When considering the smallest strip of wood available for purchase, it’s important to understand that dimensions can vary widely depending on the supplier, type of wood, and intended use. Typically, wood strips are sold in standard sizes, with the thinnest options often ranging from 1/8 inch to 1/4 inch in thickness and 1/2 inch to 1 inch in width. However, specialty suppliers or custom milling services may offer even narrower strips, sometimes as thin as 1/16 inch or less, particularly for crafts, model building, or intricate woodworking projects. Availability also depends on the wood species, as softer woods like pine or balsa are more commonly found in smaller dimensions compared to harder woods like oak or maple. To find the smallest strip of wood, it’s advisable to consult local lumberyards, online woodworking retailers, or specialty craft stores, as they may cater to niche needs.

Explore related products

What You'll Learn

- Standard Lumber Sizes: Common dimensions for wood strips in hardware stores

- Craft Wood Options: Thin wood strips available for small DIY projects

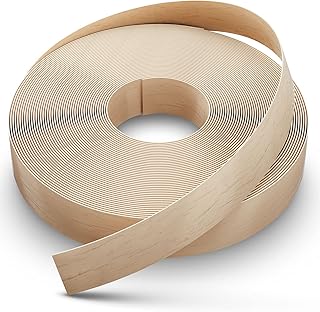

- Veneer Strips: Ultra-thin wood layers for decorative applications

- Custom Wood Cutting: Services offering tailored wood strip sizes

- Online Retailers: Specialized vendors selling narrow wood strips for various uses

Standard Lumber Sizes: Common dimensions for wood strips in hardware stores

Wood strips in hardware stores typically adhere to standard lumber dimensions, which are categorized by nominal and actual measurements. Nominal sizes refer to the rough, pre-planed dimensions (e.g., 1x4), while actual sizes reflect the final, smoothed measurements (e.g., ¾” x 3½”). The smallest wood strips commonly available are often labeled as 1x2, but their actual dimensions are usually ¾” x 1½”. These strips are versatile for trim work, edging, or lightweight framing. Understanding this discrepancy between nominal and actual sizes is crucial for accurate project planning.

For those seeking even narrower options, hardware stores occasionally stock ¼” x ¾” or ½” x ½” strips, often sold in hobby or craft wood sections. These micro-dimensions are ideal for detailed modeling, dollhouse construction, or intricate woodworking projects. However, availability varies by retailer, and specialty suppliers may offer more precise sizes. When sourcing such thin strips, consider the wood species, as softer woods (e.g., pine) are easier to work with but less durable than hardwoods (e.g., oak or maple).

If standard sizes don’t meet your needs, custom milling is an option. Many lumberyards offer ripping services to cut larger boards into thinner strips. For example, a 1x4 board can be ripped into two ¾” x 1½” strips or narrower, depending on your requirements. This approach ensures exact dimensions but may incur additional costs. Always measure twice and communicate clearly with the millworker to avoid errors.

When selecting wood strips, consider the project’s structural demands. Thinner strips (e.g., ¼” thickness) are prone to warping or breaking under stress, making them unsuitable for load-bearing applications. For strength, opt for wider or thicker strips, even if they’re slightly larger than your ideal size. Additionally, factor in finishing techniques—sanding and planing can reduce dimensions further, so leave a margin for error.

Finally, explore alternative materials if wood strips aren’t feasible. Thin plywood, MDF, or even plastic strips can serve as substitutes for non-structural projects. For example, 1/8” plywood is a lightweight, stable option for model building. While not traditional lumber, these materials offer flexibility in achieving precise dimensions without relying on standard wood strip sizes. Always weigh the trade-offs in durability, aesthetics, and cost before deciding.

Ultimate Guide to Choosing and Purchasing the Perfect Wooden Barrel

You may want to see also

Explore related products

Craft Wood Options: Thin wood strips available for small DIY projects

For those seeking the smallest strip of wood for DIY projects, the market offers a variety of thin wood strips, typically ranging from 1/16 inch to 1/4 inch in thickness. These strips are often available in lengths of 12 to 24 inches, making them ideal for intricate crafts, model building, or delicate woodworking. Common materials include balsa, basswood, and pine, each with unique properties suited for different applications.

Analytical Perspective:

Balsa wood stands out as the lightest and most pliable option, often used in model airplanes and lightweight structures. Its softness, however, requires careful handling to avoid breakage. Basswood, slightly denser and more durable, is favored for detailed carvings and architectural models. Pine, while harder, offers a balance of strength and workability, though it may require sanding to achieve a smooth finish. Understanding these material differences ensures the right choice for your project’s demands.

Instructive Approach:

To work with thin wood strips effectively, start by selecting the appropriate thickness for your project. For example, 1/16-inch strips are ideal for miniature furniture or jewelry, while 1/4-inch strips work well for structural elements in small-scale models. Use a sharp hobby knife or fine-toothed saw for precise cuts, and sand edges with 220-grit sandpaper to prevent splintering. For joining pieces, wood glue or small brads are recommended, but avoid excessive force to prevent cracking.

