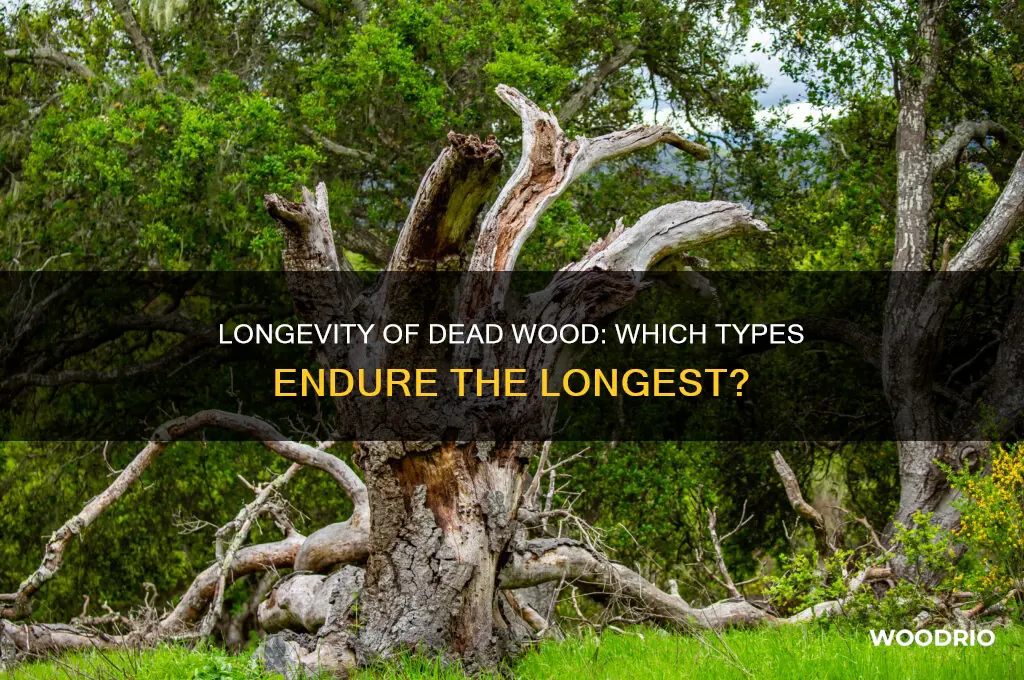

When considering which types of dead wood last longer, several factors come into play, including the species of the tree, the environment in which the wood is placed, and the specific conditions it is exposed to. Generally, hardwoods like oak, hickory, and teak tend to endure longer due to their dense cellular structure and natural resistance to decay. These woods are less susceptible to rot, insect damage, and weathering compared to softer woods like pine or cedar. Additionally, wood that is kept in dry, well-ventilated areas or treated with preservatives can significantly extend its lifespan. Understanding these variables helps in determining which dead wood will persist the longest in various settings.

| Characteristics | Values |

|---|---|

| Wood Type | Dense, hardwoods like oak, teak, cedar, and black locust |

| Density | High density (heavier woods) |

| Natural Oils/Resins | Presence of natural oils or resins (e.g., teak, cedar) |

| Rot Resistance | High resistance to decay and insect damage |

| Moisture Content | Low moisture content at time of death |

| Environment | Dry, well-ventilated environments slow decay |

| Heartwood vs. Sapwood | Heartwood (inner part of the tree) lasts longer than sapwood |

| Preservative Treatments | Untreated wood relies on natural properties; treated wood can last longer |

| Exposure to Elements | Minimal exposure to water, soil, and sunlight prolongs lifespan |

| Microbial Activity | Low microbial activity in the surrounding environment |

| Insect Resistance | Natural resistance to termites, beetles, and other wood-boring insects |

| Chemical Composition | High levels of tannins, lignin, and other decay-resistant compounds |

| Durability Class | Class 1 or 2 (very durable to durable) in wood durability standards |

| Typical Lifespan | 20-50+ years depending on conditions and wood type |

Explore related products

$5.82 $6.99

$7.99 $14.49

What You'll Learn

- Moisture Resistance: Dry environments preserve wood longer than wet ones, reducing decay and fungal growth

- Hardwood vs. Softwood: Dense hardwoods like oak outlast softwoods like pine due to durability

