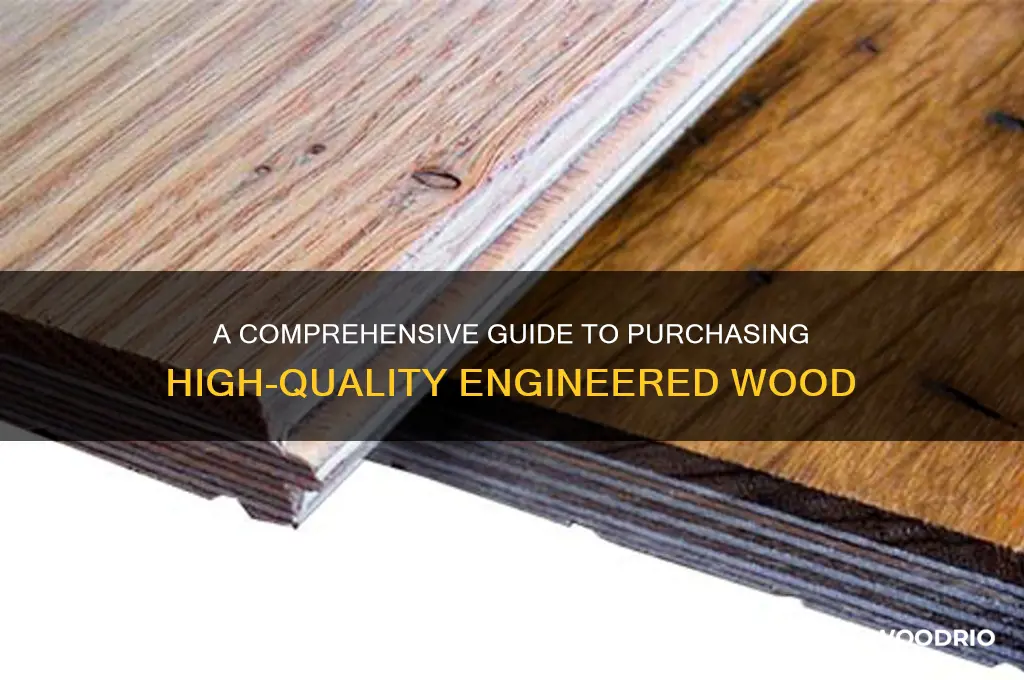

When considering purchasing engineered wood, it's essential to start by understanding your specific needs, such as the intended use, durability requirements, and aesthetic preferences. Engineered wood, a versatile and cost-effective alternative to solid wood, is composed of multiple layers of wood veneer glued together, offering enhanced stability and resistance to warping. Begin by researching reputable suppliers or retailers who specialize in engineered wood products, ensuring they provide detailed specifications about the wood’s composition, finish, and certifications. Compare prices, read customer reviews, and request samples to assess the quality and appearance firsthand. Additionally, consider factors like moisture resistance, thickness, and compatibility with your flooring or furniture project. Always verify the warranty and return policy to ensure satisfaction with your purchase. By taking these steps, you can make an informed decision and select the best engineered wood for your needs.

Explore related products

What You'll Learn

Understanding Engineered Wood Types

Engineered wood is not a one-size-fits-all solution. Unlike solid wood, which is milled from a single piece of timber, engineered wood is a composite material designed for specific applications. Understanding the types of engineered wood is crucial for making an informed purchase, as each type offers unique benefits and limitations. For instance, plywood, with its cross-laminated layers, provides exceptional strength and stability, making it ideal for structural applications like subflooring and roofing. In contrast, MDF (Medium Density Fiberboard) is prized for its smooth surface and uniformity, often used in cabinetry and furniture where a flawless finish is essential.

When selecting engineered wood, consider the core construction, which significantly impacts performance. Particleboard, made from wood chips and resin, is cost-effective but prone to swelling when exposed to moisture, limiting its use to dry indoor environments. Oriented Strand Board (OSB), on the other hand, is more resistant to warping and is commonly used in sheathing and subflooring. For high-moisture areas like kitchens or bathrooms, opt for engineered wood with a moisture-resistant core, such as marine-grade plywood, which is treated to withstand damp conditions.

The veneer or laminate surface of engineered wood also plays a critical role in its appearance and durability. A thick hardwood veneer allows for multiple sanding and refinishing cycles, extending the life of the product, while a thin veneer or laminate offers a budget-friendly option with limited refinishing potential. For example, engineered hardwood flooring with a 3mm wear layer can be sanded and refinished several times, whereas a 1mm veneer is typically only suitable for light-traffic areas.

