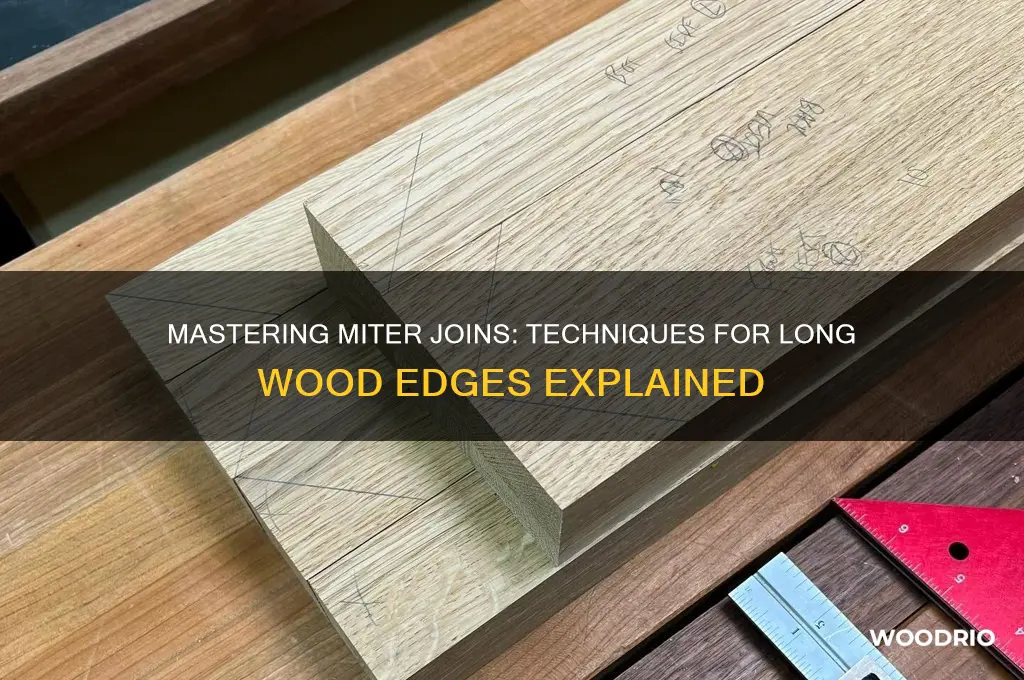

Miter joining the long edge of wood is a precise and effective technique used to create seamless, angled connections, typically at 45 degrees, ideal for corners in frames, molding, or furniture. This method involves cutting the ends of two pieces of wood at complementary angles so they fit together perfectly, forming a clean, professional joint. To achieve this, you’ll need a miter saw, miter box, or a sharp handsaw with a miter guide, along with careful measurement and marking to ensure accuracy. Proper clamping and gluing are essential to secure the joint, and sanding may be required to smooth any imperfections. Mastering this technique enhances the structural integrity and aesthetic appeal of woodworking projects, making it a valuable skill for both beginners and experienced craftsmen.

Explore related products

What You'll Learn

Measuring and Marking Angles

Accurate angle measurement is the linchpin of a successful miter joint. Even a slight miscalculation can result in gaps or misalignment, undermining the structural integrity and aesthetic appeal of your project. To avoid this, invest in a quality combination square or sliding bevel gauge. These tools allow you to precisely transfer angles from your wood piece to your miter saw or table saw, ensuring a seamless fit. Remember, the goal is to create a 45-degree angle on each piece, which, when joined, forms a perfect 90-degree corner.

Consider the following scenario: you're crafting a picture frame from 1x3 pine boards. To miter the long edges, you'll need to mark a 45-degree angle on each end of the boards. Begin by setting your combination square to 45 degrees. Place the square's base flat against the wood's edge, with the blade aligned with the top surface. Draw a line along the blade's edge, ensuring it's crisp and visible. Repeat this process on the adjacent edge, creating a mirrored angle. This technique guarantees a precise, symmetrical miter joint.

