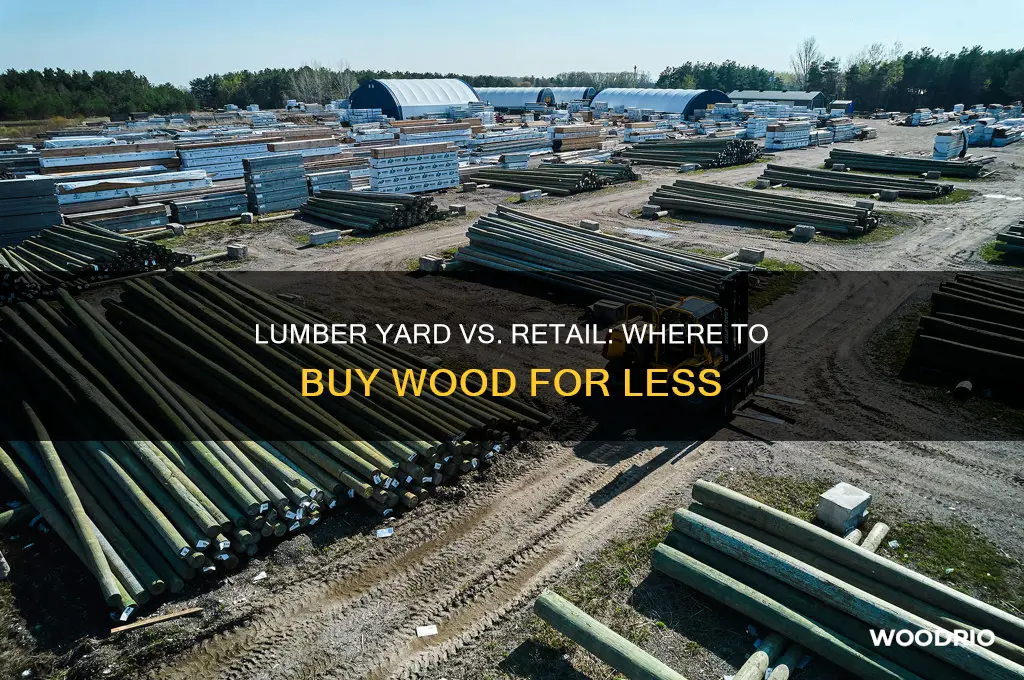

When considering whether it’s cheaper to buy wood at a lumber yard, several factors come into play. Lumber yards often offer a wider selection of wood types, grades, and sizes compared to big-box stores, which can be advantageous for specific projects. While prices at lumber yards may sometimes be higher due to specialized inventory and smaller-scale operations, they often provide better quality materials and expert advice. Additionally, buying in bulk or establishing a relationship with a local lumber yard can lead to discounts or better deals. Conversely, big-box stores may offer lower prices on common wood types but with limited options and potentially lower quality. Ultimately, the cost-effectiveness depends on the project’s requirements, the quantity needed, and the value placed on quality and expertise.

| Characteristics | Values |

|---|---|

| Price per Board Foot | Generally lower at lumber yards compared to big-box stores (e.g., Home Depot, Lowe's) due to bulk purchasing and lower overhead costs. |

| Variety of Wood Types | Lumber yards often offer a wider selection of wood species, grades, and sizes, including specialty and exotic woods. |

| Quality of Wood | Typically higher quality at lumber yards, with fewer defects and better grading standards. |

| Custom Cutting Services | Many lumber yards provide custom milling and cutting services, which can save time and reduce waste. |

| Bulk Discounts | Available at lumber yards for large purchases, making it more cost-effective for big projects. |

| Expertise and Advice | Staff at lumber yards are often more knowledgeable about wood and can provide tailored advice for specific projects. |

| Delivery Options | Some lumber yards offer delivery services, which can be cost-effective for large or heavy orders. |

| Environmental Impact | Locally sourced wood from lumber yards may have a smaller carbon footprint compared to big-box stores that source globally. |

| Consistency in Supply | Lumber yards may have more consistent stock levels and fewer supply chain disruptions compared to big-box stores. |

| Pricing Transparency | Prices at lumber yards are often more stable and less subject to frequent fluctuations seen in big-box stores. |

| Convenience | Big-box stores may be more convenient for small, quick purchases due to their widespread locations and extended hours. |

| Return Policies | Policies vary, but lumber yards may have more flexible return policies for contractors and regular customers. |

| Seasonal Availability | Some wood types may be seasonally available at lumber yards, offering better prices during specific times of the year. |

| Membership Benefits | Some lumber yards offer contractor or membership programs with additional discounts and perks. |

| Online Presence | Many lumber yards now have online catalogs and ordering options, though availability and pricing may differ from in-store. |

Explore related products

What You'll Learn

Comparing prices: Lumber yard vs. home improvement stores

Buying wood for a project often leads to a critical decision: should you head to a lumber yard or a home improvement store? The answer hinges on understanding the pricing dynamics between the two. Lumber yards typically source wood directly from mills, cutting out middlemen and potentially offering lower prices for bulk purchases. However, they may lack the convenience and variety found at big-box stores. Home improvement stores, like Home Depot or Lowe’s, often mark up prices to cover overhead costs but provide pre-cut, ready-to-use lumber in smaller quantities, ideal for DIYers. To determine the cheaper option, consider the scale of your project and your willingness to process raw materials.

