When purchasing wood, the term per RF is commonly used in the lumber industry, referring to the pricing or measurement based on a Railroad Tie or Railroad Car load. An RF, or Railroad Tie, is a standard unit of measurement for wood, typically representing a bundle or package of lumber secured with straps or wires for easy transportation. In the context of wood buying, understanding per RF pricing is crucial, as it allows buyers to compare costs across different suppliers and wood types, ensuring they get the best value for their investment. This pricing structure takes into account factors such as wood species, grade, and quantity, providing a standardized way to quote and purchase lumber in bulk. By familiarizing themselves with the concept of per RF, wood buyers can make informed decisions, optimize their purchasing strategies, and ultimately, secure high-quality wood products at competitive prices.

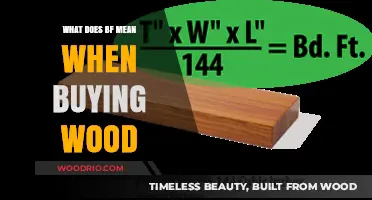

| Characteristics | Values |

|---|---|

| Meaning | "Per RF" in wood buying stands for "Per Random Foot" or "Per Running Foot". |

| Definition | A unit of measurement used to price and sell wood products, typically lumber, based on the length of the board. |

| Calculation | Price is determined by multiplying the length of the board (in feet) by the price per RF. |

| Common Usage | Widely used in the lumber industry for pricing dimensional lumber (e.g., 2x4s, 2x6s). |

| Advantages | Simplifies pricing for varying lengths of lumber, allowing for easy calculation of total cost. |

| Disadvantages | Does not account for width, thickness, or quality of the wood, which can affect overall value. |

| Related Terms | Board Foot (BF): A unit of volume (144 cubic inches) used for pricing larger quantities of lumber. |

| Industry Standard | Commonly used in North America, particularly in the United States and Canada. |

| Example | If the price is $5 per RF and you buy a 10-foot board, the total cost would be $50 (10 ft x $5/RF). |

| Latest Data (as of 2023) | No significant changes in the definition or usage of "Per RF" in the lumber industry. Prices may fluctuate due to market conditions, but the unit of measurement remains consistent. |

Explore related products

What You'll Learn

Understanding Per RF in Lumber Pricing

In the lumber industry, "per RF" is a term that often puzzles buyers, yet it’s a critical component of pricing. RF stands for "Random Foot," a unit of measurement used to quantify lumber in a way that accounts for varying board lengths within a shipment. Unlike linear feet, which measure a single, consistent length, RF pricing reflects the total board feet in a bundle, regardless of individual piece lengths. For instance, a bundle containing 10 boards of 8 feet each would total 80 board feet, priced per RF. This method ensures buyers pay for the actual volume of wood received, not just the average length.

To calculate the cost per RF, multiply the total board feet in a shipment by the price per RF. For example, if a shipment contains 500 board feet and the price is $5 per RF, the total cost would be $2,500. This calculation is straightforward but requires knowing the exact board footage, which is typically provided by the supplier. Buyers should always verify this measurement to avoid overpaying. Additionally, understanding RF pricing helps in comparing quotes from different suppliers, as it standardizes the cost based on volume rather than length.

One common misconception is that RF pricing disadvantages buyers by obscuring the cost of shorter boards. However, this system actually promotes efficiency in the lumber industry. Suppliers often bundle boards of varying lengths to minimize waste, and RF pricing ensures they can sell these bundles fairly. For buyers, this means access to a wider range of lengths at a predictable cost. To maximize value, buyers should prioritize bundles with lengths that align with their project needs, reducing the need for additional cuts or purchases.

Practical tips for navigating RF pricing include requesting detailed bundle specifications, such as the range of lengths included, and negotiating based on the average length if shorter boards are less desirable. For large orders, consider working with suppliers who offer custom bundling to better match project requirements. Finally, always factor in transportation and handling costs, as heavier, more voluminous RF bundles may incur additional expenses. By mastering RF pricing, buyers can make informed decisions that balance cost, quality, and usability in their lumber purchases.

Do Rock Shops Purchase Petrified Wood? A Comprehensive Guide

You may want to see also

Explore related products

How Per RF Affects Wood Cost Calculations

Understanding the term "per RF" is crucial for anyone involved in wood buying, as it directly impacts cost calculations and budgeting. RF stands for "Random Foot," a unit of measurement used in the lumber industry to quantify wood based on its volume. One RF equals one board foot, which is a piece of wood 12 inches long, 12 inches wide, and 1 inch thick. When purchasing wood, prices are often quoted per RF, making it essential to grasp how this measurement affects overall costs.

