When considering flooring options, one of the most common questions is whether engineered wood or hardwood lasts longer. Both materials have their unique advantages and durability factors, making the choice dependent on specific needs and conditions. Hardwood flooring, known for its timeless appeal and robustness, can last for decades, even centuries, if properly maintained. Engineered wood, on the other hand, offers a more versatile and cost-effective solution, with a lifespan that typically ranges from 20 to 30 years, depending on the wear layer thickness and quality. While hardwood can be refinished multiple times to extend its life, engineered wood has a limited number of refinishes due to its thinner top layer. Ultimately, the longevity of either option is influenced by factors such as foot traffic, environmental conditions, and maintenance practices.

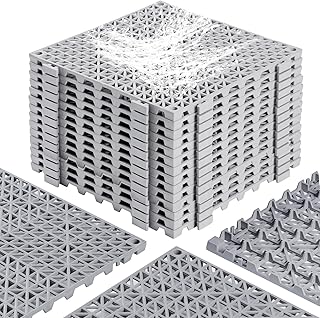

Explore related products

What You'll Learn

Durability Comparison: Engineered vs. Hardwood

Engineered wood and hardwood each have distinct durability profiles, shaped by their construction and environmental responses. Hardwood, a solid plank of natural timber, boasts inherent strength and longevity, often lasting 25–100 years with proper care. Engineered wood, composed of a plywood base topped with a hardwood veneer, typically endures 20–30 years but can be refinished fewer times due to its thinner wear layer. The key difference lies in their structural integrity: hardwood’s uniform density resists deep scratches and dents, while engineered wood’s layered design can delaminate under extreme moisture or temperature fluctuations.

Consider the installation environment to maximize durability. Hardwood thrives in stable, dry conditions, making it ideal for living rooms or bedrooms but risky in kitchens or basements prone to humidity. Engineered wood’s plywood base offers better dimensional stability, reducing warping in moisture-prone areas, though its veneer limits sanding to 2–3 times compared to hardwood’s 5–7. For high-traffic zones, hardwood’s resilience to wear is superior, but engineered wood’s pre-finished options minimize installation time and dust, a practical advantage for quick renovations.

Maintenance practices further influence lifespan. Hardwood requires periodic refinishing every 10–15 years to address scratches and fading, a labor-intensive but rejuvenating process. Engineered wood’s surface, while less durable, benefits from protective finishes that resist stains and UV damage. Avoid harsh chemicals or excessive water on either material, as both can compromise finishes and structural integrity. For engineered wood, prioritize felt pads under furniture and immediate spill cleanup to prevent veneer damage.

Cost-effectiveness ties into durability. Hardwood’s higher upfront cost reflects its longevity and refinish potential, making it a long-term investment. Engineered wood, more affordable and easier to install, suits renters or those prioritizing short-term aesthetics. However, its limited refinishing capacity means replacement may be necessary sooner, offsetting initial savings. Evaluate your timeline and usage patterns: hardwood for permanence, engineered wood for flexibility.

Ultimately, the choice hinges on balancing durability with practical needs. Hardwood excels in stability and repairability, ideal for long-term homeowners seeking timeless appeal. Engineered wood offers versatility and moisture resistance, catering to dynamic spaces or budget-conscious projects. Neither outlasts the other universally—durability depends on material quality, environmental conditions, and care. Assess your priorities, then select the option that aligns with your lifestyle and space demands.

Mineral Oil Soaking Time for Wood: A Complete Guide

You may want to see also

Explore related products

Maintenance Needs for Longevity in Both Materials

Engineered wood and hardwood both demand specific maintenance routines to maximize their lifespan, but the nature of these routines differs significantly. For hardwood, the primary focus is on preserving the integrity of the natural wood surface. Regular sweeping or vacuuming with a soft brush attachment is essential to remove abrasive dirt and debris that can scratch the finish. Every 3-6 months, depending on foot traffic, apply a pH-neutral wood cleaner to maintain the floor’s luster without stripping its protective layer. Reapply a polyurethane finish every 5-7 years to shield against wear and moisture. For engineered wood, the emphasis shifts to protecting the delicate top layer and preventing moisture infiltration. Use felt pads under furniture legs to avoid scratches, and immediately wipe up spills to prevent warping. Unlike hardwood, engineered wood cannot be sanded more than once or twice due to its thin wear layer, so preventive care is critical.

The environmental conditions in which these materials are installed also dictate their maintenance needs. Hardwood is highly sensitive to humidity fluctuations, requiring homeowners to maintain indoor humidity levels between 30-50% to prevent warping or gapping. A hygrometer can help monitor these levels, and a humidifier or dehumidifier may be necessary in extreme climates. Engineered wood, while more stable due to its layered construction, still benefits from similar humidity control, especially in areas prone to moisture, like kitchens or basements. For both materials, direct sunlight can cause fading, so using UV-protective window films or curtains is advisable.

