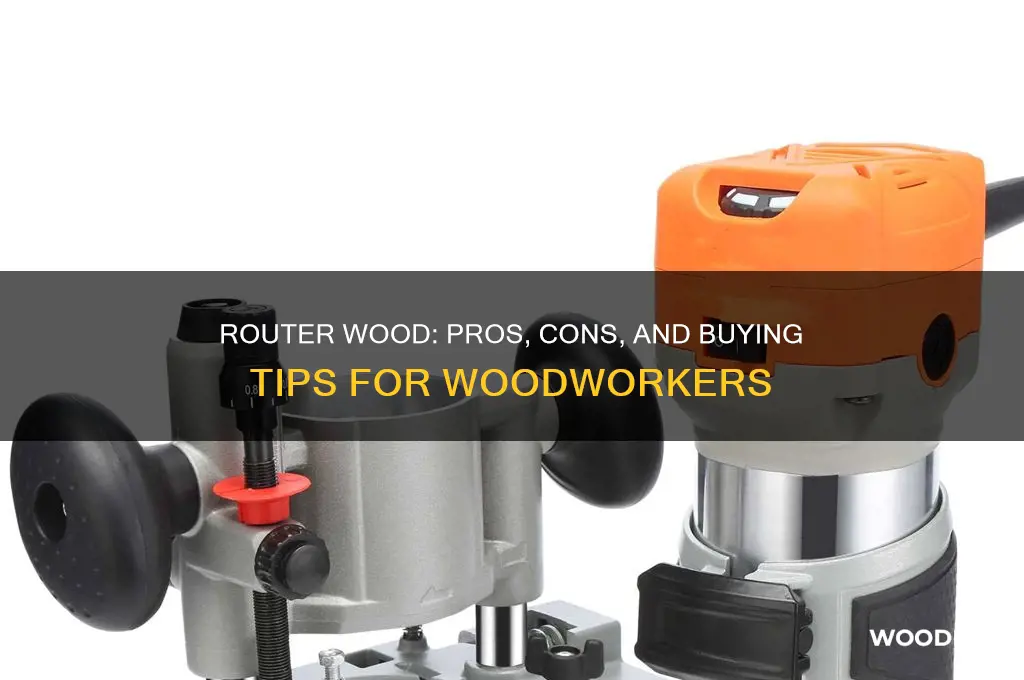

If you're considering whether to buy a router for woodworking, it’s important to assess your needs and skill level. A router is a versatile tool that can enhance your woodworking projects by allowing you to create intricate designs, edges, and joints with precision. It’s ideal for tasks like shaping edges, cutting grooves, and crafting decorative patterns. However, routers require practice to master, and they come in various types, such as fixed-base and plunge routers, each suited for different applications. Before purchasing, consider the frequency of use, the complexity of your projects, and your budget. If you’re a hobbyist or professional looking to elevate your craftsmanship, investing in a router could be a valuable addition to your toolkit.

Explore related products

What You'll Learn

- Router Types: Compare plunge, fixed-base, and CNC routers for woodworking needs

- Bit Selection: Choose bits for edging, carving, or joinery projects

- Safety Tips: Essential safety practices to prevent accidents while routing wood

- Cost vs. Quality: Balance budget with durability and performance for long-term use

- Project Suitability: Determine if a router is necessary for your woodworking goals

Router Types: Compare plunge, fixed-base, and CNC routers for woodworking needs

Choosing the right router for your woodworking projects hinges on understanding the distinct capabilities of plunge, fixed-base, and CNC routers. Each type excels in specific applications, and selecting the wrong one can limit your creativity or frustrate your workflow. Let’s dissect their strengths and ideal use cases.

Plunge routers are the chameleons of the router world, offering unmatched versatility. Their key feature is a spring-loaded base that allows the bit to plunge into the material mid-cut, making them ideal for tasks like mortises, dadoes, and starting cuts in the center of a workpiece. For example, if you’re creating a through-dovetail joint, a plunge router lets you position the bit precisely before engaging the motor. However, their complexity and heavier weight can make them less intuitive for beginners. Pro tip: Always lower the bit slowly and steadily to avoid tear-out, especially in hardwoods.

Fixed-base routers, on the other hand, are the workhorses of edge profiling and repetitive cuts. Their rigid base provides stability, making them perfect for rounding edges, chamfering, or using with a router table. If you’re crafting cabinet doors with consistent profiles, a fixed-base router ensures precision and efficiency. Their simplicity and lighter weight make them beginner-friendly, but their inability to start cuts mid-material limits their versatility. Caution: Always secure your workpiece firmly when using a fixed-base router to prevent kickback.

CNC routers represent the pinnacle of precision and automation in woodworking. These computer-controlled machines carve intricate designs, 3D reliefs, and complex joinery with minimal human intervention. Imagine crafting a custom inlay or a set of interlocking gears—tasks that would be painstaking by hand. However, CNC routers are expensive, require digital design skills, and occupy significant workshop space. They’re best suited for professionals or hobbyists committed to high-volume, intricate work. Practical tip: Start with simpler software like Easel or Carbide Create if you’re new to CNC programming.

