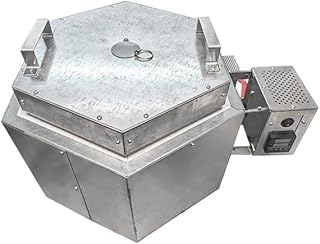

When considering where to buy a wood kiln, it’s essential to evaluate both online and local options to find the best fit for your needs. Online retailers like Amazon, eBay, and specialty woodworking or pottery supply websites often offer a wide range of models, from small portable kilns to large industrial units, with detailed specifications and customer reviews to guide your decision. Local suppliers, such as woodworking stores or pottery studios, can provide hands-on advice and may offer custom-built kilns tailored to your specific requirements. Additionally, exploring secondhand markets like Craigslist, Facebook Marketplace, or woodworking forums can yield affordable, pre-owned options. Always consider factors like kiln size, fuel efficiency, and warranty when making your purchase.

Explore related products

$52.99 $69.99

What You'll Learn

Local suppliers and dealers

Supporting local businesses when purchasing a wood kiln offers distinct advantages, from personalized service to reduced shipping costs. Start by identifying regional manufacturers or dealers through online directories like Thomasnet or industry-specific platforms such as the Ceramic Arts Network. Many local suppliers specialize in custom builds, allowing you to tailor kiln size, heating efficiency, or fuel systems to your specific needs. For instance, a small-scale pottery studio might opt for a top-loading kiln with a 20-cubic-foot capacity, while a larger operation could benefit from a front-loading model with automated temperature controls.

Visiting a local dealer’s showroom provides a hands-on experience that online shopping cannot replicate. You can inspect build quality, test door mechanisms, and discuss insulation materials like ceramic fiber or firebrick. Dealers often offer installation services, ensuring your kiln meets safety standards and integrates seamlessly with your workspace. For example, a dealer might recommend a venting system with a heat-resistant chimney kit, priced around $300–$500, to comply with local fire codes. This level of expertise is invaluable, particularly for first-time buyers.

Price comparisons between local and national suppliers reveal surprising parity, especially when factoring in shipping and handling fees for heavy equipment. Local dealers frequently offer bundled deals, such as a kiln, kiln shelves, and pyrometers, at a 10–15% discount. Additionally, building a relationship with a nearby supplier can lead to priority service for repairs or upgrades. For instance, a local dealer might provide expedited replacement parts, minimizing downtime during peak production periods.

Finally, consider the environmental impact of your purchase. Local suppliers often source materials regionally, reducing the carbon footprint associated with long-distance transportation. Some dealers even offer kilns with eco-friendly features, such as waste heat recovery systems or solar-assisted preheating. By choosing a local provider, you not only support your community but also align your purchase with sustainable practices. This dual benefit makes local suppliers a compelling choice for both practical and ethical reasons.

Discover Visalia's Best Spots to Buy Live Edge Wood Today

You may want to see also

Explore related products

Online marketplaces for wood kilns

Online marketplaces have revolutionized the way artisans and hobbyists source specialized equipment like wood kilns. Platforms such as eBay and Etsy offer a wide range of options, from pre-owned models at discounted prices to custom-built kilns crafted by independent makers. These sites often include detailed seller reviews and product ratings, helping buyers make informed decisions. For instance, eBay’s auction format can yield significant savings, while Etsy’s focus on handmade and unique items ensures access to one-of-a-kind designs. However, buyers should verify shipping costs and return policies, as large items like kilns may incur substantial fees.

For those seeking new, commercially manufactured wood kilns, Amazon and Specialty Equipment Direct (SED) are go-to destinations. Amazon’s vast inventory includes brands like Olympic Kilns and Jen-Ken, with detailed product descriptions and user reviews to guide purchases. SED, on the other hand, specializes in industrial and craft equipment, offering expert advice and warranties that provide added peace of mind. Both platforms often feature competitive pricing and financing options, making high-quality kilns more accessible. A practical tip: filter search results by customer ratings and price range to quickly narrow down options.

