When venturing into laser cutting projects, sourcing the right wood is crucial for achieving precise and high-quality results. The ideal wood for laser cutting is typically untreated, natural, and free from resins or adhesives, with plywood, MDF, and hardwoods like birch or maple being popular choices. To purchase wood for laser cutting, consider specialty craft stores, online retailers like Amazon or Etsy, or dedicated woodworking suppliers such as Rockler or Woodcraft. Additionally, local hardware stores or lumberyards often carry suitable options, though it’s essential to verify the wood’s compatibility with laser cutting to avoid damage to the machine or unsatisfactory outcomes. Always prioritize materials labeled as laser-safe or consult with suppliers for recommendations tailored to your project needs.

Explore related products

What You'll Learn

Local Wood Suppliers

Supporting local wood suppliers for laser cutting projects offers a unique blend of sustainability, customization, and community engagement. Unlike large retailers, local suppliers often source their wood regionally, reducing transportation emissions and supporting nearby forests. This proximity also means fresher, less processed materials, which can enhance the quality of your laser-cut designs. By choosing local, you’re not just buying wood—you’re investing in a supply chain that prioritizes environmental responsibility and regional economies.

To locate a local wood supplier, start with a simple online search using terms like “wood suppliers near me” or “local lumberyards.” Many suppliers now have websites or social media profiles showcasing their inventory, including specialty woods ideal for laser cutting, such as birch plywood, maple, or walnut. Don’t overlook hardware stores or craft shops, as some carry smaller quantities of high-quality wood suitable for hobbyists. If digital searches fall short, ask fellow makers or laser-cutting enthusiasts in local forums or community groups—word-of-mouth recommendations can lead you to hidden gems.

When visiting a local supplier, come prepared with specific requirements for your laser-cutting project. Know the dimensions, thickness, and type of wood you need, as well as any finishing preferences (e.g., sanded, untreated). Local suppliers often offer personalized advice, helping you select the best wood for your machine’s capabilities and your project’s aesthetic. For instance, they might suggest Baltic birch plywood for its smooth layers and minimal voids, ensuring cleaner cuts. Building a relationship with your supplier can also lead to bulk discounts or access to rare wood varieties.

One often-overlooked advantage of local suppliers is their willingness to accommodate small orders. Unlike online retailers that may require minimum purchases, local suppliers typically sell wood by the board or sheet, making them ideal for one-off projects or experimentation. Additionally, many offer custom milling or cutting services, saving you time and ensuring the wood is ready for your laser cutter. This flexibility is particularly valuable for hobbyists or small businesses testing new designs without committing to large quantities.

Finally, supporting local wood suppliers fosters a sense of community and craftsmanship. Many suppliers are family-owned or have deep roots in the area, and their expertise can enrich your understanding of wood as a material. Some even host workshops or demonstrations, providing hands-on learning opportunities. By sourcing locally, you’re not just acquiring materials—you’re becoming part of a network that values skill-sharing, sustainability, and the art of creating with wood. This connection can inspire your work and deepen your appreciation for the materials you use.

Best Places to Buy Quality Wood for DIY Shelving Projects

You may want to see also

Explore related products

Online Wood Retailers

When choosing an online retailer, consider their sourcing practices and sustainability claims. Retailers like Sustainable Lumber Co. and EcoWoodSupply prioritize FSC-certified or reclaimed wood, appealing to eco-conscious makers. However, these options may come at a premium, so weigh the environmental benefit against your budget. Additionally, check for bulk discounts—many suppliers offer tiered pricing for larger orders, which can significantly reduce costs for frequent users.

Shipping logistics are another critical factor when buying wood online. Retailers like LaserCuttingSupply.com offer flat-rate shipping for sheet materials, while others may charge by weight or dimension. Be wary of oversized shipping fees for large sheets (e.g., 24" x 48"), and consider retailers that provide protective packaging to prevent warping or damage during transit. Some even offer local pickup options if you’re near their warehouse, saving both time and money.

