When looking to buy wood for CNC projects, it's essential to consider both the type of wood and the supplier to ensure quality and compatibility with your machine. Hardwoods like maple, oak, and birch are popular choices due to their durability and smooth finish, while softer woods like pine or MDF are cost-effective for prototyping. Specialty woods such as walnut or cherry can elevate the aesthetic appeal of your project. Reliable sources for purchasing wood include local lumberyards, which often offer a wide selection and expert advice, and online retailers like Amazon, Rockler, or Woodcraft, which provide convenience and a variety of options. Additionally, CNC-specific suppliers often carry pre-cut sheets optimized for machining, saving time and reducing waste. Always check for flatness, moisture content, and any defects to ensure the wood meets your CNC requirements.

| Characteristics | Values |

|---|---|

| Online Retailers | Woodcraft, Rockler, Amazon, eBay, CNC Router Parts, Inventables |

| Specialty Wood Suppliers | Hearne Hardwoods, Woodworkers Source, The Wood Database, Exotic Lumber |

| Local Options | Home Depot, Lowe's, Local lumberyards, Woodworking stores |

| Types of Wood Available | Plywood, MDF, Hardwoods (e.g., oak, maple, walnut), Softwoods (e.g., pine) |

| Sheet Sizes | Standard (4'x8'), Custom sizes available |

| Thickness Options | 1/4", 1/2", 3/4", 1", Custom thicknesses |

| Quality Grades | Furniture grade, Cabinet grade, CNC-specific grade |

| Pricing | Varies by type, quality, and supplier; generally $10-$50 per sheet |

| Shipping Options | Standard shipping, Expedited shipping, Local pickup |

| Bulk Discounts | Available from some suppliers for large orders |

| Customer Support | Varies; some offer CNC-specific advice and material recommendations |

| Return Policy | Varies by supplier; typically 30-day return window |

| Sustainability Options | FSC-certified wood available from select suppliers |

| Additional Services | Cutting to size, Pre-sanding, Custom milling |

Explore related products

What You'll Learn

Local lumber yards

When visiting a local lumber yard, start by asking the staff about their CNC-friendly options. Many yards stock hardwoods like oak, walnut, and cherry, which are popular for their strength and finish. Softwoods such as pine or poplar are also available and are excellent for prototyping due to their lower cost and ease of machining. Pro tip: Bring your CNC project plans or dimensions to ensure you purchase the right thickness and length, as lumber yards often sell wood in standard sizes that may require minimal cutting.

One of the standout advantages of local lumber yards is the ability to handpick your wood. Unlike online orders, where you’re at the mercy of the supplier’s selection, you can inspect each board for knots, grain patterns, and moisture content. Aim for wood with straight, consistent grain and minimal defects, as these factors significantly impact CNC performance. For example, a board with tight, even grain will yield smoother cuts and reduce the risk of tool breakage.

However, there are a few cautions to keep in mind. Lumber yards may not always have the same level of organization or labeling as larger retailers, so be prepared to spend time browsing or asking for assistance. Additionally, prices can vary widely depending on the rarity of the wood and market demand. To save money, consider purchasing rough-cut lumber, which is less expensive than pre-planed boards and can be surfaced at home or with your CNC machine if it has the capability.

In conclusion, local lumber yards offer a hands-on, personalized experience that online retailers can’t match. By leveraging their regional expertise, diverse inventory, and the ability to select your own materials, you can secure high-quality wood tailored to your CNC projects. While it may require more effort than a quick online order, the results—in terms of both craftsmanship and satisfaction—are well worth it.

Best Places to Purchase Beveled Wood Siding for Your Home

You may want to see also

Explore related products

Online wood suppliers

When selecting an online supplier, consider factors like shipping costs, lead times, and return policies. Some suppliers, like Hardwood World, offer flat-rate shipping for large orders, which can significantly reduce expenses for bulk purchases. Others, such as The Wood Database, provide educational resources alongside sales, helping beginners understand wood properties like hardness (measured on the Janka scale) and workability. For example, walnut scores around 1,010 lbf on the Janka scale, making it durable yet easy to machine, while balsa wood, with a score of 100 lbf, is ideal for lightweight projects but requires careful handling.

