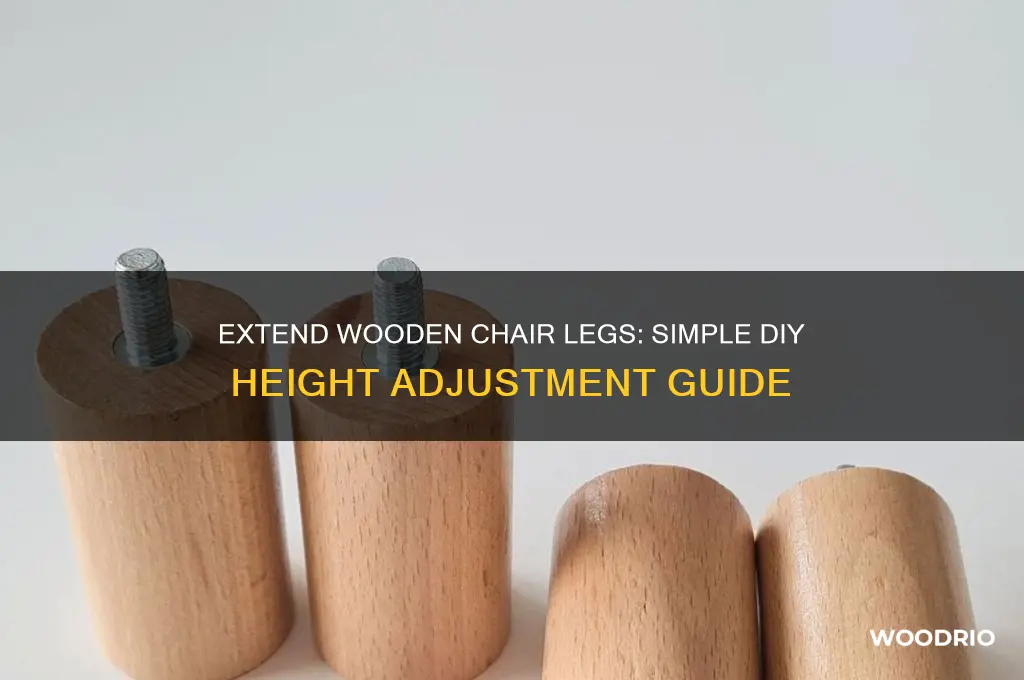

Extending the length of wooden chair legs can be a practical solution to adjust seating height or improve stability, but it requires careful planning and execution to maintain structural integrity. The process typically involves cutting the existing legs at the desired point, preparing additional wooden sections to match the original material and style, and securely joining them using techniques like doweling, mortise and tenon joints, or metal brackets. Reinforcing the connection with wood glue and screws ensures durability, while sanding and finishing the extended sections seamlessly blends them with the original legs. Always consider the chair’s weight-bearing capacity and balance to avoid compromising its safety or aesthetics.

| Characteristics | Values |

|---|---|

| Method 1: Adding Wooden Extensions | Use hardwood matching the chair legs; cut extensions to desired length; attach using dowels, screws, or adhesive; sand and finish to match. |

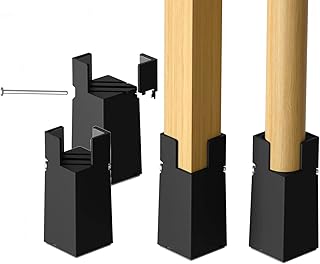

| Method 2: Metal or Wood Ferrules | Attach metal or wooden ferrules (caps) to the bottom of legs; provides additional height and protects legs from wear. |

| Method 3: Tapered Wooden Plugs | Drill holes in the bottom of legs; insert tapered wooden plugs for added height; secure with adhesive or screws. |

| Method 4: Stacked Blocks | Attach wooden blocks to the bottom of legs using screws or adhesive; sand and finish to blend. |

| Tools Required | Saw, drill, sander, measuring tape, clamps, wood glue, screws, dowels. |

| Materials Needed | Matching hardwood, ferrules, wooden plugs, blocks, adhesive, finish. |

| Difficulty Level | Intermediate (requires basic woodworking skills). |

| Cost | Low to moderate (depends on materials chosen). |

| Time Required | 2-4 hours per chair (excluding drying time for adhesive/finish). |

| Durability | High (if properly attached and finished). |

| Aesthetic Impact | Can be seamless if matched and finished correctly. |

| Safety Considerations | Ensure stability after modification; avoid overloading the chair. |