Consider a scenario where you’re buying hardwood for a flooring project. The supplier quotes a price of $5 per RF. To calculate the total cost, you’ll need to determine the total board footage required. For instance, if your project needs 500 board feet, the calculation is straightforward: 500 RF × $5/RF = $2,500. However, the complexity arises when dealing with varying thicknesses or widths, as the RF count adjusts accordingly. A 2-inch thick board, for example, would count as 2 RF per square foot, doubling the cost per unit area.

The impact of per RF pricing becomes more pronounced when comparing different wood types or grades. High-grade hardwoods like oak or maple often cost significantly more per RF than softwoods like pine. Additionally, specialty woods or exotic species can command prices upwards of $10–$20 per RF, making precise calculations critical for budget management. For instance, a 1,000 RF order of walnut at $15/RF totals $15,000, whereas the same volume of pine at $3/RF would cost only $3,000.

To optimize costs, buyers should factor in waste and additional material needs. Most projects require 10–20% extra wood to account for cuts, defects, or mistakes. Using the earlier flooring example, you’d need to purchase 600 RF (500 RF + 20% extra) at $5/RF, totaling $3,000 instead of $2,500. This highlights the importance of accurate RF calculations in avoiding underestimation and overspending.

In conclusion, per RF pricing is a foundational concept in wood buying that demands careful attention to detail. By understanding how RF measurements translate to costs, buyers can make informed decisions, compare prices effectively, and plan budgets with precision. Whether for small DIY projects or large-scale construction, mastering per RF calculations ensures financial efficiency and project success.

Essential Guide to Choosing and Buying the Perfect Wood Planer

You may want to see also

Explore related products

Common Units in Per RF Wood Transactions

In the world of wood buying, understanding the units used in transactions is crucial for accurate pricing and inventory management. One common unit you'll encounter is the Random Length (RL) or Random Foot (RF), which refers to lumber sold in varying lengths within a specified range, typically 6 to 16 feet. This unit is particularly prevalent in softwood lumber markets, where standardization is less rigid compared to hardwoods. For instance, a buyer might purchase "2x4s per RF," meaning they’re buying 2x4 boards in random lengths, with the total volume calculated by multiplying the board’s thickness, width, and total lineal feet, then dividing by 12 to get board feet (BF).

Analyzing the practicality of RF units reveals their efficiency in reducing waste and optimizing production. Since mills cut lumber to maximize yield from logs, RF allows them to sell boards of varying lengths without the constraints of fixed sizes. For buyers, this means flexibility in usage—shorter pieces for framing, longer ones for spans—while paying a fair price based on volume. However, it also requires careful measurement and calculation to ensure accuracy. For example, a bundle of 2x4s per RF might include boards totaling 300 lineal feet, which equates to 50 board feet (300 × 2 × 4 / 12 = 50 BF). This method ensures both parties agree on the value exchanged.

When engaging in RF transactions, it’s essential to verify the grade and moisture content of the lumber, as these factors significantly impact quality and price. Higher-grade lumber commands a premium, while moisture content affects weight and dimensional stability. For instance, green lumber (freshly sawn) contains more moisture and is heavier, whereas kiln-dried lumber is lighter and more stable but often more expensive. Buyers should also be aware of nominal vs. actual dimensions—a 2x4 per RF is actually 1.5x3.5 inches due to drying and planing. This discrepancy can affect calculations if not accounted for.

Comparing RF to other units like board feet (BF) or lineal feet (LF) highlights its unique advantages and limitations. While BF is volume-based and LF is length-based, RF combines length variability with volume calculation, making it ideal for bulk purchases of softwood. However, it’s less common in hardwood transactions, where fixed lengths and BF dominate. For example, a hardwood buyer might specify 8-foot boards in BF, whereas a softwood buyer might opt for RF to accommodate random lengths. Understanding these distinctions ensures buyers choose the right unit for their needs and avoid costly misunderstandings.

To navigate RF transactions effectively, follow these steps: first, confirm the length range included in the RF bundle to ensure it meets your project requirements. Second, calculate the total board feet by multiplying the thickness, width, and lineal feet, then dividing by 12. Third, inspect the lumber for defects and moisture content to ensure quality. Finally, negotiate pricing based on grade and market conditions. For instance, during a lumber shortage, RF pricing might surge, making it critical to lock in rates early. By mastering these specifics, buyers can confidently engage in RF transactions and maximize their investment.

Why People Buy Wood: Exploring Its Timeless Appeal and Practical Uses

You may want to see also

Explore related products

Comparing Per RF to Other Wood Pricing Methods

Per RF pricing, short for "per random foot," is a wood-buying method that charges based on the volume of a board, calculated as thickness × width × length (in feet) ÷ 12. Unlike board foot pricing, which standardizes to a 1-inch thickness, per RF allows for precise billing on irregular dimensions, making it ideal for custom projects requiring non-standard sizes. For instance, a 1.5-inch thick, 10-inch wide, 8-foot long board would cost exactly for its 10 square feet of surface area, whereas board foot pricing would round down to 8 board feet, potentially undercharging the supplier.

