Buying wood requires careful consideration of several factors to ensure you get the right material for your project. Start by identifying the type of wood needed, such as hardwood (e.g., oak, maple) for durability or softwood (e.g., pine, cedar) for lighter applications. Determine the required dimensions, including thickness, width, and length, based on your project specifications. Consider the wood’s grade, which affects quality and price, and whether it needs to be treated or finished. Research reputable suppliers, whether local lumberyards, hardware stores, or online retailers, and compare prices, availability, and customer reviews. Inspect the wood for defects like knots, warping, or cracks before purchasing. Finally, factor in delivery or transportation options, especially for large or heavy pieces, to ensure a smooth and cost-effective buying experience.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwood (e.g., oak, maple, walnut), Softwood (e.g., pine, cedar, spruce) |

| Grade | Select, #1 Common, #2 Common, etc. (based on defects and appearance) |

| Moisture Content | Air-dried (12-15%), Kiln-dried (6-8%), Green (freshly cut) |

| Dimensions | Standard sizes (e.g., 2x4, 1x6) or custom cuts |

| Finish | Rough-sawn, planed, sanded, or pre-finished |

| Sustainability | FSC-certified, reclaimed, or locally sourced |

| Cost | Varies by type, grade, and quantity (e.g., $3-$20 per board foot) |

| Supplier | Local lumberyards, big-box stores, online retailers, or specialty mills |

| Transport | Delivery options, pickup, or shipping (consider weight and size) |

| Quantity | Sold by board feet, lineal feet, or in bundles/packs |

| Inspection | Check for cracks, warping, insect damage, and moisture levels |

| Storage | Store in a dry, well-ventilated area to prevent warping or mold |

| Usage | Furniture, construction, flooring, cabinetry, or crafts |

| Treatment | Pressure-treated, heat-treated, or untreated (for outdoor use) |

| Availability | Seasonal or year-round, depending on supplier and type |

Explore related products

What You'll Learn

- Types of Wood: Hardwood vs. softwood, grain patterns, durability, and best uses for each type

- Wood Grades: Understanding quality levels, defects, and how grades affect price and appearance

- Sourcing Wood: Local suppliers, online stores, reclaimed wood, and sustainable sourcing options

- Measuring Needs: Calculating required quantities, standard sizes, and avoiding waste in purchases

- Cost Factors: Price per board foot, shipping fees, and negotiating bulk discounts effectively

Types of Wood: Hardwood vs. softwood, grain patterns, durability, and best uses for each type

Understanding the difference between hardwood and softwood is the first step in making an informed wood purchase. Contrary to what their names suggest, the distinction isn't solely about hardness. Hardwoods come from deciduous trees, like oak and maple, and are generally denser and more durable. Softwoods, sourced from coniferous trees such as pine and cedar, tend to be lighter and easier to work with. This fundamental categorization influences not only the wood's strength but also its cost, availability, and suitability for specific projects.

Grain patterns play a pivotal role in both the aesthetic and structural qualities of wood. Hardwoods often exhibit tighter, more complex grain patterns, which can add visual appeal to furniture or flooring. For instance, the swirling grain of walnut or the straight, uniform lines of cherry can elevate a piece's design. Softwoods, on the other hand, typically have simpler, straighter grains, making them ideal for projects where uniformity is key, such as framing or paneling. Understanding grain direction is also crucial for preventing warping or splitting during construction.

Durability is a critical factor when selecting wood for a project. Hardwoods, with their denser composition, are more resistant to wear and tear, making them excellent choices for high-traffic areas like hardwood floors or outdoor decks. Softwoods, while less durable, can still perform well in the right applications. For example, cedar’s natural resistance to rot and insects makes it a popular choice for outdoor furniture and siding. Treating softwoods with sealants or stains can also enhance their longevity, bridging the durability gap between the two types.

The best use of each wood type ultimately depends on the project's requirements. Hardwoods are ideal for fine woodworking, such as cabinetry, tables, and decorative pieces, where strength and appearance are paramount. Softwoods shine in structural applications, like framing houses or building shelves, where cost-effectiveness and ease of use are more important than aesthetic appeal. For outdoor projects, consider the specific properties of each wood: teak’s weather resistance for patio furniture, or pressure-treated pine for decking. By matching the wood type to the project’s demands, you ensure both functionality and longevity.

Practical tips can further guide your wood selection. For indoor projects, prioritize hardwoods for their durability and visual appeal, but be prepared for higher costs. When working with softwoods, always inspect for knots and defects that could weaken the material. For outdoor applications, research the specific resistance properties of each wood type—for instance, redwood’s natural ability to repel pests. Finally, consider sustainability by opting for certified wood products, ensuring your purchase supports responsible forestry practices. Armed with this knowledge, you can confidently choose the right wood for any project.

