If you're looking to purchase a laser cutting wood machine, there are several reputable sources to consider. Online marketplaces like Amazon, eBay, and Alibaba offer a wide range of options, from entry-level models to industrial-grade machines, often with detailed specifications and user reviews to guide your decision. Specialized retailers such as Epilog Laser, Trotec, and Boss Laser provide high-quality, professional-grade machines with dedicated customer support and warranties. Additionally, local suppliers and distributors may offer personalized advice and hands-on demonstrations, ensuring you find the right machine for your specific needs. Before buying, assess factors like cutting area, laser power, software compatibility, and budget to make an informed choice.

Explore related products

What You'll Learn

Online Retailers for Laser Cutters

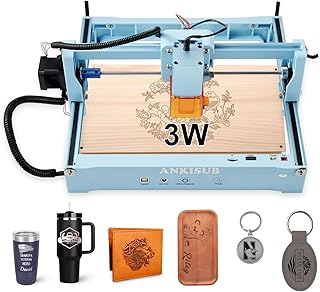

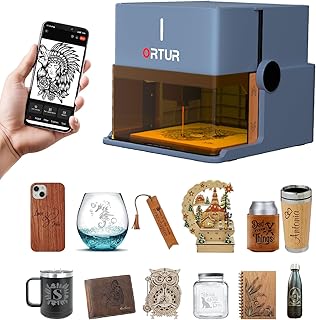

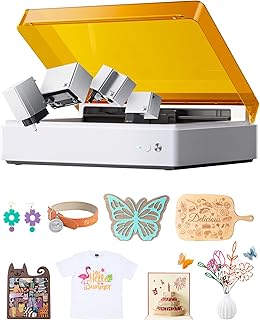

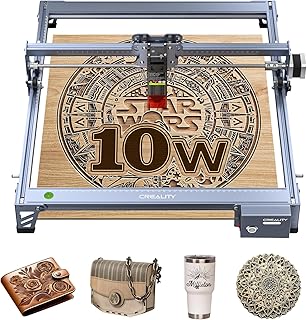

For those seeking to purchase a laser cutting wood machine, online retailers offer a vast array of options, from entry-level models to industrial-grade systems. Websites like Amazon and eBay provide a wide selection, often with user reviews that can guide decision-making. However, these platforms may lack specialized support, so buyers should research brands and specifications thoroughly. For instance, a 40W CO2 laser cutter is ideal for hobbyists, while a 100W or higher model suits professional woodworking businesses. Always verify the seller’s reputation and warranty terms before purchasing.

Specialized online stores like Full Spectrum Laser and Glowforge cater specifically to laser cutting enthusiasts, offering machines designed for precision and ease of use. These retailers often include detailed product guides, video tutorials, and customer support tailored to beginners. For example, Glowforge’s Pro model is popular for its user-friendly interface and compatibility with various materials, including wood, acrylic, and leather. While prices may be higher than general marketplaces, the added expertise and resources can justify the investment for serious users.

For budget-conscious buyers, Chinese manufacturers like Cloudray and OMTech dominate the market with affordable laser cutters, often available on platforms like AliExpress or their official websites. These machines typically range from $500 to $3,000, depending on power and features. However, buyers should be aware of potential shipping delays, language barriers, and limited warranties. Assembling the machine may also be required, so technical proficiency is beneficial. Despite these challenges, many users report satisfactory performance for small-scale projects.

When comparing online retailers, consider factors like shipping costs, return policies, and after-sales support. Some retailers offer financing options, which can make higher-end models more accessible. For instance, Boss Laser provides payment plans for their industrial-grade cutters, starting at $4,000. Additionally, check for compatibility with design software like LightBurn or RDWorks, as this can enhance functionality. Ultimately, the best retailer depends on your budget, technical needs, and willingness to navigate potential drawbacks.

To maximize value, look for bundle deals that include essential accessories like air assist systems, rotary attachments, or fume extractors. These add-ons can significantly improve cutting quality and safety but are often sold separately. For example, a 60W laser cutter with an air pump and honeycomb bed might cost $1,500, while purchasing these components individually could add $300 or more. By prioritizing retailers that offer comprehensive packages, buyers can save time and money while ensuring their setup is ready for immediate use.

Best Places to Buy Campfire Wood for Your Outdoor Adventure

You may want to see also

Explore related products

Local Suppliers & Showrooms

Local suppliers and showrooms offer a tactile, hands-on experience that online shopping can’t replicate. Walking into a showroom allows you to see laser cutting machines in action, hear their operation, and assess their build quality firsthand. This is particularly valuable for woodworkers who need to gauge the machine’s precision, speed, and compatibility with various wood types. Many local suppliers also provide live demonstrations, letting you test-cut samples of your own materials to ensure the machine meets your specific needs.

