Choosing the right sandpaper for wood projects is crucial for achieving a smooth, professional finish. Sandpaper is categorized by grit size, ranging from coarse (low numbers like 40-60) for aggressive material removal to fine (high numbers like 220-400) for polishing and smoothing. For woodworking, common grits include 80-120 for initial sanding, 150-180 for smoothing, and 220 or higher for final finishing. Consider the type of wood—softer woods like pine may require finer grits sooner, while harder woods like oak may need coarser grits initially. Additionally, choose between open-coat sandpaper for clog resistance or closed-coat for faster material removal. Whether using sheets, discs, or belts, selecting the appropriate grit and type ensures efficient sanding and optimal results for your wood project.

Explore related products

What You'll Learn

Grit Selection Guide

Choosing the right sandpaper grit is crucial for achieving a smooth, professional finish on wood projects. Grit size determines the coarseness of the abrasive particles, with lower numbers indicating rougher grit and higher numbers representing finer grit. For wood, grits typically range from 40 (coarse) to 400 (very fine). Understanding the purpose of each grit level ensures you remove imperfections efficiently without damaging the wood.

Step-by-Step Grit Progression: Begin with a lower grit (60–80) to remove rough surfaces, old finishes, or saw marks. Progress to medium grits (100–150) to smooth out scratches left by coarser grits. Finish with higher grits (180–220) for a polished surface ready for staining or painting. For ultra-smooth finishes, such as those required for fine furniture, use grits up to 320–400. Always sand in the direction of the wood grain to avoid scratches.

Cautions and Common Mistakes: Skipping grits can leave visible scratches, as finer grits cannot always remove deeper grooves left by coarser ones. Avoid using too fine a grit too early, as it will take longer and may clog the sandpaper. Additionally, over-sanding with high grits can compress the wood fibers, altering the surface texture. Test each grit on a scrap piece of wood to ensure it achieves the desired effect before applying it to your project.

Practical Tips for Efficiency: Use open-coat sandpaper for woodworking, as it resists clogging from wood dust. For power sanders, choose aluminum oxide or silicon carbide grits, which are durable and long-lasting. Hand sanding benefits from flexible sandpaper that conforms to wood contours. Keep a grit progression chart nearby to avoid confusion and ensure a systematic approach.

Takeaway: Grit selection is not one-size-fits-all—it depends on the wood type, project requirements, and desired finish. By following a logical grit progression and avoiding common pitfalls, you’ll achieve professional results efficiently. Remember, the goal is to remove imperfections gradually, not to rush the process.

Discover Top Places to Buy Quality Wooden Boxes Online & Locally

You may want to see also

Explore related products

$13.29 $14.99

Sandpaper Types (Aluminum Oxide, Silicon Carbide)

Choosing the right sandpaper for wood projects hinges on understanding the grit and material. Aluminum oxide and silicon carbide are two dominant types, each with distinct characteristics. Aluminum oxide, a versatile and cost-effective option, excels at sanding wood due to its durability and self-sharpening properties. It’s ideal for general-purpose sanding, from smoothing rough surfaces to preparing wood for finishing. Silicon carbide, on the other hand, is harder and sharper, making it better suited for finer grits and non-wood materials like metal or plastic. However, it can still be used on wood for final polishing or when working with harder woods like oak or maple.

When selecting grit, consider the project stage. Coarse grits (40–80) are for heavy material removal, while medium grits (100–150) refine surfaces. Fine grits (180–220) prepare wood for staining or painting, and very fine grits (320–400) achieve a smooth, polished finish. Aluminum oxide performs consistently across these ranges, making it a go-to for most woodworkers. Silicon carbide shines in the finer grits, delivering a smoother finish but at a higher cost. For beginners, start with aluminum oxide and experiment with silicon carbide for specialized tasks.

Durability is another factor. Aluminum oxide wears more slowly, offering longer use before replacement. Silicon carbide, while sharper, tends to break down faster, especially on wood. This makes aluminum oxide more economical for large projects. However, silicon carbide’s sharpness can justify its cost when precision and speed are critical. For example, use silicon carbide for quick touch-ups or when sanding between coats of finish to avoid clogging.