- Chemical Treatments: Preservatives like creosote extend wood life by preventing rot and pests

- Wood Density: Higher density woods resist decay better, ensuring longer-lasting dead wood

- Environmental Factors: Exposure to sun, rain, and insects significantly impacts wood longevity

Moisture Resistance: Dry environments preserve wood longer than wet ones, reducing decay and fungal growth

Wood preservation is a battle against nature’s relentless forces, and moisture stands as the primary adversary. In wet environments, wood absorbs water, swelling and contracting with every cycle, which weakens its cellular structure. This process, known as weathering, accelerates decay by creating micro-cracks where fungi and insects gain entry. For instance, oak wood exposed to constant dampness can show signs of rot within 5–10 years, while the same wood in a dry climate might endure for centuries. The takeaway is clear: controlling moisture exposure is the first line of defense in extending the lifespan of dead wood.

To combat moisture-induced decay, consider the environment where the wood will be used. In humid climates, elevate wooden structures off the ground using pressure-treated posts or stone foundations to minimize direct contact with soil. For indoor applications, maintain relative humidity levels below 50% using dehumidifiers or proper ventilation. Treat wood surfaces with moisture-resistant finishes like epoxy resins or linseed oil, which form a protective barrier against water infiltration. These proactive measures can double or even triple the wood’s expected lifespan, making them essential for long-term preservation.

A comparative analysis of wood in dry versus wet environments reveals stark differences. In arid regions like deserts, ancient wooden artifacts and structures remain intact for millennia due to the absence of moisture-driven decay. Conversely, tropical rainforests, with their high humidity and rainfall, see wood decompose within decades. This contrast underscores the role of moisture in fungal proliferation, particularly species like *Serpula lacrymans* (dry rot fungus), which thrives in damp conditions. By mimicking the dryness of desert climates, even in humid areas, wood can be preserved far beyond its natural lifespan.

For practical implementation, prioritize wood species naturally resistant to moisture, such as teak, cedar, or cypress, which contain oils that repel water and inhibit fungal growth. When using less resistant woods like pine, apply borate-based preservatives during the initial treatment phase. These compounds penetrate the wood, preventing fungal and insect damage without altering its appearance. Regularly inspect wood for signs of moisture accumulation, such as discoloration or soft spots, and address issues promptly. By combining material selection, treatment, and maintenance, even wood in moderately wet environments can achieve longevity comparable to that in dry climates.

Understanding the Duration of WOODS EFT Training Programs

You may want to see also

Explore related products

Hardwood vs. Softwood: Dense hardwoods like oak outlast softwoods like pine due to durability

Dense hardwoods like oak inherently outlast softwoods like pine due to their cellular structure and natural defenses. Hardwoods, derived from deciduous trees, feature tightly packed cells with abundant lignin, a polymer that resists decay and insect damage. This density makes them less susceptible to moisture absorption, a primary cause of rot. Softwoods, from coniferous trees, have larger, less compact cells with resin canals that, while offering some protection, are less effective against long-term degradation. For outdoor projects like decking or fencing, choosing oak over pine can double or triple the lifespan of the wood, reducing maintenance and replacement costs.

Consider the practical implications of this durability gap. A hardwood deck made from oak can last 30 to 50 years with proper care, whereas a pine deck typically deteriorates within 10 to 15 years, even with regular staining and sealing. This longevity difference is particularly critical in high-moisture environments, such as coastal areas or regions with heavy rainfall. For example, oak’s resistance to fungal decay makes it ideal for garden structures like raised beds or pergolas, where constant soil contact or water exposure is unavoidable. Pine, while cheaper upfront, often requires frequent repairs or replacements, negating its initial cost advantage.

To maximize the lifespan of either wood type, specific treatments are essential. For softwoods like pine, apply a high-quality wood preservative containing copper azole or alkaline copper quaternary (ACQ) to enhance resistance to rot and insects. Reapply every 2 to 3 years, especially in humid climates. Hardwoods benefit from oil-based sealants that penetrate deeply, preserving their natural oils and preventing cracking. Avoid water-based sealers, as they can trap moisture within the dense grain. For both woods, ensure proper installation with adequate ventilation and drainage to minimize water retention, a key factor in premature decay.

