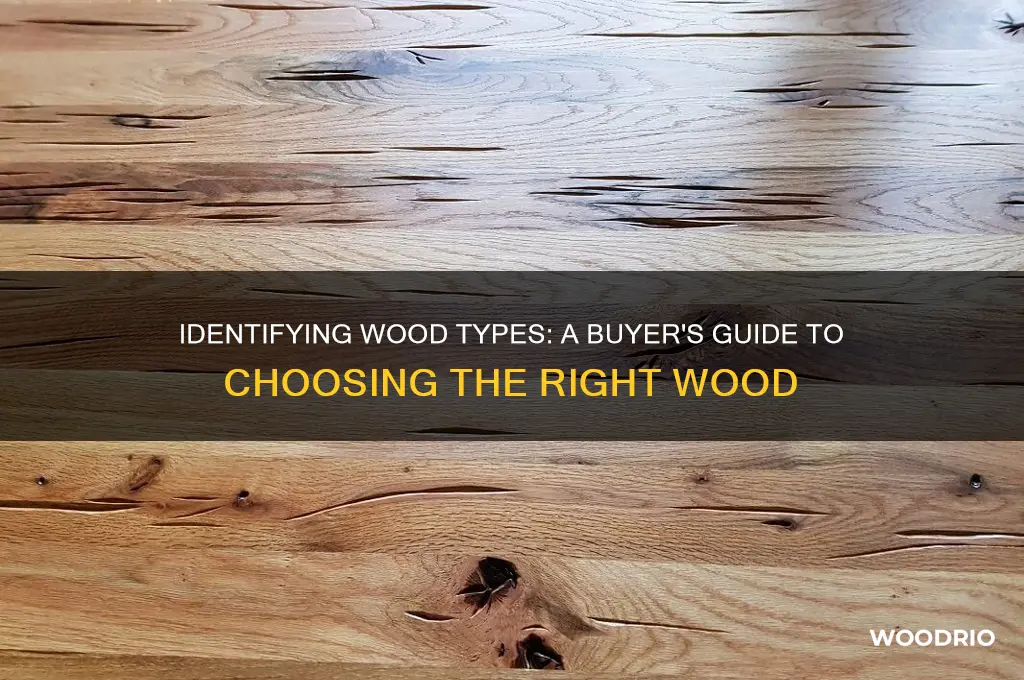

Identifying the type of wood you’re purchasing is essential for ensuring quality, durability, and suitability for your project. Different woods have unique characteristics, such as grain patterns, color, hardness, and texture, which can help distinguish one species from another. Common methods include examining the wood’s appearance, performing a smell or burn test, and checking its weight or density. Additionally, understanding the origin and labeling of the wood, such as whether it’s hardwood or softwood, can provide valuable clues. By familiarizing yourself with these traits and using reliable resources, you can confidently determine the type of wood you’re buying and make an informed decision.

Explore related products

What You'll Learn

- Check grain patterns: Examine unique textures, colors, and growth ring patterns for wood type identification

- Test wood density: Measure weight or hardness to distinguish softwoods from hardwoods accurately

- Smell the wood: Different woods have distinct aromas when cut or sanded

- Observe color variations: Note natural hues, which vary by species and aging

- Check for knots/defects: Identify imperfections that indicate specific wood types or quality

Check grain patterns: Examine unique textures, colors, and growth ring patterns for wood type identification

Wood grain patterns are nature's fingerprints, each species leaving behind a unique mark that tells its story. These patterns, a result of the tree's growth and environment, offer a visual roadmap for identification. The texture, for instance, can range from the coarse, open pores of oak to the fine, even lines of maple. By running your hand over the surface, you can often distinguish between softwoods and hardwoods—softwoods like pine tend to have a more resinous, less dense feel, while hardwoods such as walnut exhibit a smoother, tighter grain. This tactile approach is the first step in deciphering the wood's identity.