For those new to laser cutting, educational resources provided by online retailers can be invaluable. Websites like MakerWoodShop include tutorials on material selection, laser settings (e.g., speed and power for different woods), and project ideas. They often recommend starting with baltic birch plywood for its affordability and ease of use, while cautioning against exotic woods that may contain resins harmful to laser machines. These insights can help beginners avoid costly mistakes and achieve better results.

Finally, customer reviews and community feedback are essential when selecting an online wood retailer. Platforms like LaserCuttingForum.org often feature discussions on the quality and consistency of materials from various suppliers. Look for patterns in reviews—consistent complaints about warped sheets or poor customer service should raise red flags. Conversely, retailers praised for fast shipping, accurate sizing, and responsive support are worth prioritizing. By leveraging these insights, you can ensure a smoother purchasing experience and higher-quality materials for your laser cutting projects.

Best Places to Buy Quality Wood for String Art Projects

You may want to see also

Explore related products

Craft Stores Options

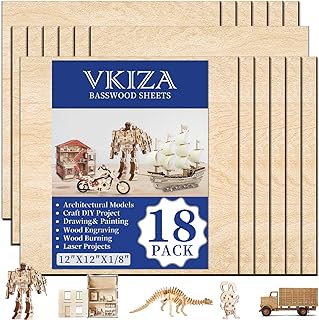

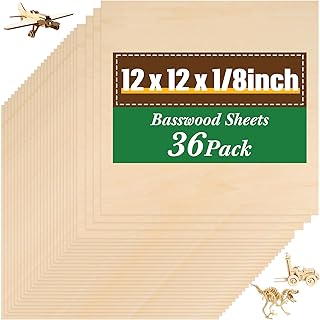

Craft stores are treasure troves for laser cutting enthusiasts, offering a curated selection of woods tailored to creative projects. Stores like Michaels, Hobby Lobby, and JOANN carry plywood sheets in various thicknesses (1/8", 1/4", 3/8") ideal for beginners. Look for birch or basswood options, which laser-cut cleanly with minimal charring. Pro tip: Check the store’s website for weekly coupons to save on bulk purchases.

While craft stores excel in accessibility, their wood variety is limited compared to specialty suppliers. You’ll find pre-cut shapes (circles, squares, hearts) and thin veneers, perfect for small-scale crafts like ornaments or jewelry. However, exotic woods or larger sheets are rarely stocked. If your project demands unique grains or sizes, consider pairing craft store purchases with online orders for specialty items.

For those prioritizing convenience, craft stores offer an immediate solution. Most locations have in-store pickup or same-day delivery, eliminating shipping delays. Additionally, their wood is often pre-sanded and ready for cutting, saving prep time. Keep in mind, though, that quality can vary—inspect sheets for warping or imperfections before purchasing.

A lesser-known advantage of craft stores is their project inspiration. Browse the aisles to discover complementary materials like acrylic paints, stains, or adhesives for finishing your laser-cut pieces. Some stores even host workshops or provide free project guides, making them a one-stop shop for both materials and ideas.

In summary, craft stores are ideal for hobbyists seeking convenience, affordability, and inspiration. While their wood selection may not cater to advanced projects, they’re perfect for prototyping or small-scale creations. Pair their offerings with online resources for a well-rounded supply chain.

Best Places to Buy Fluted Wood Panels for Stylish Interiors

You may want to see also

Explore related products

Specialty Laser Wood Shops

When selecting a specialty laser wood shop, consider their material sourcing and expertise. Many of these shops partner directly with sustainable suppliers, ensuring the wood is kiln-dried to the ideal moisture content (typically 6-8%) for laser cutting. This reduces warping and ensures consistent results. Additionally, staff at these shops often have hands-on experience with laser cutting, offering advice on grain direction, thickness (commonly 1/8" to 1/4" for most projects), and compatibility with specific laser machines. For example, they might recommend MDF for intricate designs due to its uniformity, but caution against using it in high-humidity environments.

