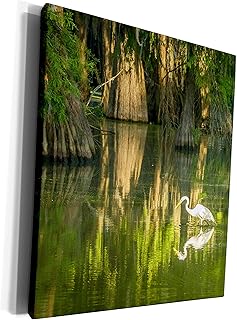

Cypress wood, renowned for its durability, natural resistance to decay, and distinctive beauty, is highly sought after in Louisiana, a state with a rich tradition of woodworking and a deep connection to its wetlands and forests. In Louisiana, cypress wood is primarily purchased by homeowners, contractors, and artisans who value its versatility for applications such as outdoor furniture, decking, siding, and interior paneling. Additionally, local sawmills and lumber suppliers cater to both individual buyers and businesses, while restoration projects and eco-conscious consumers increasingly seek sustainably harvested cypress. The demand is also driven by the wood’s cultural significance, as it has been a staple in Louisiana’s architectural and crafting heritage for generations.

Explore related products

$249.99

What You'll Learn

- Local furniture makers sourcing cypress wood for custom pieces in Louisiana

- Builders purchasing cypress for outdoor decking and siding projects

- Artists and craftsmen using cypress for sculptures and decorative items

- Homeowners buying cypress for durable, weather-resistant outdoor furniture

- Restoration experts acquiring cypress for historic building repairs in Louisiana

Local furniture makers sourcing cypress wood for custom pieces in Louisiana

In Louisiana, local furniture makers are increasingly turning to cypress wood for crafting custom pieces, drawn by its durability, natural beauty, and deep cultural roots in the region. Cypress, with its rich, reddish-brown tones and resistance to decay, is ideal for both indoor and outdoor furniture. Makers like those in New Orleans and Baton Rouge are reviving traditional techniques while incorporating modern designs, creating pieces that resonate with both heritage and contemporary tastes. This trend not only supports local artisans but also promotes sustainable forestry practices, as cypress is often harvested from managed wetlands.

For furniture makers, sourcing cypress wood locally is both practical and purposeful. Louisiana’s abundant cypress forests provide a steady supply, reducing transportation costs and carbon footprints. Artisans often collaborate with mills in areas like Houma or Lafayette, where cypress is milled to specification. This direct relationship ensures quality control and allows makers to select wood with unique grain patterns or characteristics, enhancing the individuality of their custom pieces. For instance, a maker in Shreveport might choose a cypress slab with natural burls for a one-of-a-kind dining table, appealing to clients seeking bespoke, story-driven furniture.

Clients commissioning custom cypress furniture in Louisiana are typically homeowners, interior designers, or businesses looking for pieces that reflect the state’s natural and cultural identity. A cypress bed frame or credenza becomes more than just furniture—it’s a conversation piece that ties a space to its surroundings. Makers often educate clients on cypress’s properties, such as its natural resistance to insects and moisture, making it suitable for humid climates. For outdoor pieces, artisans may recommend a protective finish like tung oil to preserve the wood’s appearance while maintaining its rustic charm.

To ensure sustainability, furniture makers must navigate the ethical sourcing of cypress. While Louisiana’s wetlands are a primary source, over-harvesting can harm ecosystems. Responsible artisans prioritize suppliers who adhere to guidelines from organizations like the Cypress Forest Project, which promotes balanced harvesting. Clients can support this by asking makers about their sourcing practices and opting for pieces made from reclaimed or certified wood. This approach not only preserves Louisiana’s wetlands but also ensures that cypress furniture remains a viable craft for future generations.

In practice, commissioning a custom cypress piece involves collaboration between maker and client. Start by discussing design preferences, whether it’s a minimalist coffee table or an ornate headboard. Makers will then source the appropriate cypress, considering factors like grain direction and moisture content. Clients should expect a timeline of 4–8 weeks, depending on complexity. For maintenance, a yearly application of linseed oil or wax will keep the wood vibrant. By choosing cypress furniture, Louisianans invest in a piece that embodies both craftsmanship and the spirit of their homeland.

Best Places to Buy Quality Wood for Furniture Making

You may want to see also

Explore related products

Builders purchasing cypress for outdoor decking and siding projects

Builders seeking durable, aesthetically pleasing materials for outdoor projects often turn to cypress wood, a staple in Louisiana’s construction industry. Cypress is prized for its natural resistance to rot, insects, and moisture, making it ideal for decking and siding in the state’s humid, wet climate. Unlike pressure-treated pine, which relies on chemical treatments, cypress achieves its durability through its inherent properties, appealing to builders who prioritize both longevity and environmental sustainability. This wood’s ability to withstand Louisiana’s harsh weather without warping or decaying ensures that outdoor structures remain structurally sound and visually appealing for decades.