The choice between hardwood and softwood ultimately hinges on the project’s demands and budget. While softwoods like pine are suitable for temporary or indoor applications where durability is less critical, hardwoods like oak are non-negotiable for long-term outdoor use. For instance, oak is the preferred material for boatbuilding and outdoor furniture due to its strength and resilience. Pine, however, excels in interior carpentry, such as framing or paneling, where its lightweight nature and ease of workability outweigh its shorter lifespan. By aligning wood selection with the specific requirements of the project, you can ensure both longevity and cost-effectiveness.

Finally, sustainability should factor into your decision. Hardwoods, often slower-growing, are typically harvested from managed forests to ensure long-term ecological balance. Softwoods, with their faster growth cycles, are more readily renewable but may come from less regulated sources. Opting for certified sustainable hardwoods or recycled softwoods can mitigate environmental impact while still leveraging the inherent durability of dense woods like oak. This approach not only extends the life of your project but also contributes to responsible resource management, ensuring that the wood you choose today remains a viable option for future generations.

Durability of Wood Decks: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

$13.99

Chemical Treatments: Preservatives like creosote extend wood life by preventing rot and pests

Chemical treatments, particularly preservatives like creosote, have long been relied upon to extend the lifespan of dead wood by combating rot and deterring pests. Creosote, a tar-based preservative, penetrates deep into the wood fibers, creating a barrier against moisture and fungi, the primary culprits behind decay. Its effectiveness lies in its ability to repel wood-boring insects and microorganisms, ensuring structural integrity for decades. For instance, utility poles treated with creosote often last 40 to 60 years, compared to untreated wood, which may deteriorate within a decade. This longevity makes it a staple in industrial and outdoor applications, despite its strong odor and environmental concerns.

Applying creosote requires precision to maximize its benefits. The treatment process involves immersing the wood in a creosote bath or using pressure methods to force the preservative into the grain. Dosage is critical: a concentration of 3 to 5 gallons of creosote per 100 square feet of wood surface is typically recommended for optimal protection. After treatment, the wood must cure for several weeks to allow the solvent to evaporate, leaving behind a protective layer. Safety precautions are essential, as creosote is toxic and requires protective gear, proper ventilation, and disposal of runoff to prevent soil and water contamination.

While creosote is highly effective, its environmental impact has led to the development of alternative chemical preservatives. Copper azole, for example, offers similar protection against rot and pests but is less toxic and more environmentally friendly. It is commonly used in residential applications like decking and fencing, where its green tint blends naturally with wood. Another alternative is alkaline copper quat (ACQ), which provides excellent resistance to decay and insects but requires proper disposal due to its copper content. These alternatives balance longevity with sustainability, making them suitable for eco-conscious projects.

The choice of preservative depends on the wood’s intended use and exposure conditions. For heavy-duty applications like marine pilings or railroad ties, creosote remains unmatched due to its durability in harsh environments. However, for home projects or areas with strict environmental regulations, copper-based preservatives are often the better choice. Regardless of the chemical used, proper maintenance, such as periodic inspections and reapplication, can further extend the wood’s life. By understanding the strengths and limitations of each treatment, users can make informed decisions to ensure their wood structures stand the test of time.

Termite Damage Timeline: How Quickly Can They Destroy Wood?

You may want to see also

Explore related products

Wood Density: Higher density woods resist decay better, ensuring longer-lasting dead wood

Dense woods, such as teak, mahogany, and oak, inherently resist decay better than their less dense counterparts. This resistance stems from their tightly packed cellular structure, which makes it harder for fungi, insects, and moisture to penetrate. For instance, teak, with a density of around 700 kg/m³, can last decades in outdoor conditions without treatment, while pine, at roughly 420 kg/m³, deteriorates much faster. If you’re selecting wood for long-term outdoor use, prioritize species with a density above 600 kg/m³ to maximize durability.

To understand why density matters, consider the role of moisture in wood decay. Higher density woods have fewer voids, reducing the space available for water absorption. This is critical because moisture fuels fungal growth and insect activity, the primary culprits behind wood degradation. A practical tip: if you’re unsure about a wood’s density, perform a simple water droplet test. Dense wood will repel water more effectively than porous, low-density varieties, giving you a quick indication of its decay resistance.

