The world of woodwind instruments is fascinating, with a rich history and diverse range of materials used in their construction. While the name woodwind suggests that these instruments are traditionally made of wood, advancements in technology and changing musical preferences have led to the development of alternative materials. One intriguing question that arises is: which woodwind instrument is no longer made of wood? The answer lies in the evolution of instrument manufacturing, where materials like metal and plastic have become increasingly popular, offering unique tonal qualities and durability. Among the woodwind family, the saxophone stands out as a prime example of an instrument that, despite its name, is typically crafted from brass, marking a significant departure from its wooden origins.

Explore related products

What You'll Learn

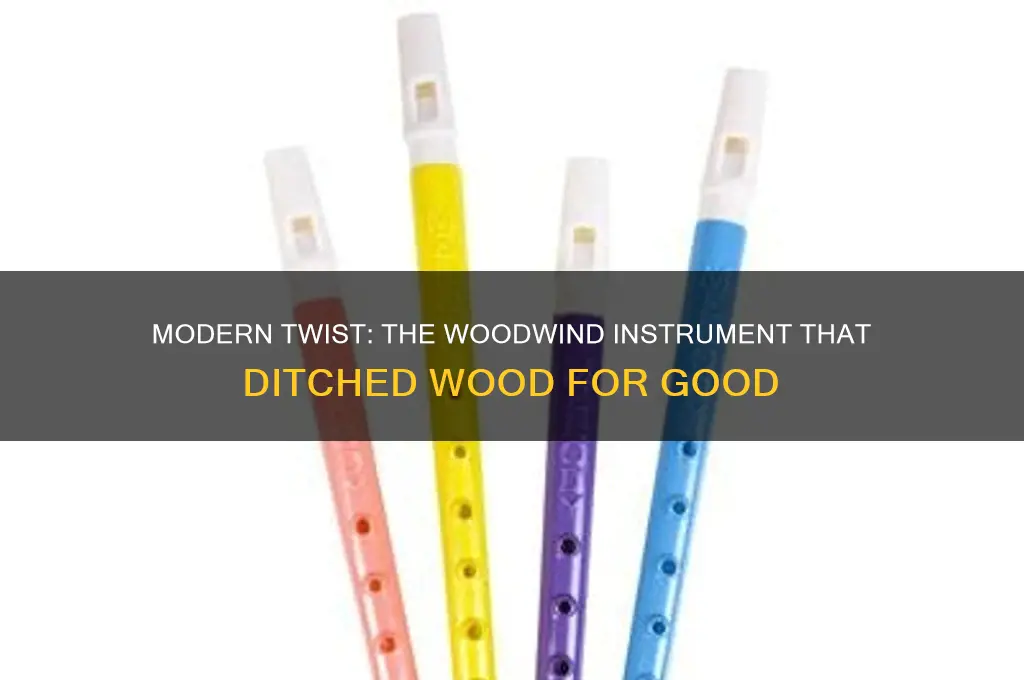

- Plastic vs. Wood Flutes: Modern flutes often use plastic, not wood, for durability and cost-effectiveness

- Metal Clarinets: Clarinets are now commonly made of metal, not wood, for better tuning stability

- Resin Oboes: Oboes use resin instead of wood to resist cracking and improve consistency

- Synthetic Bassoons: Bassoons are increasingly made from synthetic materials for enhanced durability and playability

- Composite Piccolos: Piccolos often use composite materials, not wood, for lightweight design and weather resistance

Plastic vs. Wood Flutes: Modern flutes often use plastic, not wood, for durability and cost-effectiveness

The flute, a staple in orchestras and bands worldwide, has undergone a significant transformation in its construction materials. Traditionally crafted from wood, modern flutes now predominantly feature plastic, a shift driven by practicality and economics. This change raises questions about sound quality, durability, and the instrument's identity in the digital age.

The Rise of Plastic Flutes: A Practical Choice

Plastic flutes have become increasingly popular, especially among beginners and schools, due to their affordability and resilience. Unlike wooden flutes, which require meticulous care to prevent cracking and warping, plastic flutes are virtually maintenance-free. They can withstand extreme temperatures, humidity, and rough handling, making them ideal for young students and outdoor performances. For instance, the Yamaha YRS-23 plastic soprano recorder is a common choice for school music programs, offering a durable and cost-effective solution for large-scale instrument needs.

