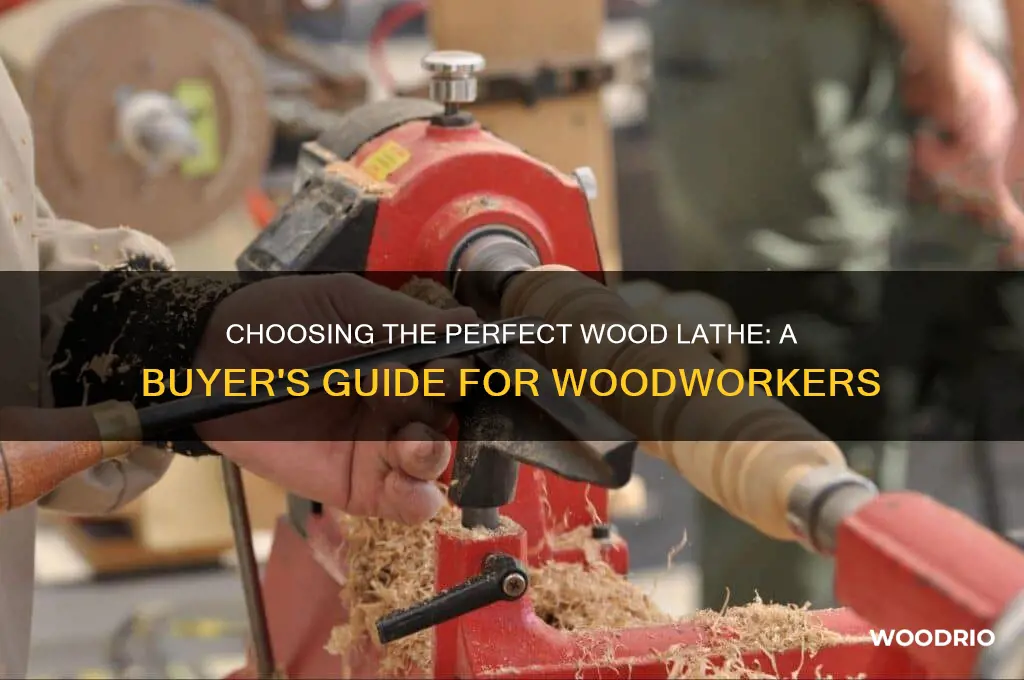

Choosing the right wood lathe can be a pivotal decision for both hobbyists and professionals, as it significantly impacts the quality and efficiency of your woodworking projects. Factors such as the size of the lathe, motor power, speed variability, and additional features like digital readouts or indexing capabilities should align with your skill level and intended use. Beginners might prioritize user-friendly models with lower speed settings and compact designs, while advanced woodturners may seek heavy-duty machines with higher horsepower and larger swing capacities. Additionally, considering your budget, available workspace, and the types of projects you plan to undertake will help narrow down the options to a lathe that best suits your needs. Researching reviews and comparing brands can also provide valuable insights to ensure you make an informed investment.

Explore related products

$313.49 $329.99

What You'll Learn

- Budget Considerations: Determine your budget range for a wood lathe purchase

- Project Size: Match lathe size to the scale of your woodworking projects

- Power & Speed: Choose a motor with adequate power and variable speed control

- Brand Reliability: Research trusted brands known for durability and performance

- Features & Accessories: Evaluate additional features like tool rests, stands, and dust collection

Budget Considerations: Determine your budget range for a wood lathe purchase

Before diving into the world of wood lathes, it's crucial to establish a clear budget range. This will not only narrow down your options but also prevent overspending on features you may not need. A typical entry-level wood lathe for beginners can cost anywhere from $150 to $500, while mid-range models suitable for intermediate users often fall between $500 and $1,500. High-end, professional-grade lathes can easily exceed $2,000, offering advanced features like variable speed controls, larger swing capacities, and heavier-duty construction. Understanding your skill level, intended usage, and long-term goals will help you pinpoint where your budget should lie within this spectrum.