When comparing wood species, density isn’t the only factor, but it’s a reliable predictor of longevity. For example, while cedar is moderately dense (around 400 kg/m³), its natural oils provide additional decay resistance, making it an exception. However, in the absence of such protective compounds, density remains the key determinant. If you’re working with untreated wood, aim for species like ipe (density: 1,000 kg/m³) or black locust (770 kg/m³) for projects requiring maximum durability, such as fence posts or garden beds.

Finally, while higher density woods are more expensive upfront, their longevity often justifies the cost. For instance, investing in dense wood for a deck can save you from frequent replacements, reducing long-term expenses. To extend the life of any wood, regardless of density, ensure proper installation—elevate it from direct ground contact and apply sealants regularly. By combining high-density wood with good maintenance practices, you can create structures that withstand the test of time.

Driving from Woods Hole to Logan Airport: Time and Tips

You may want to see also

Explore related products

Environmental Factors: Exposure to sun, rain, and insects significantly impacts wood longevity

Sunlight, a silent yet potent force, accelerates the degradation of dead wood through a process known as photodegradation. Ultraviolet (UV) rays break down lignin, the natural glue that binds wood fibers, causing surface cracking, warping, and discoloration. Hardwoods like teak and cedar fare better due to their higher natural oils and resins, which act as built-in UV blockers. For instance, teak exposed to direct sunlight retains its structural integrity for up to 50 years, while softer woods like pine may deteriorate within a decade. To mitigate sun damage, apply UV-resistant sealants or position wood in shaded areas, reducing exposure by at least 50%.

Rain, while essential for life, becomes wood’s adversary by fostering moisture absorption and fungal growth. Prolonged wetness weakens cellulose fibers, leading to rot and decay. Tropical hardwoods like ipe and mahogany, with their dense grain and natural resistance to moisture, can withstand rainy climates for 40–75 years. In contrast, spruce or fir may succumb to rot within 5–10 years in damp conditions. Practical measures include elevating wood structures to improve air circulation and using water-repellent treatments. For outdoor furniture, tilt surfaces to shed water and inspect annually for signs of mold or warping.

Insects, particularly termites and carpenter ants, pose a hidden but devastating threat to dead wood. These pests bore into wood, creating internal cavities that compromise its strength. Pressure-treated pine, infused with insecticides like chromated copper arsenate (CCA), offers 20–30 years of protection against infestations. Alternatively, naturally insect-resistant woods like redwood and cypress contain tannins that deter pests. To safeguard wood, maintain a 6-inch clearance from soil, apply insecticidal barriers, and regularly inspect for frass (insect waste) or hollow-sounding areas.

The interplay of sun, rain, and insects creates a trifecta of challenges for wood longevity. For example, sun-weakened wood absorbs more moisture during rain, making it an ideal breeding ground for fungi and insects. In coastal regions, where salt spray exacerbates UV damage and accelerates corrosion, choosing woods like cypress or using marine-grade sealants becomes critical. By understanding these environmental interactions, you can strategically select wood types and protective measures to maximize durability. For instance, combining UV-resistant finishes with regular waterproofing and insect inspections can extend the lifespan of outdoor wood structures by decades.

In practice, tailoring wood selection and maintenance to local environmental conditions yields the best results. In arid, sunny climates, prioritize UV resistance; in wet regions, focus on moisture and insect protection. For instance, a deck in Arizona might use sealed cedar with annual UV reapplication, while a dock in Florida benefits from ipe with bi-annual waterproofing and termite inspections. By addressing these environmental factors proactively, you ensure that dead wood not only lasts longer but also retains its aesthetic and structural integrity over time.

Seasoning Wood Indoors: Optimal Time for Perfectly Dry Firewood

You may want to see also

Frequently asked questions

Hardwoods like oak, hickory, and black locust tend to last the longest due to their natural resistance to decay and insects.

Yes, denser woods generally last longer because they are more resistant to rot, moisture, and pests compared to softer, less dense woods.

Yes, treating dead wood with preservatives like creosote, paint, or sealants can significantly extend its lifespan by protecting it from moisture and insects.

Absolutely, wood in dry, well-ventilated environments lasts longer than wood in wet, humid, or soil-contact conditions, which accelerate decay.