Comparative Analysis:

When comparing thin wood strips to alternatives like plastic or metal, wood offers natural warmth and ease of customization. Unlike rigid materials, wood can be shaped, stained, or painted to match any aesthetic. However, it’s less durable in humid conditions and may warp over time. For projects requiring longevity, consider sealing wood strips with a clear coat or varnish. This preserves their appearance while enhancing resistance to moisture and wear.

Descriptive Insight:

Imagine crafting a delicate birdhouse or a detailed ship model—thin wood strips become the backbone of such projects. Their slender profile allows for intricate layering and precise detailing, transforming simple pieces into works of art. Whether stained to highlight natural grain or painted for a bold statement, these strips offer versatility that elevates small-scale creations. With patience and the right techniques, even beginners can achieve professional-looking results.

Practical Tips:

For sourcing thin wood strips, specialty craft stores and online retailers often carry pre-cut packs in various dimensions. Bulk purchases can reduce costs, especially for larger projects. Always measure twice before cutting to minimize waste, and store strips flat to prevent warping. If working with children, opt for softer woods like balsa and supervise cutting tasks. With the right materials and techniques, thin wood strips unlock endless possibilities for creative DIY endeavors.

Where to Buy Poplar Wood: Top Suppliers and Online Stores

You may want to see also

Explore related products

Veneer Strips: Ultra-thin wood layers for decorative applications

Veneer strips, typically ranging from 0.5mm to 3mm in thickness, represent the smallest commercially available wood strips for decorative applications. These ultra-thin layers are sliced or peeled from high-quality hardwood logs, preserving the natural grain and texture while minimizing material waste. Unlike solid wood strips, which can be bulky and expensive, veneer strips offer a lightweight, cost-effective solution for adding warmth and elegance to surfaces. Their thinness allows for flexible application on curved or irregular shapes, making them ideal for furniture inlays, wall panels, and even small-scale DIY projects.

When selecting veneer strips, consider the wood species and finish to match your project’s aesthetic. Popular choices include oak, walnut, and maple, each with distinct grain patterns and colors. Pre-finished veneer strips save time, but raw options allow for custom staining or sealing. For durability, ensure the veneer is backed with a substrate like plywood or MDF, especially for high-traffic areas. Pro tip: Use a sharp utility knife and a straightedge to cut veneer strips cleanly, avoiding splintering or tearing.

Applying veneer strips requires precision and patience. Start by cleaning and sanding the surface to ensure adhesion. Apply a thin, even layer of contact cement or wood glue, following the manufacturer’s instructions. Position the veneer carefully, as it cannot be repositioned once adhered. Use a roller or brayer to remove air bubbles and ensure a smooth finish. For intricate designs, such as marquetry, plan the layout beforehand and use double-sided tape to hold pieces in place temporarily.

One of the most compelling advantages of veneer strips is their sustainability. By utilizing only a fraction of the wood required for solid strips, veneer production reduces deforestation and carbon footprint. Additionally, veneer allows for the use of rare or exotic woods without depleting resources. For eco-conscious projects, look for veneer certified by organizations like the Forest Stewardship Council (FSC), ensuring responsible sourcing. This makes veneer strips not just a decorative choice, but an ethical one.

In comparison to other thin wood alternatives, such as edge banding or paper-thin wood sheets, veneer strips strike a balance between durability and versatility. Edge banding is primarily functional, used to cover exposed edges, while paper-thin wood sheets are too delicate for most applications. Veneer strips, however, offer the best of both worlds: the strength to withstand wear and tear, coupled with the flexibility to enhance both flat and curved surfaces. Whether you’re a professional craftsman or a hobbyist, veneer strips unlock endless creative possibilities with minimal investment.

Where to Buy Wide Maple Wood: A Comprehensive Guide

You may want to see also

Explore related products

Custom Wood Cutting: Services offering tailored wood strip sizes

The smallest strip of wood commercially available typically measures around 1/8 inch in thickness and 1/4 inch in width, often sold in hobby or craft stores for miniature projects. However, for those requiring even more precise dimensions, custom wood cutting services emerge as a game-changer. These services cater to niche demands, offering tailored wood strip sizes that defy standard limitations. Whether you’re crafting intricate models, restoring antique furniture, or designing bespoke jewelry, custom cutting ensures you get exactly what you need without waste or compromise.

Analytical Perspective: Custom wood cutting services leverage advanced machinery like laser cutters, CNC routers, and precision saws to achieve dimensions as thin as 1/16 inch or even 1/32 inch in some cases. This level of precision is particularly valuable in industries like electronics, where thin wood strips serve as insulators, or in architectural modeling, where scale accuracy is critical. The cost of such services varies based on material type, complexity, and quantity, but the investment often outweighs the challenges of manual cutting or settling for suboptimal sizes.

