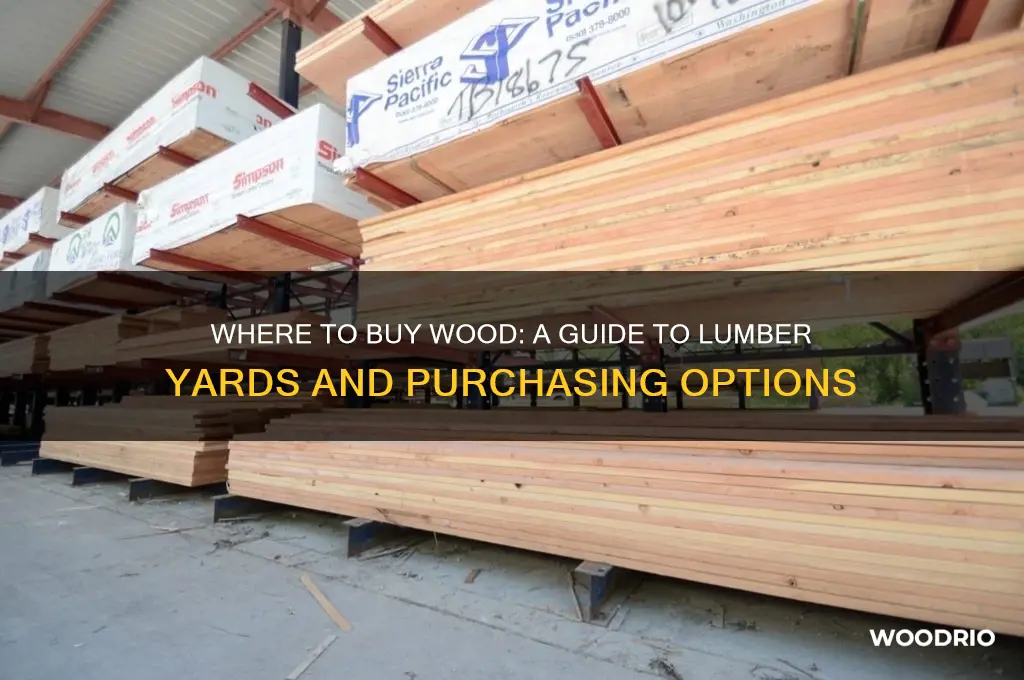

If you're considering purchasing wood for a project, buying from a lumber yard is a practical and efficient option. Lumber yards offer a wide variety of wood types, sizes, and grades, catering to both professional builders and DIY enthusiasts. They typically stock hardwoods, softwoods, and specialty woods, ensuring you can find the right material for your needs. Additionally, lumber yards often provide services like cutting wood to specific dimensions, which can save time and effort. Before visiting, it’s helpful to know the type and quantity of wood you need, as well as any specific requirements for your project. Many lumber yards also offer advice and expertise, making them a valuable resource for anyone working with wood.

| Characteristics | Values |

|---|---|

| Availability | Yes, most lumber yards sell wood to both contractors and individual buyers. |

| Types of Wood | Hardwoods (e.g., oak, maple, cherry), softwoods (e.g., pine, cedar, spruce), exotic woods, and engineered wood products. |

| Forms Available | Boards, planks, beams, dimensional lumber, plywood, veneers, and custom cuts. |

| Pricing | Varies by type, quality, and quantity; bulk purchases often receive discounts. |

| Quantity Options | Sold by the board foot, linear foot, or in pre-packaged bundles. |

| Quality Grades | Ranging from select/premium grades to standard/construction grades. |

| Customization | Many yards offer milling, cutting, and planing services for specific project needs. |

| Delivery Options | Some yards provide delivery services for large orders, often for an additional fee. |

| Sustainability | Many lumber yards offer FSC-certified or sustainably sourced wood options. |

| Expert Advice | Staff can provide guidance on wood selection, usage, and project planning. |

| Payment Methods | Cash, credit/debit cards, and sometimes account credit for regular customers. |

| Operating Hours | Typically open during standard business hours; some may have weekend hours. |

| Location | Widely available in urban and rural areas; check local directories or online for nearby yards. |

| Seasonal Availability | Some woods may be more readily available during certain seasons due to harvesting cycles. |

| Return Policy | Varies by yard; some may accept returns of unused, undamaged wood with a receipt. |

