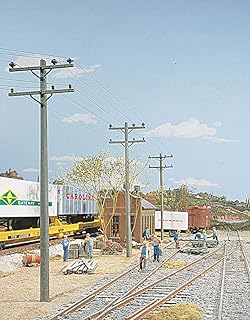

Alabama Power, a major utility provider in the southeastern United States, sources its wood poles from a variety of domestic suppliers, primarily within the region. These suppliers often include timber companies and specialized manufacturers that adhere to strict industry standards for durability, strength, and sustainability. The wood poles, typically made from Southern Yellow Pine due to its resilience and availability, are harvested from sustainably managed forests in states like Alabama, Georgia, and Mississippi. Alabama Power ensures that its suppliers comply with environmental regulations and practices, such as reforestation efforts, to maintain ecological balance. The procurement process involves rigorous quality checks to guarantee the poles meet safety and performance requirements for supporting electrical infrastructure across the state.

Explore related products

What You'll Learn

- Local Suppliers: Alabama Power sources wood poles from local timber suppliers across Alabama and neighboring states

- Sustainability Practices: Ensures wood poles are harvested from sustainably managed forests to minimize environmental impact

- Quality Standards: Poles must meet strict specifications for strength, durability, and treatment to withstand weather and wear

- Treatment Processes: Wood poles undergo creosote or CCA treatment to prevent decay and insect damage

- Logistics & Delivery: Suppliers coordinate transportation to ensure timely delivery to Alabama Power’s distribution centers

Local Suppliers: Alabama Power sources wood poles from local timber suppliers across Alabama and neighboring states

Alabama Power’s reliance on local timber suppliers for wood poles is a strategic decision rooted in both practicality and sustainability. By sourcing materials from within Alabama and neighboring states, the company minimizes transportation costs and reduces its carbon footprint. This approach aligns with broader industry trends toward localized supply chains, ensuring that the poles used to support power infrastructure are both cost-effective and environmentally responsible. For instance, suppliers in regions like the Alabama Black Belt, known for its dense pine forests, play a critical role in meeting the utility’s demand while supporting local economies.

Selecting local suppliers also allows Alabama Power to maintain tighter quality control over the wood poles it purchases. Timber from nearby sources is often better suited to the region’s climate and soil conditions, resulting in poles that are more durable and resistant to decay. Suppliers in states like Georgia, Mississippi, and Tennessee adhere to strict industry standards, such as those set by the American National Standards Institute (ANSI), ensuring that the poles meet or exceed safety and performance requirements. This localized focus reduces the risk of material defects and extends the lifespan of the poles, ultimately benefiting both the utility and its customers.

From a community perspective, Alabama Power’s partnership with local timber suppliers creates a ripple effect of economic benefits. These suppliers employ thousands of workers across the region, from loggers and mill operators to truck drivers and sales staff. By investing in these relationships, the utility helps sustain rural economies that might otherwise struggle in the face of declining manufacturing and agricultural sectors. For example, in towns like Demopolis, Alabama, timber-related industries account for a significant portion of local employment, making Alabama Power’s procurement decisions a vital lifeline for families and businesses.

Practical considerations for other utilities or organizations looking to emulate this model include conducting thorough supplier audits to ensure compliance with environmental and labor standards. Alabama Power’s success in this area highlights the importance of building long-term relationships with suppliers, as these partnerships foster trust and reliability. Additionally, utilities should prioritize suppliers who practice sustainable forestry, such as those certified by the Forest Stewardship Council (FSC), to further enhance their environmental credentials. By following these steps, companies can replicate Alabama Power’s approach, achieving both operational efficiency and community impact.

Where to Buy Crystalac Wood Grain Filler: Top Retailers Guide

You may want to see also

Explore related products

Sustainability Practices: Ensures wood poles are harvested from sustainably managed forests to minimize environmental impact

Alabama Power's commitment to sustainability is evident in its sourcing of wood poles, a critical component of its infrastructure. The company prioritizes purchasing poles from sustainably managed forests, ensuring that the environmental impact of its operations is minimized. This approach not only supports ecological balance but also aligns with global efforts to combat deforestation and promote responsible resource use. By partnering with certified suppliers, Alabama Power guarantees that the wood poles it uses are harvested in a manner that maintains biodiversity, protects water quality, and preserves soil health.

One key aspect of sustainable forest management is the adherence to certification standards such as those set by the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI). These certifications require foresters to implement practices like selective harvesting, where only mature trees are cut down, allowing younger trees to grow and maintain the forest’s ecological integrity. Alabama Power’s reliance on certified suppliers ensures that the wood poles it purchases contribute to the long-term health of forests rather than their depletion. This practice also supports local economies by promoting jobs in sustainable forestry.