Top Places to Purchase High-Quality Wooden Canvas Frames Online

You may want to see also

Explore related products

Wood Grades: Understanding quality levels, defects, and how grades affect price and appearance

Wood grades are the unsung heroes of your project’s success, dictating everything from durability to aesthetics. Think of them as a report card for lumber, where A+ means fewer defects, tighter grain patterns, and a higher price tag. Lower grades, while cheaper, often come with knots, cracks, or uneven textures that can compromise both function and appearance. Understanding these grades isn’t just about saving money—it’s about matching the wood’s quality to your project’s demands. For instance, a premium grade like FAS (First and Seconds) is ideal for fine furniture, while No. 3 Common works perfectly for structural framing where imperfections are hidden.

Defects in wood aren’t always dealbreakers, but they’re worth scrutinizing. Knots, for example, can add character to a rustic table but weaken a load-bearing beam. Checks (cracks across the grain) and splits may indicate drying issues, while wane (bark within the board) reduces usable surface area. Each defect lowers the grade and price, but strategically, they can be concealed or embraced depending on your project. Pro tip: Inspect wood in natural light to spot defects that might be missed under harsh store lighting.

Grades aren’t arbitrary—they’re governed by standards like the National Hardwood Lumber Association’s rules, which categorize wood based on clarity, size, and defect allowance. For softwoods, the Structural Appearance Lumber (SAL) grading system balances strength and look. Hardwoods often follow a 1-5 grading scale, with 1 being the highest quality. Knowing these systems empowers you to negotiate prices or select the right grade for your budget. For example, a 2-inch thick hardwood board graded as Select might cost 30% more than its No. 2 Common counterpart but offers a smoother, more uniform surface.

The grade you choose directly impacts your project’s appearance. Higher grades provide a consistent color and grain, essential for cabinetry or flooring where patterns need to align. Lower grades, with their natural imperfections, are perfect for distressed finishes or outdoor projects where character trumps perfection. Consider this: a live-edge coffee table made from FAS walnut will showcase a flawless grain, while the same design in No. 2 Common oak will highlight knots and variations, creating a unique, organic look.

Finally, price is the most tangible effect of wood grades. Premium grades can cost 2-3 times more than lower ones, but they save time in sanding, finishing, and rework. For DIYers, mid-range grades like No. 1 Common offer a balance of quality and affordability. Always calculate the total cost per square foot, factoring in waste from defects in lower grades. A practical approach: If you’re building a bookshelf, opt for a higher grade for the visible shelves and a lower grade for the hidden supports. This way, you get the best of both worlds—aesthetic appeal and cost efficiency.

Discover the Best Places to Buy Wood Stumps Online and Locally

You may want to see also

Explore related products

Sourcing Wood: Local suppliers, online stores, reclaimed wood, and sustainable sourcing options

Local suppliers offer a tactile, personalized experience unmatched by digital alternatives. Visiting a lumberyard allows you to inspect grain patterns, moisture levels, and overall quality firsthand—critical for projects requiring specific densities or finishes. Establish a relationship with suppliers; they often provide insights into seasonal availability (e.g., oak is best sourced in late winter to avoid warping) or custom milling options. For instance, a small-scale carpenter in Portland might negotiate bulk discounts on maple by committing to quarterly purchases, ensuring consistent supply for furniture commissions. Proximity also reduces carbon footprints, as transportation emissions are minimized compared to cross-country shipping.

Online stores democratize access to exotic or specialty woods, but due diligence is non-negotiable. Platforms like Woodworkers Source or eBay list rare species like zebrawood or reclaimed barn beams, often with detailed moisture content readings (ideal range: 6–8% for indoor use). Beware of vague listings; verify seller reviews and request high-resolution photos to assess cracks or insect damage. For example, a hobbyist building a koa guitar body should prioritize sellers offering kiln-dried stock to prevent warping during instrument assembly. Factor in shipping costs—a 4x8 sheet of marine-grade plywood can weigh over 100 lbs, doubling delivery fees—and consider flat-rate freight services for bulk orders.

Reclaimed wood merges sustainability with character, but sourcing requires vigilance. Salvage yards and deconstruction nonprofits (e.g., Habitat for Humanity’s ReStore) offer beams, flooring, or siding with patina from decades of use. However, test for lead paint (common in pre-1978 structures) using $10 DIY kits before sanding. A Brooklyn designer repurposed 100-year-old Douglas fir joists into a conference table, preserving nail holes for aesthetic contrast, but first treated the wood with borate solution to eliminate pests. Reclaimed materials often cost 20–40% more than new lumber due to labor-intensive recovery, yet their durability and carbon-sequestering properties justify the investment for eco-conscious projects.

Sustainable sourcing hinges on certifications, but not all labels are created equal. FSC (Forest Stewardship Council) certification ensures timber is harvested without clear-cutting or habitat destruction, while PEFC standards prioritize regional forestry practices. For tropical hardwoods like ipe or teak, demand proof of legal export under CITES regulations to combat illegal logging. A Seattle architect specifies FSC-certified cedar for decking projects, pairing it with non-toxic sealants to maintain LEED compliance. Alternatively, consider fast-growing alternatives like bamboo (matures in 5 years vs. 30 for oak) or thermally modified pine, which resists rot without chemical treatment. Cross-reference suppliers’ claims with databases like Global Forest Watch to verify sustainability practices.