Sound Quality: A Matter of Perception

One of the most debated aspects of plastic flutes is their sound quality. Purists argue that wooden flutes produce a warmer, richer tone, while plastic flutes are often described as brighter and more consistent. However, advancements in plastic manufacturing have narrowed this gap. High-quality plastic flutes, such as those made from ABS resin, can mimic the tonal qualities of wood, providing a satisfactory alternative for many players. A study by the *Journal of the Acoustical Society of America* found that experienced musicians could not consistently distinguish between the sound of a wooden and a high-grade plastic flute in a blind test, highlighting the subjective nature of sound preference.

Environmental and Economic Considerations

The shift to plastic flutes also reflects broader environmental and economic trends. Wooden flutes, particularly those made from exotic hardwoods, contribute to deforestation and habitat destruction. Plastic flutes, on the other hand, are often made from recyclable materials, reducing their environmental footprint. Additionally, the lower production costs of plastic flutes make them accessible to a wider audience, democratizing music education. However, it’s crucial to consider the long-term environmental impact of plastic waste. Musicians can mitigate this by choosing flutes made from recycled materials and ensuring proper disposal or recycling at the end of the instrument’s life.

Practical Tips for Choosing Between Plastic and Wood

When deciding between a plastic and wooden flute, consider the intended use and the player’s skill level. For beginners, a plastic flute is often the best choice due to its durability and low maintenance requirements. Intermediate and advanced players may prefer a wooden flute for its nuanced sound and aesthetic appeal. If opting for a plastic flute, look for models with a matte finish to reduce the "toy-like" appearance and enhance grip. For wooden flutes, ensure proper storage in a controlled environment to prevent damage. Regardless of material, regular cleaning and proper handling will extend the life of the instrument.

The Future of Flute Making: Innovation and Tradition

As technology advances, the line between plastic and wooden flutes continues to blur. Hybrid models, combining the durability of plastic with the tonal qualities of wood, are emerging as a viable option. For example, some manufacturers are experimenting with composite materials that offer the best of both worlds. This innovation ensures that the flute remains a versatile and accessible instrument, catering to the needs of modern musicians while honoring its rich history. Whether made of wood or plastic, the flute’s enduring appeal lies in its ability to adapt to changing times without losing its essence.

Wood Look Tile Lengths: Are Options Longer Than 48 Inches Available?

You may want to see also

Explore related products

Metal Clarinets: Clarinets are now commonly made of metal, not wood, for better tuning stability

The clarinet, once synonymous with wooden craftsmanship, has undergone a material metamorphosis. Modern clarinets are increasingly crafted from metal, a shift driven by the pursuit of tuning stability. Wood, while prized for its tonal warmth, is susceptible to environmental fluctuations. Changes in humidity and temperature can cause wooden clarinets to warp, crack, or swell, leading to tuning inconsistencies. Metal, by contrast, remains impervious to such variations, offering players a reliable instrument that stays in tune across diverse performance conditions.

This transition to metal is particularly evident in professional and student models alike. Manufacturers like Yamaha and Buffet Crampon produce metal clarinets that cater to musicians seeking durability and precision. For instance, the Yamaha YCL-450 intermediate clarinet features a silver-plated nickel silver body, ensuring consistent intonation and resistance to environmental wear. Similarly, the Buffet Crampon Prodige student clarinet, made of ABS resin with a matte finish, mimics the look and feel of metal while providing affordability and stability for beginners.

However, the choice between wood and metal clarinets is not without trade-offs. While metal clarinets excel in tuning stability, wooden clarinets are often preferred for their rich, resonant sound. Professional musicians may opt for grenadilla or rosewood clarinets in orchestral or chamber settings, where tonal depth takes precedence over environmental resilience. Conversely, metal clarinets dominate in marching bands, jazz ensembles, and outdoor performances, where stability and durability are paramount.

