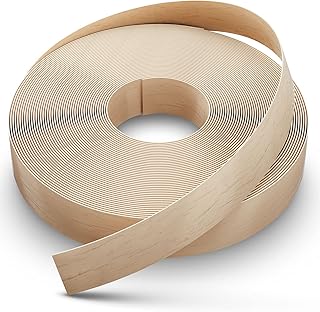

Buying wood veneer requires careful consideration to ensure you get the right product for your project. Start by determining the type of wood species you need, as options range from common choices like oak and maple to exotic varieties such as zebrawood or mahogany. Next, assess the thickness and grade of the veneer, with thicker options offering more durability and higher grades providing a more uniform appearance. Consider the size and quantity needed, as veneer is often sold in sheets or rolls, and ordering slightly more than required can account for waste. Finally, research reputable suppliers or retailers, comparing prices, quality, and customer reviews to make an informed decision that aligns with your budget and project requirements.

| Characteristics | Values |

|---|---|

| Type of Veneer | Natural, Reconstituted, Engineered, or Paper-backed |

| Wood Species | Oak, Maple, Walnut, Cherry, Mahogany, Teak, etc. |

| Grain Pattern | Straight, Flat-cut, Quarter-cut, Rotary-cut, or Rift-cut |

| Thickness | Typically 0.6mm to 6mm (0.024" to 0.24") |

| Sheet Size | Standard sizes: 4' x 8' (1220mm x 2440mm), but custom sizes available |

| Finish | Raw, Pre-finished, or Backed with adhesive |

| Quality | A (highest), B, C, or D (lowest) based on defects and color consistency |

| Price Range | $1 to $50 per square foot, depending on species, quality, and finish |

| Supplier | Local lumberyards, online retailers (e.g., Woodcraft, Amazon), or specialty veneer suppliers |

| Application | Furniture, cabinetry, wall paneling, or decorative accents |

| Durability | Varies by species; harder woods (e.g., Oak, Maple) are more durable |

| Environmental Impact | Look for FSC-certified or sustainably sourced veneers |

| Installation | Requires adhesive (e.g., contact cement, veneer glue) and proper tools (e.g., veneer hammer, scraper) |

| Maintenance | Regular cleaning and occasional refinishing to maintain appearance |

| Custom Orders | Available for specific sizes, thicknesses, or species |

| Shipping | Consider shipping costs and packaging to prevent damage during transit |

Explore related products

What You'll Learn

- Types of Wood Veneer: Understand species, grain patterns, and finishes for your project needs

- Veneer Grades Explained: Learn quality differences (A, B, C) to match budget and aesthetics

- Measuring & Ordering: Calculate square footage accurately to avoid waste and extra costs

- Suppliers & Sources: Find reputable vendors, compare prices, and check reviews for reliability

- Handling & Storage Tips: Protect veneer from moisture, heat, and damage during transport and storage

Types of Wood Veneer: Understand species, grain patterns, and finishes for your project needs

Wood veneer is not a one-size-fits-all material. The species of wood you choose dramatically influences the aesthetic and durability of your project. For instance, mahogany veneer exudes warmth and richness, making it ideal for high-end furniture or paneling, while maple veneer offers a lighter, more contemporary look suited for modern interiors. Exotic species like zebrawood or teak bring unique grain patterns and textures but come at a higher cost. Consider the project’s environment too—oak veneer is durable and resists wear, perfect for flooring or countertops, whereas cherry veneer may darken over time, adding character but requiring careful placement.

Grain patterns are the visual fingerprint of wood veneer, dictating its style and flow. Straight grain patterns, found in woods like walnut or ash, create a clean, linear look that elongates spaces. Quarter-sawn grain, often seen in white oak, provides a distinctive ray-fleck pattern and greater stability, reducing warping over time. For a bold statement, rotary-cut veneer showcases a swirling, chaotic grain, commonly used in decorative panels. When selecting grain, align it with the project’s scale—fine, uniform patterns work well in small spaces, while dramatic grains can anchor larger areas.

Finishes are the final layer that protect and enhance wood veneer’s natural beauty. Polyurethane finishes offer robust protection against scratches and moisture, ideal for high-traffic areas like tabletops. Oil-based finishes, such as tung or linseed oil, penetrate the wood, highlighting its grain while providing a matte, natural look. For a glossy, reflective surface, lacquer finishes are applied in multiple coats, though they require more maintenance. Consider the maintenance level you’re willing to commit to—some finishes need periodic reapplication, while others, like catalyzed finishes, provide long-lasting durability with minimal upkeep.

Matching veneer species, grain, and finish to your project’s functional and aesthetic needs is crucial. For example, a birch veneer with a straight grain and satin finish works well for minimalist cabinetry, while a burl walnut veneer with a high-gloss finish can elevate a statement piece. Always test samples under the intended lighting conditions, as finishes can alter the wood’s perceived color. Additionally, factor in sustainability—opt for FSC-certified veneers or reclaimed wood to minimize environmental impact. By understanding these elements, you’ll ensure the veneer not only looks stunning but also performs flawlessly in its intended role.

