When considering where to buy a wood CNC machine, it’s essential to evaluate both online and offline options to find the best fit for your needs and budget. Online platforms like Amazon, eBay, and Alibaba offer a wide range of models, from entry-level machines for hobbyists to industrial-grade equipment for professionals, often with detailed reviews and competitive pricing. Specialized retailers such as CNC Router Parts, Camaster, and ShopSabre provide expert advice and customized solutions, ensuring you get a machine tailored to your woodworking projects. Local machinery dealerships and trade shows are also valuable resources, allowing you to see the machines in person, test their capabilities, and negotiate deals. Additionally, second-hand markets like Craigslist or Facebook Marketplace can offer cost-effective options, though thorough inspection and research are crucial to avoid purchasing a machine in poor condition. Ultimately, the choice depends on your specific requirements, budget, and preference for hands-on support or convenience.

Explore related products

What You'll Learn

Local suppliers and dealers

When selecting a local supplier, consider their reputation and expertise. Established dealers typically have a track record of customer satisfaction and can offer insights into the best machines for your budget and skill level. Look for suppliers who specialize in woodworking tools, as they’re more likely to carry a curated selection of CNC machines tailored to this niche. Additionally, inquire about after-sales support, such as maintenance services, spare parts availability, and training programs, which can significantly extend the life of your investment.

One practical tip is to compare prices and warranties from multiple local dealers before making a decision. While some suppliers may offer competitive pricing, others might bundle additional benefits like free delivery, installation, or extended warranties. Don’t hesitate to negotiate, especially if you’re purchasing a high-end model or buying multiple machines. Local dealers often have more flexibility in pricing compared to large online retailers, making it worth your while to haggle for a better deal.

Finally, leverage local networks to find hidden gems. Join woodworking forums, attend trade shows, or visit community workshops where CNC machines are in use. Fellow woodworkers can provide firsthand recommendations on reliable suppliers and share their experiences with specific models. This grassroots approach not only helps you find a trustworthy dealer but also connects you with a community that can support your CNC journey long after the purchase.

Where to Buy Simple Wood TBC: Top Retailers and Online Sources

You may want to see also

Explore related products

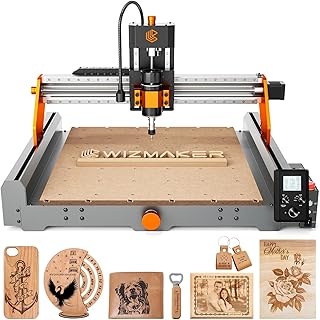

Online marketplaces for CNC machines

Online marketplaces have revolutionized the way woodworkers and hobbyists access CNC machines, offering a vast array of options from entry-level to industrial-grade models. Platforms like Amazon and eBay dominate the space, providing both new and used machines with detailed specifications, user reviews, and competitive pricing. For instance, Amazon’s product pages often include videos demonstrating machine capabilities, while eBay’s auction format allows buyers to snag deals on pre-owned equipment. However, these general marketplaces lack specialized support, so buyers must rely on their own research to ensure compatibility with woodworking needs.

Specialized platforms like CNC Router Parts and Sainsmart cater specifically to CNC enthusiasts, offering curated selections of machines tailored for wood carving, engraving, and cutting. These sites often include detailed guides, compatibility charts, and customer support from experts in the field. For example, CNC Router Parts provides customizable kits for those who want to build or upgrade their machines, while Sainsmart bundles software and accessories with their CNC routers, making them ideal for beginners. Such niche marketplaces bridge the gap between general e-commerce sites and manufacturer-direct purchases.

For those seeking high-end or industrial CNC machines, Alibaba and AliExpress connect buyers directly with manufacturers, often at wholesale prices. These platforms are particularly useful for small businesses or workshops looking to invest in robust, large-format CNC routers for heavy-duty woodworking. However, buyers must exercise caution: international shipping costs, customs fees, and potential language barriers can complicate transactions. Additionally, verifying the manufacturer’s reputation and requesting samples or detailed specifications is crucial to avoid subpar equipment.

A lesser-known but valuable resource is Facebook Marketplace and Craigslist, where local sellers often list used CNC machines at significantly lower prices. This option is ideal for buyers who prefer to inspect the machine in person before purchasing. However, it requires patience and persistence, as listings are sporadic and vary by location. Joining woodworking or CNC-specific groups on Facebook can also yield leads, as members often share recommendations or sell their own equipment.

In conclusion, online marketplaces offer diverse pathways to purchasing a wood CNC machine, each with its own advantages and challenges. General platforms provide convenience and variety, specialized sites offer expertise and tailored solutions, international marketplaces deliver affordability at the cost of complexity, and local listings prioritize inspection and immediate availability. By understanding these nuances, buyers can navigate the digital landscape effectively and find the machine that best suits their woodworking goals.

The World's Priciest Timbers: Unveiling the Most Expensive Woods to Buy

You may want to see also

Explore related products

Manufacturer direct purchases

Buying a wood CNC machine directly from the manufacturer can significantly reduce costs by eliminating middlemen markups. This approach often allows for customization, as manufacturers can tailor the machine to your specific needs—whether it’s adjusting the work area size, spindle power, or adding advanced features like automatic tool changers. For instance, companies like BobsCNC and Stepcraft offer direct-to-consumer models with options to upgrade components like the Z-axis or control software. However, this route requires thorough research to ensure the manufacturer is reputable and offers reliable post-purchase support.

One of the key advantages of manufacturer direct purchases is the ability to negotiate terms, especially for bulk orders or specialized configurations. Manufacturers often provide discounts for direct buyers, particularly if you’re purchasing multiple units or committing to long-term partnerships. For example, OMTECH and Jinan Senke are known for offering competitive pricing and flexible payment plans for direct buyers. To maximize savings, request detailed quotes from multiple manufacturers and compare not just the price, but also warranty terms, delivery timelines, and included accessories like dust collection systems or tool kits.