For those considering a metal clarinet, it’s essential to evaluate playing style and performance context. Metal clarinets require less maintenance than their wooden counterparts, as they are less prone to cracking or warping. However, they may demand a slightly different embouchure and air support to achieve optimal sound quality. Beginners should prioritize comfort and ease of play, while advanced players may focus on tonal projection and responsiveness.

In conclusion, the rise of metal clarinets reflects a broader trend in instrument design: the balance between tradition and innovation. While wood remains the material of choice for purists, metal clarinets offer a practical solution for musicians seeking reliability and consistency. Whether for a student’s first instrument or a professional’s versatile tool, metal clarinets have carved their niche in the woodwind family, proving that sometimes, progress sounds just as sweet.

Cedar Wood Durability: How Long It Lasts Outdoors and Why

You may want to see also

Explore related products

Resin Oboes: Oboes use resin instead of wood to resist cracking and improve consistency

The oboe, a double-reed woodwind instrument, has traditionally been crafted from grenadilla wood, prized for its density and tonal qualities. However, this material is susceptible to cracking due to changes in humidity and temperature, a persistent challenge for musicians. Enter resin oboes—a modern innovation that replaces wood with synthetic resin, offering a solution to these age-old problems. Resin oboes are designed to resist cracking, ensuring the instrument remains stable across varying environmental conditions, from dry concert halls to humid outdoor performances.

From a practical standpoint, resin oboes are particularly beneficial for students and professionals alike. For beginners, the durability of resin reduces the risk of damage during the learning phase, making it a cost-effective choice. Advanced players appreciate the consistency in tone and intonation, as resin is less prone to warping than wood. Manufacturers often recommend resin oboes for younger players (ages 10–18) due to their resilience, though they are suitable for all age groups. To maintain a resin oboe, regular cleaning of the keys and bore is essential, but unlike wood, resin does not require oiling or special humidity control measures.

Comparatively, while wooden oboes are revered for their rich, complex tone, resin oboes offer a brighter, more consistent sound that some musicians find preferable for contemporary ensembles. The choice between the two often boils down to personal preference and playing context. For instance, a symphony orchestra oboist might opt for wood to blend with the ensemble’s timbre, while a marching band musician would favor resin for its weather resistance. Resin oboes also tend to be lighter, reducing fatigue during extended performances.

Persuasively, the environmental impact of resin oboes cannot be overlooked. Grenadilla wood, sourced from African blackwood trees, is increasingly scarce and classified as vulnerable due to overharvesting. By choosing resin, musicians contribute to conservation efforts while enjoying a sustainable alternative. Additionally, resin oboes are often more affordable than their wooden counterparts, making high-quality instruments accessible to a broader audience. This democratization of music aligns with the evolving needs of modern musicians.

In conclusion, resin oboes represent a significant advancement in woodwind instrument design, addressing the limitations of traditional materials without compromising performance. Whether for durability, consistency, or sustainability, resin oboes offer a compelling option for musicians seeking reliability in their craft. As technology continues to evolve, such innovations ensure that the art of oboe playing remains accessible and adaptable for generations to come.

How Long Does Bow Wood Last Before Losing Quality?

You may want to see also

Explore related products

Synthetic Bassoons: Bassoons are increasingly made from synthetic materials for enhanced durability and playability

The bassoon, a double-reed woodwind instrument known for its rich, complex tone, has traditionally been crafted from wood, primarily maple or cherry. However, in recent years, there has been a notable shift toward synthetic materials in bassoon construction. This transition is driven by the desire to enhance durability and playability, addressing common challenges associated with wooden instruments, such as susceptibility to temperature and humidity changes. Synthetic bassoons, often made from materials like ABS plastic or resin, offer a modern alternative that appeals to both professional musicians and students alike.

One of the most significant advantages of synthetic bassoons is their resilience to environmental factors. Wooden instruments can warp, crack, or swell when exposed to extreme conditions, requiring meticulous care and frequent adjustments. Synthetic materials, on the other hand, maintain their structural integrity across a wide range of temperatures and humidity levels, making them ideal for musicians who perform in diverse settings. For instance, a student traveling between a humid rehearsal space and a dry concert hall would find a synthetic bassoon far more reliable than its wooden counterpart.