Color is another critical aspect of grain pattern analysis. The hues can vary dramatically, from the deep, rich browns of mahogany to the pale, almost golden tones of birch. Some woods, like cherry, change color over time, darkening with exposure to light. Others, such as teak, have natural oils that give them a distinctive luster. When examining color, consider the wood's age and treatment—freshly cut wood may look different from seasoned or finished pieces. A magnifying glass can help reveal subtle variations in color that might otherwise go unnoticed, providing additional clues to the wood's origin.

Growth rings, the circular patterns visible in a cross-section of wood, are perhaps the most telling feature. These rings form annually, with each layer representing a year of growth. In temperate climates, trees typically produce one light-colored ring (spring growth) and one dark-colored ring (summer growth) per year. The width of these rings can indicate the tree's growing conditions—narrow rings suggest slower growth in harsher environments, while wider rings indicate favorable conditions. For example, pine often has clearly defined, evenly spaced rings, whereas hickory’s rings may be irregular and wavy. Counting and measuring these rings not only helps identify the species but also provides insight into the tree's history.

To effectively use grain patterns for identification, start by examining the wood in good lighting, preferably natural daylight. Take note of the overall pattern—is it straight, wavy, or interlocking? Are there any distinctive features like knots or mineral streaks? Compare your observations to known examples using a wood identification guide or online database. For instance, if you notice a pronounced ray fleck pattern, you might be looking at sycamore. If the grain is interlocked and wavy, it could be rosewood. Practice makes perfect, so the more you study and compare, the sharper your identification skills will become.

Finally, remember that grain patterns are just one piece of the puzzle. Combine this analysis with other methods, such as density testing or smell identification, for a more accurate result. For example, sandalwood has a distinct fragrance that can confirm its identity even if the grain pattern is ambiguous. Always handle wood samples carefully, especially if they are rare or valuable, and consider consulting an expert if you’re unsure. With patience and attention to detail, checking grain patterns can become a rewarding skill that deepens your appreciation for the beauty and diversity of wood.

Top Retailers to Purchase Blaze King Wood Stoves: A Comprehensive Guide

You may want to see also

Explore related products

Test wood density: Measure weight or hardness to distinguish softwoods from hardwoods accurately

Wood density is a critical factor in distinguishing between softwoods and hardwoods, offering a tangible way to assess quality and suitability for specific projects. Softwoods, like pine or cedar, generally have lower densities, making them lighter and more workable, while hardwoods, such as oak or maple, are denser and heavier, often prized for durability. To test density, start by weighing a known volume of the wood—a 12-inch by 12-inch by 1-inch sample, for instance. Compare the weight to standard density values: softwoods typically range from 20 to 40 pounds per cubic foot, whereas hardwoods can exceed 45 pounds per cubic foot. This method provides a quick, quantitative assessment without specialized tools.

For a more hands-on approach, test hardness using a simple tool like a nail or a hardness tester. Softwoods yield easily to pressure, allowing a nail to penetrate with minimal force, while hardwoods resist indentation, requiring significantly more effort. The Janka hardness test, a standardized method, measures the force needed to embed a steel ball into wood. For example, balsa wood (a softwood) has a Janka rating of 100 pounds-force, while hickory (a hardwood) reaches 1820. While professional equipment isn’t always accessible, improvising with common tools can still yield useful insights into the wood’s hardness and, by extension, its density.

Practical tips can enhance accuracy in density testing. Always ensure the wood sample is dry, as moisture skews weight measurements. For hardness tests, apply consistent force and observe the wood’s response—does it dent, splinter, or remain unchanged? Cross-reference your findings with known wood types: if your sample weighs 40 pounds per cubic foot and dents easily, it’s likely a softwood like spruce. Conversely, a 50-pound sample that resists indentation points to a hardwood like walnut. Combining weight and hardness tests provides a robust method for identification.

One caution: density alone doesn’t determine wood quality or application suitability. Softwoods like cedar are lightweight but naturally resistant to decay, making them ideal for outdoor projects despite their lower density. Hardwoods like balsa, an exception, are dense yet surprisingly light, often used in model-making. Always consider the wood’s intended use alongside density tests. For instance, a dense hardwood might be overkill for lightweight furniture but essential for structural beams.

