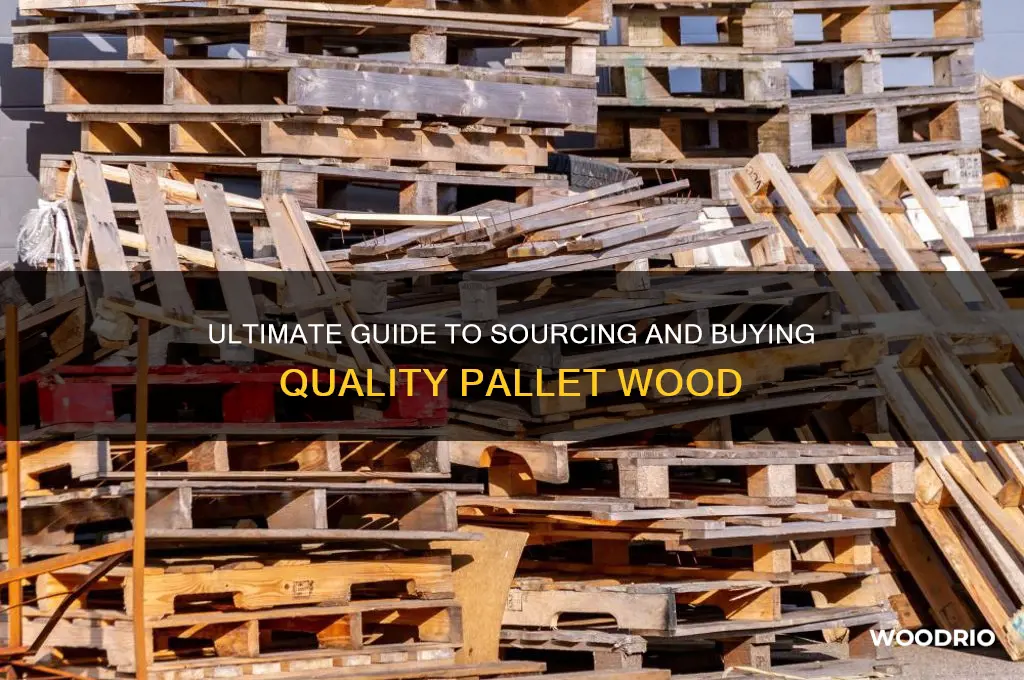

Buying pallet wood can be a cost-effective and sustainable way to source materials for DIY projects, furniture, or crafts. To start, research local suppliers, such as warehouses, distribution centers, or pallet recycling companies, as they often sell or give away used pallets. Ensure the pallets are safe for reuse by checking for stamps marked HT (heat-treated) or DB (debarked), avoiding those treated with chemicals labeled MB (methyl bromide). Online marketplaces like Craigslist, Facebook Marketplace, or specialized pallet resale sites are also great resources. Always inspect pallets for damage, rot, or pests before purchasing, and consider the type of wood and pallet size based on your project needs. With careful selection, pallet wood can be a versatile and eco-friendly option for your creative endeavors.

| Characteristics | Values |

|---|---|

| Sources | Local businesses, hardware stores, online marketplaces (e.g., Craigslist, Facebook Marketplace, eBay), pallet recycling centers, or directly from manufacturers. |

| Cost | Free to $20 per pallet, depending on condition, type, and source. |

| Types of Pallets | New, used, heat-treated (HT stamped), chemically treated (MB stamped), or untreated. |

| Material | Hardwood (oak, maple) or softwood (pine), with hardwood being more durable. |

| Size | Standard sizes: 48" x 40" (most common), 42" x 42", or custom sizes. |

| Condition | Inspect for damage, rot, stains, or chemical treatment marks. |

| Safety | Avoid pallets with "MB" stamp (chemically treated) for indoor projects. Use heat-treated (HT) or untreated pallets. |

| Transportation | Bring a truck or trailer, as pallets are bulky and heavy. |

| Quantity | Often sold in bulk, but some sellers offer single pallets. |

| Recycling | Some recycling centers pay for used pallets or offer them for free. |

| DIY Potential | Ideal for furniture, decor, gardening, and crafting projects. |

| Environmental Impact | Reusing pallets reduces waste and is eco-friendly. |

| Legal Considerations | Ensure pallets are not stolen property and verify ownership before taking. |

| Seasonal Availability | More readily available during shipping peak seasons (e.g., holidays). |

| Additional Tips | Ask local businesses for free pallets or join pallet-sharing communities. |

