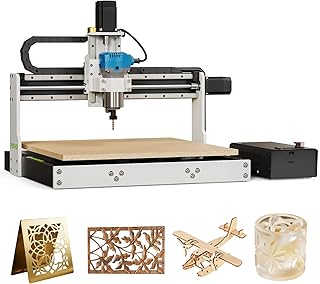

When considering where to buy a CNC wood machine, it’s essential to evaluate factors such as the machine’s quality, precision, and reliability, as well as the manufacturer’s reputation and after-sales support. Popular options include established brands like Boscaro, Biesse, and CNC Factory, which are known for their advanced technology and durability. Online platforms like Alibaba, Amazon, or specialized CNC machinery marketplaces offer a wide range of choices, often with competitive pricing. However, for personalized service and expert advice, local distributors or authorized dealers are highly recommended. Additionally, attending trade shows or industry exhibitions can provide hands-on experience and insights into the latest models. Ultimately, aligning your purchase with your specific needs, budget, and long-term goals will ensure the best investment.

Explore related products

What You'll Learn

Local vs. Online Purchase Options

Buying a CNC wood machine locally offers immediate advantages that online purchases can’t match. Walking into a physical store lets you inspect the machine firsthand, ensuring it meets your quality standards. Local dealers often provide hands-on demonstrations, allowing you to test the machine’s precision, speed, and ease of use. This tactile experience is invaluable, especially if you’re new to CNC technology. Additionally, local purchases typically come with quicker delivery times and lower shipping costs, as the machine doesn’t need to travel long distances. If you prioritize reliability and want to avoid the guesswork of online shopping, a local purchase is a solid choice.

However, online purchases open up a world of options that local stores may not offer. E-commerce platforms like Alibaba, Amazon, or specialized CNC retailers often feature a broader range of models, brands, and price points. You can compare specifications, read user reviews, and hunt for deals without leaving your desk. For instance, a mid-range CNC router that costs $5,000 locally might be available for $4,000 online, especially during sales events. Online retailers also frequently offer financing options, making high-ticket items more accessible. If variety and cost-efficiency are your priorities, online shopping is hard to beat.

One critical drawback of online purchases is the lack of personalized support. Local dealers often provide installation assistance, training, and ongoing maintenance services, which can be a lifesaver for beginners. Online purchases, on the other hand, may leave you to figure out assembly and troubleshooting on your own. For example, a local dealer might offer a free two-hour training session, while an online purchase could require you to rely on YouTube tutorials or paid consultations. If you’re not tech-savvy or prefer guided support, this could be a deal-breaker.

Ultimately, the decision between local and online purchases depends on your specific needs and circumstances. If you’re a hobbyist on a tight budget, the cost savings and variety of online options might outweigh the lack of hands-on support. Conversely, if you’re a professional woodworker who needs a reliable machine ASAP, the convenience and added services of a local purchase could justify the higher price. Consider your skill level, budget, and timeline before making a decision. For instance, if you’re willing to wait a few weeks for delivery, an online purchase could save you hundreds of dollars. But if you need the machine tomorrow, a local dealer might be your only option. Weigh the pros and cons carefully to ensure you get the best value for your investment.

Where to Find Wood Master 5500 Replacement Parts for Purchase

You may want to see also

Explore related products

New vs. Used CNC Machine Benefits

Buying a CNC wood machine is a significant investment, and the decision between new and used models hinges on your priorities. New machines offer cutting-edge technology, ensuring compatibility with the latest software and materials. They come with warranties, providing peace of mind and reducing downtime in case of malfunctions. For instance, a new CNC router might feature automatic tool changers or advanced dust collection systems, which can streamline production and improve workshop safety. However, this innovation comes at a premium, often costing 30-50% more than a comparable used machine.

Used CNC machines, on the other hand, provide a cost-effective entry point for hobbyists or small businesses. A well-maintained second-hand machine can deliver reliable performance at a fraction of the price. For example, a 5-year-old CNC engraver with a 4x8 foot bed might cost $10,000, compared to $25,000 for a new model. However, buyers must exercise caution. Inspect the machine for wear on critical components like spindle bearings or stepper motors, and verify its maintenance history. A machine with over 5,000 hours of runtime may require costly repairs, negating the initial savings.

