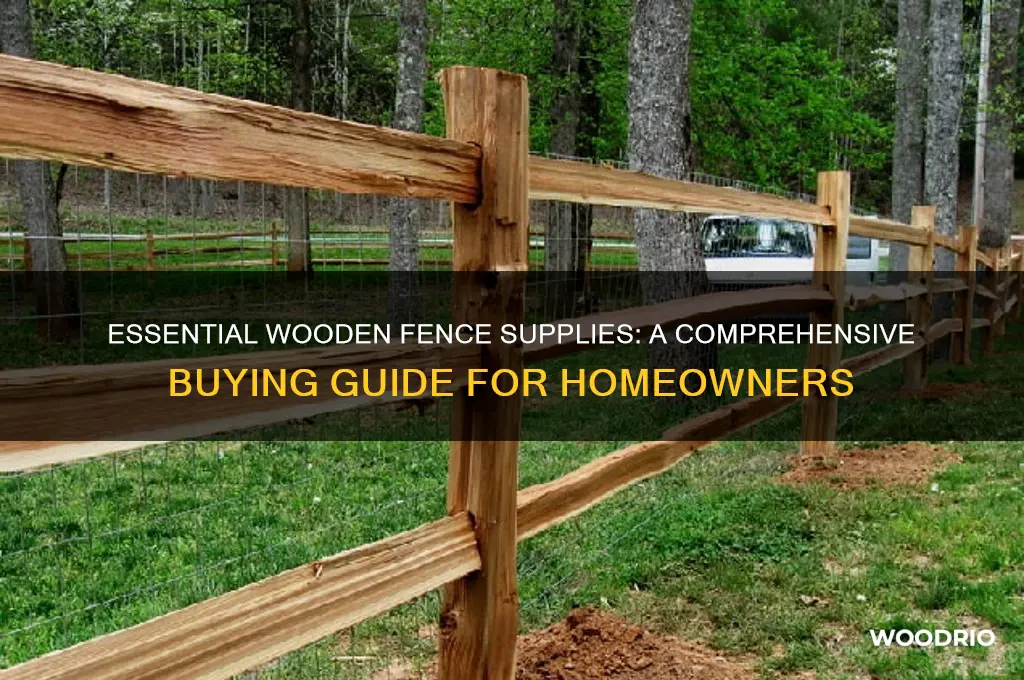

When planning to buy materials for a wooden fence, it's essential to consider both functionality and aesthetics. Start by selecting high-quality, weather-resistant wood such as cedar, redwood, or pressure-treated pine, which can withstand rot, insects, and moisture. Determine the fence height, style (e.g., picket, privacy, or split rail), and length to calculate the amount of lumber needed, including posts, rails, and boards. Don’t forget essential hardware like galvanized nails, screws, brackets, and post caps for durability. Additionally, consider gate kits if access points are required, and stain or sealant to protect the wood and enhance its appearance. Finally, factor in tools for installation, such as a post-hole digger, level, and saw, or budget for professional installation if DIY isn’t an option.

Explore related products

$35.99

What You'll Learn

Fence Posts and Rails

Choosing the right fence posts and rails is critical to the longevity and stability of your wooden fence. Posts serve as the backbone, bearing the weight and wind pressure, while rails distribute the load and support the pickets. Opt for pressure-treated lumber, which resists rot and insect damage, especially for posts that are buried in the ground. A standard 4x4 post is ideal for most residential fences, but taller or heavier fences may require 6x6 posts for added strength. Ensure posts are set at least 3 feet deep in concrete to prevent shifting, and use gravel at the base for drainage to avoid water pooling and decay.

Rails, typically 2x4 or 2x6 boards, connect the posts horizontally and provide a framework for attaching pickets. For a 6-foot fence, use three rails: one at the top, one at the bottom, and one in the middle for stability. Consider using galvanized or stainless steel fasteners to secure rails to posts, as these resist rust and corrosion. If you’re aiming for a more decorative look, opt for rounded or chamfered rails, which add visual appeal without compromising function. Always measure twice and cut once to ensure rails fit snugly between posts, maintaining the fence’s structural integrity.

When comparing materials, cedar and redwood are premium choices for rails due to their natural resistance to decay and insects, though they come at a higher cost. Pressure-treated pine is a budget-friendly alternative but may require additional staining or sealing to enhance durability. For eco-conscious homeowners, composite materials offer a low-maintenance option, though they are less traditional in appearance. Weigh the upfront cost against long-term maintenance when deciding, as the right choice depends on your climate, budget, and aesthetic preferences.

A common mistake is underestimating the number of posts and rails needed. Calculate the total linear footage of your fence and divide by the spacing between posts (typically 6 to 8 feet apart) to determine the number of posts required. Add extra for gates and corners. Rails should span the distance between posts without sagging, so factor in their length and the number of layers needed. Pro tip: purchase 10-15% extra material to account for cuts, mistakes, or future repairs, ensuring you’re not left scrambling mid-project.