In conclusion, testing wood density through weight and hardness measurements offers a reliable way to differentiate softwoods from hardwoods. By weighing samples, performing hardness tests, and cross-referencing results with known values, you can make informed decisions about wood selection. Remember, while density is a key indicator, it’s just one piece of the puzzle—consider the wood’s properties and your project’s requirements for the best match. This method empowers both hobbyists and professionals to choose wood with confidence and precision.

Where to Find and Purchase Untreated Wood for Your Projects

You may want to see also

Explore related products

$36.48

Smell the wood: Different woods have distinct aromas when cut or sanded

The scent of freshly cut or sanded wood is more than just a pleasant aroma—it’s a diagnostic tool. Cedar, for instance, emits a sharp, almost spicy fragrance reminiscent of a sauna or closet liner, thanks to its natural oils. In contrast, pine smells sweet and resinous, like a forest after rain. These olfactory cues are rooted in the wood’s chemical composition, which varies by species. While smell alone isn’t definitive, it’s a quick, sensory way to narrow down possibilities when identifying wood types.

To use scent effectively, start by sanding a small, clean area of the wood to release its freshest aroma. Hold the wood close to your nose and inhale deeply, noting the intensity and character of the smell. For example, walnut gives off a mild, nutty scent, while oak has a sweeter, more subtle fragrance. Be cautious of treated or painted wood, as these finishes can mask the natural smell. Pair this method with visual inspection for grain patterns or color to increase accuracy.

One practical tip is to compare the wood’s scent to known samples if available. Hardware stores often carry small blocks of common woods like maple, cherry, or mahogany. Smelling these side by side can train your nose to recognize differences. For instance, cherry wood has a fruity, slightly almond-like aroma, while maple is milder and slightly sweet. This comparative approach is especially useful for beginners learning to distinguish between similar-looking species.

While smell is a valuable identifier, it’s not foolproof. Environmental factors like humidity or storage conditions can alter a wood’s aroma over time. Additionally, some woods, such as poplar or birch, have faint or neutral scents that are harder to pinpoint. Always cross-reference smell with other characteristics like weight, hardness, or grain pattern for a more reliable identification. Used thoughtfully, however, this sensory method adds a unique layer to your wood-buying toolkit.

Are Wooden Boats Still Popular? Exploring Their Enduring Appeal Today

You may want to see also

Explore related products

$28.19 $34.99

Observe color variations: Note natural hues, which vary by species and aging

Wood’s color is its silent signature, a visual fingerprint shaped by species, environment, and time. Mahogany, for instance, boasts a deep, reddish-brown hue that darkens with age, while maple often presents a creamy white or pale blond tone. These natural variations aren’t random—they’re clues. By observing the spectrum of colors, from the golden amber of oak to the near-black of ebony, you can narrow down the wood’s identity. Start by comparing the shade to known species, keeping in mind that even within a single type, colors can range widely due to factors like heartwood versus sapwood.

To effectively analyze color, examine the wood under natural light, as artificial lighting can distort hues. Hold a sample near a window and note whether the color is uniform or if it contains streaks, swirls, or darker patches. For example, walnut often displays a rich chocolate brown with purplish undertones, while cherry starts as a pale pinkish-brown and deepens to a reddish-brown over decades. Aging plays a critical role here: freshly cut wood may appear lighter, while older pieces develop patina, a surface sheen that enhances depth. If you’re unsure, compare your sample to high-quality images of aged and new wood from the same species.

A persuasive argument for focusing on color is its reliability compared to other identifiers. Grain patterns and hardness tests require experience, but color is accessible to even a novice. However, caution is necessary. Stains, finishes, and weathering can mimic natural hues, so look for consistency. If a piece labeled “teak” appears too uniformly golden, it might be stained pine. Conversely, untreated wood reveals its true character. For practical application, carry a small color chart of common wood species when shopping, and cross-reference with online databases for accuracy.

