When venturing into woodworking, selecting the right tools is crucial for both beginners and seasoned craftsmen. Essential wood tools to consider include a reliable tape measure for accurate dimensions, a sharp handsaw or circular saw for cutting, and a set of chisels for detailed carving and shaping. A sturdy workbench provides a stable foundation, while clamps ensure precision during assembly. For smoothing and finishing, a block plane and sandpaper are indispensable. Additionally, investing in a power drill and a set of drill bits can significantly enhance efficiency. Prioritize high-quality, durable tools from reputable brands to ensure longevity and optimal performance in your woodworking projects.

Explore related products

What You'll Learn

- Hand Tools Essentials: Planes, chisels, saws, and measuring tools for precise woodworking tasks

- Power Tools Must-Haves: Table saw, router, drill, and sander for efficient wood shaping

- Safety Gear: Ear protection, dust masks, goggles, and gloves for safe woodworking

- Clamping Tools: Clamps, vises, and hold-downs for securing wood during cutting and assembly

- Sharpening & Maintenance: Sharpeners, stones, and oils to keep tools in top condition

Hand Tools Essentials: Planes, chisels, saws, and measuring tools for precise woodworking tasks

Woodworking precision begins with the right hand tools. Planes, chisels, saws, and measuring tools form the core of any woodworker’s arsenal, each serving a distinct purpose in shaping, refining, and assembling wood. A well-chosen plane can transform rough lumber into a smooth, dimensionally accurate board, while a sharp chisel allows for intricate joinery and fine detailing. Saws, from crosscut to dovetail, dictate the efficiency and accuracy of your cuts, and measuring tools ensure every mark and cut aligns with your design. Together, these essentials bridge the gap between raw material and finished masterpiece.

Consider the plane as the cornerstone of surface preparation. A bench plane, such as a No. 4 or No. 5, is versatile for flattening and smoothing, while a block plane excels at end grain and fine adjustments. When selecting a plane, prioritize one with a sturdy body, adjustable mouth, and high-quality blade. Proper technique—maintaining a consistent angle and even pressure—is critical. For beginners, start with a medium-sized smoothing plane and practice on scrap wood to develop a feel for the tool. Regular sharpening and tuning will keep your plane performing at its best, ensuring clean, tear-out-free surfaces.

Chisels are indispensable for joinery, carving, and cleanup work. A set of bench chisels in sizes ranging from 1/4" to 1" covers most tasks, with firmer chisels ideal for heavier work and paring chisels suited for delicate operations. Keep your chisels razor-sharp; a dull edge will tear wood fibers and compromise precision. Use a honing guide and waterstones for consistent sharpening, and always work with the grain to avoid chipping. For mortise and tenon joints, a mallet is essential for controlled force, but practice striking accurately to avoid damaging the wood or tool.

Saws are the backbone of cutting tasks, and choosing the right type for the job is crucial. A crosscut backsaw, like a tenon saw, is perfect for cutting across the grain, while a ripcut saw handles cuts parallel to the grain. For finer work, a dovetail saw offers thin, precise cuts ideal for joinery. Japanese pull saws, with their fine teeth and cutting on the pull stroke, provide exceptional control for detailed work. Always mark your cut lines clearly and use a miter box or guide for straight, accurate cuts. Maintain your saw blades by cleaning them after use and storing them in a dry place to prevent rust.

Measuring tools are the unsung heroes of precision woodworking. A combination square is invaluable for checking right angles, marking lines, and measuring depths. Pair it with a marking gauge for consistent layout lines and a sliding bevel for transferring angles. For fine measurements, a digital caliper offers accuracy to the thousandth of an inch, while a tape measure handles larger dimensions. Always double-check your measurements and mark with a sharp pencil or knife to avoid errors. Remember, in woodworking, "measure twice, cut once" isn’t just a saying—it’s a rule.