The choice also depends on your production needs. If you’re running a high-volume operation, a new machine’s efficiency and reliability can justify the higher cost. For instance, a new CNC with a 20,000 RPM spindle can cut intricate designs faster and with greater precision than an older model. Conversely, a part-time woodworker might find a used machine sufficient for occasional projects, especially if they’re willing to invest time in maintenance and troubleshooting.

Finally, consider the resale value and upgrade potential. New machines depreciate quickly but retain value longer due to their longevity and relevance. Used machines, while cheaper upfront, may have limited resale appeal as technology advances. If you plan to upgrade in a few years, a new machine might offer better long-term value. Conversely, a used machine can serve as a low-risk trial run, helping you assess your needs before committing to a larger investment.

In summary, new CNC machines excel in performance, reliability, and support but demand a higher budget. Used machines offer affordability and accessibility but require careful evaluation and acceptance of potential limitations. Your decision should align with your budget, production scale, and long-term goals.

Best Wood Stud Finder: Top Picks for Accurate Wall Scanning

You may want to see also

Explore related products

Key Features to Look For

Precision and Accuracy: The Foundation of CNC Woodworking

A CNC wood machine’s primary purpose is to transform raw wood into precise, repeatable designs. Look for machines with high-resolution stepper or servo motors, as these directly impact cutting accuracy. A machine with a positioning accuracy of ±0.03 mm or better is ideal for intricate designs. Additionally, check the machine’s backlash compensation features, which minimize errors caused by mechanical play in the axes. Without these, even the most sophisticated designs will fall short of professional standards.

Build Quality and Durability: Longevity Matters

CNC machines are an investment, and their build quality determines how well they withstand the test of time. Opt for machines with robust frames made of steel or cast iron, as these materials resist vibration and warping under heavy use. Avoid aluminum frames unless portability is a priority. Inspect the spindle’s quality—a 1.5 kW to 3 kW spindle is suitable for most woodworking tasks, but ensure it’s water-cooled to prevent overheating during prolonged operation. A durable machine pays for itself by reducing downtime and maintenance costs.

Software Compatibility and Ease of Use: Bridging the Gap Between Idea and Execution

The machine’s software is its brain, and compatibility with industry-standard CAD/CAM programs like Fusion 360 or Vectric VCarve is non-negotiable. Look for machines that support G-code, the universal language of CNC machining. User-friendly interfaces and intuitive controls lower the learning curve, especially for beginners. Some machines even offer Wi-Fi connectivity for wireless file transfers, streamlining workflow. Without seamless software integration, even the most powerful hardware becomes cumbersome.

Work Area and Scalability: Matching Machine to Project

The size of the machine’s work area dictates the scale of projects you can undertake. For hobbyists, a 24” x 24” bed may suffice, but professionals should consider machines with beds of 48” x 48” or larger. Modular designs that allow for future upgrades—such as adding a rotary axis for cylindrical carving—ensure the machine grows with your ambitions. Always measure your workspace and compare it to the machine’s footprint, including clearance for dust collection systems.

Safety and Maintenance: Protecting Your Investment and Yourself

CNC machines are powerful tools that demand respect. Look for features like emergency stop buttons, enclosed designs to contain debris, and automatic tool changers that minimize manual intervention. Dust extraction ports are essential to prevent wood particles from damaging the machine’s internals. Regular maintenance, such as lubricating guide rails and checking belt tension, extends the machine’s lifespan. A machine with accessible components and clear maintenance guidelines saves time and frustration in the long run.

After-Sales Support and Community: Beyond the Purchase

A CNC machine is only as good as the support behind it. Prioritize brands with responsive customer service, comprehensive warranties, and active user communities. Forums, tutorials, and troubleshooting guides can be lifesavers when encountering issues. Some manufacturers offer training sessions or certification programs, which are invaluable for beginners. A strong support network turns a standalone machine into a gateway to a thriving woodworking community.

Where to Find Hinged Wooden Boxes for Purchase Online

You may want to see also

Explore related products

Budget-Friendly Brands and Models

For those seeking a CNC wood machine without breaking the bank, several brands and models stand out for their affordability and performance. SainSmart, for instance, offers the Genmitsu PROVerXL 4030, a machine that balances cost and functionality. Priced under $1,500, it’s ideal for hobbyists and small workshops, featuring a 400x300mm working area and a robust aluminum frame. Its GRBL control system ensures compatibility with popular software like LightBurn, making it user-friendly for beginners.

