When it comes to woodworking and crafting, one commonly sought-after material is thin sheet wood, often referred to as veneer, plywood, or lumber panels. These versatile sheets are available in various thicknesses, typically ranging from 1/16 inch to 1/4 inch, making them ideal for a wide array of applications, from furniture making and cabinetry to model building and DIY projects. Thin sheet wood can be purchased in different types, including hardwoods like oak, maple, and cherry, as well as softwoods like pine and cedar, each offering unique grain patterns, colors, and textures to suit diverse aesthetic preferences and functional requirements. Whether you're a professional woodworker or a hobbyist, understanding the characteristics and uses of thin sheet wood is essential for selecting the right material for your project.

Explore related products

What You'll Learn

- Plywood Types: Birch, oak, pine, and more, each with unique grain patterns and uses

- Veneer Sheets: Thin wood layers for decorative surfaces, furniture, and interior design

- Luan Plywood: Lightweight, flexible, ideal for crafting, backing, and temporary projects

- Hardboard Panels: Dense, smooth sheets for furniture, cabinets, and DIY projects

- Balsa Wood: Ultra-light, perfect for model building, crafts, and lightweight applications

Plywood Types: Birch, oak, pine, and more, each with unique grain patterns and uses

Plywood, a versatile and widely used thin sheet wood, comes in various types, each with distinct characteristics suited to specific applications. Among the most popular are birch, oak, and pine, but the spectrum extends to include maple, mahogany, and even exotic species like teak. The choice of plywood type hinges on factors such as grain pattern, durability, and intended use, making it essential to understand the nuances of each.

Birch plywood stands out for its fine, uniform grain and smooth surface, making it a favorite for furniture, cabinetry, and interior design projects. Its light color and ability to accept stains and finishes well allow for creative customization. For structural applications, birch plywood’s strength and stability under load make it a reliable choice. However, its cost is higher compared to pine, positioning it as a premium option for projects where aesthetics and durability are paramount.

Oak plywood, with its prominent, open grain, exudes a rustic charm that is highly sought after in flooring, wall paneling, and high-end furniture. Its natural resistance to moisture and wear makes it ideal for areas with heavy foot traffic or exposure to the elements. While oak plywood is more expensive than pine or birch, its longevity and timeless appeal often justify the investment. When working with oak, pre-drilling holes for screws is recommended to prevent splitting due to its dense nature.

Pine plywood, known for its affordability and ease of use, is a go-to for DIY enthusiasts and budget-conscious projects. Its soft texture makes it easy to cut and shape, though it is less durable than hardwood alternatives. Pine’s knotty, rustic appearance lends itself well to rustic decor, shelving, and temporary structures. For outdoor use, ensure pine plywood is treated with a weather-resistant sealant to prolong its lifespan.

Beyond these staples, specialty plywood types like maple and mahogany cater to niche needs. Maple plywood, with its light, creamy tone and subtle grain, is prized in musical instruments and high-end cabinetry. Mahogany, on the other hand, offers a rich, reddish-brown hue and exceptional rot resistance, making it ideal for boatbuilding and outdoor furniture. Exotic plywoods like teak, though costly, provide unparalleled beauty and durability for luxury projects.

In selecting the right plywood type, consider the project’s functional and aesthetic requirements, as well as your budget. Whether crafting a bespoke piece of furniture or constructing a durable outdoor structure, understanding the unique properties of birch, oak, pine, and other plywood varieties ensures a successful outcome. Always prioritize quality and proper finishing to maximize the material’s potential.

Is Wood Group a Buy? Analyzing Investment Potential and Risks

You may want to see also

Explore related products

Veneer Sheets: Thin wood layers for decorative surfaces, furniture, and interior design

Veneer sheets, typically ranging from 0.5mm to 6mm in thickness, are thin slices of wood used to enhance surfaces with the natural beauty of wood grain without the bulk or cost of solid timber. These sheets are produced by slicing or peeling logs into layers, which are then glued to a substrate like plywood, MDF, or particleboard. This process maximizes the use of high-quality wood species, making exotic or rare woods accessible for decorative applications. For instance, a single log of mahogany can yield hundreds of square feet of veneer, compared to the limited yield of solid lumber.

Selecting the right veneer sheet depends on the project’s aesthetic and functional requirements. For high-traffic furniture or flooring, choose durable species like oak or maple, often backed with a thicker substrate for stability. For delicate interior accents, such as wall panels or cabinet doors, thinner veneers in walnut or cherry can add warmth without overwhelming the space. Always consider the grain pattern—book-matched or slip-matched veneers create symmetrical designs, while quarter-sliced options highlight unique textures. Pro tip: Seal veneer edges with edge banding to prevent peeling and ensure longevity.