Finally, consider the environmental impact of your choices. Pressure-treated wood contains chemicals that can leach into the soil, so avoid using it near vegetable gardens or playgrounds. Alternatively, look for sustainably sourced or recycled materials to minimize your ecological footprint. Proper installation and maintenance, such as regular staining and inspections for damage, will extend the life of your fence, making your investment in quality posts and rails pay off in the long run.

Is Fire-Resistant Wood a Real Option for Home Safety?

You may want to see also

Explore related products

Wood Types and Durability

Choosing the right wood for your fence is a decision that balances aesthetics, budget, and longevity. Among the most popular options are cedar, redwood, and pressure-treated pine, each with distinct characteristics that influence durability. Cedar and redwood, for instance, contain natural oils that resist rot, decay, and insect damage, making them ideal for humid climates or areas prone to pests. Pressure-treated pine, while less naturally resistant, undergoes a chemical treatment that enhances its durability, often lasting 15–20 years with proper maintenance. Understanding these differences ensures your fence not only looks good but stands the test of time.

For those prioritizing sustainability and low maintenance, tropical hardwoods like ipe or teak are worth considering. These dense woods boast exceptional resistance to weathering, insects, and decay, often outlasting softer woods by decades. However, their durability comes at a higher cost and raises environmental concerns due to deforestation. If opting for tropical hardwoods, ensure they are sourced from certified sustainable suppliers. Alternatively, consider reclaimed wood, which offers unique character while reducing environmental impact, though it may require more careful selection to ensure structural integrity.

When evaluating wood types, consider your local climate and the fence’s exposure to elements. In regions with harsh winters, wood prone to warping or splitting, like spruce or fir, may not be the best choice. Instead, opt for more stable options like cedar or redwood, which handle temperature fluctuations better. Additionally, factor in maintenance requirements—while all wood fences benefit from periodic sealing or staining, some woods, like pressure-treated pine, may need more frequent treatments to maintain their appearance and structural integrity.

Finally, weigh the initial cost against long-term value. Cheaper options like spruce or fir may save money upfront but often require replacement sooner, increasing costs over time. Investing in higher-quality woods like cedar, redwood, or tropical hardwoods may have a steeper initial price but can provide decades of service with minimal upkeep. For budget-conscious projects, pressure-treated pine offers a middle ground, combining affordability with reasonable durability. Ultimately, the right choice depends on your specific needs, climate, and willingness to maintain the fence over its lifespan.

Where to Buy Wood Paneling: Top Retailers and Online Stores

You may want to see also

Explore related products

Gates and Hardware

Gates serve as both the focal point and the functional core of a wooden fence, blending security with aesthetic appeal. Selecting the right gate material is paramount; cedar and pressure-treated pine are popular choices due to their durability and resistance to rot. For a gate that withstands daily use, opt for a frame constructed with 4x4 or 6x6 posts and reinforced with steel brackets at the corners. Hinges, often overlooked, are critical—choose heavy-duty, rust-resistant options like stainless steel or galvanized metal to ensure smooth operation and longevity. A well-built gate not only enhances curb appeal but also provides a secure entry point that complements the overall fence design.

Hardware selection transforms a basic gate into a seamless extension of your wooden fence. Latches, for instance, come in various styles—from simple gravity latches to self-closing mechanisms with key locks for added security. Consider the gate’s purpose: a garden gate might benefit from a decorative latch, while a driveway gate requires a robust, lockable system. Handles should be ergonomic and weather-resistant, with materials like wrought iron or powder-coated aluminum offering both durability and style. For added convenience, integrate smart hardware like keypad locks or wireless entry systems, especially if the gate is part of a larger security setup.

The installation of gates and hardware demands precision to avoid common pitfalls. Ensure the gate is level during installation, as even a slight tilt can lead to sagging over time. Use a gate kit with adjustable hinges to simplify alignment and allow for future adjustments. When attaching hardware, pre-drill holes to prevent wood splitting, and use exterior-grade screws for maximum hold. For larger gates, consider adding a wheel or roller at the bottom to distribute weight and reduce strain on hinges. Proper installation not only extends the gate’s lifespan but also ensures it operates smoothly year after year.

Comparing hardware options reveals a balance between cost and functionality. Basic hinges and latches are budget-friendly but may lack durability in harsh climates. Mid-range options, such as ball-bearing hinges and magnetic latches, offer improved performance without breaking the bank. High-end hardware, including hydraulic closers and corrosion-resistant coatings, provides premium features ideal for high-traffic or exposed areas. When budgeting, allocate 15-20% of your total fence cost to gates and hardware, as skimping on these elements can compromise both security and aesthetics. Investing wisely here ensures your wooden fence remains both beautiful and functional for years to come.