Choosing a local supplier often comes with added benefits like personalized customer support and faster troubleshooting. Unlike distant online vendors, local businesses can offer on-site repairs, maintenance training, and spare parts availability. For instance, if your laser tube malfunctions or your software glitches, a nearby supplier can dispatch a technician within hours, minimizing downtime. This level of service is especially critical for professionals relying on the machine for consistent production.

Showrooms also serve as hubs for community and education. Many local suppliers host workshops, training sessions, or user groups where you can learn advanced techniques, share tips, and network with fellow woodworkers. These events often include insights into optimizing machine settings for different wood densities, reducing material waste, and achieving intricate designs. For beginners, this hands-on learning environment can significantly shorten the learning curve.

While local options may seem pricier upfront, they often provide better long-term value. Showroom models frequently include bundled accessories like rotary attachments, fume extractors, or upgraded cooling systems, which can add hundreds to an online purchase. Additionally, local suppliers may offer financing plans tailored to small businesses or hobbyists, making high-end machines more accessible. Always compare total costs, including delivery, installation, and after-sales support, before deciding.

Finally, buying locally supports regional businesses and fosters accountability. A supplier with a physical presence is more likely to stand behind their products and maintain a reputation for quality service. Before committing, read reviews from local customers, ask about warranty terms, and inquire about trade-in options if you plan to upgrade later. A well-chosen local supplier can become a long-term partner in your woodworking journey, not just a one-time vendor.

Where to Buy Composite Wood: A Comprehensive Guide for Homeowners

You may want to see also

Explore related products

Industrial Machinery Auctions

One of the key advantages of industrial machinery auctions is the transparency they provide. Most auction houses offer detailed listings, including the machine’s age, condition, and maintenance records. For laser cutting wood machines, this information is invaluable, as it helps you assess whether the equipment meets your specific needs, such as cutting thickness, laser power (typically ranging from 40W to 150W for wood), and compatibility with your workflow. Additionally, many auctions allow on-site inspections, giving you a hands-on opportunity to evaluate the machine before placing a bid.

While auctions can be cost-effective, they come with risks that require careful navigation. For instance, some machines may have hidden issues, such as worn-out parts or outdated software, which can lead to unexpected repair costs. To mitigate this, consider hiring a machinery expert to inspect the equipment or consult online forums and communities for insights on common issues with specific models. Another cautionary note is the urgency of auction environments—it’s easy to get caught up in bidding wars, so always stick to your predetermined budget and avoid emotional decisions.

For those new to industrial machinery auctions, starting with online platforms like Bidspotter, AuctionTime, or Euro Auctions can be a less intimidating entry point. These platforms often feature detailed photos, videos, and descriptions, allowing you to participate remotely. However, traditional live auctions can offer a more dynamic experience, with the added benefit of immediate possession once the auction concludes. Regardless of the format, familiarize yourself with the auctioneer’s terms, including buyer’s premiums (typically 10-15% of the final bid) and payment deadlines, to ensure a smooth transaction.

In conclusion, industrial machinery auctions are a strategic avenue for acquiring laser cutting wood machines, blending affordability with access to high-quality equipment. By conducting thorough research, setting clear boundaries, and leveraging both online and live auction platforms, you can secure a machine that aligns with your needs and budget. Whether you’re a seasoned professional or a first-time buyer, auctions provide a unique opportunity to invest in industrial-grade technology without the retail markup.

Choosing the Perfect Wood Table: A Buyer's Guide to Quality

You may want to see also

Explore related products

Second-Hand Marketplaces

The second-hand marketplace is a treasure trove for those seeking a laser cutting wood machine without breaking the bank. Platforms like eBay, Craigslist, and Facebook Marketplace offer a wide array of options, often at a fraction of the cost of new machines. However, navigating these platforms requires a keen eye for detail and a bit of patience. Start by filtering your search with specific keywords such as "CO2 laser cutter," "CNC laser engraver," or "wood laser machine" to narrow down the results. Pay close attention to the machine’s specifications, such as laser power (typically ranging from 40W to 150W for hobbyist models), bed size, and included software compatibility. Always ask the seller for proof of functionality, such as a recent video of the machine in operation, to ensure it’s in working condition.

Analyzing the condition and history of a second-hand laser cutting machine is crucial to avoid costly mistakes. Look for signs of wear, such as rust on metal components or frayed wiring, which could indicate poor maintenance. Machines with lower operational hours (ideally under 1,000 hours) are generally more reliable. Additionally, inquire about the machine’s previous use—whether it was in a professional setting or for personal projects—as industrial machines may have endured heavier usage. If possible, arrange an in-person inspection to test the machine’s precision by engraving a simple design on a piece of wood. This hands-on approach can reveal issues that photos or descriptions might conceal.