To further reduce environmental impact, Alabama Power encourages the use of wood poles treated with eco-friendly preservatives. Traditional treatments often involve chemicals like pentachlorophenol, which can leach into the soil and water. However, modern alternatives, such as copper naphthenate or micronized copper azole, are less toxic and more durable. By specifying these treatments in their procurement process, Alabama Power ensures that its wood poles are both long-lasting and environmentally responsible. This dual focus on sustainability and functionality exemplifies a forward-thinking approach to utility management.

A comparative analysis reveals that sustainably sourced wood poles offer advantages beyond environmental benefits. For instance, wood from well-managed forests tends to be of higher quality, reducing the likelihood of premature pole failure and the need for frequent replacements. This not only lowers maintenance costs but also decreases the overall carbon footprint associated with pole production and transportation. Alabama Power’s investment in sustainable practices thus translates into operational efficiency and long-term cost savings, demonstrating that environmental stewardship and economic viability can go hand in hand.

Practical tips for utilities looking to emulate Alabama Power’s approach include conducting thorough supplier audits to verify sustainability certifications, investing in research on eco-friendly preservatives, and engaging with local communities to promote sustainable forestry practices. Additionally, utilities can explore partnerships with organizations like the Arbor Day Foundation or The Nature Conservancy to further their sustainability goals. By adopting these strategies, companies can ensure that their infrastructure needs are met without compromising the health of the planet. Alabama Power’s model serves as a blueprint for how utilities can responsibly source materials while contributing to a more sustainable future.

Best Places to Buy Wood Glue: Top Retailers and Online Stores

You may want to see also

Explore related products

Quality Standards: Poles must meet strict specifications for strength, durability, and treatment to withstand weather and wear

Alabama Power sources its wood poles from suppliers who adhere to stringent quality standards, ensuring these critical infrastructure components can withstand the test of time and nature. The selection process begins with identifying the right type of wood, typically Southern Yellow Pine or Douglas Fir, known for their natural strength and resilience. However, raw material alone isn’t enough; poles must undergo rigorous treatment to enhance durability. One common method is pressure treatment with preservatives like chromated copper arsenate (CCA) or creosote, which protect against decay, insects, and fungal growth. These treatments are applied under specific conditions—pressure levels of 100–150 psi and retention levels of 0.60–0.80 pounds per cubic foot—to ensure deep penetration and long-lasting protection.

Beyond treatment, the structural integrity of the poles is paramount. Alabama Power requires poles to meet or exceed standards set by organizations like the American National Standards Institute (ANSI) and the National Electrical Safety Code (NESC). For instance, a 40-foot pole must support a minimum bending strength of 3,000 pounds per square inch (psi) to handle wind loads, ice accumulation, and the weight of electrical equipment. Suppliers often conduct non-destructive testing, such as sonic resonance or electrical resistance measurements, to verify strength without damaging the wood. Poles that fail these tests are rejected, ensuring only the most robust materials are used.

Weather resistance is another critical factor. Alabama’s humid subtropical climate subjects poles to extreme conditions, from scorching summers to freezing winters and occasional hurricanes. To combat this, poles are often treated with water repellents and UV inhibitors to prevent moisture absorption and sun damage. Additionally, the taper and straightness of the pole are inspected to ensure stability and reduce the risk of cracking or splitting under stress. A pole with a defect as small as a 1-inch knot or a 2-inch crack can compromise its structural integrity, making meticulous quality control essential.

Finally, sustainability plays a role in Alabama Power’s sourcing decisions. While the focus is on durability, the company also prioritizes responsibly harvested wood, often certified by the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI). This ensures that the poles not only meet technical specifications but also align with environmental stewardship. By balancing strength, treatment, and sustainability, Alabama Power guarantees its wood poles are fit to support the state’s electrical grid for decades, even in the harshest conditions.

Eco-Friendly Marine Safe Wood Sealer: Top Buying Options and Tips

You may want to see also

Explore related products

Treatment Processes: Wood poles undergo creosote or CCA treatment to prevent decay and insect damage

Wood poles, essential for supporting power lines, face constant threats from decay and insect damage. To ensure longevity, these poles undergo specific treatment processes, primarily involving creosote or chromated copper arsenate (CCA). These treatments penetrate the wood, creating a barrier against environmental and biological threats. Understanding these processes reveals why they are critical for maintaining the integrity of Alabama Power’s infrastructure.