A lesser-known but valuable resource is eBay, where small-scale sellers and woodworkers often list exotic or reclaimed woods at lower prices. However, exercise caution when buying from individual sellers—verify the wood’s condition, moisture content (ideally 6-8% for CNC work), and authenticity. For instance, reclaimed barn wood can add unique character to projects but may contain hidden nails or uneven surfaces requiring extra prep work. Always request high-resolution photos or samples if possible.

For those prioritizing sustainability, suppliers like Woodworkers Source and Hearne Hardwoods specialize in FSC-certified or domestically sourced woods. These options ensure your CNC projects align with eco-friendly practices without compromising quality. For example, FSC-certified maple offers the same tight grain and machinability as non-certified varieties but supports responsible forestry. While prices may be slightly higher, the environmental benefits and peace of mind are often worth the investment.

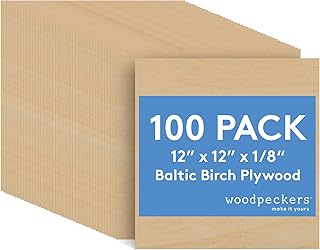

Finally, leverage customer reviews and community forums to gauge supplier reliability. Websites like CNCZone and Reddit’s r/CNC frequently discuss experiences with online wood suppliers, highlighting hidden gems like Woodpeckers Crafts, known for their precision-cut sheets, or Craftsman Industry, praised for their fast shipping and customer service. By combining research with practical insights, you can confidently choose an online supplier that meets your CNC wood needs, whether you’re crafting intricate designs or prototyping functional parts.

Are Classic Wooden Boats Still Available for Purchase Today?

You may want to see also

Explore related products

Specialty CNC wood stores

When selecting a specialty CNC wood store, consider their ability to provide detailed material specifications. Reputable stores will list moisture content (typically 8-10% for CNC work), grain orientation, and surface finish. Some even offer pre-treated or coated woods, like UV-cured MDF, to reduce tool wear and improve cutting efficiency. For example, a store might recommend using hardwoods with a Janka hardness rating below 1500 for intricate designs, as these are easier on CNC bits while still providing durability.

Another advantage of specialty stores is their focus on customer education and support. Many provide guides or workshops on material selection, toolpath optimization, and post-processing techniques. For beginners, this can be invaluable. For instance, a store might advise starting with 3mm birch plywood for prototyping due to its affordability and ease of use, then graduating to 18mm walnut for final pieces. They may also offer custom cutting services, allowing you to order wood pre-cut to specific dimensions, saving time and reducing waste.

Price and availability are critical factors when choosing a specialty CNC wood store. While these stores often charge a premium for their specialized inventory, the cost can be justified by the time and material savings they offer. For example, purchasing a high-quality, void-free sheet of Baltic birch from a specialty store might cost $50, compared to $30 at a big-box retailer, but the reduced risk of tool breakage and rework can offset the difference. Additionally, many specialty stores offer bulk discounts or subscription models for frequent buyers, making them cost-effective for regular CNC users.

Finally, consider the sustainability practices of specialty CNC wood stores. Many prioritize responsibly sourced materials, offering FSC-certified or domestically harvested woods. Some even stock reclaimed or recycled options, such as repurposed hardwoods or composite materials. For environmentally conscious makers, this alignment of values can be a deciding factor. For example, a store might highlight their partnership with local sawmills to provide kiln-dried, regionally sourced maple, reducing the carbon footprint of your projects while ensuring top-tier quality.

Best Places to Buy High-Quality Poplar Wood Planks Online & Locally

You may want to see also

Explore related products

Hardware store options

Hardware stores are a go-to resource for CNC enthusiasts seeking wood, offering a blend of convenience and variety. Most major chains like Home Depot, Lowe’s, and Ace Hardware stock common CNC-friendly woods such as birch plywood, MDF, and pine. These materials are typically pre-cut into standard sizes (e.g., 4’x8’ sheets) and thicknesses (¼”, ½”, ¾”), making them easy to transport and use directly in your machine. While selection may vary by location, these stores often carry hardwoods like maple or oak in smaller quantities, ideal for intricate projects. Pro tip: Check the lumber’s straightness and flatness in-store, as warped pieces can cause CNC routing issues.