Practical tip: Always sand with the grain to avoid scratches. For hand sanding, fold the paper to create a fresh edge as it wears. When using power tools, match the sandpaper type to the tool’s speed—aluminum oxide works well with orbital sanders, while silicon carbide is better for detail work with a rotary tool. Test both types on scrap wood to see how they perform on your specific material and project requirements.

In conclusion, aluminum oxide is the all-rounder for wood sanding, balancing performance and affordability. Silicon carbide is the specialist, ideal for fine finishing or harder woods. By understanding their strengths, you can choose the right sandpaper to elevate your woodworking results.

Renting vs. Buying a Wood Chipper: Which Option Saves You Money?

You may want to see also

Explore related products

Best for Fine Finishing

Fine finishing on wood demands precision and the right tools. Among sandpapers, the grit range of 320 to 600 is ideal for achieving a smooth, polished surface ready for staining, painting, or sealing. This range removes minor imperfections left by coarser grits while avoiding the over-sanding that can dull the wood’s natural grain. For most hardwoods, start with 320-grit to level the surface, then progress to 400-grit for refinement, and finish with 600-grit for a glass-like smoothness. Softwoods, being more delicate, may only require up to 400-grit to prevent tearing.

Choosing the right abrasive material is equally critical. Aluminum oxide is the go-to option for fine finishing due to its durability and ability to break down evenly, ensuring consistent results. Steer clear of silicon carbide for this stage, as its aggressive cutting action can leave scratches even at higher grits. Opt for sandpaper with a flexible backing, such as cloth or film, to conform to the wood’s contours without tearing. For intricate details or curved surfaces, consider using sanding sponges or folded sheets for better control.

Hand sanding is often preferred for fine finishing to maintain precision and avoid the heat generated by power tools, which can scorch the wood. Apply light, even pressure and sand in the direction of the grain. For flat surfaces, use a sanding block to ensure uniformity. Change the sandpaper frequently to avoid clogging, which can mar the finish. A practical tip: wrap the sandpaper around a wooden block with a handle for better grip and control, especially during extended sanding sessions.

Comparing brands, 3M’s Pro Grade Advanced Sandpaper stands out for its long-lasting performance and clog resistance, making it a favorite among professionals. For budget-conscious buyers, Norton’s Sandpaper Sheets offer reliable quality at a lower price point. Both are available in pre-cut sheets or rolls, allowing customization for specific project needs. Regardless of brand, always test a small, inconspicuous area first to ensure the grit and technique align with the desired outcome.

The final takeaway: fine finishing is as much about technique as it is about the sandpaper. Patience and attention to detail are key. By selecting the appropriate grit, abrasive material, and sanding method, you can achieve a flawless surface that enhances the wood’s natural beauty. Remember, the goal isn’t just to smooth the wood but to prepare it for the next step—whether that’s applying a finish or showcasing the grain in all its glory.

Veneer vs. Solid Wood: Which Furniture Investment is Right for You?

You may want to see also

Explore related products

$32 $37.99

Sanding Techniques for Wood

Choosing the right sandpaper grit is crucial for achieving a smooth, professional finish on wood. Start with a coarse grit, such as 80 or 120, to remove imperfections, old finishes, or rough surfaces. Progress to medium grits like 150 or 180 to smooth out scratches left by the coarser paper. Finish with fine grits, 220 or higher, to create a polished surface ready for staining, painting, or sealing. Always sand in the direction of the wood grain to avoid scratches and ensure a uniform finish.

Technique matters as much as grit selection. Use long, even strokes and apply consistent pressure to avoid uneven wear. For flat surfaces, wrap sandpaper around a sanding block to maintain a level surface and prevent rounding edges. When sanding curves or contours, fold the sandpaper to fit the shape or use a flexible sanding sponge. Avoid over-sanding, as it can thin the wood or create dips. Regularly check your progress by wiping the surface with a damp cloth to reveal hidden scratches.

