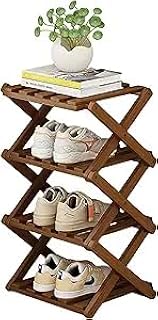

Installing wood shelves in a long closet is a practical and cost-effective way to maximize storage space while adding a touch of warmth and elegance to your home. This project requires basic carpentry skills, a few essential tools, and careful planning to ensure the shelves are sturdy, level, and tailored to your storage needs. By measuring the closet dimensions, selecting the right type of wood, and properly securing the supports and brackets, you can create a functional and durable shelving system that transforms your closet into an organized and efficient space. Whether for clothing, linens, or other items, wood shelves offer both aesthetic appeal and practicality, making them a popular choice for closet organization.

Explore related products

$32.2 $34.64

What You'll Learn

Measure Closet Space Accurately

Accurate measurements are the foundation of a successful shelving installation, ensuring your wood shelves fit seamlessly within your long closet. Begin by clearing the closet entirely, removing all clothing, boxes, and obstructions. This provides a clean slate and allows you to assess the space without interference. Use a sturdy tape measure to record the width, height, and depth of the closet. Measure at multiple points—top, middle, and bottom—to account for any irregularities in the walls. Closets, especially older ones, may not be perfectly rectangular, so noting these variations is crucial.

Consider the intended use of the shelves when determining their placement. For example, if storing folded clothes, shelves spaced 12 to 15 inches apart are practical. For bulkier items like sweaters or bins, increase the spacing to 16 to 18 inches. Measure vertically from the floor to the ceiling, marking potential shelf heights with a pencil. Ensure these marks align horizontally across the closet to maintain a level appearance. If using brackets or supports, factor in their thickness and how they’ll attach to the walls.

Depth is another critical dimension often overlooked. Standard closet depths range from 12 to 24 inches, but measure yours precisely to avoid shelves that are too shallow or deep. Subtract 1 to 2 inches from the total depth to allow for door clearance and ease of access. If your closet has sliding doors, ensure the shelves don’t obstruct their movement. For walk-in closets, consider deeper shelves for larger items but maintain consistency across the space.

Double-check all measurements before cutting or purchasing materials. A small error can lead to shelves that don’t fit or uneven spacing. Use a level to verify that your marks are straight and aligned. If working with a helper, have them hold the tape measure while you record dimensions to ensure accuracy. Taking the time to measure meticulously will save you from costly mistakes and ensure a professional finish.

Finally, document your measurements clearly. Sketch a rough diagram of the closet, labeling each dimension. Note any obstacles like light switches, outlets, or vents that might affect shelf placement. This visual reference will guide your installation process and serve as a reminder of the space’s unique characteristics. Accurate measurements aren’t just about numbers—they’re about understanding the closet’s geometry and tailoring your shelves to fit perfectly.

Mr. Garrison's Woodland Life: Duration and Survival Story Explored

You may want to see also

Explore related products

Choose Right Wood & Hardware

Selecting the right wood is crucial for both durability and aesthetics in your closet shelving project. Pine is a popular choice for its affordability and ease of installation, but it’s softer and more prone to dents. Oak offers superior strength and a premium look, though it’s heavier and more expensive. Plywood or MDF (medium-density fiberboard) are excellent for adjustable shelving systems due to their stability and resistance to warping. Consider the weight of items you’ll store: lightweight clothing can pair with pine, while heavy items like books or storage bins require oak or plywood. Always opt for pre-sanded wood to save time and ensure a smooth finish.

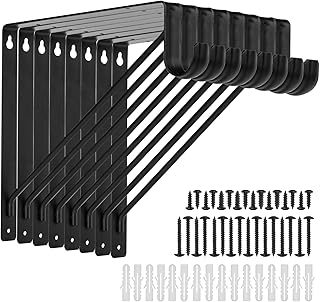

Hardware choices directly impact the functionality and longevity of your shelves. Bracket supports come in various styles, from hidden metal brackets for a minimalist look to decorative wooden corbels for a traditional feel. For long spans (over 36 inches), use shelf supports rated to hold at least 50 pounds per pair to prevent sagging. Anchors and screws must match your wall material—use plastic anchors for drywall and masonry anchors for concrete or brick. Avoid overloading shelves by spacing brackets no more than 24 inches apart. Pro tip: pre-drill holes to prevent wood splitting, especially with hardwoods like oak.