One of the most persuasive arguments for buying second-hand is the potential for customization and upgrades. Many pre-owned machines come with aftermarket modifications, such as upgraded cooling systems, rotary attachments for cylindrical objects, or advanced software integrations. These enhancements can save you time and money compared to purchasing and installing them yourself. For instance, a machine with a water chiller already installed can extend the laser tube’s lifespan, which typically costs $200–$500 to replace. When negotiating, factor in the value of these upgrades to determine a fair price.

Comparing prices across different second-hand platforms can yield significant savings. While eBay often has a broader selection, local listings on Craigslist or Facebook Marketplace may offer lower prices due to reduced shipping costs. Keep in mind that larger machines, such as those with a 40" x 28" bed size, may require freight shipping, which can add $300–$800 to the total cost. If you’re purchasing locally, consider bringing a knowledgeable friend or hiring a technician to inspect the machine before finalizing the deal. This extra step can prevent buyer’s remorse and ensure you’re getting a machine that meets your needs.

Finally, a descriptive approach to understanding the second-hand market reveals its dynamic nature. Listings come and go quickly, so set up alerts on your preferred platforms using specific search terms. For example, subscribing to eBay’s "Save Search" feature or enabling notifications on Facebook Marketplace can help you act fast when a desirable machine becomes available. Remember, the second-hand market rewards persistence and research. By combining analytical scrutiny, practical inspections, and strategic shopping, you can find a laser cutting wood machine that delivers professional results without the premium price tag.

Where to Buy Speedway Wooden Racer Wagon In-Store: A Guide

You may want to see also

Explore related products

Manufacturer Direct Purchases

Buying a laser cutting wood machine directly from the manufacturer can be a strategic move, offering both cost savings and customization options. By bypassing intermediaries, you eliminate markup fees, often reducing the purchase price by 15-30%. This approach is particularly advantageous for businesses or individuals with specific requirements, as manufacturers can tailor the machine’s power (ranging from 40W to 150W for wood cutting), bed size, and software compatibility to meet precise needs. For instance, a small workshop might opt for a 60W machine with a 400x600mm bed, while a larger production facility could invest in a 100W model with a 1300x900mm bed. Always request a detailed quote and compare it with distributor prices to ensure the savings justify the effort.

However, manufacturer direct purchases come with caveats. Communication barriers, especially with overseas manufacturers, can complicate negotiations and after-sales support. Language differences and time zone discrepancies may delay responses, so clarify communication channels and expected response times upfront. Additionally, shipping and import duties can offset cost savings, particularly for international purchases. For example, importing a machine from China might incur duties ranging from 2.5% to 25%, depending on your country’s regulations. To mitigate risks, request a sample of the manufacturer’s work, such as a laser-cut wood sample, and verify their reputation through reviews or case studies.

One of the most compelling reasons to buy directly is access to factory warranties and technical support. Manufacturers often provide 1-2 years of warranty coverage, including free replacement parts and remote troubleshooting. Some even offer on-site installation and training for an additional fee, which can be invaluable for first-time users. For instance, a manufacturer might include a 3-day training session covering machine setup, software operation, and maintenance tips. This hands-on support can significantly reduce the learning curve and minimize downtime.

To navigate a direct purchase successfully, follow these steps: First, research manufacturers thoroughly, focusing on those with a proven track record in laser cutting technology. Second, request a detailed product specification sheet and compare it with your requirements. Third, negotiate terms, including payment schedules, delivery timelines, and after-sales support. Fourth, consider using a third-party inspection service to verify the machine’s condition before shipment. Finally, factor in long-term costs, such as maintenance and consumables, when evaluating the total cost of ownership. By taking a methodical approach, you can secure a high-quality laser cutting wood machine at a competitive price while minimizing risks.

Best Places to Buy Apple Wood Chunks for Smoking and Grilling

You may want to see also

Frequently asked questions

You can purchase a laser cutting wood machine for personal use from online retailers like Amazon, eBay, or specialty stores such as Glowforge, Full Spectrum Laser, or Boss Laser.

Yes, many local industrial supply stores or machinery dealers carry laser cutting machines. Check with businesses specializing in woodworking or laser equipment in your area.

Absolutely! Many manufacturers, such as Epilog Laser, Trotec, or Thunder Laser, offer direct sales through their websites or authorized distributors.

Affordable or used machines can be found on platforms like Craigslist, Facebook Marketplace, or specialized machinery auction sites like Bid on Equipment or Exapro.

Yes, international suppliers like Alibaba, AliExpress, or DHgate offer a wide range of laser cutting machines. Ensure to check shipping, customs, and warranty details before purchasing.