For small-scale projects, home improvement stores often win on convenience, but not necessarily price. A 2x4 stud at a lumber yard might cost $2.50, while the same piece at a big-box store could be $3.25. Multiply this by a few dozen pieces, and the savings become noticeable. However, home improvement stores frequently run promotions or bundle deals, such as 10% off lumber purchases over $100, which can narrow the gap. Always check for sales or loyalty programs before committing to a purchase.

Bulk buyers, such as contractors or those tackling large projects, often find lumber yards more cost-effective. For instance, a full bundle of 2x4s (typically 294 board feet) might cost $250 at a lumber yard, compared to $320 at a home improvement store. Additionally, lumber yards may offer discounts for cash payments or repeat customers. However, be prepared to handle raw lumber, which may require cutting, planing, or drying before use—tasks that add time and effort but can still result in overall savings.

One often-overlooked factor is wood quality. Lumber yards frequently carry higher-grade, locally sourced wood, while home improvement stores prioritize consistency and availability over premium quality. For example, a select grade 2x6 at a lumber yard might be $5.00, while a similar piece at a big-box store could be $6.50 but with more knots or imperfections. If your project demands precision or aesthetics, the higher-quality lumber from a yard may justify the extra effort.

To maximize savings, combine the strengths of both sources. Purchase raw, bulk lumber from a yard for structural components, and supplement with pre-cut pieces from a home improvement store for finishing touches. Always measure twice and plan your cuts efficiently to minimize waste. By strategically sourcing materials, you can balance cost, quality, and convenience for any woodworking project.

Are Oshkosh Wood Doors Still Available for Purchase Today?

You may want to see also

Explore related products

Bulk purchasing discounts at local lumber yards

Local lumber yards often offer bulk purchasing discounts that can significantly reduce the cost of wood compared to buying in smaller quantities or from big-box stores. These discounts are typically structured as tiered pricing, where the cost per board foot decreases as the volume increases. For example, purchasing 500 board feet of lumber might save you 10% per unit compared to buying 100 board feet. This pricing model incentivizes larger orders, making it particularly advantageous for contractors, builders, or DIY enthusiasts tackling substantial projects.

To maximize these savings, it’s essential to plan your project meticulously. Calculate the total amount of wood required before visiting the lumber yard, factoring in waste and additional materials for cuts or mistakes. Many yards require bulk orders to be placed in advance, so inquire about lead times and delivery options. Some yards may also offer additional discounts for cash payments or repeat business, so don’t hesitate to negotiate or ask about available promotions.

One practical tip is to collaborate with others on bulk purchases. If your project doesn’t require a large volume, consider pooling resources with neighbors, friends, or fellow hobbyists to meet the minimum threshold for discounts. This approach not only reduces individual costs but also fosters community and resource-sharing. Just ensure everyone agrees on the type, grade, and quantity of wood to avoid discrepancies.

While bulk discounts are appealing, be mindful of storage and handling. Large quantities of wood require adequate space to prevent warping, moisture damage, or pest infestation. Invest in proper storage solutions, such as covered racks or sealed containers, especially if the wood will be stored outdoors. Additionally, verify the lumber yard’s return policy for bulk orders, as some may have stricter terms compared to smaller purchases.

In conclusion, bulk purchasing discounts at local lumber yards can yield substantial savings, but they require careful planning and execution. By understanding the pricing structure, collaborating with others, and preparing for storage, you can leverage these discounts effectively. This strategy not only reduces costs but also supports local businesses, making it a win-win for both your wallet and your community.

Ultimate Guide to Sourcing and Buying Reclaimed Barn Wood

You may want to see also

Explore related products

Quality differences affecting overall cost-effectiveness

Wood quality varies significantly between lumber yards and big-box stores, and these differences directly impact cost-effectiveness. At a lumber yard, you’re more likely to find kiln-dried wood with consistent moisture levels, reducing the risk of warping or splitting during your project. Big-box stores often stock air-dried or improperly dried wood, which can shrink or expand after purchase, leading to wasted material and rework. For example, a 2x4 from a lumber yard might cost $0.50 more upfront but saves you from replacing bowed pieces later, making it the more economical choice in the long run.

Consider the grading system, another critical factor in quality and cost. Lumber yards typically offer higher-grade wood with fewer knots, cracks, or imperfections, ensuring structural integrity and a better finish. Big-box stores often carry lower-grade options, which may be cheaper per board foot but require more sorting and culling on your end. If you’re building a deck or furniture, spending $10–$15 extra per board at a lumber yard for premium-grade wood can prevent costly repairs or replacements down the line.

The species of wood also plays a role in cost-effectiveness. Lumber yards frequently stock a wider variety of hardwoods and specialty species, allowing you to choose the best material for your project’s durability and aesthetic needs. Big-box stores often limit options to common softwoods like pine, which may not withstand outdoor or high-traffic use. For instance, investing in cedar from a lumber yard for a fence might cost $2–$3 more per linear foot but lasts 10–15 years longer than pressure-treated pine from a big-box store, making it a smarter financial decision.