Instructive Approach: To utilize custom wood cutting services effectively, start by defining your exact specifications—thickness, width, length, and quantity. Provide detailed drawings or digital files if possible, as this minimizes errors. Next, research local or online providers, comparing their capabilities, turnaround times, and customer reviews. For instance, some services specialize in exotic woods, while others focus on high-volume orders. Finally, communicate your budget constraints upfront to explore cost-saving options like bulk discounts or material alternatives.

Persuasive Argument: Opting for custom wood cutting isn’t just about precision—it’s about sustainability. By ordering only the sizes you need, you reduce material waste and minimize environmental impact. Additionally, custom services often source wood responsibly, offering FSC-certified or reclaimed options. For professionals, this aligns with eco-conscious branding, while hobbyists benefit from guilt-free creativity. In a world increasingly focused on sustainability, this approach is both practical and principled.

Comparative Insight: Unlike pre-cut wood strips, custom cutting allows for experimentation with unconventional shapes and sizes. For example, a luthier might require curved strips for a unique guitar design, or a jewelry maker might need tapered pieces for a pendant. While pre-cut options are convenient for standard projects, custom services open doors to innovation. The trade-off? Longer lead times and higher costs, but the payoff in creativity and uniqueness is unparalleled.

Descriptive Example: Imagine a model train enthusiast needing 1/64-inch thick basswood strips to replicate railway ties. Off-the-shelf options fall short, but a custom cutting service delivers precisely sized strips, pre-sanded and ready for assembly. The result? A hyper-realistic diorama that wins accolades at a hobbyist convention. This scenario underscores how tailored wood strip sizes transform vision into reality, bridging the gap between imagination and execution.

In essence, custom wood cutting services redefine what’s possible in woodworking, offering precision, sustainability, and creativity in equal measure. Whether you’re a professional or a hobbyist, embracing these services ensures your projects stand out—one perfectly sized strip at a time.

Top Sources for Woodworkers: Where to Buy Quality Wood Locally & Online

You may want to see also

Explore related products

Online Retailers: Specialized vendors selling narrow wood strips for various uses

Specialized online retailers have carved out a niche catering to enthusiasts and professionals seeking narrow wood strips for intricate projects. These vendors offer strips as thin as 1/16 inch in width and 1/32 inch in thickness, often in lengths ranging from 12 to 48 inches. Such dimensions are ideal for model building, marquetry, or detailed woodworking. For instance, Woodcraft and Craftwoods provide pre-cut strips in exotic woods like mahogany or walnut, while Balsa Wood Supply focuses on ultra-lightweight options for RC aircraft construction. These retailers understand the precision required for small-scale work, offering products that eliminate the need for extensive cutting or sanding.

When selecting a vendor, consider the wood’s grain consistency and moisture content, as these factors affect durability and workability. Rockler Woodworking and Hardware stands out by providing detailed specifications, including moisture levels (typically 8-12%) and grain orientation, ensuring the strips remain stable during use. For beginners, Amazon offers bundles of balsa or basswood strips, often with beginner-friendly thicknesses (1/8 inch or thicker) and lengths (24 inches). However, these may lack the precision of specialized retailers, making them better suited for practice than professional projects.

For niche applications like musical instrument repair or dollhouse construction, Stewart-MacDonald and Miniatures.com offer strips tailored to specific needs. Stewart-MacDonald’s strips are often pre-sanded to 150-grit, saving time for luthiers, while Miniatures.com provides strips scaled to 1:12 or 1:24 ratios for accurate dollhouse furniture. These vendors also offer finishing services, such as staining or sealing, which can be a game-changer for those without access to specialized tools.

Price and quantity are critical factors when purchasing narrow wood strips. Specialized vendors often sell in packs of 10-50 strips, with prices ranging from $0.50 to $5 per strip, depending on wood type and thickness. Bulk discounts are common, but beware of shipping costs, which can outweigh material savings. For example, Hobbywoods offers free shipping on orders over $50, making it cost-effective for larger projects. Always compare total costs, including shipping, before committing to a purchase.

Finally, consider sustainability when choosing a retailer. Many specialized vendors, such as EcoWoodWorks, source their wood from FSC-certified forests and offer reclaimed or recycled options. These strips may have slight variations in color or texture but are environmentally friendly and often more affordable. By supporting such retailers, you not only get high-quality materials but also contribute to sustainable forestry practices. Whether for a hobby or profession, the right vendor can make all the difference in your project’s success.

Where to Find a Standalone Wood Coffee Table Base for Purchase

You may want to see also

Frequently asked questions

The smallest strip of wood commonly available is typically 1/4 inch (6 mm) in width, though some suppliers offer thinner options like 1/8 inch (3 mm) or even 1/16 inch (1.5 mm) for specialized projects.

Wood strips thinner than 1/16 inch are rare and not commonly sold by standard lumber suppliers. For such thin strips, you may need to custom order or use veneer sheets instead.

Common wood types available in small strip sizes include balsa, basswood, poplar, and pine. Exotic or hardwood options may be limited to thicker sizes unless custom ordered.