When working with longer wood pieces, such as those used for crown molding or baseboards, it's essential to account for the material's curvature or imperfections. In these cases, a sliding bevel gauge becomes invaluable. Place the gauge against the wall or surface where the molding will be installed, and adjust the blade to match the angle. Transfer this angle to your miter saw, making test cuts on scrap wood to fine-tune the fit. This iterative process ensures a snug, professional-looking joint, even when dealing with complex angles or irregular surfaces.

To minimize errors, always double-check your measurements and markings before cutting. Use a pencil with a sharp, fine point to ensure clear, accurate lines. If you're working with multiple pieces, label each one to avoid confusion. For added precision, consider using a digital angle finder, which provides real-time angle readings and can be particularly useful for complex projects. By combining traditional tools with modern technology, you'll achieve miter joints that are not only strong but also visually stunning, elevating the overall quality of your woodworking projects.

Lepage Wood Filler Drying Time: Quick Guide for Perfect Repairs

You may want to see also

Explore related products

$70.99 $91.98

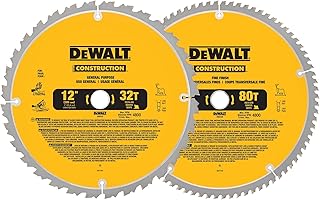

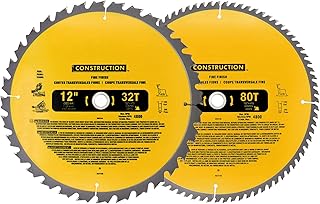

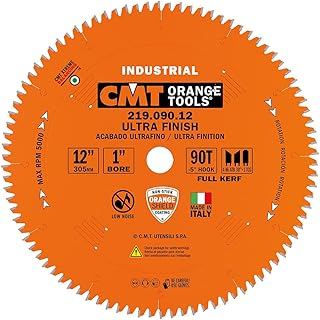

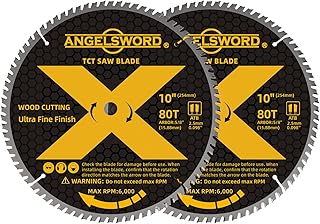

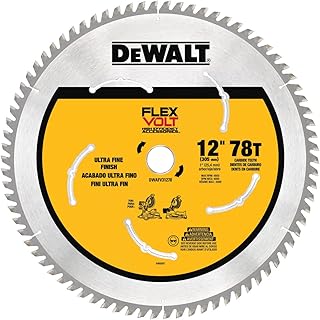

Choosing the Right Saw Blade

The precision of a miter joint hinges on the saw blade’s quality and compatibility with the task. A blade with too many teeth can burn the wood, while one with too few leaves a rough, splintered edge. For long edge miter joints, a crosscut blade with 60–80 teeth is ideal, as it minimizes tear-out and ensures a clean, chip-free cut. Carbide-tipped blades are preferred for their durability and ability to maintain sharpness over extended use, especially when working with hardwoods like oak or maple.

Selecting the correct kerf width is equally critical. A thinner kerf blade (around 0.090 inches) reduces material waste and requires less power from the saw, making it suitable for portable miter saws. However, thicker kerf blades (0.125 inches) offer greater stability and are better for stationary saws handling dense woods. Always match the blade’s arbor hole size to your saw’s spindle to avoid wobbling, which can ruin the joint’s accuracy.

Blade hook angle plays a subtle but significant role in miter cuts. A positive hook angle (10°–15°) provides aggressive cutting but increases the risk of splintering on the top edge of the wood. For long edge miters, a blade with a neutral or slightly negative hook angle is safer, as it reduces the chance of tear-out while still maintaining efficiency. This is particularly important when working with delicate veneers or thin stock.

Finally, consider the blade’s tooth grind. Alternate top bevel (ATB) blades excel at crosscutting, making them the go-to choice for miter joints. A 20°–25° ATB grind balances speed and finish, leaving a smooth edge that requires minimal sanding. For ultra-fine cuts, such as those needed for visible joints in cabinetry, a triple-chip grind (TCG) blade can further reduce splintering, though it cuts slower and is best reserved for precision work.