Consider the cost of accessories and maintenance when setting your budget. A wood lathe is just the starting point; you’ll also need tools like chisels, sandpaper, and safety gear, which can add $100 to $300 to your initial investment. Additionally, factor in ongoing expenses such as replacement parts, sharpening tools, and potential upgrades. For instance, a basic set of turning chisels might cost around $50, while a high-quality set can run upwards of $200. By allocating a portion of your budget to these essentials, you ensure a more complete and sustainable woodworking setup.

If you’re on a tight budget, explore the used market or consider refurbished models. Websites like Craigslist, eBay, or local woodworking forums often list pre-owned lathes at a fraction of their retail price. However, exercise caution—inspect the machine thoroughly for wear and tear, and ensure it meets your needs in terms of size and functionality. For example, a used mid-range lathe in good condition might cost $300 to $800, offering significant savings compared to buying new. Just be mindful of potential repair costs down the line.

Another strategy is to prioritize must-have features over nice-to-haves. For beginners, a lathe with a swing capacity of 10–12 inches and a bed length of 30–40 inches is often sufficient. Variable speed control, while convenient, can add $100–$200 to the price and may not be essential for simple projects. Similarly, a cast iron body provides better stability but is heavier and more expensive than a benchtop model. By focusing on core functionality, you can find a lathe that fits your budget without compromising on quality.

Finally, think long-term. If woodworking is a hobby you plan to pursue for years, investing in a higher-quality lathe now may save you money in the long run. A durable, versatile machine will handle more complex projects as your skills grow, reducing the need for frequent upgrades. Conversely, if you’re testing the waters, a budget-friendly option allows you to explore the craft without a significant financial commitment. Striking the right balance between immediate needs and future aspirations will guide you to a budget range that aligns with your goals.

Best Sources to Purchase High-Quality Western Red Cedar Wood

You may want to see also

Explore related products

Project Size: Match lathe size to the scale of your woodworking projects

The size of your woodworking projects is the single most important factor in choosing a wood lathe. A lathe that’s too small will limit your creativity and frustrate you with physical constraints, while one that’s too large will waste space, overcomplicate simple tasks, and unnecessarily inflate costs. For instance, a mini lathe with a 12-inch swing (the diameter of wood it can handle) and 14-inch distance between centers (the maximum length of wood it can turn) is ideal for pens, small bowls, and ornaments. Attempting to turn a 16-inch salad bowl on such a machine would be unsafe and impractical. Conversely, a full-size lathe with a 20-inch swing and 48-inch distance between centers, while perfect for furniture legs or large platters, would be overkill for someone primarily making keychains.

To determine the right size, audit your project list. If you’re a beginner focusing on small-scale items like pens, bottle stoppers, or spice mills, a benchtop lathe (10–14-inch swing, 12–20-inch between centers) is cost-effective and space-efficient. Intermediate woodworkers tackling medium-sized projects like bowls, vases, or tool handles should consider a mid-size lathe (16–18-inch swing, 24–36-inch between centers). Professionals or hobbyists working on furniture components, stair spindles, or large hollow forms need a full-size lathe (20+ inch swing, 40+ inch between centers). Remember, upgrading later is more expensive than buying the right size upfront.

A common mistake is underestimating future growth. If you’re unsure, choose a lathe that accommodates your current projects with a slight buffer. For example, if you’re making 8-inch bowls now but aspire to turn 12-inch ones, opt for a 16-inch swing rather than a 12-inch. Similarly, if you’re turning 24-inch table legs occasionally, a 36-inch between centers will provide flexibility without requiring a massive machine. This approach balances practicality with scalability.

Physical space in your workshop is another critical consideration. A full-size lathe requires not just floor area but also clearance for wood movement and tool access. Measure your workspace and account for at least 3 feet of clearance around the lathe for safe operation. For small shops, a compact lathe with a folding stand or casters can be a lifesaver. However, ensure the machine’s size doesn’t compromise stability—a wobbly lathe is dangerous at high speeds.