When selecting cypress for decking, builders must consider the wood’s grade and finish. Premium grades, such as “select” or “clear,” offer minimal knots and a smoother surface, enhancing the deck’s overall appearance. For siding, a more rustic grade like “common” can add character while maintaining durability. Builders should also account for cypress’s natural color, which ranges from honey to reddish-brown, and decide whether to stain or seal it to preserve its hue or allow it to weather to a silver-gray patina. Proper installation techniques, such as using stainless steel fasteners to prevent corrosion, are critical to maximizing the wood’s lifespan.

Comparatively, cypress outperforms many alternatives in outdoor applications. While cedar is also rot-resistant, cypress is harder and more stable, reducing the likelihood of splintering or cracking. Composite materials, though low-maintenance, lack the natural beauty and warmth of cypress and often come with a higher upfront cost. For builders in Louisiana, cypress strikes a balance between performance, cost, and aesthetics, particularly for projects where authenticity and regional character are valued. Its availability from local mills further reduces transportation costs and supports the state’s economy.

To ensure success, builders should source cypress from reputable suppliers who prioritize sustainable harvesting practices. Louisiana’s cypress forests are vital ecosystems, and responsible sourcing helps preserve them for future generations. Additionally, builders should educate clients about cypress’s maintenance needs, which are minimal but essential. Periodic cleaning and resealing every 2–3 years will keep the wood in optimal condition. By combining cypress’s natural advantages with proper care, builders can deliver outdoor decking and siding projects that stand the test of time in Louisiana’s challenging environment.

Best Places to Purchase Tiny Tot Wood Stoves for Cozy Spaces

You may want to see also

Explore related products

$1.45

Artists and craftsmen using cypress for sculptures and decorative items

Cypress wood, with its rich texture and durability, has long been a favorite among artists and craftsmen in Louisiana. Its natural resistance to decay and distinctive grain patterns make it ideal for creating sculptures and decorative items that stand the test of time. From intricate carvings to bold, statement pieces, cypress wood offers a unique canvas for creative expression.

Consider the process of selecting the right cypress wood for your project. Artists often seek out aged or reclaimed cypress, as it carries a patina that adds depth and character to their work. When sourcing, look for suppliers who specialize in sustainably harvested or salvaged cypress, ensuring your art aligns with eco-conscious practices. For beginners, start with smaller blocks or planks to practice carving techniques before tackling larger sculptures.

One standout example is the use of cypress in creating Louisiana-inspired decorative items, such as pelican sculptures or Mardi Gras masks. The wood’s ability to hold fine details allows artisans to capture the essence of these cultural symbols with precision. For instance, a cypress pelican sculpture can be sanded smooth, stained to enhance its natural color, and finished with a protective coat of tung oil to preserve its beauty. This approach not only honors the material but also connects the artwork to the region’s heritage.

Comparatively, cypress wood holds an edge over other materials like pine or oak in outdoor sculptures due to its natural resistance to moisture and insects. While oak may warp or crack over time, cypress maintains its integrity, making it a superior choice for garden art or public installations. However, artists should be cautious of its weight; cypress is denser than many woods, so larger pieces may require additional structural support during installation.

To maximize the potential of cypress in your work, experiment with combining it with other materials. For instance, pairing cypress with metal accents can create a striking contrast between organic warmth and industrial edge. Additionally, incorporating LED lighting into cypress sculptures can highlight its grain patterns, transforming a static piece into an interactive experience. Whether you’re a seasoned artist or a hobbyist, cypress wood offers endless possibilities for crafting pieces that are both beautiful and enduring.

Affordable Wood Sources for Turning: Best Places to Buy Cheap Lumber

You may want to see also

Explore related products

Homeowners buying cypress for durable, weather-resistant outdoor furniture

Louisiana homeowners seeking durable, weather-resistant outdoor furniture increasingly turn to cypress wood for its natural resilience and timeless aesthetic. Unlike pine or cedar, cypress contains cypressene, an oil that acts as a built-in preservative, repelling insects and resisting rot without chemical treatments. This makes it ideal for Louisiana’s humid, storm-prone climate, where other woods may warp, crack, or decay within a few seasons. For those investing in long-term outdoor living spaces, cypress offers a cost-effective solution that outlasts synthetic alternatives, which often fade or become brittle under intense sun exposure.

When selecting cypress for outdoor furniture, homeowners should prioritize kiln-dried lumber to minimize warping and ensure stability. Look for pieces with tight grain patterns, as these indicate higher density and better durability. For DIY enthusiasts, cypress is forgiving to work with—its straight grain allows for clean cuts, and its natural oils reduce the need for sanding. However, avoid over-sanding, as this can remove the protective oils. Pre-drilling holes for screws is essential to prevent splitting, especially in thicker pieces like table legs or bench frames.