Applying veneer sheets requires precision and the right tools. Start by sanding the substrate to ensure a smooth, adhesive-ready surface. Use a high-quality wood glue or contact cement, applying it evenly with a notched trowel to avoid air bubbles. For larger projects, a veneer hammer and roller are essential to press the sheet firmly into place. Caution: Excessive moisture can cause veneer to warp, so work in a controlled environment and allow ample drying time. Once applied, finish with a clear coat or stain to protect the wood while preserving its natural appeal.

Veneer sheets offer a sustainable alternative to solid wood, reducing waste and preserving forests. By utilizing fast-growing species or reclaimed wood for the substrate, designers can achieve luxurious looks while minimizing environmental impact. For example, a single tree can produce enough veneer to cover an entire room, whereas solid wood would require multiple trees. This eco-friendly approach aligns with modern design trends prioritizing sustainability without compromising on style. Pair veneer with recycled metal accents or low-VOC finishes for a truly green interior.

Incorporating veneer sheets into interior design opens endless creative possibilities. Use them to create feature walls, wrap columns, or craft custom headboards for a cohesive, high-end look. For a contemporary twist, experiment with dyed or textured veneers, such as wire-brushed oak or ebony-stained maple. When combining veneer with other materials, ensure color and texture harmonize—for instance, pair light birch veneer with matte black hardware for a striking contrast. With proper care, veneer surfaces can last decades, making them a timeless investment for any space.

Did Charlie Woods Buy Drinks? Unraveling the Viral Rumor

You may want to see also

Explore related products

Luan Plywood: Lightweight, flexible, ideal for crafting, backing, and temporary projects

Luan plywood, often simply called "luan," is a thin, lightweight wood panel made from layers of wood veneer glued together. Typically ranging from 1/8 inch to 1/4 inch thick, it’s a go-to material for projects where flexibility and ease of use are key. Derived from the luan tree, native to Southeast Asia, this plywood is prized for its smooth surface and ability to bend slightly without breaking, making it ideal for crafting, backing, and temporary applications.

For crafters and DIY enthusiasts, luan plywood is a versatile choice. Its thin profile allows it to be easily cut with basic tools like utility knives or scissors, while its flexibility enables it to conform to curved surfaces. Use it as a backing for paintings, a base for lightweight shelving, or a substrate for decorative veneers. Its affordability and availability in large sheets (often 4x8 feet) make it a practical option for projects that require covering large areas without adding significant weight.

When working with luan, keep in mind its limitations. While it’s durable for its thickness, it’s not suitable for structural applications or projects exposed to moisture. For temporary uses, such as event signage or prototyping, it excels. To enhance its durability, consider sealing it with paint, varnish, or laminate. For crafting, sand the edges lightly to prevent splintering, and use adhesive-backed materials for smooth finishes.

Comparatively, luan stands out from other thin wood sheets like MDF or hardwood plywood due to its flexibility and featherlight nature. MDF is denser and more rigid, while hardwood plywood is heavier and more expensive. Luan’s unique properties make it the preferred choice for projects where weight and adaptability matter more than strength. Whether you’re backing a canvas, creating a temporary partition, or crafting a lightweight model, luan plywood delivers on both practicality and performance.

Top Sources for Buying High-Quality Apitong Wood Online & Locally

You may want to see also

Explore related products

Hardboard Panels: Dense, smooth sheets for furniture, cabinets, and DIY projects

Hardboard panels are a versatile and cost-effective solution for anyone looking to enhance their furniture, cabinets, or DIY projects with a smooth, dense surface. These thin sheets, typically ranging from 1/16 to 1/4 inch in thickness, are engineered from wood fibers compressed under high pressure and temperature, resulting in a uniform and durable material. Unlike raw plywood or MDF, hardboard’s smoothness makes it ideal for painting, veneering, or laminating, ensuring a professional finish without the need for extensive sanding. Its density also provides structural stability, making it a reliable choice for backing panels, drawer bottoms, or lightweight partitions.

When selecting hardboard for your project, consider the intended application. For furniture or cabinetry, opt for tempered hardboard, which is treated with oil or resin to resist moisture and warping. This variant is particularly useful in kitchens or bathrooms where humidity is a concern. If you’re working on a DIY project like a bulletin board or model building, standard hardboard will suffice, offering a smooth canvas for customization. Always measure twice and cut once, as hardboard’s density can make it slightly more challenging to cut than softer materials. A sharp utility knife or fine-toothed saw works best for straight cuts, while a jigsaw is ideal for curves.

One of the standout advantages of hardboard is its affordability and accessibility. Available at most hardware stores in standard 4x8-foot sheets, it’s an economical choice for large-scale projects or prototyping. For smaller tasks, pre-cut panels or rolls are often available, saving time and reducing waste. To maximize durability, apply a primer or sealant to the edges and surfaces, especially if the hardboard will be exposed to moisture or wear. This simple step can significantly extend the life of your project, ensuring the material remains smooth and intact over time.