Explore related products

What You'll Learn

- Measure and Mark: Determine desired length, mark existing legs for extension, ensuring symmetry and stability

- Choose Extension Material: Select matching wood type, grain, and thickness for seamless integration

- Cut and Shape: Precision-cut extensions, shape to match leg profile, sand for smooth finish

- Attach Securely: Use dowels, screws, or glue for strong, durable connection between leg and extension

- Finish and Match: Stain, paint, or varnish extensions to match original legs, ensuring uniformity

Measure and Mark: Determine desired length, mark existing legs for extension, ensuring symmetry and stability

The first step in extending wooden chair legs is precision. Before you make any cuts or purchases, determine the exact length you need. Measure from the bottom of the existing leg to the floor, then add the desired increase. For example, if your current legs are 16 inches and you want a 4-inch boost, mark the extension point at 20 inches. Use a tape measure and double-check your calculations—a single mistake here can throw off symmetry and stability.

Symmetry is non-negotiable. Once you’ve decided on the new length, mark all legs simultaneously, ensuring consistency. Place the chair on a flat surface and use a straightedge to draw a line around each leg at the extension point. If your chair has a cross-brace or stretcher, measure from this point to maintain proportional balance. Uneven marks will result in a wobbly chair, so take your time and verify alignment from multiple angles.

Stability hinges on structural integrity. Before marking, assess the existing leg’s diameter and material. If the legs taper significantly, consider extending them from the bottom to preserve strength. For square or rectangular legs, mark the extension along the widest face to avoid weakening the structure. Use a pencil for visibility and a square to ensure straight lines. If you’re unsure, mock up the extension on scrap wood to test stability before committing.

Practical tip: Use painter’s tape as a guide. Wrap a strip of tape around each leg at the desired height, then draw your mark along the tape’s edge. This creates a clean, consistent line and prevents slipping. For added precision, pair this with a laser level to ensure all marks are at the same height. Once marked, step back and inspect the chair from all sides—symmetry should be immediately apparent. If not, adjust before proceeding.

A Walk in the Woods Play Duration: How Long Is It?

You may want to see also

Explore related products

Choose Extension Material: Select matching wood type, grain, and thickness for seamless integration

Selecting the right extension material is crucial for achieving a cohesive and professional look when lengthening wooden chair legs. The goal is to make the addition virtually indistinguishable from the original structure, ensuring both aesthetic appeal and structural integrity. Begin by identifying the wood type of your chair legs—whether it’s oak, maple, walnut, or another species. Each wood type has unique characteristics, such as hardness, grain pattern, and color, which must be matched to avoid visual discrepancies. For instance, oak’s prominent grain and warm tones require an extension piece with similar features to blend seamlessly.

Once the wood type is confirmed, focus on grain matching. Wood grain is like a fingerprint, and aligning the direction and pattern of the grain between the original leg and the extension is essential. Hold the extension piece alongside the chair leg under good lighting to compare grain orientation. If the grain runs vertically on the original leg, ensure the extension’s grain follows the same direction. For best results, source wood from the same batch or supplier as the original chair, if possible, to minimize variations in color and texture.

Thickness is another critical factor. Measure the diameter or width of the chair leg and select an extension piece with a matching profile. If the extension is too thin, it may weaken the structure; if too thick, it could create an awkward transition. For round legs, use a dowel with the same diameter, while for square or rectangular legs, cut a piece of wood to match the exact dimensions. Sanding both the original leg and the extension to the same smoothness ensures a uniform surface for finishing.