In practice, test the blade on scrap wood before committing to the final cut. Adjust the saw’s speed and feed rate to match the blade’s capabilities—slower feeds prevent burning, while steady pressure ensures a straight cut. Remember, the right blade not only improves the joint’s appearance but also extends the life of your tools and reduces rework, making it a cornerstone of successful woodworking.

Durability of Cordwood Homes: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Setting Up the Miter Saw

A miter saw is your most reliable tool for achieving precise miter joints on long wood edges, but its accuracy hinges on proper setup. Begin by ensuring the saw is placed on a stable, level surface—a wobbly stand or uneven ground will compromise your cuts. Secure the saw to a workbench or use a dedicated miter saw stand with adjustable supports to eliminate movement. Position the saw so the blade is easily accessible and the workpiece can extend safely away from the cutting area, minimizing the risk of binding or kickback.

Next, calibrate the saw for square cuts. Most miter saws come with a preset 90-degree angle, but this can drift over time. Use a speed square or a carpenter’s square to verify the blade’s alignment with the fence. Loosen the miter lock and adjust the saw until the blade sits perfectly perpendicular to the table. Tighten the lock firmly, but avoid over-tightening, as this can warp the saw’s components. Repeat this process for the bevel angle if your project requires non-90-degree cuts.

Blade selection is critical for clean, accurate miter joints. For long wood edges, a 40- or 60-tooth crosscut blade is ideal, as it balances speed and precision. Avoid using a blade with fewer teeth, as it can leave rough edges or burn marks. Ensure the blade is sharp—a dull blade will tear the wood fibers, making it harder to achieve a tight joint. If working with hardwoods, consider a blade with carbide tips for longer durability.

Before making your first cut, perform a test run on a scrap piece of wood. This allows you to verify the saw’s alignment, blade sharpness, and cutting depth. Adjust the cutting depth so the blade extends just below the wood’s thickness—typically 1/8 to 1/4 inch deeper than the material. A blade that’s too deep can cause unnecessary wear, while one that’s too shallow may not cut through cleanly. Use the test piece to fine-tune your technique and ensure the miter saw is ready for the actual workpiece.

Finally, prioritize safety throughout the setup process. Always unplug the saw or disconnect the power source when adjusting the blade or fence. Wear safety glasses and ear protection, as miter saws generate debris and noise. Keep your hands clear of the blade path and use a push stick or clamp to secure long workpieces. A well-set-up miter saw not only ensures precise miter joints but also reduces the risk of accidents, making it an indispensable tool for woodworking projects.

Wood Memorial Race Duration: Uncovering the Length of the Classic Event

You may want to see also

Explore related products

Cutting Techniques for Precision

Achieving precision in miter joins along the long edge of wood hinges on mastering the right cutting techniques. A miter joint’s strength and appearance rely on clean, accurate cuts at the correct angle. Even a fraction of a degree off can result in gaps or misalignment, undermining the integrity of the joint. Whether you’re using a miter saw, table saw, or hand tools, understanding the nuances of each method is essential for professional results.

Analyzing the Tools: Miter Saw vs. Table Saw

The miter saw is the go-to tool for most miter cuts due to its precision and ease of use. For long edges, set the saw to the desired angle (typically 45 degrees) and ensure the wood is securely clamped. The key is to measure twice and cut once, as the length of the piece can’t be adjusted after the cut. A table saw, on the other hand, requires a miter gauge or sled for accuracy. While it’s less intuitive for miter cuts, it’s ideal for thicker or wider pieces that may not fit comfortably on a miter saw. The trade-off is slower setup and a higher risk of error without proper jigs.

Hand Tools for Precision: When Machines Fall Short

For those without power tools or working on delicate projects, hand tools like a miter box and backsaw offer surprising precision. A miter box guides the saw at fixed angles, ensuring consistency. The backsaw’s fine teeth minimize tear-out, crucial for clean edges. This method is slower but provides control, especially for thin or fragile wood. Pro tip: Use a sharp blade and apply even pressure to avoid drifting off the intended line.

