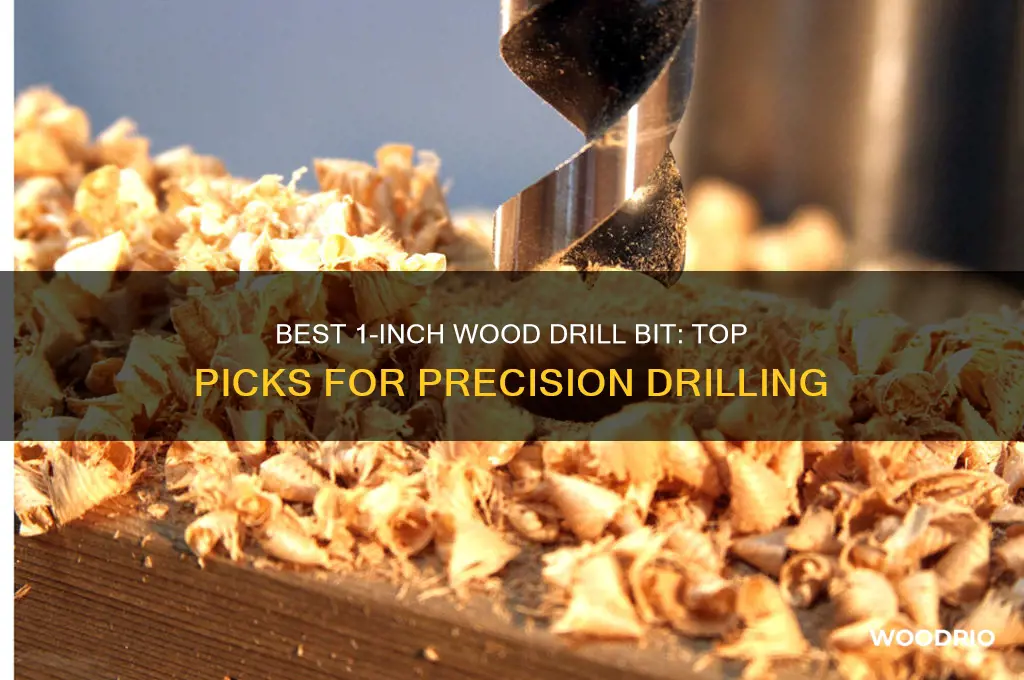

When selecting a 1-inch diameter wood drill bit, it’s essential to consider the type of wood you’re working with, the depth of the hole needed, and the specific application. For general woodworking tasks, a high-speed steel (HSS) or carbon steel bit is cost-effective and suitable for softwoods, while a cobalt or carbide-tipped bit offers greater durability for hardwoods or repetitive use. Spiral flute bits are ideal for clean, chip-free holes, whereas auger bits excel in deep or rough drilling. Ensure the bit has a sharp cutting edge and a compatible shank size for your drill. Additionally, consider pilot hole drilling for precision and to prevent splitting, especially in harder woods. Always prioritize quality to ensure longevity and performance.

Explore related products

What You'll Learn

- Material Type: Hardwood, softwood, or engineered wood Choose bits for specific wood densities

- Bit Design: Brad point, twist, or spade Select based on precision and hole quality

- Coating Options: Black oxide or titanium Coatings reduce friction and increase durability

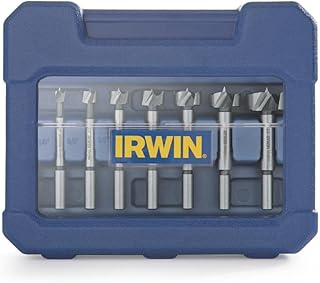

- Brand Reliability: Popular brands like Irwin, DeWalt, or Bosch offer trusted quality

- Price vs. Quality: Budget-friendly or premium Balance cost with performance and longevity

Material Type: Hardwood, softwood, or engineered wood? Choose bits for specific wood densities

Hardwoods, softwoods, and engineered woods each demand specific drill bits to ensure clean, efficient holes without damaging the material. Hardwoods like oak or maple are dense and require bits with sharper, more durable cutting edges to prevent tearing or burning. Softwoods like pine or cedar are less dense and can be drilled with standard twist bits, but using a brad-point bit will yield smoother results. Engineered woods, such as plywood or MDF, often contain adhesives and layers that dull bits quickly, so carbide-tipped or coated bits are recommended for longevity.

Selecting the right bit for hardwood involves prioritizing sharpness and heat resistance. A high-speed steel (HSS) bit with a sharp, ground point will penetrate dense fibers without excessive force. For softer hardwoods like birch, a standard brad-point bit suffices, but for harder varieties like walnut, consider a cobalt-coated bit to reduce friction and extend tool life. Always drill at a slower speed to minimize heat buildup, which can cause the wood to scorch or the bit to dull prematurely.