Investing in high-quality hand tools and learning to use them effectively will elevate your woodworking from hobbyist to craftsman. Planes, chisels, saws, and measuring tools each demand practice and care but repay the effort with unparalleled precision and control. Start with the essentials, master their use, and gradually expand your collection as your skills grow. With these tools in hand, you’ll tackle projects with confidence, knowing every cut, joint, and surface reflects your dedication to the craft.

Wood vs. Stainless Steel Cider Press: Which is Right for You?

You may want to see also

Explore related products

Power Tools Must-Haves: Table saw, router, drill, and sander for efficient wood shaping

Woodworking efficiency hinges on the right tools, and power tools are the backbone of any serious workshop. Among the myriad options, four stand out as indispensable: the table saw, router, drill, and sander. Each serves a distinct purpose, yet together they form a cohesive system for shaping wood with precision and speed. The table saw, often called the "workhorse" of the shop, excels at straight cuts and ripping boards to size. Its versatility is unmatched, allowing for crosscuts, bevels, and even dadoes with the right blade. For intricate edge profiles, joinery, and decorative details, the router takes center stage. Its ability to shape wood with precision bits transforms raw lumber into refined pieces. The drill, while seemingly basic, is essential for creating holes and driving screws, with modern models offering variable speeds and torque settings for diverse tasks. Finally, the sander smooths surfaces to a professional finish, eliminating imperfections and preparing wood for staining or painting. Together, these tools form a powerful quartet that streamlines woodworking projects, saving time and enhancing craftsmanship.

Consider the table saw as the foundation of your setup. When selecting one, prioritize features like a sturdy fence, accurate miter gauge, and a powerful motor (at least 1.5 HP for hardwoods). Blade quality matters too; invest in a carbide-tipped blade for cleaner cuts. Safety is paramount—always use a push stick and consider a blade guard with a riving knife to prevent kickback. For routers, choose between fixed-base and plunge models based on your needs. Fixed-base routers are ideal for edge work, while plunge routers offer more versatility for mid-board cuts. Variable speed settings are a must for different bit sizes and wood types. Drills come in corded and cordless varieties; opt for a cordless model with a lithium-ion battery for portability and convenience. Look for a drill with adjustable clutch settings to avoid overdriving screws. Sanders range from belt sanders for aggressive material removal to orbital sanders for fine finishing. Start with a random orbital sander, which minimizes swirl marks and is user-friendly for beginners.

The synergy between these tools becomes evident in practice. Imagine crafting a cabinet: the table saw cuts the panels to size, the router adds decorative edges and dado joints, the drill preps holes for hinges and handles, and the sander ensures a smooth, ready-to-finish surface. This workflow not only saves time but also elevates the quality of the final piece. However, mastering these tools requires practice and respect for their power. Always wear safety gear, including eye protection and dust masks, and familiarize yourself with each tool’s capabilities and limitations.

For those on a budget, prioritize purchasing tools in this order: table saw, drill, router, then sander. The table saw and drill are immediate workhorses, while the router and sander refine your projects as skills progress. Look for combo kits that bundle tools and accessories for cost savings. Maintenance is key to longevity; keep blades sharp, motors clean, and batteries charged. Regularly inspect cords for damage and replace worn parts promptly.

In conclusion, the table saw, router, drill, and sander are not just tools—they’re investments in efficiency and craftsmanship. By understanding their roles and selecting the right models, woodworkers can tackle projects with confidence and precision. Whether you’re a hobbyist or a professional, these power tools form the core of a productive workshop, turning raw wood into polished creations.

Choosing the Perfect Wood for Your Furniture: A Buyer's Guide

You may want to see also

Explore related products

Safety Gear: Ear protection, dust masks, goggles, and gloves for safe woodworking

Woodworking tools are essential, but safety gear is non-negotiable. Before you even think about a table saw or chisel, invest in ear protection. Woodworking machinery, from routers to planers, can produce noise levels exceeding 100 decibels—enough to cause permanent hearing damage after just 15 minutes of exposure. Opt for over-ear muffs with a Noise Reduction Rating (NRR) of at least 22 dB, or high-quality earplugs rated for industrial use. Pro tip: Combine both for maximum protection in extremely loud environments.

