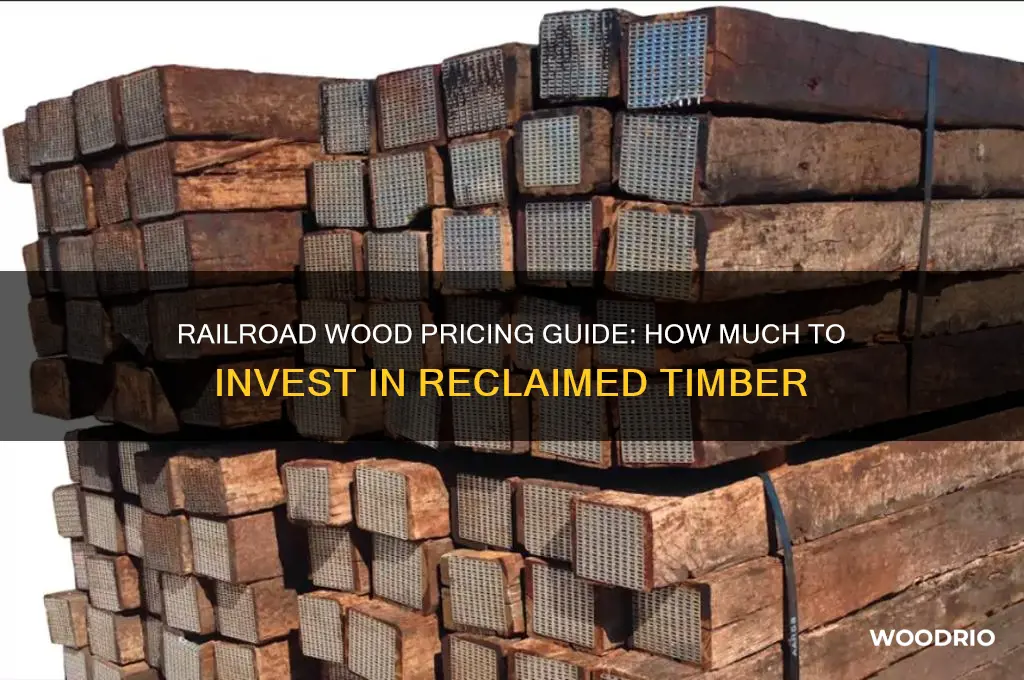

When considering purchasing railroad wood, it’s essential to understand the factors that influence its cost, including the type of wood, its condition, and the quantity needed. Railroad wood, often reclaimed from decommissioned tracks, is prized for its durability and rustic aesthetic, making it popular for DIY projects, landscaping, and furniture. Prices can vary widely, typically ranging from $1 to $5 per linear foot, depending on whether the wood is untreated, creosote-treated, or refinished. Additionally, sourcing from local suppliers or salvage yards may offer more affordable options compared to specialty retailers. Before buying, assess your project requirements and ensure the wood meets safety and environmental standards, especially if it has been treated with chemicals.

Explore related products

What You'll Learn

- Pricing Factors: Understand variables like wood type, quantity, condition, and supplier location affecting railroad wood costs

- Supplier Comparison: Research local vs. national suppliers to find the best prices and quality

- Reclaimed vs. New: Compare costs and benefits of reclaimed railroad wood versus new timber options

- Bulk Discounts: Explore savings by purchasing railroad wood in large quantities from wholesalers

- Shipping Costs: Factor in transportation expenses when calculating the total cost of railroad wood

Pricing Factors: Understand variables like wood type, quantity, condition, and supplier location affecting railroad wood costs

The cost of railroad wood isn’t fixed—it fluctuates based on a combination of factors that buyers must navigate. Wood type, for instance, plays a pivotal role. Hardwoods like oak or maple, prized for durability, command higher prices than softer woods like pine. Reclaimed railroad ties, often made from dense, pressure-treated woods, can range from $15 to $30 per piece, while less durable options may cost as little as $5 to $10. Understanding the wood’s origin and treatment is essential, as these details directly impact both price and longevity.

Quantity is another critical variable. Bulk purchases often yield discounts, but the savings depend on the supplier’s policies. For example, buying 100 railroad ties might reduce the per-unit cost by 10–20%, while smaller orders may incur higher prices due to fixed handling and shipping fees. Small-scale DIY projects might only need a handful of ties, but larger landscaping or construction endeavors require careful cost-benefit analysis to optimize spending. Always inquire about volume pricing before committing to a supplier.

Condition matters significantly, especially for reclaimed wood. New railroad ties, though more expensive (up to $25–$40 each), offer uniformity and longevity. Reclaimed ties, while cheaper ($10–$25), may show wear, splitting, or warping, necessitating inspection to ensure they meet project needs. Some buyers prefer the weathered aesthetic of reclaimed wood, but structural integrity should never be compromised. Factor in potential repairs or replacements when budgeting for used materials.

Supplier location introduces geographic pricing disparities. Local suppliers reduce transportation costs but may have limited inventory or higher overhead. Sourcing from distant regions can uncover better deals but adds shipping expenses, which can negate savings. For instance, shipping a pallet of railroad ties cross-country might cost $200–$500, depending on weight and distance. Use online calculators to estimate shipping fees and compare total costs before deciding. Proximity isn’t always the best metric—total cost, including delivery, should guide your choice.