Softwoods are forgiving but benefit from bits designed for precision. A brad-point bit with a sharp, centered tip prevents wandering and ensures a clean entry and exit hole. For larger diameters like 1 inch, a Forstner bit is ideal, as its rim guides the cut smoothly through the wood’s loose grain structure. Avoid excessive pressure, as softwoods can compress under force, leading to uneven holes. A light touch and consistent speed are key to maintaining accuracy.

Engineered woods present unique challenges due to their composite nature. MDF, for instance, wears down standard bits rapidly due to its abrasive fibers and glue content. A carbide-tipped bit or one with a titanium coating will outlast traditional steel options. When drilling plywood, use a bit with a sharp, angled point to avoid splintering the layers. Always secure the material firmly to prevent tear-out, especially when breaking through the top or bottom surface.

In summary, matching the bit to the wood density ensures both tool longevity and workpiece quality. Hardwoods require durable, heat-resistant bits; softwoods benefit from precision-focused designs; and engineered woods demand wear-resistant materials. By tailoring your choice to the specific material, you’ll achieve cleaner holes, reduce tool wear, and streamline your workflow. Always test on a scrap piece first to fine-tune speed and pressure for optimal results.

Discover Top Stores to Buy Wooden Puzzles Online & Offline

You may want to see also

Explore related products

$19.99

Bit Design: Brad point, twist, or spade? Select based on precision and hole quality

Choosing the right bit design for a 1-inch diameter wood drill bit hinges on the precision and hole quality you require. Brad point bits excel in accuracy, featuring a sharp, centered point and cutting spurs that score the wood’s perimeter. This design minimizes splintering and ensures clean, precise holes, making it ideal for fine woodworking or projects where appearance matters. However, brad point bits can be slower to drill and may require more force, especially in harder woods. If your priority is a flawless finish and you’re willing to work methodically, this is your best bet.

For faster drilling with less emphasis on precision, twist bits are a practical choice. Their spiral design evacuates chips efficiently, allowing for quicker penetration through wood. While twist bits are versatile and cost-effective, they tend to produce rougher edges and may wander slightly if not guided carefully. This makes them suitable for rough carpentry or projects where hole quality is secondary to speed. If you’re drilling multiple holes and time is a factor, a twist bit will serve you well, though you’ll need to clean up the edges afterward.

Spade bits strike a balance between speed and precision, offering a flat, paddle-like blade that removes material quickly. Their open design reduces heat buildup and clogging, but the trade-off is a higher likelihood of tear-out, especially on the exit side of the hole. Spade bits are best for applications where the backside of the workpiece won’t be visible, such as framing or installing hardware. If you need a hole fast and can tolerate some imperfections, a spade bit is a reliable option.

When selecting a bit design, consider the wood type and project requirements. Hardwoods like oak or maple demand sharper, more precise bits like brad points to avoid splitting, while softer woods like pine can tolerate the quicker action of twist or spade bits. Always start with a pilot hole for larger bits to maintain control and accuracy, regardless of design. Ultimately, the choice between brad point, twist, and spade bits comes down to balancing speed, precision, and the visibility of the hole in your final project.

Where to Find Replacement Wooden Glider Slats for Your Outdoor Furniture

You may want to see also

Explore related products

Coating Options: Black oxide or titanium? Coatings reduce friction and increase durability

Choosing the right coating for your 1-inch diameter wood drill bit can significantly impact its performance and lifespan. Black oxide and titanium coatings are two popular options, each with distinct advantages. Black oxide coatings are known for their affordability and ability to reduce friction, making them a solid choice for general woodworking tasks. They also provide mild corrosion resistance, which helps protect the bit from rust in humid environments. However, black oxide is less durable compared to titanium and may wear off faster under heavy use.

Titanium coatings, on the other hand, offer superior durability and heat resistance, making them ideal for drilling harder woods or for extended use. The titanium layer reduces friction more effectively than black oxide, allowing the bit to cut smoother and faster while generating less heat. This coating is also more resistant to wear, ensuring the bit maintains its sharpness longer. However, titanium-coated bits are typically more expensive, which may be a consideration if you’re working on a budget.

When deciding between the two, consider the frequency and intensity of your drilling tasks. For occasional use or softer woods, a black oxide-coated bit provides good value and performance. If you’re a professional or frequently work with dense hardwoods, investing in a titanium-coated bit will pay off in the long run due to its extended lifespan and enhanced efficiency.

Practical tip: Always clean your drill bit after use, regardless of the coating, to maximize its durability. For titanium-coated bits, avoid using abrasive cleaning materials that could scratch the surface and compromise the coating’s integrity. For black oxide bits, store them in a dry place to prevent premature rusting.

In summary, black oxide coatings are cost-effective and suitable for light to moderate use, while titanium coatings offer premium performance and longevity for demanding applications. Your choice should align with your specific needs and the type of wood you’ll be drilling.