Explore related products

What You'll Learn

- Finding Local Suppliers: Locate nearby pallet suppliers, recycling centers, or businesses that sell or give away used pallets

- Inspecting Pallet Quality: Check for damage, stains, and stamps to ensure pallets are safe and suitable for reuse

- Understanding Pallet Grades: Learn the difference between new, recycled, and heat-treated pallets for specific project needs

- Negotiating Prices: Tips for bargaining with suppliers to get the best deals on bulk or single pallet purchases

- Transporting Pallets Safely: Plan how to securely load, tie down, and transport pallets to avoid damage or accidents

Finding Local Suppliers: Locate nearby pallet suppliers, recycling centers, or businesses that sell or give away used pallets

One of the most effective ways to source pallet wood locally is by identifying businesses that generate pallets as part of their operations. Warehouses, distribution centers, and manufacturing plants often have surplus pallets they’re willing to sell or give away. Start by calling or visiting these locations during business hours. Many companies view used pallets as waste and are happy to offload them, sometimes for free or at a nominal cost. Bring a truck or trailer, as these businesses rarely deliver. Pro tip: Ask if they have a specific day for pallet disposal or if they work with a recycling partner—this can streamline your search.

Recycling centers are another goldmine for pallet wood enthusiasts. These facilities often collect, sort, and resell used pallets to businesses or individuals. Unlike direct suppliers, recycling centers typically grade pallets by condition, allowing you to choose based on your project needs. Prices vary, but expect to pay $1–$5 per pallet for standard sizes. Call ahead to confirm availability and hours, as some centers operate on limited schedules. Bonus: Recycling centers often have other reclaimed materials, like crates or lumber, that could complement your project.

If cold-calling businesses feels daunting, leverage online platforms to locate local pallet suppliers. Websites like Craigslist, Facebook Marketplace, and OfferUp frequently list pallets for sale or giveaway. Filter searches by location and price, and don’t hesitate to negotiate. For a more structured approach, use pallet-specific directories such as Pallet Enterprise or local business listings. These platforms often include supplier reviews and contact details, saving you time and effort. Remember: Always inspect pallets before purchasing to avoid those treated with chemicals or damaged beyond use.

For those seeking a steady supply of pallets, building relationships with local businesses can be invaluable. Small retailers, grocery stores, and landscaping companies often receive shipments on pallets and may be willing to set them aside for you. Offer to pick them up regularly to establish a mutually beneficial arrangement. Alternatively, join community groups or forums where members share tips on local pallet sources. Word-of-mouth recommendations can lead you to hidden gems, like a nearby farm supply store or a construction site clearing out excess materials. Consistency is key—reliable suppliers often prioritize repeat customers.

Before hauling away your find, inspect pallets for safety and usability. Avoid those stamped with "MB" (methyl bromide treatment) or colored green, as these may contain harmful chemicals. Opt for heat-treated pallets, marked with "HT," which are safer for indoor projects. Additionally, check for structural integrity—avoid pallets with cracked or splintered boards. If you’re unsure about a pallet’s history, sand and seal the wood to remove potential contaminants. With a bit of effort, finding local pallet suppliers can turn into a sustainable, cost-effective way to fuel your woodworking projects.

Where to Buy Tinted Wood Filler for Seamless Repairs

You may want to see also

Explore related products

Inspecting Pallet Quality: Check for damage, stains, and stamps to ensure pallets are safe and suitable for reuse

Pallet wood, with its rustic charm and versatility, has become a staple in DIY projects, from furniture to wall art. However, not all pallets are created equal, and a thorough inspection is crucial to ensure safety and suitability for reuse. Start by examining the wood for visible damage such as cracks, splinters, or warping. These flaws can compromise structural integrity, making the pallet unsafe for certain projects, especially those bearing weight. A quick run of your hand along the surface can reveal hidden splinters, while a close visual inspection will highlight cracks or uneven surfaces.

Stains on pallet wood can tell a story, but not all tales are worth retelling. Dark, oily stains may indicate chemical spills, which could pose health risks or affect the wood’s durability. Avoid pallets with such marks, particularly if you’re repurposing them for indoor use or projects involving food contact. Water stains, on the other hand, are generally less concerning but can still weaken the wood over time. Use a moisture meter to check for excessive dampness, as wet wood is prone to mold and rot. A reading above 20% moisture content is a red flag.