Finally, hidden costs can inflate the final price. Treatment chemicals, such as creosote, may require special handling or disposal, adding $5–$10 per tie in compliance fees. Custom cutting or milling services can tack on another $2–$5 per piece. Always request a detailed quote that includes all potential expenses. By accounting for these variables—wood type, quantity, condition, and supplier location—buyers can make informed decisions and avoid budget overruns.

Why You Should Avoid Buying Wood Furniture: Eco-Friendly Alternatives

You may want to see also

Explore related products

Supplier Comparison: Research local vs. national suppliers to find the best prices and quality

The cost and quality of railroad wood can vary significantly depending on whether you source it from local or national suppliers. Local suppliers often offer the advantage of lower transportation costs and the ability to inspect the wood in person, ensuring it meets your specific needs. However, national suppliers may provide a wider selection and competitive pricing due to their larger scale of operations. To make an informed decision, start by identifying your project requirements, such as the quantity of wood needed, desired quality, and budget constraints.

Analyzing the price structure of both local and national suppliers is crucial. Local suppliers typically have lower overhead costs, which can translate to savings for you. For instance, a local sawmill might offer reclaimed railroad ties at $15–$20 per piece, while a national distributor could charge $25–$30 due to shipping and handling fees. However, national suppliers often provide bulk discounts, making them more cost-effective for large-scale projects. Request detailed quotes from both types of suppliers, including delivery fees and any additional charges, to compare total costs accurately.

Quality is another critical factor in your supplier comparison. Local suppliers often specialize in regional wood types and may offer unique, weathered railroad wood with distinct character. Visiting their site allows you to handpick pieces that match your aesthetic or structural requirements. National suppliers, on the other hand, usually provide standardized products with consistent dimensions and treatment options, such as creosote-coated ties for durability. Consider whether your project prioritizes individuality or uniformity when evaluating quality.

Logistics and lead time should also influence your decision. Local suppliers can often deliver within a few days, reducing project delays, while national suppliers may require 2–4 weeks for shipping, depending on your location. If your project has a tight timeline, local sourcing might be the better option. Additionally, inquire about return policies and warranties, as these can vary widely between suppliers. A local supplier may offer more flexibility in resolving issues, whereas national suppliers often have structured policies that may or may not align with your needs.

To maximize value, combine research with negotiation. Local suppliers may be more open to bargaining, especially if you’re purchasing in bulk or establishing a long-term relationship. National suppliers, while less flexible on price, might offer incentives like free shipping or additional products at a discount. Always ask about current promotions or special deals. By carefully weighing these factors, you can determine whether a local or national supplier best aligns with your budget, quality standards, and project timeline for purchasing railroad wood.

Affordable Cabin Living: Cost Guide for Your Woodland Retreat

You may want to see also

Explore related products

$838.94

$679

$1803.48

$1616.81

Reclaimed vs. New: Compare costs and benefits of reclaimed railroad wood versus new timber options

Reclaimed railroad wood, with its weathered patina and historical charm, often comes at a premium—expect to pay $5 to $15 per square foot, depending on age, condition, and sourcing. New timber, by contrast, ranges from $2 to $8 per square foot for standard options like pine or cedar. While reclaimed wood’s higher cost reflects its scarcity and labor-intensive reclamation process, new timber offers affordability and consistency. However, the price gap narrows when factoring in the long-term durability and unique aesthetic of railroad wood, which can elevate a project’s value.

From an environmental standpoint, reclaimed railroad wood is the clear winner. By repurposing materials that might otherwise decay or be discarded, it reduces deforestation and minimizes carbon footprints. New timber, even when sustainably sourced, contributes to ongoing logging practices and habitat disruption. For eco-conscious projects, reclaimed wood’s sustainability benefits outweigh its higher upfront cost. Additionally, its natural weathering makes it resistant to rot and pests, reducing the need for chemical treatments often required with new timber.

Aesthetic appeal is where reclaimed railroad wood truly shines. Its deep, rich hues and distinctive grain patterns tell a story, adding character to furniture, flooring, or accent walls. New timber, while versatile, lacks this depth and often requires staining or aging techniques to achieve a similar look. For projects prioritizing authenticity and rustic charm, reclaimed wood is unmatched. However, new timber offers uniformity and customization options, making it ideal for modern or minimalist designs.

Durability is another critical factor. Railroad wood, treated with creosote or other preservatives during its service life, boasts exceptional hardness and resilience. It’s particularly well-suited for high-traffic areas like flooring or outdoor decking. New timber, while strong, may require additional treatments to match this level of durability. For long-term applications, reclaimed wood’s proven track record justifies its higher cost. However, new timber’s lighter weight and ease of installation can simplify DIY projects, saving on labor expenses.