The finish you choose can elevate the wood’s appearance and protect it from moisture and wear. Polyurethane provides a durable, clear coat that enhances the wood’s natural grain, ideal for closets in humid environments. Paint offers endless color options but hides the wood’s texture, making it better for modern or minimalist designs. Stain enriches the wood’s tone while maintaining its character, perfect for traditional or rustic styles. Apply at least two coats of finish, sanding lightly between layers for a professional result. Always test the finish on a scrap piece of wood to ensure it matches your vision.

Comparing wood and hardware options reveals trade-offs between cost, aesthetics, and functionality. For instance, pine with metal brackets is budget-friendly but may lack the sophistication of oak with wooden corbels. Plywood with adjustable metal supports offers versatility for changing storage needs but can look utilitarian. If you’re prioritizing longevity, invest in high-quality hardware and hardwoods, even if it means simplifying the design. Conversely, if aesthetics are key, allocate more of your budget to decorative brackets and premium finishes. Balancing these factors ensures your shelves are both practical and visually appealing.

Finally, consider sustainability and maintenance when choosing materials. Opt for FSC-certified wood to support responsibly managed forests. Reclaimed wood adds character and reduces environmental impact, though it may require more prep work. For hardware, choose stainless steel or powder-coated brackets to prevent rust, especially in damp areas. Regularly inspect shelves for loose screws or signs of wear, tightening hardware as needed. Wipe down shelves periodically with a damp cloth to remove dust and maintain their finish. With the right wood and hardware, your closet shelves will remain functional and stylish for years to come.

Maximizing Flavor: Understanding the Lifespan of Smoker Wood Chips

You may want to see also

Explore related products

$32.41

Cut Shelves & Supports Precisely

Precision is paramount when cutting shelves and supports for a long closet, as even a millimeter’s discrepancy can lead to uneven weight distribution or an unsightly fit. Begin by measuring the closet’s width at multiple points, as walls are rarely perfectly straight. Use the smallest measurement to ensure the shelves fit snugly without binding. For example, if one end measures 96 inches and the other 95.5 inches, cut your shelves to 95.5 inches. This approach avoids the frustration of forcing shelves into place and minimizes gaps that detract from the finished look.

When cutting the wood, prioritize accuracy over speed. A table saw is ideal for straight, repeatable cuts, but a circular saw with a guide rail can achieve similar results. Mark your measurements clearly with a carpenter’s square to ensure 90-degree angles, and double-check before making the cut. For supports, consider using 1x2 or 1x3 boards, cut to the height of the closet minus the thickness of the shelves. For instance, if your closet is 84 inches tall and your shelves are ¾ inch thick, cut supports to 83.25 inches. This precision ensures shelves sit level and secure.

The depth of your shelves depends on their intended use. Standard depths range from 12 to 16 inches, but measure items you plan to store to avoid wasted space. For example, folded sweaters require less depth than bulky storage bins. Cut shelves from plywood or solid wood, ensuring the grain runs parallel to the closet’s length for stability. If using plywood, edge-banding or iron-on veneer strips can conceal raw edges for a polished appearance.

Supports should be spaced no more than 36 inches apart to prevent sagging, especially with deeper shelves. Mark their positions on the closet walls using a level and tape measure, ensuring alignment across the entire length. Pre-drilling holes for screws minimizes the risk of splitting the wood, particularly when using hardwoods like oak or maple. For added strength, consider using metal shelf brackets in conjunction with wooden supports, particularly for heavy loads.

Finally, sand all cut edges to remove splinters and ensure a smooth finish. This step is often overlooked but significantly enhances the shelf’s durability and appearance. Apply a coat of paint or stain to match your closet’s aesthetic, allowing adequate drying time before installation. Precision in cutting not only ensures functionality but also elevates the overall craftsmanship of your closet project.

Safe Wood Priming After Rain: Timing Tips for Outdoor Projects

You may want to see also

Explore related products

Install Brackets & Supports Securely

Securing brackets and supports is the backbone of any shelving project, especially in a long closet where the span between walls can test the limits of even the sturdiest wood. Improperly installed brackets can lead to sagging shelves, compromised weight capacity, and potential safety hazards. The key lies in understanding the interplay between bracket type, wall material, and shelf load. For instance, hollow walls require specialized anchors like toggle bolts or molly bolts, while solid walls can accommodate standard wood screws. Always use brackets rated for the weight you intend to support—a common mistake is underestimating the cumulative load of clothing, storage bins, and other items.