Creosote treatment, a time-tested method, involves immersing wood poles in a hot, viscous mixture of coal tar derivatives. This process forces the creosote deep into the wood fibers, protecting against fungi, termites, and other wood-destroying organisms. The application typically requires a retention level of 6 to 12 pounds of creosote per cubic foot of wood, depending on the pole’s intended use and exposure conditions. While effective, creosote’s strong odor and potential environmental concerns have led to increased scrutiny, prompting utilities to explore alternatives.

CCA treatment, on the other hand, uses a water-based solution containing copper, chromium, and arsenic to preserve wood. The process involves pressure-treating the poles to ensure the chemicals penetrate evenly, providing protection against decay and insects. CCA-treated poles are often preferred for their lower environmental impact compared to creosote, though proper handling and disposal remain crucial due to the arsenic content. Alabama Power likely balances these options based on cost, availability, and regulatory compliance.

Choosing between creosote and CCA involves weighing factors like durability, environmental impact, and cost. Creosote-treated poles can last 40 to 60 years, while CCA-treated poles typically endure 20 to 30 years. However, CCA’s reduced environmental footprint and easier application make it a competitive choice. Utilities must also consider local regulations, as some regions restrict or ban certain treatments. For Alabama Power, the decision likely hinges on long-term performance and sustainability goals.

Practical considerations for treated wood poles include proper installation and maintenance. Poles should be set at least 36 inches into the ground, with adequate backfill to prevent shifting. Regular inspections for cracks, splinters, or signs of insect activity are essential to catch issues early. Additionally, utilities must adhere to safety guidelines when handling treated wood, such as wearing protective gear and avoiding burning treated poles due to toxic fumes. By prioritizing these practices, Alabama Power ensures its wood poles remain reliable components of the state’s power grid.

Where to Buy Birch Wood in Boise, ID: Top Local Suppliers

You may want to see also

Explore related products

Logistics & Delivery: Suppliers coordinate transportation to ensure timely delivery to Alabama Power’s distribution centers

Alabama Power relies on a network of suppliers to source wood poles, and the logistics of transporting these bulky, heavy materials to distribution centers is a critical component of their supply chain. Suppliers must coordinate transportation meticulously to ensure timely delivery, as delays can disrupt maintenance and construction schedules. This involves selecting the right carriers, optimizing routes, and managing schedules to align with Alabama Power’s operational needs. For instance, during peak demand periods, such as after severe weather events, suppliers often prioritize expedited shipping to meet urgent requirements.

The transportation of wood poles presents unique challenges due to their size, weight, and fragility. Poles are typically 30 to 60 feet long and weigh several hundred pounds, requiring specialized equipment like flatbed trucks or trailers with secure tie-downs. Suppliers must also comply with Department of Transportation regulations regarding oversized loads, including obtaining permits and ensuring proper escort vehicles when necessary. Additionally, weather conditions and road infrastructure play a significant role in planning routes, as detours or delays can impact delivery timelines.

To streamline logistics, many suppliers use advanced tracking systems and real-time monitoring tools. These technologies allow Alabama Power to track shipments, anticipate delays, and adjust their inventory management accordingly. For example, GPS tracking provides visibility into the location of each shipment, while predictive analytics can flag potential disruptions, such as traffic congestion or adverse weather. This level of transparency ensures that Alabama Power can maintain a steady supply of wood poles for their distribution centers.

Collaboration between suppliers and Alabama Power is essential to optimize delivery schedules. Suppliers often work closely with Alabama Power’s procurement and logistics teams to align delivery timelines with project schedules. This coordination minimizes storage costs and reduces the risk of poles being damaged while in transit or storage. For instance, just-in-time delivery strategies are employed for time-sensitive projects, ensuring poles arrive precisely when needed without overburdening storage facilities.

Finally, sustainability considerations are increasingly influencing logistics decisions. Suppliers are exploring more fuel-efficient transportation methods and consolidating shipments to reduce carbon emissions. Alabama Power may also incentivize suppliers to use locally sourced poles, shortening transportation distances and supporting regional economies. By integrating these practices, suppliers not only ensure timely delivery but also contribute to Alabama Power’s broader sustainability goals.

Discover Oahu's Best Koa Wood Sources: A Buyer's Guide

You may want to see also

Frequently asked questions

Alabama Power sources its wood poles from a variety of suppliers, including domestic timber companies and manufacturers, primarily within the southeastern United States.

Yes, Alabama Power prioritizes locally harvested wood from sustainable forestry practices in Alabama and surrounding states to support regional economies and reduce transportation costs.

Yes, the wood poles Alabama Power purchases are treated with preservatives, such as creosote or copper-based solutions, to enhance durability and protect against decay, insects, and weather damage.

While Alabama Power primarily sources wood poles domestically, they may occasionally purchase from international suppliers if there are shortages or specific needs that cannot be met locally.