Comparatively, color analysis is most effective when paired with other methods. While it can distinguish between broad categories—like separating softwoods (typically lighter) from hardwoods (often darker)—it falls short in identifying similar species. For instance, both hickory and pecan exhibit brown tones, but hickory tends to have more contrast between its heartwood and sapwood. Here, texture and grain become tiebreakers. Still, color remains the first line of identification, offering immediate insights without tools or expertise.

Descriptively, wood’s color tells a story of its life. A piece of cedar may show silvery-gray weathering on its exterior but reveal a warm, reddish interior when cut. This duality highlights how exposure alters appearance. Similarly, spalted wood—marked by dark lines caused by fungi—creates a unique, almost artistic pattern that no stain can replicate. By appreciating these nuances, you not only identify the wood but also understand its journey. For collectors or craftsmen, this knowledge adds value, ensuring you select wood that aligns with your project’s aesthetic and durability needs.

Where to Find Wood Master 5500 Replacement Parts for Purchase

You may want to see also

Explore related products

Check for knots/defects: Identify imperfections that indicate specific wood types or quality

Knots and defects are nature's fingerprints on wood, offering clues about its origin, quality, and potential uses. These imperfections, often seen as flaws, can actually be valuable indicators for the discerning buyer. For instance, tight, sound knots in pine or spruce can signify a slower growth rate, typically associated with stronger, denser wood. Conversely, loose or large knots might suggest a faster-growing tree, which could be more prone to splitting or warping. Understanding these nuances allows you to assess whether the wood aligns with your project's structural and aesthetic needs.

To effectively evaluate knots, start by examining their size, shape, and distribution. In hardwoods like oak or maple, small, tight knots are generally less concerning than large, cracked ones, which can compromise the wood's integrity. Softwoods, such as cedar or fir, often contain more knots due to their faster growth, but these can add character if they’re well-preserved. Run your hand over the surface to check for raised or cracked areas around the knots, as these can affect finishing and durability. A magnifying glass can help identify hairline cracks or decay that might not be visible to the naked eye.

Beyond knots, other defects like checks (lengthwise cracks), shakes (cross-grain separations), or wormholes provide additional insights. For example, wormholes in walnut or chestnut can be a sign of age and authenticity, often prized in rustic or antique-style projects. However, in structural applications, such defects can weaken the wood, making it unsuitable for load-bearing purposes. Always consider the intended use of the wood when evaluating these imperfections—what’s acceptable for a decorative shelf might be unacceptable for a staircase.

Persuasively, embracing wood with natural defects can be both cost-effective and environmentally conscious. Wood with minor imperfections is often cheaper, yet it can still perform well in the right application. For instance, knotty pine is a budget-friendly choice for interior paneling, where its character adds warmth and texture. By learning to read these defects, you not only save money but also reduce waste by utilizing wood that might otherwise be discarded. This approach aligns with sustainable practices, making it a win-win for both your wallet and the planet.

In conclusion, checking for knots and defects is a critical step in identifying wood types and assessing quality. By analyzing their size, shape, and impact on the wood’s structure, you can make informed decisions tailored to your project’s requirements. Whether you’re prioritizing strength, aesthetics, or sustainability, understanding these imperfections empowers you to choose wood that meets your needs while appreciating its unique story. With practice, you’ll develop an eye for detail that transforms potential flaws into features, enhancing both your craftsmanship and your connection to the material.

Essential Guide to Choosing and Purchasing Quality Wood Planes

You may want to see also

Frequently asked questions

Look for key characteristics such as grain pattern, color, hardness, and smell. Research common wood types or use a wood identification guide to match these features.

Yes, tools like a magnifying glass, density test (weighing a known volume), or a wood identification app can assist. Additionally, a simple burn test can reveal unique ash colors and smells for certain woods.

Yes, the label or seller’s information often specifies the wood type. If not, knowing the wood’s origin can narrow down possibilities, as certain woods are native to specific regions.