Playability is another area where synthetic bassoons excel. Manufacturers have engineered these instruments to produce a consistent tone quality while reducing the weight, making them more comfortable to hold and play for extended periods. For young or smaller players, this can be a game-changer, as traditional bassoons can be cumbersome and physically demanding. Additionally, synthetic bassoons often feature ergonomic designs, such as contoured keys and adjustable mechanisms, which further enhance the playing experience.

Despite these benefits, some musicians remain skeptical of synthetic bassoons, arguing that they lack the warmth and depth of tone associated with wooden instruments. While it’s true that synthetic materials may not replicate the exact acoustic properties of wood, advancements in technology have significantly narrowed this gap. High-quality synthetic bassoons now offer a sound that is both clear and expressive, suitable for a wide range of musical genres. For educators and institutions, the affordability and low maintenance of synthetic bassoons make them an attractive option for equipping ensembles and orchestras.

In conclusion, the rise of synthetic bassoons represents a practical evolution in instrument design, balancing tradition with innovation. By prioritizing durability and playability, these instruments meet the needs of modern musicians while maintaining the bassoon’s distinctive voice. Whether for a professional seeking reliability or a student needing an accessible entry point, synthetic bassoons are proving to be a valuable addition to the woodwind family, even as they move away from their wooden origins.

Durability of Wood Tables: Factors Affecting Longevity and Lifespan

You may want to see also

Explore related products

Composite Piccolos: Piccolos often use composite materials, not wood, for lightweight design and weather resistance

Piccolos, traditionally associated with wooden construction, have increasingly embraced composite materials to address modern performance demands. These materials, such as carbon fiber, resin, and ABS plastic, offer a unique blend of durability, lightweight design, and weather resistance, making them ideal for outdoor performances and varying climatic conditions. Unlike wood, which can warp or crack due to humidity or temperature changes, composite piccolos maintain their structural integrity, ensuring consistent sound quality across environments.

The shift to composite materials is not merely a trend but a response to practical challenges faced by musicians. For instance, marching band performers often encounter extreme weather conditions, from scorching heat to heavy rain. A wooden piccolo, while sonically rich, risks damage under such circumstances. Composite piccolos, however, are designed to withstand these elements, allowing musicians to focus on their performance without worrying about instrument maintenance. This reliability has made them a staple in ensembles that perform outdoors.

From a manufacturing perspective, composite materials offer precision and consistency that natural wood cannot match. Wood, being a natural resource, varies in density, grain, and quality, leading to slight differences in sound and playability between instruments. Composite piccolos, on the other hand, are engineered to exact specifications, ensuring uniformity across production batches. This standardization benefits both manufacturers and musicians, as it guarantees predictable performance and reduces the likelihood of defects.

For musicians considering a composite piccolo, several factors should guide the decision. First, assess the primary playing environment. If performances frequently occur outdoors or in humid settings, a composite piccolo is a practical choice. Second, consider the weight and ergonomics. Composite instruments are generally lighter, reducing fatigue during extended playing sessions. Lastly, evaluate the tonal qualities. While some purists argue that wood produces a warmer sound, modern composites are engineered to replicate this characteristic, often with minimal compromise.

In conclusion, composite piccolos represent a fusion of tradition and innovation, addressing the limitations of wooden instruments without sacrificing performance. Their lightweight design, weather resistance, and manufacturing precision make them a compelling option for contemporary musicians. As the woodwind family continues to evolve, composite materials are likely to play an increasingly prominent role, redefining what it means to craft an instrument that meets the demands of both art and practicality.

Deep Woods Off Bug Spray Duration: How Long Does It Last?

You may want to see also

Frequently asked questions

The flute is a woodwind instrument that is now typically made of metal, such as silver, nickel, or gold, rather than wood.

Modern flutes are primarily made of metal for durability, consistency in sound, and ease of maintenance, as wood is more susceptible to changes in temperature and humidity.

Yes, instruments like the clarinet, oboe, and bassoon are still commonly made of wood, though some modern versions may use synthetic materials for specific parts.