Calculate Wood Quantities Accurately for Your Next DIY Project

You may want to see also

Explore related products

$28.99

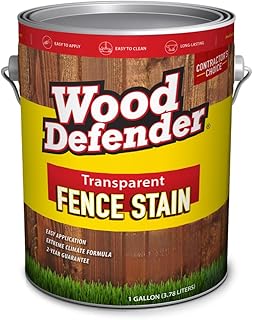

Stains and Sealants

Wooden fences, while charming and natural, are susceptible to the elements—sun, rain, and temperature fluctuations can cause warping, cracking, and fading. Stains and sealants are not just cosmetic choices; they are essential protective measures that extend the life of your fence. Without them, wood can deteriorate rapidly, leading to costly repairs or replacements. Think of these products as sunscreen and moisturizer for your fence—they shield it from UV damage while locking in moisture to prevent drying and splitting.

When selecting a stain, consider both its protective qualities and aesthetic appeal. Oil-based stains penetrate deeply, enhancing the wood’s natural grain and providing excellent water resistance. Water-based stains, on the other hand, dry faster and are more environmentally friendly, though they may not last as long. Semi-transparent stains allow the wood’s texture to show through, while solid stains offer maximum protection and color coverage, ideal for older fences with imperfections. Apply stains in thin, even coats using a brush, roller, or sprayer, ensuring complete coverage. Reapply every 2–3 years, depending on exposure and wear.

Sealants act as a barrier against moisture and pests, preventing rot and insect damage. Waterproof sealants are particularly effective in humid climates, while UV-resistant formulas are crucial in sunny regions. For best results, apply sealants after staining, allowing the stain to dry fully first. Use a synthetic brush or airless sprayer for even application, and avoid overloading the wood, which can lead to peeling. Reapply sealants every 3–5 years, inspecting the fence annually for signs of wear.

Combining stains and sealants offers dual protection, but compatibility is key. Some sealants may not adhere well to certain stains, so check manufacturer guidelines. For instance, applying a water-based sealant over an oil-based stain can cause beading or uneven drying. Always prepare the wood surface by cleaning and sanding it before application. Pressure-washing removes dirt and mildew, while sanding smooths rough patches, ensuring better adhesion.

In summary, stains and sealants are investments in your fence’s longevity. Choose products based on your climate, wood type, and desired appearance. Proper application and regular maintenance will keep your fence looking vibrant and structurally sound for years. Treat this process as preventive care, and your wooden fence will remain a durable, attractive boundary for your property.

Can You Buy Wood Flowers? A Guide to Purchasing Sola Wood Blooms

You may want to see also

Explore related products

Tools and Installation Kits

Building a wooden fence requires more than just wood—it demands the right tools and installation kits to ensure durability, precision, and efficiency. Start with a post-hole digger, the backbone of any fence project. This tool allows you to dig deep, consistent holes for fence posts, ensuring stability. For larger projects, consider a gas-powered auger, which saves time and effort, especially in hard soil. Pair this with a string line and stakes to maintain straight lines and proper alignment throughout the installation.

Next, invest in a circular saw or reciprocating saw for cutting wooden boards and posts to size. A drill with a screw-tip attachment is essential for securing boards quickly and evenly. For added convenience, pre-drilling holes with a countersink bit prevents wood splitting and ensures a clean finish. Don’t overlook the importance of a level and measuring tape—these tools guarantee your fence is plumb and evenly spaced, avoiding costly mistakes.

Installation kits often include brackets, screws, and anchors, streamlining the process. Opt for galvanized or stainless steel hardware to resist rust and prolong the fence’s lifespan. Some kits also feature concrete mix for setting posts, though you can purchase this separately. If using concrete, a mixing tub and margin trowel are handy for preparing and smoothing the material around posts.

For those prioritizing aesthetics, consider a nail gun for a seamless, nail-free appearance. However, weigh the cost against the traditional hammer-and-nail method, which remains effective for smaller projects. Lastly, safety gear—gloves, safety glasses, and ear protection—is non-negotiable, especially when operating power tools.

In summary, the right tools and installation kits transform fence-building from a daunting task into a manageable project. By selecting durable, purpose-specific equipment and prioritizing precision, you’ll achieve a professional-grade wooden fence that stands the test of time.

Where to Buy Bamboo Wood: A Sustainable and Stylish Choice

You may want to see also

Frequently asked questions

Cedar and redwood are popular choices due to their natural resistance to rot, insects, and decay. Pressure-treated pine is also a cost-effective option, though it requires regular maintenance.

Measure the perimeter of the area to be fenced and decide on the height. Typically, you’ll need fence boards, posts, rails, and hardware like nails or screws. Add 10-15% extra for cuts and mistakes.

Pre-stained wood saves time and provides immediate protection, but untreated wood allows you to choose your preferred stain or sealant. Consider your budget and maintenance preferences.

Purchase galvanized or stainless steel nails, screws, brackets, and post caps to prevent rust. You’ll also need concrete or gravel for setting posts and a gate kit if you’re installing a gate.

Yes, you’ll likely need a post-hole digger, level, string line, hammer, drill, saw, and measuring tape. Renting or borrowing specialized tools like an auger can save time and effort.