Best Places to Purchase High-Quality Wooden Barrels for Your Needs

You may want to see also

Explore related products

Veneer Grades Explained: Learn quality differences (A, B, C) to match budget and aesthetics

Wood veneer grades are not just labels—they are your roadmap to balancing cost and appearance. Grade A veneer, the crème de la crème, features consistent color, minimal defects, and striking grain patterns. Think of it as the hardwood flooring equivalent of a flawless diamond. Ideal for high-visibility projects like furniture faces or wall panels, it commands a premium price but delivers unmatched elegance. Grade B, on the other hand, allows for slight color variations and small natural imperfections, making it a smart choice for areas where character is valued over perfection, such as cabinet interiors or rustic designs. Grade C, the most budget-friendly option, embraces knots, streaks, and irregular grain, perfect for projects where a raw, organic aesthetic is desired, like accent walls or artisanal pieces.

Understanding these grades requires a practical approach. Start by defining your project’s visibility and purpose. For a dining table centerpiece, Grade A’s uniformity ensures a polished look, while Grade C’s quirks can add charm to a hidden bookshelf back panel. Next, consider the wood species, as some naturally exhibit more variation than others. For instance, walnut Grade B may still appear more refined than maple Grade A due to its inherent rich, swirling grain. Finally, inspect samples under different lighting conditions—what looks like a flaw in harsh light might blend seamlessly in a softly lit room.

A common misconception is that lower grades equate to poor quality. In reality, Grade C veneer isn’t inferior—it’s simply different. Its unique characteristics can elevate designs when used intentionally. For example, a Grade C oak veneer with prominent knots can transform a modern coffee table into a conversation piece. The key is aligning the grade with your vision, not defaulting to the highest (and priciest) option.

To maximize your investment, pair veneer grades with appropriate finishes. Grade A benefits from clear coats that highlight its pristine surface, while Grade C thrives with oils or stains that enhance its texture. Avoid over-sanding lower grades, as this can exacerbate imperfections. Instead, lean into their natural beauty. For large projects, mix grades strategically—use Grade A for focal points and Grade B or C for less prominent areas to save costs without sacrificing impact.

In conclusion, veneer grades are not a one-size-fits-all solution but a spectrum of possibilities. By understanding their nuances, you can make informed decisions that align with both your budget and design goals. Whether you’re crafting a luxury piece or embracing imperfection, the right grade ensures your project not only looks good but feels right.

Buying Land Deep in the Woods: Legal, Practical, and Environmental Considerations

You may want to see also

Explore related products

Measuring & Ordering: Calculate square footage accurately to avoid waste and extra costs

Accurate measurement is the linchpin of cost-effective wood veneer purchasing. Miscalculations, even by a fraction, can lead to significant waste or shortages, both of which inflate project costs. For instance, a 10% overestimation on a 500-square-foot project means paying for 50 square feet of unused material, while underestimating by the same margin necessitates a second order, often at a higher cost per unit. Precision in this step not only saves money but also reduces environmental impact by minimizing excess material.

To calculate square footage, break down the project into manageable sections. Measure each surface (e.g., cabinet doors, panels) in inches, then multiply length by width to get the area in square inches. Convert to square feet by dividing by 144 (since one square foot equals 144 square inches). For example, a 30-inch by 40-inch panel equals 1,200 square inches, or 8.33 square feet. Sum all sections to get the total square footage. Always add 10–15% for cutting waste, especially if the design involves intricate patterns or matching grain.

Ordering requires understanding veneer packaging. Veneer is often sold in bundles or rolls, with standard sizes like 4-foot by 8-foot sheets or 25-square-foot bundles. Compare your calculated square footage to available options, ensuring you don’t over-order. For example, if your project requires 65 square feet, two 4x8 sheets (64 square feet total) would suffice, but adding 10% waste would necessitate a third sheet. Some suppliers offer custom cuts, which can reduce waste but may increase cost—weigh the trade-off based on project scale.

A common pitfall is neglecting irregular shapes or edge banding. For curved or angled surfaces, trace the shape onto graph paper and count squares to estimate area. Alternatively, use digital tools like apps or software that calculate area from uploaded images. Edge banding, often overlooked, requires additional material—plan for 10–20 linear feet of veneer per 100 square feet of surface area, depending on edge exposure.

Finally, verify measurements twice before ordering. Cross-check calculations with a second method (e.g., using an online square footage calculator) to catch errors. If possible, consult a professional or experienced DIYer for a second opinion. Accurate ordering not only streamlines the project but also fosters a professional relationship with suppliers, who may offer discounts or advice for precise, well-planned orders.