Finally, consider the weight and portability of the lathe. Larger machines are heavier and often require permanent installation, while smaller ones can be moved or stored when not in use. If you’re working in a shared space or need to transport your lathe, prioritize models with a smaller footprint and lighter build. However, don’t sacrifice power or stability for portability—a lathe that vibrates excessively due to its lightweight design will ruin your work and frustrate you. Balance mobility with functionality based on your project needs and workspace constraints.

Discover Unique Vintage Wooden Ladders: Top Buying Spots & Tips

You may want to see also

Explore related products

Power & Speed: Choose a motor with adequate power and variable speed control

The motor is the heart of your wood lathe, and its power directly impacts your ability to turn wood efficiently and safely. Underpowered motors struggle with harder woods or larger projects, leading to strain, overheating, and potential damage. Aim for a minimum of 1 horsepower (HP) for general-purpose turning, but consider 1.5 HP or more if you plan to work with dense hardwoods or create bowls and platters exceeding 12 inches in diameter.

A variable speed control is equally crucial. Different woods and project stages demand specific speeds. Softer woods like pine require slower speeds (around 500-1000 RPM) to prevent tearing, while harder woods like maple benefit from higher speeds (1500-2500 RPM) for smoother cuts. Variable speed allows you to fine-tune your approach, ensuring clean cuts, minimizing burning, and maximizing control throughout the turning process.

Imagine shaping a delicate spindle at high speed, then seamlessly transitioning to a roughing cut on a chunky bowl blank at a lower RPM – all without stopping to manually adjust belts or pulleys. This versatility is the hallmark of a lathe equipped with variable speed control, making it an indispensable feature for both beginners and experienced turners alike.

Think of it as having a dimmer switch for your lathe – you wouldn't want to illuminate a cozy reading nook with the same intensity as a football stadium. Similarly, your lathe needs the flexibility to adapt to the unique demands of each project.

When evaluating motors, consider not only horsepower but also torque. Torque measures the motor's rotational force, crucial for powering through cuts in dense woods. Look for lathes with high torque at low speeds, ensuring you have the power needed for heavy-duty tasks. Remember, a powerful motor with variable speed control isn't just about convenience; it's about safety, precision, and unlocking the full potential of your woodturning endeavors.

Top Retailers for Realistic Wood Grain Wallpaper: A Buyer's Guide

You may want to see also

Explore related products

Brand Reliability: Research trusted brands known for durability and performance

A wood lathe is a significant investment, and brand reliability should be a top consideration. Established brands like Jet, Laguna, and Nova have built their reputations on consistent quality and performance. These companies often use higher-grade materials, such as cast iron for the bed and headstock, ensuring stability and longevity. For instance, Jet’s JWL-1221VS and Laguna’s Revo 18|36 are frequently praised for their robust construction, which minimizes vibration and wear over time. Researching these brands’ histories and customer reviews can provide insight into their commitment to durability.

When evaluating brand reliability, consider the warranty and customer support offered. Brands like Powermatic and Rikon stand out with extensive warranties—often 5 years or more—and responsive customer service teams. A longer warranty not only reflects the manufacturer’s confidence in their product but also provides peace of mind for the buyer. For example, Powermatic’s 3520B comes with a 5-year warranty, while Rikon’s 70-100 offers a lifetime warranty on certain components. These policies can save you from costly repairs or replacements down the line.

Another aspect of brand reliability is the availability of replacement parts and accessories. Trusted brands often have a wide network of dealers and distributors, making it easier to find parts when needed. Nova, for instance, offers a comprehensive range of chucks, tool rests, and other accessories that are compatible with their lathes, ensuring you can maintain and upgrade your machine without hassle. Conversely, lesser-known brands may lack this infrastructure, leaving you stranded if a critical component fails.