Best Places to Purchase High-Quality Walnut Wood for Your Projects

You may want to see also

Explore related products

Measuring Needs: Calculating required quantities, standard sizes, and avoiding waste in purchases

Accurate measurement is the cornerstone of efficient wood purchasing. Overestimating leads to unnecessary expense and storage headaches, while underestimating halts projects and incurs additional trips. Before heading to the lumberyard, grab a tape measure and sketch pad. Break your project down into individual components, noting the length, width, and thickness required for each piece. Factor in any additional material needed for joints, trim, or potential mistakes. Online project calculators can be helpful, but double-check their assumptions against your specific design.

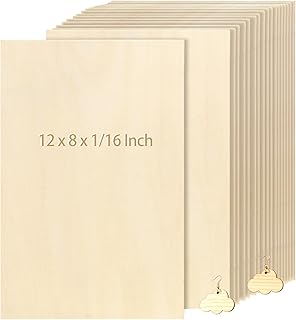

Remember, wood is sold in standard dimensions. Familiarize yourself with common lumber sizes (2x4, 1x6, plywood sheets) to ensure your measurements align with readily available options.

Let's say you're building a simple bookshelf. You'll need shelves, sides, a back panel, and perhaps a top. Measure the desired shelf depth, height of the sides, and overall width. Account for the thickness of the wood itself when calculating shelf spacing. For example, if you want 12" deep shelves and use 3/4" thick plywood, your shelf supports need to be spaced 12 3/4" apart. Don't forget to add material for the back panel and any decorative trim.

While it's tempting to round up measurements "just in case," this often results in significant waste. Consider optimizing your design to utilize standard lumber lengths. For instance, if your project requires multiple pieces of 36" length, plan to cut them from a single 8-foot (96") board. Many lumberyards offer cutting services, allowing you to have boards cut to size on-site, minimizing waste and saving you time.

Finally, think beyond the immediate project. If you frequently work with wood, consider purchasing in bulk. Lumberyards often offer discounts for larger quantities. Store leftover wood scraps systematically, labeling them with dimensions for future use. With careful planning and a mindful approach to measurement, you can minimize waste, save money, and ensure you have the right amount of wood for every project.

Best Sources to Buy Wood Ash for Your Garden: A Guide

You may want to see also

Explore related products

Cost Factors: Price per board foot, shipping fees, and negotiating bulk discounts effectively

Understanding the price per board foot is the cornerstone of budgeting for any woodworking project. This unit of measurement, which calculates the cost of a piece of wood one inch thick, one foot wide, and one foot long, varies widely based on species, grade, and market demand. For instance, hardwoods like walnut or mahogany can cost $10 to $20 per board foot, while softer woods like pine might range from $2 to $5. Always verify if the supplier includes drying and milling in the price, as these processes can add 20-30% to the total cost. Pro tip: Use online calculators to estimate total board footage needed, factoring in 10-15% for waste.

Shipping fees can quietly inflate your wood-buying budget, especially for heavy or long pieces. Domestic shipments within the U.S. often start at $150 for a full pallet, while international or expedited shipping can double or triple that cost. To mitigate this, consider local suppliers or sawmills, which may offer free pickup or discounted regional delivery. If ordering online, consolidate purchases to maximize weight and minimize trips—most carriers charge by weight and distance. For example, a 500-pound shipment from Oregon to New York might cost $300, but splitting it into two 250-pound shipments could total $450.

Negotiating bulk discounts requires strategy, not just volume. Start by researching average discounts for your desired wood type; hardwood suppliers often offer 10-15% off for orders over 1,000 board feet. Approach negotiations with data: compare prices from three suppliers and use their quotes as leverage. For instance, if Supplier A offers $12 per board foot, show them Supplier B’s $11 quote and ask for a match or better. Be prepared to commit to recurring orders or pay upfront—suppliers value long-term relationships and reduced financial risk. A well-timed negotiation can save thousands on large projects.

Balancing these cost factors demands a holistic approach. Prioritize species and grade based on project needs, then calculate total board footage and shipping logistics. For example, a 100-square-foot walnut tabletop requiring 50 board feet at $15 each totals $750 before shipping. If shipping adds $200, the project cost jumps to $950—but a 10% bulk discount could save $75, reducing the total to $875. Always request detailed quotes and ask about hidden fees like fuel surcharges or handling costs. By mastering these variables, you’ll ensure your wood purchases align with both your vision and your wallet.

Where to Buy Oxalic Acid Wood Bleach for Effective Restoration

You may want to see also

Frequently asked questions

Consider the type of wood (hardwood vs. softwood), grain pattern, moisture content, intended use, durability, and budget.

Identify the project’s requirements (e.g., indoor/outdoor use, strength, appearance) and choose wood accordingly. Hardwoods like oak are ideal for furniture, while softwoods like pine are great for framing.

Wood with high moisture content can warp or crack as it dries. Aim for wood with 6-8% moisture content for indoor projects to ensure stability.

Purchase wood from hardware stores, lumberyards, specialty wood suppliers, or online retailers. Local sawmills may also offer affordable, freshly cut options.

Look for certifications like FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) to ensure the wood comes from responsibly managed forests.