Comparing hardboard to alternatives like plywood or particleboard highlights its unique strengths. While plywood offers more structural strength for load-bearing applications, hardboard excels in surface quality and ease of finishing. Particleboard, though cheaper, is prone to crumbling and lacks the density needed for detailed work. Hardboard strikes a balance, providing a stable base for intricate designs or high-traffic areas without breaking the bank. Its compatibility with adhesives, screws, and nails also makes it a favorite among DIY enthusiasts and professionals alike.

Incorporating hardboard into your projects opens up a world of creative possibilities. Its smooth surface is perfect for stenciling, decoupage, or even laser engraving, allowing you to personalize your creations with precision. For cabinetmakers, hardboard’s consistency ensures doors and drawers align seamlessly, while its lightweight nature simplifies installation. Whether you’re crafting a custom bookshelf, upgrading kitchen cabinets, or building a school project, hardboard panels offer the density, smoothness, and versatility to bring your vision to life. With proper care and creativity, this unassuming material can transform ordinary projects into polished, professional-grade pieces.

Effective Mildew Killers for Untreated Wood: Top Products to Buy

You may want to see also

Explore related products

Balsa Wood: Ultra-light, perfect for model building, crafts, and lightweight applications

Balsa wood stands out as the quintessential thin sheet wood for projects demanding minimal weight without sacrificing structural integrity. Derived from the Ochroma pyramidale tree, it is renowned for its exceptional lightness, often weighing as little as 4 to 16 pounds per cubic foot. This makes it ideal for applications where every gram counts, such as model airplanes, drones, and architectural prototypes. Its cellular structure, characterized by large, hollow cells, contributes to its feather-like density while maintaining surprising strength. For hobbyists and professionals alike, balsa wood is a go-to material when reducing weight is as critical as ensuring durability.

When working with balsa wood, understanding its properties is key to maximizing its potential. Its softness allows for easy cutting, sanding, and shaping with basic tools, making it accessible even for beginners. However, this softness also means it requires careful handling to avoid dents or cracks. For model building, consider using thicker sheets (3–6 mm) for structural components and thinner sheets (1–2 mm) for detailing. Adhesives like wood glue or epoxy work well for joining pieces, but apply sparingly to prevent saturation, which can add unnecessary weight. Sanding should be done gently, using fine-grit paper to maintain smooth surfaces without compromising the wood’s integrity.

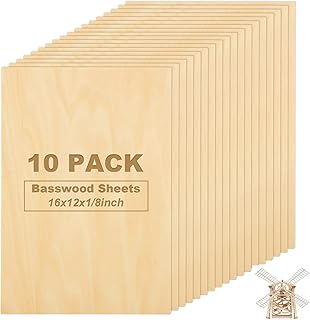

Comparatively, balsa wood outshines alternatives like basswood or plywood in lightweight applications due to its unparalleled weight-to-strength ratio. While basswood offers greater hardness and detail, it is significantly denser, making it less suitable for projects where weight is a primary concern. Plywood, though versatile, lacks the uniformity and lightness of balsa. For crafts like RC aircraft or lightweight furniture, balsa’s ability to provide stability without bulkiness is unmatched. Its affordability and availability in various thicknesses further solidify its position as the top choice for lightweight woodworking.

In practical terms, balsa wood’s versatility extends beyond model building into creative and functional projects. For DIY enthusiasts, it’s perfect for crafting lightweight shelves, decorative panels, or even custom drone frames. When painting or finishing, use thin coats of acrylic or spray paint to avoid adding weight. For added strength, consider laminating multiple thin sheets together with grain directions alternating for enhanced rigidity. Always store balsa wood in a dry, cool place to prevent warping, and handle it with clean hands to avoid oil stains. With its unique blend of lightness and workability, balsa wood transforms ideas into reality without weighing them down.

Where to Buy Raw Hardwood: A Comprehensive Guide for Buyers

You may want to see also

Frequently asked questions

The thin sheet wood you can buy is often referred to as veneer, plywood, or lumber core. Veneer is a very thin slice of wood, while plywood is a layered sheet made of thin wood plies. Lumber core is a thicker option but still relatively thin compared to solid wood.

Thin sheet wood typically ranges from 1/16 inch (1.6 mm) for veneer to 1/4 inch (6 mm) for thinner plywood or lumber core sheets.

Thin sheet wood is used for furniture making, cabinetry, craft projects, wall paneling, and model building. It’s lightweight, versatile, and easy to work with.

Thin sheet wood is available in various types, including oak, maple, pine, birch, mahogany, and walnut, as well as engineered wood options like MDF or particle board.

Thin sheet wood can be purchased at home improvement stores (e.g., Home Depot, Lowe’s), lumberyards, craft stores, or online retailers like Amazon or specialty woodworking suppliers.