Best Places to Purchase High-Quality Wooden Coat Hangers Online

You may want to see also

Explore related products

Brand Reliability: Popular brands like Irwin, DeWalt, or Bosch offer trusted quality

Choosing a 1-inch diameter wood drill bit from a trusted brand can significantly impact the precision, durability, and efficiency of your project. Brands like Irwin, DeWalt, and Bosch have built their reputations on consistent quality, ensuring that their bits maintain sharp edges, resist wear, and deliver clean holes even in hardwoods. For instance, Irwin’s Speedbor Max bits feature a tri-flute design for faster chip removal, while DeWalt’s Pilot Point tips reduce walking and ensure accurate starts. Bosch’s Daredevil bits, on the other hand, incorporate a wave design that provides a cleaner cut with less splintering. These innovations reflect each brand’s commitment to reliability, making them go-to choices for professionals and hobbyists alike.

When evaluating brand reliability, consider the material and construction of the drill bit. Irwin, for example, uses high-speed steel (HSS) in many of their bits, which enhances durability and heat resistance—ideal for prolonged use. DeWalt often incorporates a black oxide coating to prevent rust and extend the bit’s lifespan, a feature particularly useful in humid environments. Bosch’s bits frequently feature a reinforced shank to reduce breakage under high torque. These details may seem minor, but they collectively contribute to a tool that performs consistently under demanding conditions, justifying the investment in a premium brand.

Another aspect of brand reliability is compatibility and versatility. Irwin’s bits are often designed with a 1/4-inch hex shank, making them compatible with both drills and impact drivers, which adds flexibility for various tasks. DeWalt’s bits frequently include a 3-flat shank design to reduce slipping in the chuck, ensuring stability during high-torque applications. Bosch’s bits are engineered to work seamlessly with their own power tools, though they are generally compatible with other brands as well. This interoperability ensures that you can rely on these bits regardless of your existing toolkit, streamlining your workflow without requiring additional purchases.

Finally, customer support and warranties play a role in brand reliability. DeWalt, for instance, offers a 30-day money-back guarantee and a 1-year free service contract on many of their tools, including drill bits. Bosch provides a 1-year limited warranty and a 30-day satisfaction guarantee, while Irwin’s products are backed by a lifetime warranty against defects in material and workmanship. These policies not only demonstrate confidence in the product but also provide peace of mind, knowing that you’re covered if the bit fails to meet expectations. When investing in a 1-inch diameter wood drill bit, choosing a brand with strong after-sales support ensures that your purchase is protected long after you leave the store.

International Wood Buying Guide: Specifications and Tips for Importing Timber

You may want to see also

Explore related products

Price vs. Quality: Budget-friendly or premium? Balance cost with performance and longevity

Choosing a 1-inch diameter wood drill bit forces a decision between budget-friendly options and premium tools. Budget bits, often priced under $10, appeal to occasional users or those testing the waters. They’re adequate for light tasks like drilling through softwoods or occasional home repairs. However, their lower-grade materials—typically carbon steel—wear quickly under heavy use, leading to frequent replacements. Premium bits, ranging from $20 to $50, are crafted from high-speed steel (HSS) or cobalt, offering sharper edges, heat resistance, and longer lifespans. For professionals or hobbyists tackling hardwoods or repetitive drilling, the upfront investment pays off in durability and performance.

Consider the frequency and intensity of your projects. If you’re drilling a few holes annually, a budget bit suffices. For weekly use or demanding materials like oak or maple, premium bits are non-negotiable. A mid-tier option, priced around $15, often strikes a balance, featuring better materials than entry-level bits without the premium price tag. Look for features like a spiral flute design, which improves chip removal and reduces clogging, even in budget models.

Longevity isn’t just about material—it’s also about maintenance. Sharpening a premium bit extends its life, making it a cost-effective choice over time. Budget bits, however, are typically disposable due to their thinner construction. Factor in the cost of replacements when calculating long-term expenses. For instance, three budget bits at $8 each ($24 total) may wear out before a single $30 premium bit loses its edge.

Finally, read reviews to gauge real-world performance. Budget bits often receive mixed feedback, with users praising affordability but criticizing quick dulling. Premium bits consistently earn high marks for precision and endurance. If you’re unsure, start with a mid-range option and assess its performance before committing to a higher or lower tier. The goal is to match your investment to your needs, ensuring you don’t overpay for features you won’t use or skimp on quality that could hinder your work.

Where to Find Rustic Wood Ceiling Planks in New Jersey

You may want to see also

Frequently asked questions

For general woodworking, a high-speed steel (HSS) or carbon steel 1-inch Forstner bit is recommended. It provides clean, precise holes and works well with both softwoods and hardwoods.

It depends on the project. A spade bit is faster and more affordable but leaves rougher edges. A Forstner bit is slower but creates cleaner, more precise holes, making it ideal for visible or finished work.

Look for a bit with a tungsten carbide tip or cobalt coating for increased durability and heat resistance. Additionally, ensure it has a sharpened cutting edge and a sturdy shank for long-lasting performance.

Yes, but choose a Forstner bit or a brad-point bit for better control and precision in thick hardwoods. Ensure your drill has enough power, and use slow, steady pressure to avoid overheating or breaking the bit.