Finally, the milling precision of wood affects both material yield and labor costs. Lumber yards often provide smoother, straighter boards with more accurate dimensions, reducing the time spent planing, sanding, or adjusting pieces during construction. Big-box wood may require additional prep work, adding hours to your project and potentially increasing tool wear. If your time is valued at $20/hour, saving $5 on rough-cut wood from a big-box store could cost you $40 in extra labor, negating any perceived savings. Always factor in the hidden costs of lower-quality materials.

Best Places to Buy Wood Chunks for Smoking Meat and BBQ

You may want to see also

Explore related products

$75.99 $80

Transportation costs for buying wood in bulk

Transportation costs can significantly impact the overall expense of buying wood in bulk from a lumber yard. While purchasing larger quantities often reduces the per-unit cost of the wood itself, the logistics of moving heavy and bulky materials can offset these savings. For instance, a standard pickup truck can typically haul about 1,000 to 2,000 pounds of lumber, but exceeding this limit risks vehicle damage or safety hazards. If you’re buying enough wood to require multiple trips or a rented vehicle, the fuel, rental fees, and wear-and-tear expenses quickly add up.

Consider the distance between your location and the lumber yard. A round trip of 50 miles, for example, could consume 2–3 gallons of gas, depending on your vehicle’s fuel efficiency. At an average gas price of $3.50 per gallon, a single trip might cost $7–$10.50 in fuel alone. Multiply this by multiple trips, and the transportation costs rival or even surpass the savings from bulk purchasing. To mitigate this, calculate the break-even point by comparing the cost of fuel and vehicle use to the discount offered for bulk wood.

For those without access to a suitable vehicle, renting a truck or trailer becomes a necessity. Rental costs vary widely—a pickup truck rental averages $20–$50 per day, while a larger box truck can cost $100 or more. Add insurance fees, mileage charges, and fuel, and the total expense can easily reach $150–$300 for a single day. In such cases, it’s often cheaper to pay for delivery from the lumber yard, which typically ranges from $50 to $200 depending on distance and load size. Always compare delivery fees to DIY transportation costs before deciding.

Another factor is the labor involved in loading and unloading. Bulk wood purchases often weigh hundreds or even thousands of pounds, requiring physical strength and proper equipment. If you’re unable to handle the load yourself, hiring help or risking injury adds hidden costs. Lumber yards sometimes offer loading assistance, but this service may come with a fee. Alternatively, investing in tools like a dolly or forklift rental (around $50–$100 per day) can streamline the process but further increases expenses.

In conclusion, while buying wood in bulk from a lumber yard can save money on material costs, transportation expenses demand careful consideration. Evaluate your vehicle’s capacity, the distance to the yard, and the feasibility of DIY hauling versus professional delivery. Use online calculators to estimate fuel costs and compare them to delivery fees. By factoring in all transportation-related expenses, you can determine whether bulk purchasing truly offers the best value for your project.

Where to Buy Wood Ducks: A Guide for Enthusiasts

You may want to see also

Explore related products

Seasonal price fluctuations in lumber yards

Lumber prices aren't static; they ebb and flow with the seasons, much like the trees themselves. Understanding these fluctuations can save you significant money on your next woodworking project. Spring, the traditional building season, often sees prices rise as demand surges. Contractors and DIYers alike emerge from winter hibernation, driving up the cost of lumber for decks, fences, and home renovations.

Imagine paying a premium for 2x4s in April when, with a bit of foresight, you could have stocked up in January.

Several factors contribute to this seasonal dance. Lumber production slows during winter months due to harsh weather conditions, limiting supply. Simultaneously, the holiday season often sees a lull in construction activity, leading to lower demand and potentially lower prices. This creates a window of opportunity for savvy buyers. Conversely, summer's peak construction season, coupled with increased demand for outdoor projects, pushes prices upwards.

Think of it as supply and demand on a seasonal rollercoaster.

To capitalize on these fluctuations, plan your projects strategically. If your project isn't time-sensitive, consider purchasing lumber during the winter months. Many lumber yards offer discounts on slow-moving inventory during this period. Additionally, keep an eye out for end-of-season sales in late summer or early fall, as retailers clear out stock to make room for new inventory. Remember, patience and a bit of market awareness can translate into substantial savings.

By understanding the seasonal rhythm of lumber prices, you can transform yourself from a price taker to a price maker.

Choosing the Perfect Wood Table: A Buyer's Guide to Quality

You may want to see also

Frequently asked questions

It often is, as lumber yards typically offer lower prices for bulk purchases and have a wider selection of specialty woods.

Yes, lumber yards usually carry higher-quality wood with fewer defects, making it a better value despite potentially higher upfront costs.

Some lumber yards may charge for cutting or delivery services, but these costs can be offset by the savings on bulk or specialty wood purchases.

Yes, lumber yards are often more open to negotiation, especially for large orders, which can make buying directly from them even more cost-effective.