Cleaning methods for engineered wood must be gentler to avoid damaging the wear layer. Avoid steam mops or excessive water, as the heat and moisture can seep between planks and cause delamination. Instead, use a microfiber mop with a lightly dampened pad and a manufacturer-approved cleaner. Hardwood, on the other hand, can tolerate slightly more aggressive cleaning, but harsh chemicals or vinegar-based solutions should be avoided, as they can dull the finish. For stubborn stains on hardwood, a fine-grit sandpaper followed by a touch-up of finish can restore the area, a luxury engineered wood does not afford.

Long-term maintenance also involves proactive measures to minimize wear. In high-traffic areas, area rugs or runners can protect both materials, but ensure the rug backing is breathable to prevent discoloration on hardwood. For engineered wood, avoid placing heavy furniture or appliances directly on the floor, as the concentrated weight can cause indentations. Periodically rearranging furniture and using floor protectors can distribute wear more evenly. While hardwood can be refinished multiple times to address deep scratches or stains, engineered wood’s limited sanding capacity means prevention is far more cost-effective than repair.

Ultimately, the longevity of both materials hinges on consistent, tailored care. Hardwood’s durability is rewarded with meticulous preservation of its finish and structural integrity, while engineered wood’s lifespan is extended through vigilant moisture control and surface protection. By understanding the unique vulnerabilities of each material, homeowners can implement maintenance strategies that not only preserve appearance but also ensure structural stability for decades. The choice between the two often comes down to how much time and effort one is willing to invest in their care.

Gorilla Wood Glue Durability: Shelf Life and Bond Longevity Explained

You may want to see also

Explore related products

$83.59 $109.99

Environmental Factors Affecting Lifespan of Wood Types

Moisture is the arch-nemesis of both engineered wood and hardwood, but they respond differently to its relentless assault. Hardwood, being a natural product, expands and contracts with changes in humidity, leading to warping, cupping, or cracking over time. Engineered wood, with its layered construction, is designed to mitigate this issue, but excessive moisture can still penetrate the core, causing delamination or swelling. In high-humidity environments, such as coastal regions or poorly ventilated spaces, both wood types require vigilant moisture management. Use dehumidifiers to maintain indoor humidity between 30-50%, and ensure proper sealing of wood surfaces with moisture-resistant finishes. For engineered wood, avoid installation in areas prone to water exposure, like bathrooms or basements, unless specifically designed for such conditions.

Temperature fluctuations play a subtle yet significant role in the longevity of wood. Extreme heat can cause hardwood to dry out, leading to brittleness and surface checking, while engineered wood may experience adhesive failure in its layers. Conversely, cold temperatures can make both wood types more susceptible to moisture absorption when paired with high humidity. In climates with drastic seasonal shifts, acclimate wood materials to the environment before installation, allowing them to adjust to the ambient temperature and humidity. For hardwood, consider using a vapor barrier underlayment in colder regions to prevent moisture migration from the subfloor. Engineered wood, with its greater dimensional stability, is generally more forgiving but still benefits from controlled temperature conditions.

Sunlight exposure is a silent degrader of wood, particularly for hardwood, which can fade, discolor, or weaken under prolonged UV radiation. Engineered wood, often finished with protective coatings, fares better but is not immune to UV damage. In sunlit spaces, use curtains, blinds, or UV-filtering window films to minimize direct sunlight on wood surfaces. For hardwood floors, rotate rugs and furniture periodically to ensure even fading and reduce the contrast between exposed and covered areas. If discoloration occurs, light sanding and refinishing can restore hardwood’s appearance, but engineered wood may have limited refinishing options depending on its wear layer thickness.

Pest infestations, particularly termites and carpenter ants, pose a grave threat to hardwood, which is a natural food source for these insects. Engineered wood, while less appealing due to its processed nature, is not entirely immune, especially if it contains wood byproducts. In regions with high pest activity, treat wood with insecticides or opt for pest-resistant species like cedar or cypress for hardwood installations. Regular inspections and prompt addressing of infestations are critical. For engineered wood, ensure the core and adhesives are treated or naturally resistant to pests. Both wood types benefit from maintaining a dry environment, as moisture attracts pests and accelerates wood decay.

Air quality and pollution can accelerate the degradation of wood, particularly in urban or industrial areas. Particulate matter and chemicals in the air can settle on wood surfaces, leading to discoloration or surface degradation over time. For hardwood, regular cleaning with a damp (not wet) cloth and pH-neutral wood cleaner can remove pollutants. Engineered wood, with its protective finishes, may require less maintenance but still benefits from periodic cleaning. In highly polluted areas, consider applying an additional protective sealant to both wood types to create a barrier against airborne contaminants. Proper ventilation not only improves air quality but also helps regulate humidity, further extending the lifespan of wood materials.

Standard Full-Size Wooden Bed Slats Length Explained: A Quick Guide

You may want to see also

Explore related products

Cost vs. Longevity: Which Offers Better Value?

Engineered wood and hardwood flooring each present distinct cost and longevity profiles, making the choice between them a nuanced decision. Engineered wood typically costs 20-50% less than solid hardwood upfront, primarily due to its construction—a thin veneer of real wood atop layers of plywood or fiberboard. This affordability is a significant draw for budget-conscious homeowners, especially for large-scale installations. However, while solid hardwood can last 100 years or more with proper care and refinishing, engineered wood’s lifespan is limited by its wear layer thickness, usually lasting 20-30 years before replacement is necessary.