In contrast, board foot pricing remains the industry standard for lumberyards and mills, favored for its simplicity in bulk transactions. It assumes a baseline 1-inch thickness, with volume calculated as (thickness × width × length) ÷ 12. While efficient for commodity lumber, this method penalizes buyers of thicker or wider pieces, as a 2-inch thick board is billed as two board feet per linear foot, regardless of actual usage. Per RF eliminates this inefficiency, ensuring cost aligns with material consumed, though it requires more detailed measurement and invoicing.

Another competitor, per linear foot pricing, is straightforward but flawed for dimensional lumber. Charging a flat rate per foot of length ignores thickness and width variations, leading to price disparities. For example, a 2×4 and a 2×12 at the same length would cost the same, despite the latter containing 3× more wood. Per RF corrects this by factoring all dimensions, providing transparency for both buyer and seller, especially in high-value hardwoods or specialty cuts.

The choice between methods hinges on project needs and supplier capabilities. Per RF excels in bespoke woodworking, where precision and material optimization reduce waste and costs. However, its complexity may deter suppliers accustomed to board foot or linear foot systems. Buyers should verify measurement accuracy and clarify pricing terms upfront to avoid disputes. For large-scale construction, board foot remains practical, but per RF offers a fairer alternative when every inch matters.

Ultimately, per RF pricing bridges the gap between raw material volume and actual usage, rewarding efficiency in design and procurement. While not universally adopted, its growing popularity reflects a shift toward sustainability and cost-conscious craftsmanship. When negotiating wood purchases, understanding these methods empowers buyers to select the best fit, balancing budget, precision, and supplier compatibility.

Best Places to Purchase High-Quality Oak Wood for Your Projects

You may want to see also

Explore related products

$75

Tips for Negotiating Per RF Wood Purchases

Understanding the term "per RF" in wood buying is crucial for anyone looking to negotiate effectively in this market. "RF" stands for "Random Lengths," a standard measurement used in the lumber industry to describe the length of wood boards. When purchasing wood per RF, you’re buying based on a bundle of boards that average a specific length, typically 8, 10, or 12 feet. This pricing method requires a strategic approach to ensure you get the best value for your money.

One key tip for negotiating per RF wood purchases is to understand the market dynamics. Lumber prices fluctuate based on supply and demand, weather conditions, and global trade policies. For instance, a sudden increase in construction projects can drive prices up, while a surplus in supply may lower costs. Use resources like the Random Lengths Framing Lumber Composite Price Index to track trends. Knowing when prices are historically low or high gives you leverage in negotiations. For example, if you notice a downward trend, you might delay your purchase to secure a better deal.

Another critical strategy is to assess your specific needs before negotiating. Calculate the exact amount of wood required for your project, factoring in waste and additional cuts. Suppliers often offer discounts for bulk purchases, but buying more than you need can negate savings. For instance, if your project requires 500 board feet, purchasing 600 might seem like a good deal, but if 100 board feet go unused, you’ve overspent. Be precise in your measurements and communicate your needs clearly to the supplier.

Building relationships with suppliers can also significantly impact your negotiating power. Suppliers are more likely to offer favorable terms to repeat customers or those who maintain a professional rapport. For example, if you’ve worked with a supplier for several projects, you might negotiate a fixed price per RF for future purchases, protecting you from market volatility. Additionally, ask about bundled services, such as delivery or custom cutting, which can add value to your purchase without increasing costs.

Lastly, be prepared to walk away if the terms aren’t favorable. Negotiation is a two-way street, and showing willingness to explore other options can motivate suppliers to offer better deals. For instance, if a supplier insists on a high price per RF, inquire about alternatives like purchasing directly from a mill or exploring secondary markets. This approach demonstrates your market knowledge and signals that you’re a serious buyer who won’t settle for subpar terms. By combining these strategies, you can navigate per RF wood purchases with confidence and secure the best possible outcome.

Best Places to Buy Quality Wood for Custom Cabinet Projects

You may want to see also

Frequently asked questions

"Per RF" stands for "per random foot" or "per running foot," which refers to the price of wood based on its length, typically measured in linear feet.

Pricing per RF focuses solely on the length of the wood, regardless of width or thickness, whereas other methods like board feet (BF) consider volume (length × width × thickness).

Per RF pricing is often used for materials like trim, molding, or dimensional lumber where the length is the primary factor, and width or thickness remains consistent.