Dust masks are another critical component, but not all are created equal. Fine wood dust, especially from hardwoods like oak or walnut, is a known carcinogen. Skip the cheap paper masks and choose a respirator with N95 or P100 filters, which block 95% and 99.97% of airborne particles, respectively. For prolonged projects, consider a powered air-purifying respirator (PAPR) to reduce breathing resistance. Always check the mask’s seal before use—a proper fit is as important as the filter itself.

Goggles aren’t just for show; they’re your first line of defense against flying debris. Polycarbonate lenses offer impact resistance far superior to glass, and anti-fog coatings ensure clarity during long sessions. For added safety, choose goggles with side shields or a full-face shield if you’re working with high-velocity tools like routers or sanders. Remember: Prescription glasses alone are not enough—wear safety goggles over them.

Gloves in woodworking are a topic of debate, but their utility is undeniable when used correctly. For tasks like handling rough lumber or applying finishes, nitrile or leather gloves provide grip and protect against splinters and chemicals. However, avoid gloves near power tools with rotating blades—they can get caught and pull your hand into the machine. Instead, keep hands clear and use push sticks or featherboards for control. The rule is simple: gloves are for protection, not for operating machinery.

Incorporating these safety measures isn’t just about compliance—it’s about preserving your ability to work for years to come. Hearing loss, lung damage, and eye injuries are irreversible, but entirely preventable with the right gear. Treat safety equipment as an investment in your craft, not an afterthought. After all, the best tool in your workshop is the one that keeps you whole.

Cathie Wood's Weekly Trades: Latest Buys and Sells Revealed

You may want to see also

Explore related products

$196.54 $249

Clamping Tools: Clamps, vises, and hold-downs for securing wood during cutting and assembly

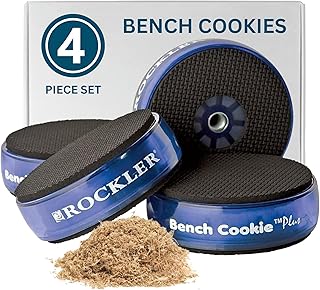

Securing wood firmly is non-negotiable in woodworking—safety and precision depend on it. Clamping tools, including clamps, vises, and hold-downs, are the unsung heroes of any workshop. Without them, cutting, sanding, or assembling wood becomes a precarious gamble. A wobbly workpiece can lead to inaccurate cuts, ruined projects, or worse, injuries. Whether you’re a beginner or a seasoned woodworker, investing in a variety of clamping tools is essential. Start with a basic F-clamp or bar clamp for general-purpose holding, and gradually expand your collection to include specialized options like pipe clamps for longer spans or quick-grip clamps for one-handed operation.

Consider the material and design when choosing clamps. Steel-bodied clamps offer durability but are heavier, while aluminum versions are lighter and rust-resistant. Jaw pads are critical—opt for rubber or plastic to prevent marring delicate surfaces. For vises, a bench vise with a swivel base provides versatility, allowing you to position your workpiece at the ideal angle. Hold-downs, often used in conjunction with a workbench, are invaluable for securing wood during routing or drilling. Featherboards, though not clamps, are worth mentioning as they work alongside clamps to keep wood steady against a fence or table saw.

The key to effective clamping is understanding force distribution. Over-tightening can warp wood, while under-tightening leads to slippage. Apply pressure gradually, ensuring the clamp is perpendicular to the workpiece. For larger projects, combine multiple clamps to distribute the load evenly. When using a vise, position the wood so the jaws grip the thickest part to minimize stress. Hold-downs should be tightened just enough to prevent movement—overdoing it can damage both the tool and the wood.