Stamps on pallets are more than just markings—they’re essential clues about the pallet’s history. Look for the IPPC (International Plant Protection Convention) logo, which indicates the pallet has been heat-treated (HT) or fumigated (MB) to kill pests. Avoid pallets marked with "MB" if you’re sensitive to chemicals, as they’ve been treated with methyl bromide. Additionally, steer clear of pallets stamped with "Chemically Treated" or "Not for Reuse," as these are unsafe for DIY projects. A pallet with an "HT" stamp is your best bet for safety and versatility.

Inspecting pallets systematically can save time and prevent costly mistakes. Begin with a visual scan for damage, then test for moisture, and finally, decode the stamps. For larger projects, consider bringing a checklist to ensure consistency. If sourcing from a supplier, ask about the pallets’ history and whether they’ve been used to transport hazardous materials. While minor imperfections can add character, prioritizing safety and quality ensures your pallet wood project stands the test of time.

Wooden Homes: A Nuclear War Shelter Alternative?

You may want to see also

Explore related products

Understanding Pallet Grades: Learn the difference between new, recycled, and heat-treated pallets for specific project needs

Pallet grades are not just industry jargon—they directly impact the quality, cost, and suitability of wood for your projects. New pallets, often made from kiln-dried hardwood or softwood, offer uniformity and strength, making them ideal for furniture or decor where appearance matters. Recycled pallets, while budget-friendly, vary widely in condition; inspect for cracks, warping, or chemical stains, especially if repurposing for indoor use. Heat-treated pallets, marked with "HT," are pest-free and safer for gardening or food-related projects, though they may lack the aesthetic appeal of new wood. Understanding these distinctions ensures you select the right grade for durability, safety, and visual appeal.

For DIY enthusiasts, the choice between new and recycled pallets often boils down to cost versus quality. New pallets, priced at $10–$20 each, provide consistency but may require sanding to achieve a smooth finish. Recycled pallets, available for as little as $2–$5, demand scrutiny—avoid those with "MB" (methyl bromide treatment) stamps, as they may contain harmful chemicals. Heat-treated pallets, slightly pricier at $5–$10, are a middle ground, offering safety without the premium of new wood. Always prioritize pallets with clear markings to avoid surprises in your projects.

When selecting pallets for outdoor projects, heat-treated options are non-negotiable. Their pest-free nature prevents infestations in garden beds or compost bins, while their durability withstands weather exposure. For indoor projects like coffee tables or wall art, new or carefully vetted recycled pallets are preferable. Sanding and sealing recycled wood can transform it into a rustic centerpiece, but always test for odors or residues that could leach into living spaces. Matching the pallet grade to the project environment ensures longevity and safety.

A practical tip for sourcing pallets: check local hardware stores, shipping companies, or online marketplaces like Craigslist or Facebook Marketplace. Many businesses sell or give away used pallets in bulk, but always ask about their history. For heat-treated or new pallets, specialty suppliers often offer delivery, though at a higher cost. Keep a small toolkit—a pry bar, hammer, and safety gloves—handy for disassembling pallets without damaging the wood. With the right grade and preparation, pallet wood can elevate any project from functional to exceptional.

Where to Buy Flow Infused Wood in Palia: A Guide

You may want to see also

Explore related products

Negotiating Prices: Tips for bargaining with suppliers to get the best deals on bulk or single pallet purchases

Buying pallet wood, whether in bulk or as single units, often involves a negotiation dance with suppliers. Understanding their pricing structure is key. Many suppliers have tiered pricing, offering discounts for larger orders. For instance, purchasing 50 pallets might reduce the cost per unit by 15-20% compared to buying just 10. Before entering negotiations, research local market rates to recognize a fair deal. Websites like Craigslist, Facebook Marketplace, and specialized pallet supply platforms can provide benchmarks. Armed with this knowledge, you’re better positioned to challenge quotes that seem inflated.

A persuasive approach can tilt negotiations in your favor. Highlight your potential as a repeat customer or emphasize the volume of your order. For example, saying, “I’m planning to purchase pallets monthly for my DIY projects” signals long-term value. Similarly, offering to pay upfront or in cash can sweeten the deal, as suppliers often prefer immediate payment over invoicing. If you’re buying single pallets, bundle your order with a friend or neighbor to increase the quantity and leverage bulk pricing.