Finally, consider the environmental impact and certifications when buying engineered wood. Look for products with FSC (Forest Stewardship Council) certification, ensuring the wood is sourced from responsibly managed forests. Additionally, formaldehyde emissions are a concern with some engineered woods, particularly those using urea-formaldehyde adhesives. Opt for products labeled as CARB Phase 2 compliant, which meet strict emission standards, especially if the wood will be used indoors. By carefully evaluating these factors, you can select the right type of engineered wood for your project, balancing performance, aesthetics, and sustainability.

Wooden Paneled Cars: Are They Available for Purchase Today?

You may want to see also

Explore related products

$149.59 $179.99

Checking Quality and Certifications

Engineered wood’s quality hinges on its construction, materials, and adherence to industry standards. Start by examining the core layers—plywood, OSB, or HDF—which determine stability and durability. A well-made core should be uniform in thickness and free of gaps or voids. Next, inspect the wear layer, typically hardwood or laminate. Thicker wear layers (2–4 mm) offer better longevity, especially in high-traffic areas. Finally, scrutinize the finish for consistency and scratch resistance. A matte or semi-gloss finish often masks imperfections better than high-gloss options.

Certifications serve as a shortcut to verifying quality and sustainability. Look for labels like the Forest Stewardship Council (FSC) or Sustainable Forestry Initiative (SFI), which ensure the wood is sourced responsibly. For emissions, CARB Phase 2 compliance guarantees formaldehyde levels are within safe limits (0.05 ppm or less). Additionally, check for FloorScore certification, which confirms the product meets indoor air quality standards. These certifications aren’t just marketing tools—they’re backed by third-party audits, providing tangible proof of quality.

A practical tip: test the wood’s resilience on-site. Press a fingernail or coin into the surface to assess hardness. High-quality engineered wood should resist dents. For moisture resistance, place a small water droplet on the surface for 10 minutes; no warping or discoloration indicates a robust seal. If possible, request a sample plank to test in your intended environment—direct sunlight, humidity, or heavy foot traffic can reveal flaws not apparent in store lighting.

Comparing certifications across brands can highlight hidden differences. For instance, while two products may both be FSC-certified, one might also carry a GreenGuard Gold label, making it safer for sensitive environments like schools or healthcare facilities. Similarly, a product with both CARB Phase 2 and FloorScore certifications outperforms one with only CARB compliance in terms of indoor air quality. These nuances can justify a higher price point for long-term benefits.

Instructively, always cross-reference certifications with the manufacturer’s warranty. A 25-year residential warranty on the wear layer, for example, should align with CARB and FSC certifications. Discrepancies—like a short warranty on a supposedly high-quality product—signal potential red flags. Keep documentation for future reference, as warranties often require proof of certification compliance for claims. By combining hands-on inspection with certification scrutiny, you ensure the engineered wood meets both immediate and long-term needs.

Where to Find a Standalone Wood Coffee Table Base for Purchase

You may want to see also

Explore related products

Measuring and Calculating Needs

Accurate measurements are the cornerstone of any successful engineered wood purchase. Underestimating your needs leads to multiple trips to the store and project delays, while overestimating wastes money and creates unnecessary clutter. Before you even consider wood species or finish, grab a tape measure and sketch pad.

Measuring for engineered wood requires precision. Start by determining the total square footage of the area to be covered. For flooring, measure the length and width of each room, multiplying these figures together. Don't forget to account for closets and nooks. For wall paneling or ceiling installations, measure the height and width of each surface. Remember, engineered wood is sold in specific plank or panel sizes, so factor in the width of each piece and any necessary expansion gaps.

Let's say you're installing engineered wood flooring in a 12' x 15' living room. That's 180 square feet. But wait! You need to add 5-10% for waste due to cutting and fitting. So, your actual purchase quantity should be closer to 190-198 square feet. This buffer ensures you have enough material to complete the job without running short.

Some engineered wood products come in bundles or boxes with specific square footage coverage. Carefully read the product specifications to understand how much area each unit covers. This information is crucial for calculating the number of bundles or boxes you'll need.

Don't rely solely on visual estimation. A room that seems small might require more material than you think, especially with intricate layouts or diagonal installations. Always double-check your measurements and calculations before making a purchase. Consider sketching a rough floor plan to visualize the layout and identify potential challenges. By taking the time to measure accurately and calculate your needs precisely, you'll ensure a smooth and efficient engineered wood installation, saving yourself time, money, and frustration in the long run.

Wood Grain Laminate for Tabletops: Where to Buy and How

You may want to see also

Explore related products

Comparing Prices and Suppliers

Engineered wood prices vary widely based on factors like thickness, finish, and brand reputation. A quick scan of suppliers reveals that a 12mm oak engineered wood plank can range from $2.50 to $7.00 per square foot. Before diving into comparisons, identify your project’s specific needs—traffic level, moisture exposure, and aesthetic preferences—to narrow down suitable options. High-traffic areas like kitchens may require thicker wear layers, while basements demand moisture-resistant cores.