Finally, consider the brand’s track record in innovation and user feedback. Brands like Laguna and Nova are known for incorporating user suggestions into their designs, resulting in lathes that are more intuitive and efficient. For example, Laguna’s Revo series features a sliding headstock and electronic variable speed control, addressing common pain points among woodturners. By choosing a brand that values continuous improvement, you’re more likely to end up with a machine that meets your evolving needs.

In summary, prioritizing brand reliability involves looking beyond the initial price tag. Investigate the materials used, warranty terms, parts availability, and the brand’s responsiveness to user feedback. Brands like Jet, Powermatic, and Nova consistently score high in these areas, making them safer bets for long-term satisfaction. While lesser-known brands might offer lower prices, the potential risks—such as poor durability or limited support—often outweigh the savings. Make an informed decision by treating brand reliability as a cornerstone of your purchasing criteria.

Mastering Wood Purchases in Tradelands: A Comprehensive Buyer's Guide

You may want to see also

Explore related products

Features & Accessories: Evaluate additional features like tool rests, stands, and dust collection

Tool rests are the unsung heroes of woodturning, providing stability and control during shaping and sanding. A well-designed tool rest should be sturdy, adjustable, and positioned at the correct height and angle relative to the workpiece. Look for rests with smooth edges to prevent catching your tools and causing damage. Some lathes come with multiple rests or modular systems, allowing you to switch between tasks without constant repositioning. For instance, a longer rest is ideal for roughing out, while a shorter one offers precision during detailing. Ensure the rest’s material is durable—cast iron or steel is preferable over flimsy aluminum. A wobbly or poorly designed rest can ruin your project, so prioritize this feature when comparing models.

Stands are often overlooked but can significantly impact your workflow. A dedicated stand raises the lathe to a comfortable working height, reducing strain on your back and shoulders. Portable lathes may include foldable stands for easy storage, while heavier-duty models might have stationary stands with built-in storage for accessories. Consider the stand’s stability—vibrations during operation can compromise precision. Some stands come with leveling feet to ensure your lathe remains steady on uneven surfaces. If you plan to move your lathe frequently, opt for a stand with wheels and locking mechanisms. A well-matched stand not only enhances ergonomics but also prolongs the life of your machine by minimizing stress on its components.

Dust collection is a critical yet frequently neglected aspect of woodturning. Fine wood dust is a health hazard and can damage your lathe’s motor if left unchecked. Look for lathes with integrated dust collection ports that connect directly to a shop vacuum or dust collector. The port size matters—a 2.5-inch or 4-inch port is more efficient than smaller diameters. Some models include chip deflectors or hoods to direct debris toward the collection system. If your lathe lacks this feature, consider aftermarket solutions like magnetic dust shields or DIY attachments. Regularly emptying the dust collection system is essential; a clogged system reduces suction and increases the risk of fire. Prioritizing dust management not only protects your health but also keeps your workspace clean and your tools functioning optimally.

When evaluating these features, consider your specific needs and long-term goals. A hobbyist turning small pens may prioritize portability and affordability, while a professional crafting furniture components will need robust, high-capacity solutions. Test the adjustability of tool rests and the stability of stands before purchasing, if possible. For dust collection, ensure compatibility with your existing system or budget for additional equipment. Remember, these accessories are investments in your craft—skimping on quality may save money upfront but can hinder your progress and safety in the long run. Choose features that align with your workflow and elevate your woodturning experience.

Discover the Best Places to Buy Forever-in-Time Wood Stickers

You may want to see also

Frequently asked questions

Consider your skill level, project size, available space, budget, and desired features like variable speed control, power, and bed length.

Benchtop lathes are compact and affordable, ideal for beginners or small spaces, while freestanding lathes offer more stability and capacity for larger projects.

For beginners or small projects, 1/2 to 1 HP is sufficient. For larger or more demanding projects, consider 1.5 HP or higher.

Yes, variable speed control is essential for working with different wood types and project sizes, allowing for better precision and safety.

Popular and reliable brands include Jet, Laguna, Nova, and Rikon, offering a range of models for beginners to professionals.