While cost savings are appealing, direct purchases come with risks that require careful navigation. Manufacturers may prioritize production over customer support, leaving buyers to troubleshoot issues independently. To mitigate this, verify the manufacturer’s after-sales service policies, including response times, technical support availability, and the process for handling repairs or replacements. Additionally, check for certifications like CE or ISO, which indicate compliance with safety and quality standards. For instance, CNC Router Machine and Woodpecker CNC are manufacturers that provide comprehensive documentation and video tutorials to assist direct buyers.

Finally, consider the long-term value of a direct purchase. Manufacturers often offer exclusive upgrades, software updates, and access to community forums or training resources. These perks can enhance the machine’s functionality and extend its lifespan. For example, Onefinity provides direct buyers with access to its user community and firmware updates, ensuring the machine remains cutting-edge. By weighing these benefits against the initial investment, you can determine if a manufacturer direct purchase aligns with your woodworking goals and budget.

Where to Buy Wood Bleach in Australia: Top Retailers and Tips

You may want to see also

Explore related products

Second-hand and used options

The second-hand market for wood CNC machines offers a cost-effective entry point for hobbyists and small businesses. Platforms like eBay, Craigslist, and Facebook Marketplace are treasure troves for used machinery, often featuring models from reputable brands like ShopBot, CNC Shark, or Stepcraft. When browsing, filter listings by location to minimize shipping costs and inspect the machine in person if possible. Look for signs of wear, such as rust on the rails or excessive play in the spindle, which could indicate maintenance issues.

Analyzing the value of a used CNC machine requires a balance between price and condition. A machine priced at 50-70% of its original cost is often a fair deal, but factor in potential repair expenses. For instance, replacing a worn-out spindle can cost $500-$1,500, while new stepper motors might run $200-$400 each. Request maintenance records and ask about usage history—a machine used lightly in a home workshop will likely outlast one from a high-volume production environment.

Persuasive arguments for buying used include the environmental benefits of extending a machine’s lifespan and the opportunity to upgrade components incrementally. For example, a used CNC router with a 2.2 kW spindle can be enhanced with a dust collection system or a rotary axis for under $1,000, tailoring it to specific woodworking needs. However, avoid machines with proprietary software or discontinued parts, as these can become costly to maintain in the long run.

Comparing second-hand options to new machines highlights trade-offs. While a new CNC router from brands like Onefinity or X-Carve offers warranties and modern features, a used industrial-grade machine like a Laguna SmartShop might provide superior build quality and precision at a similar price point. Consider your project scale: a 4’x4’ used machine is ideal for furniture making, while a smaller 2’x3’ model suits intricate carvings or signage.

Descriptive details can help buyers visualize their purchase. Imagine a used CNC machine with a cast iron frame, its surface etched with the patina of years of service, yet still humming smoothly under power. Check for upgrades like hybrid ceramic bearings or a water-cooled spindle, which add value. Always test the machine’s accuracy by running a simple cutting pattern—a deviation of more than 0.005 inches could signal alignment issues. With careful selection, a second-hand CNC machine can deliver professional results without breaking the bank.

Best Places to Purchase Durable Wooden Sawhorses for Your Workshop

You may want to see also

Explore related products

Specialty woodworking stores

When visiting a specialty store, take advantage of the expertise of the staff. These professionals often have hands-on experience with the machines they sell and can provide personalized recommendations based on your skill level, project needs, and budget. For example, if you’re a beginner, they might suggest a desktop CNC machine like the CarveKing, which is compact and user-friendly. Conversely, if you’re running a small business, they could guide you toward a larger, industrial-grade model like the Laguna SmartShop. This level of guidance is invaluable, especially when navigating the technical specifications of CNC machines.

One of the key advantages of specialty woodworking stores is their focus on after-sales support. Many offer training sessions, workshops, or online resources to help you master your new machine. For instance, some stores partner with CNC manufacturers to provide certification courses or troubleshooting guides. Additionally, these stores often stock replacement parts and accessories, ensuring you can maintain your machine without lengthy delays. This comprehensive support system is particularly beneficial for those new to CNC technology, as it minimizes downtime and maximizes productivity.

While specialty stores may have higher price points compared to online retailers, the value lies in the quality and service they provide. Many offer financing options or package deals that include essential accessories like dust collection systems or tool kits, making the investment more manageable. Furthermore, the ability to see and test the machines in person can prevent costly mistakes. For example, you can assess the machine’s build quality, noise level, and ease of use before committing, ensuring it aligns with your workspace and workflow requirements.

In conclusion, specialty woodworking stores are unparalleled resources for purchasing wood CNC machines, offering expertise, support, and a carefully curated selection. By leveraging their knowledge and services, you can make an informed decision that meets your specific woodworking needs. Whether you’re crafting custom furniture or producing intricate designs, these stores provide the tools and guidance to elevate your projects to the next level.

Best Places to Buy High-Quality Teak Wood Rocking Chairs

You may want to see also

Frequently asked questions

Popular online platforms for purchasing wood CNC machines include Amazon, eBay, Alibaba, and specialized CNC retailers like CNC Router Parts, CNC Factory, and Full Spectrum Laser.

Yes, many local woodworking supply stores, industrial machinery dealerships, and authorized distributors of brands like ShopBot, Laguna Tools, or Next Wave Automation offer wood CNC machines for purchase.

Consider the seller’s reputation, warranty options, after-sales support, machine specifications, and customer reviews. Ensure the seller provides training, maintenance services, and spare parts availability.