To compare suppliers effectively, create a spreadsheet listing key details: price per square foot, shipping costs, return policies, and warranty terms. For instance, Supplier A might offer lower prices but charge steep shipping fees, while Supplier B includes free delivery but has a no-return policy. Analyze total costs, not just unit prices, and consider long-term value. A slightly pricier option with a 25-year warranty could save money over time compared to a cheaper product with limited durability.

When evaluating suppliers, look beyond price to assess reliability and customer service. Read reviews for insights into delivery times, product quality, and responsiveness to issues. For example, a supplier with a 4.8-star rating and consistent praise for timely deliveries may be worth a small premium. Conversely, a supplier offering the lowest prices but with frequent complaints about damaged shipments could end up costing more in hassle and replacements.

Finally, leverage bulk discounts and seasonal promotions to maximize savings. Many suppliers offer 10–15% discounts for orders over 500 square feet or run sales during slower months like winter. If your project timeline is flexible, wait for these opportunities. Additionally, request samples from multiple suppliers to compare grain patterns, finishes, and overall quality firsthand. This tangible comparison ensures you’re not sacrificing aesthetics for price.

In conclusion, comparing prices and suppliers for engineered wood requires a balance of cost analysis, quality assessment, and strategic timing. By focusing on total value, reliability, and practical considerations, you can secure the best product for your budget and needs.

Cathie Wood's Latest Move: Did She Invest in BNGO?

You may want to see also

Explore related products

Inspecting and Handling Delivery

Engineered wood arrives at your doorstep as a significant investment, and its condition upon delivery is crucial for the success of your project. A thorough inspection is not just a formality but a necessary step to ensure you receive exactly what you ordered and that it’s in pristine condition. Start by checking the packaging for any visible damage, such as tears, dents, or moisture stains, which could indicate mishandling during transit. Even if the exterior looks intact, carefully examine the wood itself for warping, cracks, or discoloration. Manufacturers often provide detailed inspection guidelines, so refer to these to ensure you’re not missing critical defects. Document any issues with photos and notes immediately, as this evidence will be vital if you need to file a claim or request a replacement.

Handling engineered wood requires precision and care to avoid damage during unloading and transportation to your project site. Always use proper equipment, such as forklifts with padded attachments or A-frame carriers, to prevent scratches or dents. If manual handling is necessary, ensure at least two people are involved to distribute the weight evenly and avoid dropping the material. Keep the wood flat and level during movement, as stacking or tilting can cause stress fractures or misalignment. Additionally, protect the wood from environmental factors like direct sunlight, rain, or extreme temperatures, which can warp or discolor the material. Store it in a dry, well-ventilated area until installation, and cover it with breathable materials if necessary.

Comparing the delivered product to your order specifications is a critical step often overlooked by first-time buyers. Verify the quantity, dimensions, and grade of the engineered wood against the invoice and product documentation. Discrepancies in thickness, width, or finish can derail your project timeline and budget. For example, a ¾-inch plank instead of a ½-inch one may not fit your subfloor or cabinetry design. If you notice any mismatches, contact the supplier immediately to resolve the issue before proceeding with installation. This proactive approach saves time and prevents costly rework later.

Persuading yourself to invest time in proper inspection and handling might seem tedious, but consider the long-term benefits. A thorough inspection ensures you’re not stuck with subpar material, while careful handling preserves the wood’s integrity and appearance. Think of it as safeguarding your investment—a few extra minutes now can prevent hours of frustration and additional expenses down the line. For instance, a single warped plank in a flooring project can compromise the entire installation, leading to uneven surfaces and potential safety hazards. By prioritizing these steps, you’re not just buying engineered wood; you’re ensuring its quality and longevity in your space.

Finally, establish a clear communication channel with your supplier or delivery team to streamline the inspection and handling process. Confirm delivery details in advance, including the date, time, and any special requirements for unloading. If possible, schedule the delivery when you or a trusted representative can be present to oversee the process. After inspection, promptly notify the supplier of any issues and follow their guidelines for returns or replacements. This collaborative approach minimizes misunderstandings and ensures a smoother resolution if problems arise. With these practices in place, you’ll be well-prepared to handle your engineered wood delivery with confidence and efficiency.

Best Places to Buy Quality Bonfire Wood Near You

You may want to see also

Frequently asked questions

Consider the intended use (flooring, furniture, etc.), the wood’s durability, moisture resistance, thickness of the wear layer, and the warranty provided by the manufacturer.

Choose based on the project’s requirements—opt for thicker wear layers for high-traffic areas, select moisture-resistant options for bathrooms or kitchens, and match the wood species and finish to your aesthetic preferences.

Purchase from reputable suppliers, home improvement stores, or specialized wood retailers. Ensure quality by checking for certifications (e.g., FSC), reading reviews, and inspecting samples for consistency in color, texture, and construction.