Teachers Seeking Wooden Classroom Supplies: Connect with Sellers Today

You may want to see also

Explore related products

Suppliers & Sources: Find reputable vendors, compare prices, and check reviews for reliability

Reputable suppliers are the backbone of any successful wood veneer purchase, ensuring quality, consistency, and reliability. Start by identifying vendors with a proven track record in the industry. Established companies often have detailed websites showcasing their product range, certifications, and customer testimonials. Look for suppliers who specialize in wood veneer, as their expertise can provide valuable insights into species, thicknesses, and finishes. For instance, companies like *VeneerSupplies.com* or *Columbia Forest Products* are known for their extensive catalogs and industry reputation. These vendors typically offer both domestic and exotic wood options, catering to diverse project needs.

Comparing prices is a critical step, but it’s not just about finding the cheapest option. Analyze cost per square foot, shipping fees, and bulk discounts. Some suppliers offer sample packs at a nominal cost, allowing you to assess quality before committing to a larger order. For example, a 10’ x 4’ sheet of walnut veneer might range from $150 to $300 depending on the supplier and grade. Use price comparison tools or request quotes from multiple vendors to ensure you’re getting the best value. Keep in mind that lower prices may indicate thinner veneer or inferior quality, so balance cost with reliability.

Reviews and ratings are your best allies in gauging a supplier’s reliability. Check platforms like Google Reviews, Trustpilot, or industry-specific forums for customer feedback. Pay attention to recurring themes—consistent complaints about shipping delays or product defects are red flags. Conversely, praise for customer service, product accuracy, and timely delivery signals a trustworthy vendor. For instance, a supplier with a 4.5-star rating and numerous positive reviews for their oak veneer is likely a safer bet than one with a 2.8-star rating and unresolved complaints.

Practical tips can streamline your search. First, verify the supplier’s return policy—reputable vendors often offer hassle-free returns for damaged or incorrect items. Second, inquire about sourcing practices; ethically harvested wood is not only environmentally responsible but also ensures better quality. Third, consider local suppliers to reduce shipping costs and support regional businesses. Finally, don’t hesitate to ask questions—a responsive and knowledgeable vendor is a strong indicator of reliability. By combining research, comparison, and due diligence, you can confidently select a supplier that meets your wood veneer needs.

Choosing Quality Solid Wood Furniture: A Buyer's Essential Guide

You may want to see also

Explore related products

Handling & Storage Tips: Protect veneer from moisture, heat, and damage during transport and storage

Wood veneer is a delicate material, and its susceptibility to moisture, heat, and physical damage necessitates careful handling and storage. Exposure to humidity can cause warping or delamination, while heat may lead to cracking or discoloration. Even minor impacts during transport can result in chips or splits, compromising the veneer’s integrity. Understanding these vulnerabilities is the first step in ensuring your investment remains pristine from purchase to application.

To protect veneer from moisture, store it in a climate-controlled environment with humidity levels between 40% and 60%. Use desiccant packs in storage areas to absorb excess moisture, particularly in humid climates. During transport, wrap veneer sheets in moisture-resistant paper or plastic, ensuring the material is sealed but not airtight to prevent condensation buildup. Avoid storing veneer near windows, exterior walls, or basements where temperature and humidity fluctuations are common.

Heat can be just as damaging as moisture, so keep veneer away from direct sunlight, radiators, or other heat sources. Ideal storage temperatures range from 60°F to 75°F (15°C to 24°C). When transporting veneer in vehicles, avoid leaving it in direct sunlight or in a closed car for extended periods. Use insulated packaging or reflective covers to shield the material from heat exposure, especially during summer months.

Physical damage is often preventable with proper handling techniques. Stack veneer sheets horizontally on a flat, stable surface, using soft spacers like foam or cardboard between layers to prevent abrasion. When moving veneer, use a rigid, smooth panel as a carrier to avoid bending or cracking. For long-distance transport, secure the veneer in a sturdy crate lined with cushioning material, ensuring it cannot shift during transit. Always handle veneer by its edges to minimize fingerprints or surface damage.

Finally, inspect veneer regularly during storage to catch potential issues early. Look for signs of moisture damage, such as swelling or discoloration, and address the cause immediately. Rotate stock periodically to ensure older sheets are used first and to prevent prolonged pressure on the bottom layers. By implementing these handling and storage practices, you can maintain the quality and appearance of wood veneer, ensuring it performs as beautifully as intended in your projects.

Wine Wood Barrel Costs: A Comprehensive Guide to Buying Prices

You may want to see also

Frequently asked questions

Consider the type of wood (e.g., oak, maple, walnut), veneer thickness (typically 0.6mm to 6mm), grain pattern, color, and intended use (furniture, cabinetry, etc.). Also, check for defects like splits, patches, or uneven color.

Wood veneer is available at specialty woodworking stores, online retailers, lumberyards, and veneer suppliers. Ensure the supplier has a good reputation and offers high-quality, sustainably sourced products.

Measure the surface area you plan to cover and add 10-15% extra to account for waste or mistakes. Veneer is often sold in sheets or rolls, so calculate the total square footage needed before purchasing.