Consider the practical aspects of joining the extension to the chair leg. A strong, invisible joint is key to both durability and aesthetics. Techniques like dowel joints, spline joints, or epoxy adhesives work well for this purpose. For example, drilling a hole through the top of the extension and into the original leg, then securing it with a wooden dowel and wood glue, creates a sturdy connection. Always test the joint’s strength before finalizing the attachment, ensuring it can bear the chair’s weight without wobbling or splitting.

Finally, finishing touches play a significant role in seamless integration. Stain or paint the extension to match the chair’s existing color, applying multiple thin coats for consistency. If the chair has a natural finish, use a wood conditioner to ensure even absorption of the stain. Seal the entire leg, including the joint, with a protective finish like polyurethane to prevent moisture damage and enhance durability. With careful material selection and meticulous execution, the extended chair legs will appear as though they were always part of the original design.

Optimal Aging Time for Wood: Splitting Secrets for Perfect Firewood

You may want to see also

Explore related products

Cut and Shape: Precision-cut extensions, shape to match leg profile, sand for smooth finish

Precision is paramount when extending wooden chair legs, as even a slight misalignment can compromise both aesthetics and stability. Begin by selecting a hardwood that matches the existing legs in grain, color, and density. Measure the desired extension length, adding an extra inch for shaping and sanding. Use a table saw or circular saw to cut the extension pieces, ensuring straight, clean edges. For curved or tapered legs, a band saw offers greater control to replicate the profile accurately. Remember, the goal is not just to add length but to create a seamless continuation of the original design.

Shaping the extensions to match the leg profile requires careful observation and patience. Trace the cross-section of the existing leg onto the extension piece as a template. Use a jigsaw or coping saw to rough out the shape, staying slightly outside the lines to allow for sanding. For tapered legs, mark the angle of the taper on both the original leg and the extension, ensuring consistency. A belt sander or spindle sander can refine the shape, but hand tools like rasps and files provide finer control for intricate details. Always work gradually, checking the fit against the original leg at each stage.

Sanding is the final step in achieving a smooth, cohesive finish. Start with medium-grit sandpaper (120-grit) to remove tool marks and refine the shape, progressing to fine-grit (220-grit) for a polished surface. Pay special attention to the joint between the original leg and the extension, ensuring it blends seamlessly. For curved legs, use a sanding block or sponge to maintain the contour. Wipe the surface with a tack cloth to remove dust before applying a finish. This meticulous sanding process not only enhances appearance but also ensures the extension bonds securely during assembly.

While cutting and shaping extensions may seem straightforward, common pitfalls can derail the project. Avoid using softwoods or mismatched grains, as they will detract from the chair’s visual harmony. Over-sanding can weaken the joint, so work methodically and check frequently. If the legs have a complex profile, consider practicing on scrap wood before committing to the final piece. For added durability, pre-drill pilot holes when attaching the extensions to prevent splitting. With precision, patience, and attention to detail, the extended legs will appear as though they were always part of the original design.

Drying Oak Wood: Essential Timeframe and Techniques for Perfect Results

You may want to see also

Explore related products

Attach Securely: Use dowels, screws, or glue for strong, durable connection between leg and extension

A secure attachment between the chair leg and its extension is critical for safety and longevity. Dowels, screws, and glue each offer distinct advantages, but their effectiveness depends on proper application. Dowels, for instance, create a strong mechanical bond when used with a tight-fitting hole and reinforced with glue. For a 1.5-inch diameter leg, a 0.75-inch dowel is ideal, ensuring stability without compromising the wood’s integrity. Pre-drilling the hole slightly smaller than the dowel diameter ensures a snug fit, while a wood glue like Titebond III adds moisture resistance for durability.

Screws provide a more adjustable and visible method of attachment, ideal for those who may need to disassemble the chair later. Use 2-inch wood screws with a pilot hole to prevent splitting, especially in hardwoods like oak or maple. Countersinking the screws and filling the holes with wood putty creates a seamless finish. For added strength, combine screws with glue, applying a thin layer of epoxy adhesive along the joint before fastening. This hybrid approach maximizes both mechanical and adhesive bonding, ensuring the extension can support weight without wobbling.