Another budget-friendly option is the JFT 3040T, a compact CNC router priced around $800. While its 300x400mm workspace is smaller, it’s perfect for intricate projects like signage or small furniture components. Its 800W spindle provides ample power for softwoods and plastics, though it may struggle with harder materials. This model is a great entry point for those testing the waters of CNC woodworking without a significant investment.

If you’re looking for a larger workspace on a budget, the Vevor 3040 is worth considering. At approximately $1,000, it offers a 300x400mm area and a 500W spindle, striking a balance between size and affordability. Its water-cooled system extends the spindle’s lifespan, and its offline controller allows operation without a computer. However, assembly can be time-consuming, so factor in a few hours for setup.

For those prioritizing precision over size, the Bob’s CNC Evolution 4 is a standout choice. Priced around $1,200, it boasts a 24”x24” working area and a rigid design that minimizes vibration. Its open-source firmware allows for customization, appealing to tech-savvy users. While it requires more technical know-how, its accuracy and build quality make it a favorite among DIY enthusiasts.

When selecting a budget CNC wood machine, consider your project needs, workspace size, and material compatibility. While cheaper models may lack advanced features, they offer excellent value for hobbyists and small-scale producers. Always check for community support and available upgrades, as these can extend the machine’s lifespan and functionality. With careful research, you can find a machine that fits your budget without compromising on quality.

Choosing the Perfect Wooden Shed: Top Types and Buying Tips

You may want to see also

Explore related products

Warranty and After-Sales Support Tips

A CNC wood machine is a significant investment, and its warranty and after-sales support can make or break your experience. Consider the warranty period, typically ranging from 1 to 3 years, and whether it covers parts, labor, or both. A comprehensive warranty should include on-site service, especially for heavy-duty machines, as transporting them for repairs can be costly and inconvenient. For instance, a 2-year warranty with on-site support for the first year and parts coverage for the second year is a common and reasonable offer.

When evaluating after-sales support, look for providers that offer 24/7 technical assistance, either via phone, email, or live chat. This is crucial for minimizing downtime, as CNC machines often operate around the clock in production environments. Additionally, inquire about the availability of replacement parts. A supplier with a well-stocked inventory of common components can reduce repair times from weeks to days. For example, a company that guarantees next-day shipping for essential parts like spindle motors or control boards can save you significant time and money.

Training and resources are another critical aspect of after-sales support. Opt for suppliers that provide hands-on training sessions, either on-site or at their facility, to ensure your team can operate the machine efficiently. Online tutorials, user manuals, and access to a community forum can also be invaluable for troubleshooting and learning advanced techniques. A supplier that invests in your success through education demonstrates long-term commitment to their customers.

Finally, read customer reviews and case studies to gauge the reliability of a supplier’s warranty and support claims. Pay attention to how companies handle issues like machine malfunctions or delayed part deliveries. For instance, a supplier that proactively communicates updates and offers temporary solutions during repairs shows a customer-centric approach. Conversely, recurring complaints about unresponsive support or voided warranties due to minor technicalities should raise red flags. Prioritize suppliers with a proven track record of standing by their products and customers.

Where to Buy Quality Wooden Coat Hangers in Johannesburg

You may want to see also

Frequently asked questions

Consider the machine's size, precision, power, software compatibility, and your budget. Also, evaluate your specific woodworking needs, such as the type of projects you'll undertake and the materials you'll use.

Both options have pros and cons. Local dealers offer hands-on support, demonstrations, and faster service, while online purchases may provide more competitive pricing and a wider selection. Choose based on your priority for convenience, cost, or support.

Yes, reputable brands include ShopBot, CNC Router Parts, and Stepcraft for hobbyists, while industrial users might consider Biesse, Thermwood, or MultiCam. Research reviews and compare features to find the best fit.

After-sales support is crucial, especially for beginners. Look for sellers or manufacturers that offer training, technical support, warranty, and easy access to replacement parts to ensure smooth operation and longevity of your machine.

If budget is a concern, a used machine can be cost-effective, but ensure it’s in good condition and compatible with your needs. New machines offer the latest features, warranties, and reliability, making them a better long-term investment for serious users.