Niche marketplaces like Woodcraft and Sheffield Pottery cater specifically to woodworking and ceramic enthusiasts, offering wood kilns alongside complementary tools and materials. Woodcraft, for example, provides kits for DIY kiln construction, ideal for those who prefer a hands-on approach. Sheffield Pottery focuses on ceramic kilns but often includes wood-fired models suitable for multi-purpose use. These specialized sites excel in product knowledge, offering detailed guides and customer support tailored to the craft. Caution: verify compatibility with your intended use, as some models may be optimized for specific applications.

Social media platforms like Facebook Marketplace and Craigslist can be treasure troves for local deals on wood kilns. These sites allow buyers to inspect items in person and negotiate prices directly with sellers, reducing shipping costs and risks. However, transactions lack the protections of established marketplaces, so it’s essential to meet in safe, public locations and thoroughly inspect the kiln before purchasing. Pro tip: join woodworking or pottery groups on Facebook to access community listings and advice from fellow enthusiasts.

In conclusion, online marketplaces offer diverse options for purchasing wood kilns, each with unique advantages. General platforms like eBay and Amazon provide convenience and variety, while niche sites like Woodcraft and Sheffield Pottery offer specialized expertise. Local marketplaces such as Facebook Marketplace and Craigslist are ideal for budget-conscious buyers willing to invest time in research and negotiation. By understanding the strengths and limitations of each platform, buyers can confidently select the best source for their needs.

Where to Buy Snuggle Pink Peony & Rose Wood: Top Retailers

You may want to see also

Explore related products

Second-hand or used options

The market for second-hand wood kilns is a treasure trove for those willing to dig. Online platforms like eBay, Craigslist, and specialized pottery forums often list pre-owned models at a fraction of the cost of new ones. These listings can range from small, hobbyist-sized kilns to industrial units, depending on your needs. However, buyer beware: always request detailed photos and maintenance records to assess the kiln’s condition. A well-maintained used kiln can offer years of service, but neglect can lead to costly repairs.

Analyzing the pros and cons reveals a clear trade-off. On the positive side, second-hand kilns are budget-friendly, often priced 30–50% below retail. They also come with a history, which can be an advantage if the previous owner upgraded components like burners or insulation. On the downside, older models may lack energy efficiency or safety features found in newer designs. Additionally, shipping or transporting a kiln can be expensive and logistically challenging, especially for larger units.

For those considering this route, a step-by-step approach ensures a smart purchase. Start by defining your kiln size and fuel type (e.g., gas, wood, or hybrid). Research brands known for durability, such as L&L or Skutt, even if you’re buying used. Next, inspect the kiln in person if possible, checking for cracks, rust, or worn parts. If buying remotely, request a video call to see the kiln in operation. Finally, negotiate the price based on its condition and factor in potential repair costs.

A comparative look at used versus new kilns highlights why second-hand options are appealing. While a new kiln guarantees the latest technology and a warranty, it comes with a premium price tag. A used kiln, however, allows you to enter the craft with lower financial risk, making it ideal for beginners or those testing the waters. For instance, a used 8-cubic-foot wood kiln might cost $2,000–$3,000, compared to $6,000–$8,000 new, freeing up funds for tools or materials.

Descriptively, imagine finding a 1990s-era wood kiln with a brick interior and a patina of use—a testament to its durability. Such a kiln might bear the marks of countless firings but still radiate heat evenly, its steel frame sturdy despite the years. This isn’t just a tool; it’s a piece of history, ready to serve another generation of artisans. With proper care, it could become the heart of your studio, blending nostalgia with functionality.

Where to Buy Rainbow Eucalyptus Wood: A Colorful Lumber Guide

You may want to see also

Explore related products

Custom kiln manufacturers

When engaging a custom kiln manufacturer, it’s crucial to define your needs clearly. Start by outlining the intended use—whether for ceramics, lumber drying, or heat-treating metals. Provide detailed specifications, such as desired temperature range (e.g., 1800°F to 2350°F for high-fire ceramics), chamber size, and fuel type (wood, gas, or electric). Manufacturers often request sketches or CAD files to visualize the design. Be prepared to discuss budget constraints, as custom kilns can range from $5,000 to $50,000 depending on complexity. A reputable manufacturer will guide you through material choices, such as refractory brick or ceramic fiber insulation, balancing durability with cost.