Specialized clamps cater to specific tasks. Spring clamps are ideal for light-duty holding during gluing, while corner clamps ensure precise 90-degree joints. For repetitive tasks, consider a clamp rack to keep your tools organized and within reach. If you’re working with curved or irregular shapes, strap clamps offer flexibility. When assembling large panels, pipe clamps with extendable bars are indispensable. Pairing these with a clamping square ensures your corners remain true.

In conclusion, clamping tools are not just accessories—they’re foundational to woodworking success. A well-equipped workshop includes a mix of general-purpose and task-specific clamps, vises, and hold-downs. Prioritize quality over quantity, as durable tools will serve you for years. Regularly inspect your clamps for wear and tear, especially the threads and pads. With the right clamping setup, you’ll achieve cleaner cuts, tighter joints, and a safer working environment. Master the art of securing wood, and you’ll elevate every project you undertake.

Where to Buy Wide Maple Wood: A Comprehensive Guide

You may want to see also

Explore related products

Sharpening & Maintenance: Sharpeners, stones, and oils to keep tools in top condition

Sharp edges are the lifeblood of woodworking. A dull chisel tears wood fibers, a blunt plane leaves jagged surfaces, and a rusty saw binds in the cut. Regular sharpening and maintenance aren't optional; they're the cornerstone of precision, efficiency, and safety in your workshop.

The Trinity of Sharpening: Stones, Angles, and Consistency

Think of sharpening as a three-legged stool: the stone, the angle, and your consistency. Waterstones, with their fine grits and ability to create a mirror finish, are the gold standard for chisels, plane irons, and carving tools. Start with a coarse grit (400-800) to remove nicks and establish the bevel, then progress to finer grits (1000-4000) for a razor-sharp edge. Oil stones, while messier, are durable and excel at sharpening harder steels. Remember, the angle is paramount. A consistent bevel angle, typically between 25-30 degrees, ensures a strong, long-lasting edge. Use a honing guide for beginners, but strive to develop the muscle memory for freehand sharpening – it's a skill that separates the novice from the master.

Beyond Stones: Sharpening Jigs and Steels

For those seeking speed and repeatability, sharpening jigs are invaluable. These devices hold your tool at a fixed angle, guiding the sharpening process with precision. They're particularly useful for beginners or when sharpening complex profiles like gouges and skew chisels. A honing steel, while primarily associated with kitchen knives, can be used to quickly touch up the edge of a chisel or plane blade between stone sharpenings.

The Unsung Hero: Lubrication and Rust Prevention

Sharpening generates heat, which can damage your tool's temper. Waterstones require constant lubrication, while oil stones need a light coating of honing oil. After sharpening, wipe your tools clean and apply a thin layer of camellia oil or rust preventative to ward off corrosion. Think of it as sunscreen for your tools – a small investment that pays dividends in longevity.

Maintenance: A Stitch in Time Saves Nine

Regular cleaning and inspection are just as crucial as sharpening. Wipe down your tools after each use, removing dust, pitch, and moisture. Check for cracks, chips, or loose handles. A few minutes of preventative maintenance can prevent costly repairs or replacements down the line. Remember, a well-maintained tool is a joy to use, while a neglected one is a source of frustration and potential danger.

Where to Find Barn Wood: Home Depot Options Explored

You may want to see also

Frequently asked questions

Essential tools for beginners include a tape measure, combination square, claw hammer, utility knife, hand saw, and a set of screwdrivers.

Start with hand tools like chisels, hand planes, and a coping saw to build foundational skills, then gradually invest in power tools like a drill, circular saw, or router as needed.

Invest in a variety of clamps, including F-clamps, bar clamps, and quick-grip clamps, to handle different project sizes and shapes.

Start with mid-range tools that balance quality and affordability. Upgrade to higher-end tools as your skills and needs grow.

Essential safety gear includes safety glasses, hearing protection, dust masks, and work gloves to protect against injuries and dust inhalation.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)