Comparing suppliers is a tactical move that pays dividends. Don’t settle for the first quote you receive. Reach out to at least three suppliers and request detailed breakdowns of their pricing, including delivery fees and taxes. Use these quotes as bargaining chips. For instance, if Supplier A charges $12 per pallet but Supplier B offers $10, politely inform Supplier A of the competing offer. Often, they’ll match or beat it to secure your business. This method works particularly well in competitive markets where suppliers are eager to retain clients.

Descriptive negotiation tactics involve building rapport and timing your approach. Engage suppliers in conversation to understand their pain points, such as excess inventory or slow-moving stock. If a supplier mentions they have a surplus of heat-treated pallets, propose a deal to clear their backlog. Additionally, timing matters—negotiate at the end of the month or quarter when suppliers are more likely to offer discounts to meet sales targets. A friendly yet firm tone, coupled with patience, can yield significant savings.

Finally, be prepared to walk away if the deal doesn’t meet your expectations. Suppliers often sense desperation and may hold firm on pricing. However, showing willingness to explore other options can prompt them to reconsider. For example, if a supplier refuses to budge on a $15 per pallet price, thank them for their time and mention you’ll check with competitors. More often than not, they’ll call back with a better offer. This strategy requires confidence and research but can result in substantial savings, especially for bulk purchases.

Why People Choose Maple Wood: Benefits, Uses, and Popularity Explained

You may want to see also

Explore related products

Transporting Pallets Safely: Plan how to securely load, tie down, and transport pallets to avoid damage or accidents

Securing pallets for transport isn’t just about strapping them down—it’s about understanding weight distribution, friction, and the forces at play during transit. A single pallet can weigh anywhere from 30 to 70 pounds when loaded, and improper loading can shift cargo, causing damage or even accidents. Start by assessing the weight and dimensions of your pallets. Use a forklift or pallet jack to position them centrally on the truck bed or trailer, ensuring the heaviest pallets are at the bottom to maintain stability. Distribute weight evenly across the vehicle to prevent tipping or uneven tire wear.

Once loaded, tying down pallets requires more than just rope or straps. Use industrial-grade ratchet straps with a minimum breaking strength of 5,000 pounds for most loads. Secure each pallet by crisscrossing straps over the top and anchoring them to the vehicle’s tie-down points. Avoid placing straps directly on wood corners, as this can cause breakage; instead, use edge protectors or padding. Tighten straps until the pallets are immobile but not crushed. For taller stacks, consider adding a top restraint like a net or additional straps to prevent shifting during sudden stops or turns.

Transporting pallets safely also involves anticipating road conditions. Sharp turns, potholes, and sudden braking can destabilize even the most secure load. Drive defensively, maintaining a steady speed and avoiding abrupt maneuvers. If transporting over long distances, periodically stop to inspect the load. Look for signs of shifting, loosened straps, or damaged pallets. Carry extra straps, tools, and padding in case adjustments are needed. Remember, a well-planned load is a safe load—and safety saves time, money, and potential liability.

Comparing methods, some opt for shrink-wrapping pallets before transport, but this doesn’t replace proper strapping. Shrink-wrap can tear or loosen, especially in adverse weather. A better approach is combining physical restraints with environmental precautions. Cover pallets with tarps to protect against rain or debris, but ensure the tarp itself is secured to avoid becoming a hazard. For oversized or oddly shaped loads, consult a professional or refer to DOT regulations for specific guidelines. Safe pallet transport isn’t just about following rules—it’s about protecting your cargo, your vehicle, and everyone on the road.

Best Places to Purchase New Wood Pallets for Your Needs

You may want to see also

Frequently asked questions

You can buy pallet wood from local pallet suppliers, lumberyards, recycling centers, or online marketplaces like Craigslist, Facebook Marketplace, or eBay.

The cost of pallet wood varies, but it typically ranges from $10 to $20 per pallet, depending on the quality, size, and location. Some places may offer them for free if you’re willing to pick them up.

Look for pallets marked with "HT" (heat-treated) or "DB" (debarked), as these are safe for reuse. Avoid pallets marked with "MB" (methyl bromide), as they may contain chemicals harmful for indoor use.

Not all pallets are suitable for DIY projects. Avoid pallets with signs of mold, rot, or chemical stains. Hardwood pallets (e.g., oak or pine) are generally better for crafting than softwood or pressed wood pallets.

Use a pry bar, hammer, or pallet dismantling tool to carefully separate the boards. Work slowly to avoid splitting the wood, and consider using a reciprocating saw for stubborn nails.