One of the standout advantages of custom kilns is their adaptability to unique environments. For example, a kiln designed for outdoor use might feature weather-resistant coatings and reinforced structures to withstand temperature fluctuations. Conversely, an indoor kiln could incorporate advanced ventilation systems to meet safety codes. Manufacturers like Jen-Ken Kilns often include smart technology, such as programmable controllers and Wi-Fi connectivity, enabling remote monitoring and precise firing schedules. This level of customization not only enhances efficiency but also extends the kiln’s lifespan, making it a worthwhile investment for professionals.

However, working with custom kiln manufacturers requires patience and collaboration. The process typically involves multiple consultations, design revisions, and a production timeline of 8 to 12 weeks. Clients should ask for prototypes or simulations to ensure the kiln meets expectations before final assembly. Additionally, inquire about warranties and after-sales support, as custom kilns may require specialized maintenance. While the initial cost is higher than pre-built models, the long-term benefits—such as reduced energy consumption and tailored functionality—often outweigh the expense. For those committed to their craft, a custom kiln is not just a tool but a cornerstone of their artistic or industrial practice.

Where to Buy Mesquite Wood in Tucson: Top Local Sources

You may want to see also

Explore related products

DIY kiln building materials

Building a wood kiln yourself requires careful selection of materials to ensure durability, efficiency, and safety. Start with firebricks, the backbone of your kiln’s structure. These refractory bricks withstand extreme temperatures (up to 3000°F) and are available at masonry supply stores or online retailers like Amazon and Grainger. A standard kiln will need approximately 300–500 bricks, depending on size, so calculate your needs based on the kiln’s dimensions. Avoid using regular clay bricks, as they’ll crack under high heat.

Next, consider insulation materials to retain heat and reduce fuel consumption. Ceramic fiber blankets or boards, such as those from brands like Kaowool, are lightweight and easy to install. These can be purchased from ceramic supply stores or specialty retailers like Sheffield Pottery. For a budget-friendly option, perlite or vermiculite mixed with cement works well but requires more labor. Ensure the insulation is at least 2–3 inches thick for optimal efficiency.

The metal framework provides structural support and is crucial for larger kilns. Mild steel or stainless steel is ideal due to its heat resistance. Local metal suppliers or online platforms like Online Metals offer pre-cut sheets or custom orders. Welding skills or a professional welder are necessary to assemble the frame securely. Coat the metal with high-temperature paint to prevent rust and extend its lifespan.

For the kiln doors and vents, use sheet metal or cast iron, ensuring they fit tightly to control airflow. Hinges and handles should be made of heat-resistant materials like brass or stainless steel. Hardware stores or online vendors like McMaster-Carr carry these components. Add a gasket made of ceramic fiber rope to seal the door effectively, preventing heat loss.

Finally, thermocouples and controllers are essential for monitoring and regulating temperature. Brands like Omega Engineering offer reliable thermocouples and PID controllers suitable for DIY kilns. These tools ensure precise firing schedules, critical for achieving desired wood-firing effects. Pair them with a small fan or vent system to manage airflow during firing. With these materials, your DIY wood kiln will be functional, efficient, and ready for creative experimentation.

Ultimate Guide to Buying Koa Wood: Tips, Sources, and Quality Checks

You may want to see also

Frequently asked questions

The best places to buy a wood kiln include specialty woodworking supply stores, online retailers like Amazon or eBay, and directly from kiln manufacturers such as L&L Kiln, Olympic Kilns, or Jen-Ken Kilns.

You can often find wood kilns at local woodworking or pottery supply stores. However, buying online provides a wider selection and the ability to compare prices and features from different manufacturers.

Yes, second-hand wood kilns can be found on platforms like Craigslist, Facebook Marketplace, or specialized woodworking forums. Ensure to inspect the kiln thoroughly or have it checked by a professional before purchasing.

Consider the kiln’s size, firing capacity, fuel efficiency, and warranty. Research reviews, compare prices, and check if the manufacturer offers customer support or installation services.