Comparing cypress to popular alternatives highlights its advantages. Teak, while highly durable, is significantly more expensive and often sourced unsustainably. Pressure-treated pine, though affordable, leaches chemicals and requires frequent sealing. Cypress strikes a balance, offering comparable durability to teak at a fraction of the cost and without the environmental concerns. Its warm, honey-toned color ages gracefully to a silver-gray patina, blending seamlessly with both modern and rustic outdoor designs.

To maximize cypress furniture’s lifespan, apply a UV-protective sealant annually to maintain its color and prevent weathering. For a natural look, use linseed or tung oil, which enhance the wood’s grain without obscuring it. Position furniture in areas with partial shade to reduce direct sun exposure, and use waterproof covers during prolonged rain or winter months. With proper care, cypress outdoor furniture can last 20–30 years, making it a smart choice for homeowners who value both functionality and beauty in their outdoor spaces.

Best Sources to Purchase Premium Black American Walnut Wood Online

You may want to see also

Explore related products

Restoration experts acquiring cypress for historic building repairs in Louisiana

Cypress wood, with its natural durability and resistance to decay, has been a cornerstone of Louisiana’s architectural heritage for centuries. Restoration experts tasked with preserving historic buildings in the state often seek out this prized material to maintain authenticity and structural integrity. Unlike modern alternatives, cypress’s ability to withstand moisture and insect damage aligns perfectly with the humid, flood-prone climate of Louisiana. However, sourcing old-growth cypress—the type originally used in many historic structures—has become increasingly challenging due to deforestation and environmental regulations. This scarcity drives experts to explore reclaimed cypress from dismantled buildings or sustainably harvested new-growth options, ensuring both preservation and ecological responsibility.

For restoration projects, the process of acquiring cypress wood involves meticulous planning and research. Experts often collaborate with local mills, salvage companies, and specialty suppliers who stock reclaimed cypress beams, planks, and siding. One notable example is the restoration of antebellum homes along the Mississippi River, where original cypress elements are carefully replaced or repaired using wood sourced from deconstructed barns or river-recovered logs. These materials, often aged over a century, match the patina and grain patterns of the original construction, preserving the building’s historical character. Restoration teams must also navigate legal considerations, such as ensuring the wood’s provenance complies with the Lacey Act, which prohibits trade in illegally harvested timber.

The choice of cypress for historic repairs is not merely aesthetic; it’s a practical decision rooted in the wood’s unique properties. Cypress contains natural oils that repel insects and fungi, reducing the need for chemical treatments that could alter the building’s historical appearance. Its dimensional stability minimizes warping and cracking over time, a critical factor in structures exposed to Louisiana’s extreme weather. For instance, in the restoration of St. Martin de Tours Church in St. Martinville, cypress was used to replace deteriorated support beams, ensuring the 18th-century structure could withstand future hurricanes and flooding. This blend of historical accuracy and functional resilience underscores why cypress remains the material of choice for restoration experts.

Despite its advantages, working with cypress in restoration projects presents challenges. The wood’s density makes it heavier and more difficult to work with than modern alternatives, requiring skilled craftsmen familiar with traditional techniques. Additionally, the cost of reclaimed or sustainably sourced cypress can be prohibitive, often exceeding that of pressure-treated pine or composite materials. To mitigate expenses, some experts adopt a hybrid approach, using cypress for visible or load-bearing elements and more affordable options for hidden structural components. This strategic use ensures the building retains its historical essence without compromising on budget or sustainability.

In conclusion, the acquisition of cypress wood for historic building repairs in Louisiana is a delicate balance of preservation, practicality, and innovation. Restoration experts must navigate a landscape shaped by environmental concerns, material scarcity, and the imperative to honor architectural heritage. By leveraging reclaimed wood, collaborating with specialized suppliers, and employing traditional craftsmanship, they ensure that Louisiana’s historic structures endure for future generations. This commitment not only safeguards the state’s cultural legacy but also highlights the timeless value of cypress as a building material.

Best Places to Purchase Wood Pellet Stoves for Your Home

You may want to see also

Frequently asked questions

Primary buyers include lumber mills, woodworking artisans, construction companies, furniture makers, and specialty wood retailers.

Yes, homeowners often purchase cypress wood for decking, siding, outdoor furniture, and interior woodworking projects due to its durability and aesthetic appeal.

Yes, industries such as boatbuilding, dock construction, and restoration projects for historic homes and buildings frequently buy cypress wood for its rot-resistant properties.

Yes, international buyers, particularly from Europe and Asia, purchase Louisiana cypress wood for high-end furniture, flooring, and specialty woodworking projects.

Yes, local sawmills, lumberyards, and wood suppliers in Louisiana specialize in buying and selling cypress wood, often sourcing it from sustainable forestry operations.