One of the standout advantages of specialty laser wood shops is their ability to cater to niche needs. Whether you’re crafting jewelry, architectural models, or custom signage, these shops often carry exotic woods like walnut, padauk, or even veneer-layered composites. Some even offer custom cutting services, allowing you to purchase wood pre-cut to your specifications. This is particularly useful for large-scale projects or when working with expensive materials where waste must be minimized. For instance, a shop might suggest using 3mm walnut veneer bonded to a plywood base for a cost-effective yet premium finish.

Despite their benefits, specialty laser wood shops may come with a higher price tag compared to big-box stores. However, the investment often pays off in terms of time saved and project quality. To maximize value, inquire about bulk discounts or loyalty programs, which many shops offer to regular customers. Additionally, some shops provide sample packs of various woods, allowing you to test their laser performance before committing to larger quantities. This trial-and-error approach can be invaluable for refining your designs and techniques.

In conclusion, specialty laser wood shops are more than just suppliers—they are partners in your creative process. By offering specialized materials, expert advice, and tailored services, they help you achieve professional results with less hassle. Whether you’re a hobbyist or a commercial creator, leveraging these shops can elevate your laser cutting projects from good to exceptional. Start by researching local or online options, and don’t hesitate to ask questions—their knowledge is as valuable as the wood they sell.

Where to Buy Wood Letters: Top Retailers and Online Stores

You may want to see also

Explore related products

Hardware Store Selections

Hardware stores are a go-to resource for laser cutting enthusiasts seeking wood materials, offering a blend of convenience and variety. Most major chains like Home Depot, Lowe’s, and Ace Hardware stock plywood, MDF, and hardwood sheets in standard sizes (e.g., 2’x4’, 4’x8’), often in thicknesses ranging from 1/8” to 1”. These pre-cut sheets are ideal for laser cutting due to their consistent dimensions and flat surfaces, minimizing warping during engraving or cutting. Look for birch plywood, a popular choice for its smooth grain and affordability, typically priced between $10 and $30 per sheet depending on thickness and grade.

When selecting wood from hardware stores, prioritize quality over cost to ensure laser-cutting success. Avoid low-grade plywood with voids or knots, as these can cause uneven cuts or machine damage. MDF (medium-density fiberboard) is another excellent option, known for its uniformity and low cost (around $5–$15 per sheet), but be cautious of its tendency to char under high laser power. For best results, test-cut a small section at 70–80% power and adjust settings based on material response. Always check for formaldehyde-free labels, especially if the project involves indoor use or prolonged handling.

One often-overlooked advantage of hardware stores is their ability to cut wood to custom sizes, saving time and reducing waste. Most stores offer this service for a small fee (typically $1–$3 per cut), allowing you to work with manageable dimensions for your laser cutter’s bed size. For instance, a 4’x8’ sheet of plywood can be divided into four 2’x4’ sections, making it easier to transport and load into smaller machines. Pair this service with a quick sanding of edges to ensure smooth, splinter-free material ready for laser cutting.

While hardware stores provide accessibility, their selection may not cater to niche laser-cutting needs. Exotic woods like walnut or cherry are rarely available in sheet form, and thickness options beyond 1” are limited. For specialized projects, consider pairing hardware store purchases with online suppliers or local woodworking mills. However, for prototyping, educational projects, or quick replacements, hardware stores remain a reliable, cost-effective solution. Always inspect wood for warping or damage before purchasing, and store it flat in a dry environment to maintain its integrity until use.

Top Places to Purchase Quality Wood Fence Panels Online & Locally

You may want to see also

Frequently asked questions

Popular online stores include Amazon, Etsy, and specialty suppliers like Johnson Plastics Plus, LaserBits, and Woodcraft. These platforms offer a variety of laser-friendly woods like birch plywood, MDF, and acrylic-coated options.

Yes, local hardware stores like Home Depot, Lowe's, or specialty woodworking shops often carry plywood and MDF suitable for laser cutting. Ensure the wood is untreated and free of knots for best results.

Yes, hardwood plywood (e.g., birch, maple), MDF, and balsa wood are ideal due to their smooth surfaces and consistent density. Avoid woods with resins or high moisture content, like pine or exotic hardwoods, as they may produce poor results or damage the laser cutter.