In summary, plunge routers offer adaptability for diverse tasks, fixed-base routers excel in edge work and simplicity, and CNC routers redefine precision for advanced projects. Assess your project scope, skill level, and budget before investing. For instance, a weekend warrior crafting furniture might prioritize a plunge router, while a small business owner could justify a CNC router for custom commissions. Choose wisely—the right router transforms woodworking from labor to art.

Where to Buy Window Sill Wood: A Comprehensive Guide

You may want to see also

Explore related products

Bit Selection: Choose bits for edging, carving, or joinery projects

Selecting the right router bit is akin to choosing the perfect tool for a surgical procedure—precision matters. For edging projects, straight bits are your go-to. These bits create clean, sharp edges on wood, ideal for crafting moldings or trimming laminate. A ¼-inch straight bit is versatile for most edging tasks, but consider a ½-inch bit for thicker materials or deeper cuts. Pair this with a router table for maximum control, ensuring the wood feeds smoothly against the bit’s rotation direction to avoid chipping.

Carving projects demand a different approach. Here, ball nose or roundover bits shine. Ball nose bits are perfect for creating smooth, rounded contours or 3D carvings, while roundover bits add decorative edges to furniture or cabinetry. For intricate designs, a V-groove bit can mimic hand-carved details, especially when used at low speeds (around 12,000 RPM) to prevent burning the wood. Experiment with bit angles—a 45-degree V-groove bit, for instance, adds depth and shadow to your carvings.

Joinery projects require bits designed for structural integrity. Dovetail bits are essential for creating strong, interlocking joints, often used in drawer construction. A ½-inch dovetail bit with a 14-degree angle is standard, but adjust the depth to match your wood thickness. For simpler joints, a rabbeting bit excels at creating recesses for panels or shelves. Always use a fence or template guide to ensure consistent cuts, especially when working with hardwoods like oak or maple, which can splinter if mishandled.

Material compatibility is often overlooked but critical. Carbide-tipped bits last longer and handle harder woods better than high-speed steel (HSS) bits, though they come at a higher cost. For occasional use, HSS bits suffice for softer woods like pine or cedar. Regardless of material, keep bits sharp—dull edges tear wood fibers, ruining your project. A diamond sharpening stone or professional resharpening service can extend bit life significantly.

Finally, safety and technique cannot be overstated. Always secure your workpiece with clamps or a vise to prevent kickback. Wear safety goggles and ear protection, as routers operate at high decibels. Start with shallow passes, gradually increasing depth to avoid overheating the bit or wood. Practice on scrap wood to familiarize yourself with each bit’s behavior, especially when transitioning from edging to carving or joinery tasks. Mastery of bit selection transforms a router from a simple tool into an artist’s brush, capable of turning raw wood into refined craftsmanship.

Are Wooden Ladders Still Available for Purchase Today?

You may want to see also

Explore related products

Safety Tips: Essential safety practices to prevent accidents while routing wood

Wood routing, while rewarding, demands respect for its inherent risks. A single moment of inattention can lead to serious injury. Understanding and implementing essential safety practices isn't just advisable – it's non-negotiable.

Let's delve into the critical measures that transform a potentially hazardous activity into a controlled and enjoyable craft.

Prioritize Personal Protective Equipment (PPE): Before even powering up your router, don a comprehensive suite of PPE. Safety glasses with side shields are mandatory to protect against flying debris. Ear protection is crucial to mitigate the router's high-pitched whine, which can cause hearing damage over time. Dust masks or respirators are essential to prevent inhalation of fine wood particles, which can lead to respiratory issues. Finally, consider gloves with good grip to enhance control while minimizing the risk of splinters.

Remember, PPE is your first line of defense – don't compromise on quality or skip any element.

Master the Router's Anatomy and Controls: Familiarize yourself intimately with your router's components and controls. Understand the on/off switch location, speed adjustment, and bit-changing mechanism. Practice engaging and disengaging the safety lock before starting any project. Knowing your tool inside and out allows for swift reactions in case of emergencies and prevents accidental activations.

Secure Your Workpiece and Maintain Control: A wobbling workpiece is a recipe for disaster. Secure your wood firmly to a stable workbench using clamps or a vice grip. Ensure the clamps are tight enough to prevent movement but not so tight as to distort the wood. Maintain a firm, two-handed grip on the router at all times, keeping your hands behind the cutting edge. Avoid overreaching or awkward positions that compromise control.

Remember, a stable workpiece and a controlled grip are fundamental to safe routing.

Choose the Right Bit and Feed Direction: Selecting the appropriate router bit for the task is paramount. Different bits are designed for specific cuts, and using the wrong one can lead to binding, kickback, or breakage. Always feed the router against the rotation of the bit, pushing it in the direction that feels natural and controlled. Forcing the router or feeding it in the wrong direction can cause the bit to grab the wood, leading to loss of control and potential injury.

Maintain a Clean and Organized Workspace: A cluttered workspace is a hazardous workspace. Keep your work area free of debris, tools, and other obstacles that could cause trips or interfere with your routing. Regularly clear away wood chips and dust to maintain visibility and prevent slipping. Good organization not only enhances safety but also improves efficiency and the overall quality of your work.