Consider the spacing of brackets as a critical factor in shelf stability. As a rule of thumb, place brackets no more than 32 inches apart for standard 12-inch deep shelves. For longer spans or heavier loads, reduce this distance to 16 inches. Use a level to ensure each bracket is perfectly aligned, both horizontally and vertically. Misaligned brackets not only compromise aesthetics but also distribute weight unevenly, increasing the risk of failure. If your closet walls are uneven, shim the brackets with thin wood or plastic wedges to achieve a level surface.

The choice of fasteners is equally important. For drywall over wood studs, 2.5-inch wood screws provide a secure hold. If studs are not available, use hollow-wall anchors designed for the weight of your shelves. Avoid over-tightening screws, as this can strip the threads or damage the wall. Instead, tighten until the bracket is snug against the wall, then test its stability by applying gentle pressure. For added strength, consider using L-brackets or corbels, which provide both vertical and horizontal support. These are particularly useful for shelves holding heavy items like books or tools.

A practical tip for ensuring long-term durability is to pre-drill holes for screws, especially in hardwood or dense wall materials. This prevents splitting and ensures a clean installation. Additionally, apply a bead of construction adhesive to the back of each bracket before securing it to the wall. This adhesive acts as a secondary bond, reducing movement and increasing load capacity. While it may seem like an extra step, this small effort can significantly extend the life of your shelving system.

Finally, test the installation before loading the shelves. Place a few heavy items on the shelf and observe for any signs of sagging or movement. If the shelf holds firm, proceed with confidence. If not, reassess bracket placement, fastener type, and wall anchoring. Remember, a well-installed bracket system is invisible in its function but indispensable in its role. By prioritizing precision and using the right materials, you can create a closet shelving system that is both functional and enduring.

Night in the Woods DLC: Unveiling the Length of Its Nights

You may want to see also

Explore related products

$17.99 $19.99

Attach Shelves & Level Properly

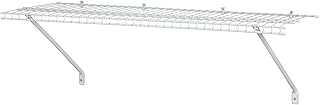

Attaching shelves and ensuring they are level is a critical step in installing wood shelves in a long closet. Proper alignment not only enhances the aesthetic appeal but also ensures structural integrity and functionality. Begin by marking the wall studs using a stud finder, as securing shelves to studs provides maximum support. If studs are not available at the desired height, use wall anchors rated for the weight of the shelves and their intended load. Pre-drill holes in both the shelf brackets and the wall to prevent wood splitting and ensure a snug fit.

Once the brackets are securely fastened, place the wooden shelf onto them, checking for stability. Use a level to confirm the shelf is perfectly horizontal. Even a slight tilt can cause items to slide off or create an uneven appearance. If adjustments are needed, loosen the bracket screws slightly, reposition the shelf, and retighten. For longer shelves, consider adding a center support bracket to prevent sagging, especially if the shelf spans more than 36 inches. This extra step can significantly extend the shelf’s lifespan and load capacity.

A common mistake is assuming the floor or ceiling is level and using it as a reference point. Instead, rely solely on a level tool to ensure accuracy. If the closet walls are uneven, shim the brackets or adjust their placement to compensate. For a polished look, use wood screws that match the shelf’s finish or countersink them and fill with wood putty. This attention to detail transforms a functional installation into a professional-grade finish.

Comparing DIY methods, using a laser level can streamline the process, particularly in longer closets where maintaining consistency is challenging. While traditional bubble levels are reliable, laser levels offer precision across greater distances. Additionally, pre-made shelf kits often include adjustable brackets, which simplify leveling by allowing fine-tuning after installation. However, custom installations may require more meticulous measurements and adjustments to achieve the same result.

In conclusion, attaching shelves and leveling them properly demands patience and precision. By securing brackets to studs, using a level consistently, and addressing uneven walls proactively, you can achieve a sturdy and visually appealing shelf system. Whether opting for DIY tools or pre-made kits, the key lies in attention to detail and adaptability to the closet’s unique characteristics. This approach ensures the shelves not only look great but also function flawlessly for years to come.

Wood Roach Lifespan: How Long Until They Perish Naturally?

You may want to see also

Frequently asked questions

You will need a tape measure, level, stud finder, pencil, drill, screwdriver, circular saw or miter saw, sandpaper, and a shelf bracket kit or wooden supports.

Measure the height of the closet and decide on the number of shelves. Divide the height by the number of shelves plus one to determine even spacing. Common shelf heights are 12–16 inches apart for practicality.

For longer shelves, brackets are recommended as they provide better support and prevent sagging. Wooden supports can work for shorter spans but may require additional reinforcement for longer lengths.

Use a stud finder to locate wall studs and mark their positions. Attach brackets or supports directly into the studs for maximum stability. Use a level to ensure the brackets are straight before securing the shelves.