36.53

Monitoring Techniques: Use moisture meters and kiln schedules to ensure optimal drying without defects

Moisture meters are the kiln operator's compass, guiding the drying process with precision. These handheld devices measure the wood's moisture content (MC) by sending low-frequency electromagnetic waves through the material. For softwoods, aim for a final MC of 12-15%, while hardwoods typically require 8-10%. Calibrate your meter regularly and take readings at multiple depths to account for variability. A 2% MC gradient between the shell and core is acceptable, but exceeding 4% risks internal stresses and cracks.

Kiln schedules are the roadmap to defect-free drying, balancing temperature, humidity, and time. Start with a gentle 100-120°F (38-49°C) pre-heating phase to prevent surface checking. Gradually increase the temperature by 5-10°F (3-6°C) per day, monitoring MC daily. For 4/4 hardwoods, a 14-day schedule is common, while 8/4 stock may require 21-28 days. Incorporate a dehumidification stage when MC reaches 20-25% to minimize casehardening. Always allow for a 2-3 day cooling period to acclimate the wood before removing it from the kiln.

The interplay between moisture meters and kiln schedules is critical. For instance, if a meter reading shows a rapid MC drop (e.g., 4% in 24 hours), reduce the kiln temperature by 5°F (3°C) to prevent overheating. Conversely, a plateauing MC may indicate casehardening, requiring increased humidity or a temporary temperature reduction. Advanced kilns with automated controls can adjust settings based on real-time MC data, but manual oversight remains essential.

Consider the wood species and thickness when fine-tuning your approach. Dense hardwoods like oak dry slower than softwoods like pine, necessitating longer schedules. Thicker stock (e.g., 6/4 or 8/4) requires lower temperatures and extended drying times to avoid honeycomb or end splits. For example, a 6/4 walnut board might follow a 30-day schedule starting at 110°F (43°C), while a 4/4 pine board could complete in 10 days at 130°F (54°C). Always consult species-specific guidelines and adjust based on meter readings.

Practical tips can further enhance your monitoring techniques. Use stickers or spacers between lumber stacks to promote airflow, reducing drying time by up to 20%. Apply end sealants to thicker boards to minimize moisture loss through end grain, cutting down on end checks. For small-scale operations, invest in a data logger to track kiln conditions, providing insights for future schedules. Finally, maintain detailed records of each drying cycle, noting MC trends, defects, and adjustments—this historical data becomes a valuable reference for optimizing future batches.

Sara Bareilles' Into the Woods Stint: Duration and Highlights

You may want to see also

Frequently asked questions

The time to kiln-dry wood varies depending on the wood species, thickness, and moisture content, but it generally takes between 2 to 14 days.

Yes, kiln-drying can be expedited by increasing temperature and airflow, but this must be done carefully to avoid damaging the wood.

Factors include wood species, initial moisture content, thickness of the wood, kiln temperature, humidity, and airflow.

Yes, kiln-dried wood is typically ready for use immediately, as the process reduces moisture content to optimal levels for construction, furniture, or other applications.