For those prioritizing affordability and accessibility, hardware stores excel in providing budget-friendly options. MDF, for instance, is a staple for CNC prototyping due to its low cost ($10–$20 per sheet) and smooth finish, though it’s less durable than hardwoods. Pine is another economical choice, often priced at $5–$10 per board foot, and works well for less demanding projects. However, be cautious of knots and grain inconsistencies, which can lead to tool breakage or uneven cuts. If you’re new to CNC work, start with these materials to refine your techniques before investing in pricier woods.

One often-overlooked advantage of hardware stores is their ability to special-order materials not available in-store. If your local branch lacks the specific hardwood or sheet size you need, inquire about ordering through their network. For example, Home Depot can source exotic woods like walnut or cherry through their Pro Desk, though lead times may range from 1–3 weeks. This service bridges the gap between off-the-shelf convenience and specialized suppliers, making hardware stores a versatile option for CNC users with diverse project needs.

Despite their strengths, hardware stores have limitations that CNC users should consider. The wood available is often treated for general construction rather than precision machining, meaning surfaces may require sanding or flattening before use. Additionally, exotic or rare woods are rarely stocked, pushing enthusiasts toward specialty suppliers. For best results, pair hardware store purchases with a surface mapping technique on your CNC to account for minor imperfections. This hybrid approach maximizes the benefits of accessibility while minimizing drawbacks.

Where to Find and Buy a Wooden Lil Slugger Bat

You may want to see also

Explore related products

Salvaged or reclaimed wood sources

Salvaged or reclaimed wood offers a sustainable and character-rich alternative for CNC projects, blending environmental responsibility with unique aesthetic appeal. Sourcing this material requires a strategic approach, as it’s often found in unconventional places. Start by exploring local demolition sites, where old barns, warehouses, or homes are being dismantled. Contractors or site managers may allow you to purchase or even take discarded wood, provided you ask permission and ensure safety. Always inspect the wood for nails, rot, or excessive warping, as these can damage CNC tools or compromise project quality.

For a more curated selection, visit reclaimed wood suppliers or specialty lumberyards that focus on sustainable materials. These vendors often clean, mill, and prepare the wood for immediate use, saving you time and effort. Prices vary widely—expect to pay a premium for rare species or exceptionally well-preserved pieces. Online marketplaces like eBay, Craigslist, or Facebook Marketplace can also yield hidden gems, but exercise caution: verify the seller’s reputation, request detailed photos, and clarify shipping costs, as reclaimed wood can be heavy and expensive to transport.

If you’re crafty and resourceful, consider salvaging wood yourself from discarded furniture, pallets, or construction waste. Pallets, in particular, are a popular choice due to their availability, but ensure they’re heat-treated (marked with "HT") rather than chemically treated (marked with "MB"), as the latter can release toxins during cutting. Stripping old paint or finishes may be necessary, but this labor-intensive process can reveal stunning grain patterns or patina beneath. Always prioritize safety when dismantling or processing salvaged wood, using gloves, masks, and proper tools to avoid injury.

Finally, think beyond traditional sources. Local sawmills or woodworking shops may have offcuts or discarded pieces that, while not technically reclaimed, still reduce waste. Community groups or woodworking forums often share leads on free or low-cost materials. By embracing salvaged or reclaimed wood, you not only reduce your environmental footprint but also infuse your CNC projects with a story—a tangible connection to the past that sets your work apart.

Where to Buy 2 1/2 Inch Wooden Shaker Pegs Online

You may want to see also

Frequently asked questions

Popular online stores for CNC wood include Amazon, Woodcraft, and Rockler. These platforms offer a wide variety of wood types, sizes, and grades suitable for CNC machining.

Yes, local lumberyards, hardwood suppliers, and specialty woodworking stores often carry CNC-friendly wood. Check directories like Yelp or Google Maps for nearby options, and call ahead to ensure they stock the type and size you need.

Common CNC-friendly woods include MDF, plywood, hardwoods (like maple or walnut), and softwoods (like pine). You can find these at lumberyards, woodworking stores, or online retailers like eBay, Specialty Wood Products, or The Wood Database. Always ensure the wood is flat, dry, and free of defects for optimal CNC results.