To maximize value, consider the intended use and location. Engineered wood’s shorter lifespan is less of a drawback in high-traffic areas or rental properties, where durability over decades, not centuries, is sufficient. For instance, installing engineered wood in a rental unit can provide a cost-effective, aesthetically pleasing solution without the long-term commitment of hardwood. Conversely, hardwood’s longevity makes it a better investment for permanent homes, particularly in low-traffic areas like bedrooms or formal living rooms, where its lifespan aligns with the property’s value appreciation.

Refinishing potential further complicates the cost-longevity equation. Hardwood floors can be sanded and refinished 5-10 times, depending on thickness, effectively resetting their appearance and extending their life. Engineered wood, however, can only be refinished 1-3 times, if at all, due to its thin wear layer. This limitation means that while engineered wood may save money initially, hardwood’s refinishability reduces long-term replacement costs, making it a more economical choice over 50+ years.

A practical tip for balancing cost and longevity is to assess the wear layer thickness of engineered wood products. Thicker wear layers (2-4mm) allow for more refinishing, extending the floor’s life closer to that of hardwood. For example, a 3mm wear layer can be refinished 2-3 times, adding 10-15 years to its lifespan. Pairing this with strategic placement—using engineered wood in kitchens or entryways and hardwood in less trafficked areas—can optimize both budget and durability.

Ultimately, the better value depends on your timeline and priorities. If you plan to stay in your home long-term and prioritize minimal maintenance, hardwood’s higher upfront cost is offset by its century-long lifespan and refinishability. For shorter-term needs or tighter budgets, engineered wood offers immediate savings and sufficient durability, especially when paired with thicker wear layers. By aligning your choice with your specific circumstances, you can ensure that your flooring investment delivers the best value over time.

Wood Epoxy Drying Time: Factors Affecting Cure Speed and Hardening

You may want to see also

Explore related products

Refinishing Potential to Extend Wood Flooring Life

One of the most significant advantages of hardwood flooring over engineered wood is its refinishing potential. Solid hardwood can be sanded down and refinished multiple times, often up to 10 or more, depending on the thickness of the wear layer. This process removes scratches, stains, and wear, restoring the floor to its original beauty. Engineered wood, on the other hand, typically has a thinner wear layer, limiting it to 1–3 refinishes before the veneer is too thin to sand safely. For homeowners seeking a long-term investment, this disparity is crucial: hardwood’s ability to be refinished repeatedly can extend its lifespan by decades, while engineered wood may require replacement sooner.

Refinishing hardwood floors is not just about longevity; it’s also a cost-effective way to update a space. Instead of replacing the entire floor, which can cost $8–$15 per square foot for materials and installation, refinishing averages $3–$5 per square foot. The process involves sanding the floor to remove the old finish and any imperfections, then applying a new stain (optional) and sealant. Homeowners can choose from various finishes, such as polyurethane, which offers durability and a glossy look, or oil-based finishes for a more natural, matte appearance. Properly maintained, a refinished hardwood floor can last another 10–20 years before needing attention again.

While refinishing is a powerful tool for extending wood flooring life, it’s not without limitations. Engineered wood’s thin wear layer restricts the depth of sanding, making it unsuitable for deep scratches or extensive damage. Additionally, not all hardwood floors are candidates for refinishing—those with severe structural damage or extremely thin planks may not withstand the process. Before starting, assess the floor’s condition: measure the thickness of the wear layer (for engineered wood) or the overall plank thickness (for hardwood) to ensure there’s enough material to sand. Hiring a professional is often recommended, as improper sanding can cause irreversible damage.

For those considering refinishing, timing is key. Address wear and tear before it becomes severe; waiting too long can reduce the effectiveness of the process. Signs it’s time to refinish include widespread scratching, fading from sunlight, or a worn finish that no longer protects the wood. Regular maintenance, such as using felt pads under furniture and avoiding harsh cleaning chemicals, can delay the need for refinishing. For engineered wood, prioritize preventive care, as its limited refinishing potential makes each sanding count. By understanding these nuances, homeowners can maximize the lifespan of their wood floors and make informed decisions about when to refinish or replace.

Durability of Wood Playsets: Lifespan and Maintenance Tips Revealed

You may want to see also

Frequently asked questions

Hardwood generally lasts longer than engineered wood, as it can be refinished multiple times over decades, while engineered wood has a limited number of refinishes due to its thin top layer.

Yes, engineered wood can be refinished, but only a few times due to its thin hardwood veneer. Hardwood, on the other hand, can be refinished many times, extending its lifespan significantly.

Engineered wood is more resistant to moisture and temperature changes, making it a better choice for high-moisture areas like basements or bathrooms, where hardwood may warp or expand.

Warranty periods vary by brand, but hardwood often comes with longer warranties due to its solid construction. Engineered wood warranties are typically shorter, reflecting its limited refinishing potential.

Hardwood generally offers better long-term resale value due to its durability, timeless appeal, and ability to be refinished multiple times, whereas engineered wood may depreciate faster.