The Role of Blade Quality and Technique

Blade quality is often overlooked but critical for precision. A dull or low-quality blade can burn the wood or create jagged edges, ruining the joint. For miter cuts, use a blade with at least 80 teeth for clean results. Additionally, cutting technique matters: let the blade do the work without forcing it. For crosscuts on long edges, lower the blade slowly and maintain a steady pace to prevent binding or chipping.

Final Adjustments: Sanding and Fitting

Even the most precise cuts may require minor adjustments. Sanding the mitered edges with 120-grit paper can smooth imperfections and ensure a tight fit. Dry-fit the joint before gluing to check alignment, and use clamps to hold the pieces together while the adhesive sets. This step is where attention to detail pays off, transforming a good joint into a seamless one. Precision in cutting is the foundation, but finishing touches elevate the craftsmanship.

Oven Drying Wood: Optimal Time for Perfectly Seasoned Wood Pieces

You may want to see also

Explore related products

Sanding and Fitting Joints

Achieving seamless miter joints along the long edge of wood hinges on meticulous sanding and fitting. Even the most precise cuts leave microscopic imperfections that compromise alignment and appearance. Sanding becomes the sculptor’s chisel, refining the joint until it achieves a gapless, flush union. Start with a coarse grit (80–120) to address any saw blade discrepancies, then progress to finer grits (150–220) for a smooth, splinter-free surface. Always sand along the grain, not across, to prevent tear-out and maintain the wood’s integrity.

The fitting process demands patience and a keen eye. Dry-fit the joint repeatedly, checking for alignment from multiple angles. Use a thin piece of paper or a feeler gauge to identify gaps—even the slightest discrepancy will cast shadows and detract from the finished piece. Adjust the fit by sanding the high spots, not the entire surface, to preserve the joint’s integrity. For stubborn gaps, consider a sanding block wrapped in high-grit paper to ensure even pressure and precision.

Comparing sanding techniques reveals the importance of tool selection. Hand sanding offers control but risks uneven pressure, while power sanders expedite the process but demand a steady hand to avoid rounding edges. Orbital sanders are ideal for flat surfaces, whereas detail sanders excel in tight corners. Regardless of method, frequent dry-fitting during sanding ensures progress aligns with the desired outcome, preventing over-sanding that could weaken the joint.

Persuasively, investing time in sanding and fitting pays dividends in the final product. A well-fitted miter joint not only strengthens the structure but also elevates its aesthetic appeal. The absence of gaps or visible seams creates a professional finish that distinguishes craftsmanship from amateur work. Think of sanding as the final polish on a gem—it transforms a rough cut into a gleaming masterpiece.

Practically, maintain a clean workspace during sanding to avoid clogging the paper and ensure consistent results. Use a tack cloth to remove dust between grit changes, and consider sealing the joint with wood glue before final assembly for added stability. For long edges, work in sections to maintain control and uniformity. Remember, the goal isn’t just to join wood but to create a union so seamless it appears as one continuous piece.

How Long Do Essential Oils Scent Wood Surfaces?

You may want to see also

Frequently asked questions

A miter joint is created by cutting the ends of two pieces of wood at an angle (typically 45 degrees) and joining them to form a corner. It is used for long edges to create a seamless, clean appearance, often seen in frames, moldings, and furniture.

Essential tools include a miter saw, table saw with a miter gauge, or a hand saw with a miter box. A clamp, measuring tape, and a marking tool (like a pencil) are also necessary for accuracy.

Measure and mark the wood precisely, ensuring both pieces are cut at the same angle. Use a sharp blade and secure the wood firmly during cutting. Test-fit the pieces before gluing or fastening to ensure a tight joint.

Reinforce the joint with wood glue and use additional support like splines, biscuits, or dowels. For added strength, consider using screws or nails, but ensure they are countersunk and hidden for a clean finish.

Ensure the cuts are precise and the angles match perfectly. Use clamps to hold the pieces tightly together while the glue dries. Sanding the edges slightly can also help achieve a snug fit.