In conclusion, the choice between reclaimed railroad wood and new timber hinges on project priorities. Reclaimed wood offers unmatched sustainability, durability, and aesthetic appeal but comes with a steeper price tag. New timber provides affordability, consistency, and ease of use, making it a practical choice for budget-conscious or contemporary designs. Assess your project’s needs—whether it’s environmental impact, visual impact, or cost efficiency—to determine which option aligns best with your goals.

Affordable Faux Wooden Blinds: Cost Guide for Budget-Friendly Window Treatments

You may want to see also

Explore related products

$1434.42

$1269.26

Bulk Discounts: Explore savings by purchasing railroad wood in large quantities from wholesalers

Purchasing railroad wood in bulk from wholesalers can unlock significant savings, but understanding the pricing structure is key. Wholesalers typically offer tiered discounts based on volume, with price breaks at specific thresholds. For instance, buying 100 ties might reduce the cost per unit by 10%, while purchasing 500 or more could slash prices by up to 25%. These discounts are designed to incentivize large orders, reducing the supplier’s handling and shipping costs while passing savings onto the buyer. Before committing, request a detailed quote outlining the cost per unit at various quantities to identify the optimal order size for your budget.

To maximize bulk discounts, plan your project with scalability in mind. Railroad wood is versatile, used in landscaping, construction, and DIY projects, so consider future needs alongside immediate requirements. For example, if you’re building a retaining wall and foresee additional outdoor projects, ordering enough wood for both can save money in the long run. However, balance this with storage constraints—railroad ties are heavy and bulky, requiring adequate space to prevent damage or obstruction. Collaborating with neighbors or contractors on a joint purchase can also help meet higher discount thresholds without overbuying.

While bulk discounts are appealing, they come with logistical challenges. Transportation is a critical factor, as railroad ties weigh 150–300 pounds each, and large orders may require specialized equipment or delivery services. Wholesalers often charge delivery fees based on distance and order size, so factor this into your cost analysis. Alternatively, arranging pickup with a truck or trailer can reduce expenses but demands careful planning to ensure safe loading and transport. Always verify the condition of the wood upon delivery, as wholesalers may have different quality standards than retail suppliers.

Finally, leverage negotiation to enhance your savings. Wholesalers often have flexibility in pricing, especially for cash payments or repeat customers. If you’re purchasing regularly or for a large-scale project, inquire about additional discounts or customized pricing. Building a relationship with a supplier can also lead to perks like priority inventory access or waived fees. Remember, bulk buying is a strategic decision—by combining volume discounts, logistical efficiency, and negotiation, you can secure railroad wood at a fraction of retail prices while ensuring you have the materials needed for current and future projects.

Best Places to Buy High-Quality Wood for Cutting Boards

You may want to see also

Explore related products

$936.01

$1055.14

$894.78

$754.38

Shipping Costs: Factor in transportation expenses when calculating the total cost of railroad wood

Transportation expenses can significantly inflate the total cost of railroad wood, often catching buyers off guard. For instance, a single 16-foot reclaimed oak railroad tie might retail for $20–$40, but shipping it from a Midwest supplier to the West Coast could add $150–$250 per piece due to its weight (200–300 lbs) and dimensional freight charges. Always request a freight quote before finalizing a purchase, as carriers like FedEx Freight or flatbed services price shipments based on weight, distance, and handling complexity.

To minimize shipping costs, consider bulk ordering. Buying 10–20 ties at once can reduce per-unit freight expenses by 30–50%, as carriers often charge less per pound for larger, consolidated loads. Alternatively, explore local suppliers or salvage yards within a 100-mile radius, where delivery fees might drop to $50–$100 total. If you’re sourcing from out of state, factor in fuel surcharges (typically 15–20% of the base freight rate) and potential accessorial fees, such as liftgate services ($75–$150) if you lack a loading dock.

For DIY enthusiasts, arranging pickup directly from the supplier can eliminate shipping costs entirely. However, ensure your vehicle or trailer can handle the load—a standard pickup truck can carry 2–4 ties safely, while a flatbed trailer might accommodate up to 10. If renting a vehicle, weigh the rental fee ($50–$150/day) against freight charges to determine the more cost-effective option. Pro tip: Use freight comparison tools like Freightquote or uShip to scout competitive rates and negotiate with carriers.

Finally, don’t overlook hidden costs tied to shipping delays or damage. Insure your shipment (typically 1–3% of the cargo value) to protect against transit damage, as railroad wood’s rough texture and weight make it prone to cracks or splinters. If time is critical, prioritize expedited shipping, though this can double or triple standard freight rates. By meticulously factoring transportation into your budget, you’ll avoid surprises and secure railroad wood at a price that aligns with your project’s scope.

Are Wooden Hockey Sticks Still Available for Purchase Today?

You may want to see also

Frequently asked questions

The cost of railroad wood varies depending on the type, condition, and source, but it generally ranges from $1 to $5 per linear foot for reclaimed or used ties, and up to $10 or more for new or specialty wood.

Factors affecting the price include the wood's age, condition (reclaimed vs. new), type of wood (e.g., oak, pine), treatment (creosote or untreated), quantity purchased, and supplier location.

The amount needed depends on your project's size and design. Measure the area or length required and add 10-15% extra for cuts and waste. For example, a 10-foot garden border might need 11-12 ties.