Glue alone can be sufficient for lighter chairs or temporary extensions, but the type and application matter. Polyurethane glue, such as Gorilla Wood Glue, expands as it cures, filling gaps and creating a watertight seal. Apply a thin, even coat to both surfaces, clamp the joint with 100–150 psi pressure, and allow 24 hours for curing. Avoid over-gluing, as excess can weaken the bond by creating a brittle layer. For best results, roughen the mating surfaces with 80-grit sandpaper to increase surface area and adhesion.

Comparing these methods, dowels excel in aesthetics and strength but require precision. Screws offer versatility and ease of removal but may detract from the chair’s appearance if not concealed. Glue is simple and cost-effective but lacks the mechanical reinforcement of dowels or screws. The ideal choice depends on the chair’s use, wood type, and desired permanence. For instance, a dining chair bearing daily weight benefits from dowels and glue, while a decorative chair might suffice with screws alone. Always test the joint’s strength before full use, applying gradual pressure to ensure it can withstand real-world conditions.

Restoring Wood Tables: Effective Techniques to Repair Deep, Long Dents

You may want to see also

Explore related products

Finish and Match: Stain, paint, or varnish extensions to match original legs, ensuring uniformity

Achieving a seamless blend between the original chair legs and their extensions hinges on meticulous finishing. Stain, paint, or varnish must be applied with precision to ensure the additions don’t scream "afterthought." Begin by sanding both the original legs and the extensions to create a uniform surface, removing any rough patches or inconsistencies. This step is crucial, as even the slightest texture difference can betray your efforts once the finish is applied. Use fine-grit sandpaper (220-grit works well) and wipe away dust with a tack cloth before proceeding.

Selecting the right finish is equally critical. If the original legs are stained, match the color by testing the stain on a scrap piece of the same wood species. Wood types absorb stain differently, so this trial run ensures accuracy. For painted legs, bring a sample to a paint store to color-match, or use a paint-mixing service for an exact replica. Varnished legs require a clear coat that matches the sheen level—satin, semi-gloss, or gloss—of the original finish. Always apply finishes in thin, even coats, allowing ample drying time between layers to avoid drips or uneven coverage.

One common pitfall is overlooking the aging or wear on the original legs. If the chair has been around for years, its finish may have faded, darkened, or developed a patina. To replicate this, lightly distress the extensions after finishing, focusing on edges and corners where natural wear would occur. Alternatively, apply a thin wash of a darker stain or glaze to mimic aging, blending it into the finish for a subtle, authentic look. This attention to detail elevates the extension from a mere addition to an integral part of the chair’s character.

For those seeking a professional finish, consider using a spray gun for paint or varnish, as it provides a smoother, more consistent application than brushing. However, this method requires practice and proper ventilation. If brushing is your only option, use high-quality brushes and apply the finish in the direction of the wood grain. After the final coat dries, inspect the chair under different lighting conditions to ensure the extensions match the original legs from all angles. A well-executed finish not only preserves the chair’s aesthetic but also enhances its longevity, protecting the wood from moisture and wear.

Finally, maintain the finish over time by periodically cleaning the chair with a soft, damp cloth and reapplying a protective coat as needed. Avoid harsh chemicals that can strip or discolor the finish. By investing time in the finishing process, you ensure the chair legs’ extensions are indistinguishable from the originals, preserving both functionality and beauty. This meticulous approach transforms a simple repair into a testament to craftsmanship.

Drying Time for Wood Veneer: A Comprehensive Guide to Patience

You may want to see also

Frequently asked questions

Yes, you can extend wooden chair legs by adding wooden extensions or blocks to the bottom of the existing legs, ensuring they are securely attached.

You’ll need a saw, drill, wood glue, screws, clamps, sandpaper, and possibly a router for a seamless finish.

Use sturdy wood for the extensions, secure them with screws and wood glue, and ensure the joints are reinforced for even weight distribution.

Yes, sand the extended part to match the texture of the original legs, then apply paint or stain to achieve a uniform appearance.

The simplest method is to attach pre-cut wooden blocks to the bottom of the legs using screws and wood glue, then sand and finish to blend them in.