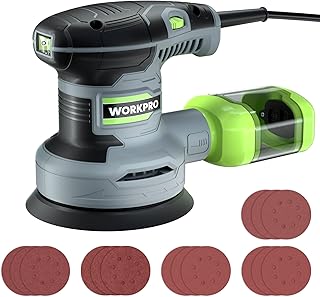

Hand sanding is ideal for small projects or delicate areas, but power sanders save time on larger surfaces. Orbital sanders are versatile for most tasks, while belt sanders are aggressive and best for rapid material removal. When using power tools, start at a lower speed and gradually increase to maintain control. Always wear a dust mask and work in a well-ventilated area to avoid inhaling wood particles. Clean the sander’s dust bag or filter frequently to prevent clogging and ensure efficient operation.

For intricate details or tight spaces, consider using sanding sticks or folded sandpaper. These tools allow precision without damaging surrounding areas. When sanding between coats of finish, use a fine grit like 320 to lightly scuff the surface, ensuring better adhesion for the next layer. After sanding, vacuum and wipe the wood thoroughly to remove all dust before applying any finish. This step is critical for a flawless final result.

Mastering sanding techniques transforms wood from raw material to refined masterpiece. By combining the right grits, tools, and methods, you can achieve a professional-grade finish tailored to your project’s needs. Practice consistency and patience, as rushing can lead to mistakes. With the proper approach, sanding becomes less of a chore and more of an art, elevating the quality of your woodworking projects.

A Comprehensive Guide to Purchasing High-Quality HWMP Wood

You may want to see also

Explore related products

Durability and Cost Comparison

Choosing the right sandpaper for wood projects involves balancing durability and cost, as these factors directly impact both performance and budget. High-grit sandpapers, such as 220-grit or finer, are ideal for finishing but wear out faster, especially on hardwoods like oak or maple. Coarser grits, like 80-grit, last longer but are less suited for final smoothing. For example, a 50-pack of 80-grit aluminum oxide sandpaper costs around $15, while a similar pack of 220-grit may cost $20. The trade-off lies in how quickly you’ll need to replace them based on your project’s demands.

Analyzing durability reveals that ceramic and zirconia sandpapers outlast traditional aluminum oxide options, particularly for aggressive sanding tasks. Ceramic sandpapers, though 2–3 times more expensive, can last up to 3 times longer, making them cost-effective for heavy-duty projects like refinishing floors or stripping paint. For instance, a 10-pack of ceramic 80-grit sandpaper might cost $30 but will outperform a $15 aluminum oxide pack in longevity. However, for light sanding or one-time use, cheaper options suffice without sacrificing quality.

A practical tip for maximizing durability is to match the sandpaper type to the wood species. Softwoods like pine require less durable grits, while hardwoods demand tougher materials. Additionally, using a sanding block or power sander reduces uneven wear, extending the sandpaper’s life. For example, pairing a $20 orbital sander with mid-range sandpaper can yield better results than manual sanding with premium grits, saving both time and money.

Instructively, consider the project scale when budgeting. Small DIY tasks, like smoothing a wooden shelf, may only need a $5 pack of 120-grit sandpaper. Larger projects, such as refinishing a table, could require $50–$70 worth of assorted grits. Bulk purchases often offer discounts—a 100-pack of mixed grits for $40 can be more economical than buying individual packs. Always factor in replacement frequency to avoid mid-project interruptions.

Persuasively, investing in higher-quality sandpaper pays off for professionals or frequent woodworkers. While a single sheet of premium sandpaper costs $2–$3 compared to $0.50 for basic options, the reduced need for replacements and improved finish quality justify the expense. For hobbyists, mid-range options strike a balance, offering decent durability without breaking the bank. Ultimately, the goal is to align your choice with both the project’s needs and your long-term woodworking goals.

Buying Wood by the Foot at Home Depot: What You Need to Know

You may want to see also

Frequently asked questions

For initial sanding of rough wood surfaces, start with a coarse grit like 40-60 to remove imperfections and level the surface efficiently.

For a smooth finish, use a fine grit like 120-220 to prepare the wood for staining, painting, or sealing, ensuring a polished surface.

Choose sheets for hand sanding, rolls for power tools or large projects, and discs for orbital or disc sanders, depending on your tool and task.