By adhering to these essential safety practices, you can significantly reduce the risk of accidents while routing wood. Remember, safety is not an afterthought – it's an integral part of the woodworking process. With proper precautions, you can confidently enjoy the precision and creativity that wood routing offers.

Choosing the Perfect Wood for Your Table: A Buyer's Guide

You may want to see also

Explore related products

$187.99 $219

Cost vs. Quality: Balance budget with durability and performance for long-term use

Investing in a wood router demands a strategic approach to cost versus quality, as this tool’s longevity and performance directly impact your woodworking projects. Entry-level routers, priced between $50 and $150, often feature plastic components and underpowered motors, making them suitable for occasional hobbyists but prone to wear under frequent use. Mid-range models ($150–$300) strike a better balance, offering metal construction, variable speed controls, and improved precision, ideal for intermediate users. High-end routers ($300+) boast premium features like soft-start motors, ergonomic designs, and advanced dust collection systems, catering to professionals seeking reliability and efficiency. The key is to align your budget with your usage frequency and project complexity, ensuring the router’s durability matches your long-term needs.

Consider the cost of maintenance and accessories when evaluating a router’s overall value. Cheaper models may require frequent bit replacements or motor repairs, offsetting their initial affordability. For instance, a $100 router with a 1.25 HP motor might struggle with dense hardwoods, leading to premature burnout, while a $250 model with a 2.25 HP motor and aluminum housing can handle such materials with ease, reducing long-term expenses. Additionally, investing in a router with a universal base or compatibility with multiple accessories (e.g., edge guides, dust ports) enhances versatility, maximizing your return on investment.

A persuasive argument for prioritizing quality lies in the tool’s impact on project outcomes. A low-cost router with inconsistent speed control or poor vibration dampening can mar intricate designs, forcing rework or material waste. Conversely, a higher-quality router ensures clean cuts, precise detailing, and smoother finishes, elevating the craftsmanship of your pieces. For professionals or serious enthusiasts, this difference justifies the premium, as it directly translates to time saved and client satisfaction.

To strike the right balance, start by assessing your skill level and project scope. Beginners might opt for a mid-range router, such as the Bosch 1617EVSPK ($250), which offers a 2.25 HP motor, variable speeds, and a durable build. Advanced users could consider the Festool OF 1400 EQ ($600), known for its precision and ergonomic design, albeit at a steeper price. Regardless of choice, look for warranties and user reviews to gauge reliability. Remember, a router is an investment—prioritize quality within your budget to avoid costly upgrades or replacements down the line.

Where to Buy Teak Wood: Top Sources and Tips for Quality Purchases

You may want to see also

Explore related products

$29.99 $39.99

Project Suitability: Determine if a router is necessary for your woodworking goals

A router is a versatile tool, but its necessity hinges on the complexity and scope of your woodworking projects. If your goals involve intricate joinery, decorative edges, or custom profiles, a router becomes indispensable. For simpler tasks like basic cuts or assembly, it might be overkill. Assess your project list: are you crafting dovetail joints, rounding over edges, or creating dadoes? If so, a router is a wise investment. Conversely, if your work primarily involves straight cuts and minimal detailing, you may achieve your goals with fewer tools.

Consider the scale of your projects as well. Small-scale woodworking, such as crafting jewelry boxes or picture frames, often benefits from a router’s precision. Larger projects, like building furniture, may require a router for consistent edge treatments or joinery, but the tool’s utility diminishes if your designs are straightforward. Evaluate whether the added functionality justifies the cost and learning curve. A router’s value lies in its ability to elevate craftsmanship, but only if your projects demand its capabilities.

For beginners, start with a plunge router if your projects require depth adjustments mid-cut, such as when creating mortises or inlay work. A fixed-base router is ideal for tasks like edge profiling or rounding, where consistent depth is key. If you’re unsure, opt for a combo kit that offers both bases, providing flexibility as your skills and project complexity grow. Remember, the router’s bits are equally important—invest in high-quality carbide bits to ensure clean, precise cuts.

Practical tip: Test the waters with a rented router or borrow one from a fellow woodworker before committing to a purchase. This hands-on experience will help you gauge its relevance to your specific goals. Additionally, watch tutorials or take a class to understand the router’s potential and limitations. By aligning the tool’s capabilities with your project needs, you’ll make an informed decision that enhances, rather than hinders, your woodworking journey.

Is Boca Woods Country Club Worth the Investment? A Comprehensive Review

You may want to see also

Frequently asked questions

Yes, a router is a versatile tool that can help beginners learn essential woodworking skills like edge profiling, joinery, and decorative detailing. Start with a basic model and practice on scrap wood to build confidence.

While not strictly necessary, a router can significantly enhance the precision and finish of small projects. It’s especially useful for tasks like rounding edges, creating grooves, or adding decorative elements.

Corded routers offer consistent power and are ideal for heavy-duty or extended use, while cordless routers provide portability and convenience for smaller tasks. Choose based on your project needs and workspace setup.

For occasional use, a mid-range router with basic features is often sufficient. High-end routers are more suitable for professionals or those who require advanced capabilities and frequent use.