Explore related products

What You'll Learn

- Types of Wood Available: Hardwoods, softwoods, exotic, treated, and untreated options at lumber yards

- Pricing and Quantity: Cost per board foot, bulk discounts, and minimum purchase requirements

- Wood Quality and Grades: Understanding grades, defects, and selecting the right quality for projects

- Delivery and Pickup Options: In-store pickup, delivery fees, and scheduling for large wood orders

- Custom Cutting Services: Availability of cutting, planing, and milling services at lumber yards

Types of Wood Available: Hardwoods, softwoods, exotic, treated, and untreated options at lumber yards

Lumber yards are treasure troves for woodworkers, builders, and DIY enthusiasts, offering a diverse array of wood types to suit any project. Among the most common categories are hardwoods and softwoods, each with distinct characteristics. Hardwoods, like oak, maple, and cherry, are denser and more durable, making them ideal for furniture, flooring, and cabinetry. Softwoods, such as pine, cedar, and spruce, are lighter and easier to work with, often used for framing, decking, and outdoor projects. Understanding the differences between these two broad categories is the first step in selecting the right wood for your needs.

For those seeking something unique, exotic woods like teak, mahogany, and walnut are often available at well-stocked lumber yards. These woods are prized for their rich colors, distinctive grain patterns, and exceptional durability, though they come at a higher price point. Exotic woods are perfect for high-end furniture, decorative accents, or projects where aesthetics are paramount. However, it’s essential to consider sustainability when purchasing exotic woods, as some species are endangered or harvested irresponsibly. Look for certifications like FSC (Forest Stewardship Council) to ensure ethical sourcing.

Another critical distinction is between treated and untreated wood. Treated wood, typically pressure-treated with chemicals like CCA (chromated copper arsenate) or ACQ (alkaline copper quat), is designed to resist rot, insects, and moisture, making it ideal for outdoor applications like decks, fences, and playground equipment. Untreated wood, on the other hand, is free from chemicals and better suited for indoor projects or applications where natural finishes are desired. Always wear protective gear when handling treated wood, as the chemicals can be harmful if inhaled or absorbed through the skin.

When visiting a lumber yard, take the time to inspect the wood for quality. Look for straight grains, minimal knots, and absence of cracks or warping. Ask the staff about the wood’s origin, treatment, and best uses—their expertise can save you time and money. Additionally, consider purchasing slightly more than you need to account for cuts, mistakes, or future repairs. With the right knowledge and preparation, buying wood from a lumber yard can transform your project from ordinary to exceptional.

Where to Find Extra Wood Dowels for Your IKEA Furniture

You may want to see also

Explore related products

Pricing and Quantity: Cost per board foot, bulk discounts, and minimum purchase requirements

Wood pricing at lumber yards typically revolves around the board foot, a unit of measurement that calculates volume (144 cubic inches, or 1" x 12" x 12"). This standardizes costs across different wood species and dimensions, allowing for apples-to-apples comparisons. For instance, a 2" x 4" x 8' board contains 5.33 board feet (2 x 4 x 8 / 144). Prices per board foot vary widely: common pine might range from $0.50 to $2.00, while exotic hardwoods like mahogany can exceed $20.00. Understanding this metric is crucial for budgeting, as it directly ties material costs to project scale.

For larger projects, bulk discounts become a pivotal factor in reducing overall expenses. Lumber yards often offer tiered pricing based on volume, with discounts kicking in at thresholds like 100, 500, or 1,000 board feet. For example, purchasing 500 board feet of oak might reduce the price from $6.00 to $5.00 per board foot, saving $500. However, these discounts usually apply to a single species or grade, so plan purchases accordingly. Pro tip: If your project requires multiple wood types, negotiate with the yard to bundle orders for a collective discount.

While bulk discounts incentivize large purchases, minimum purchase requirements can pose a barrier for smaller projects. Some lumber yards enforce minimums, often 50 to 100 board feet, to streamline operations and ensure profitability. For hobbyists or DIYers needing only a few boards, this can be frustrating. Solution: Look for yards that cater to smaller buyers or consider splitting orders with a friend. Alternatively, some yards may waive minimums for premium wood species or repeat customers.

Finally, practical strategies can maximize value within these pricing structures. First, calculate your project’s exact board footage to avoid overbuying. Second, inquire about offcuts or shorts—smaller, discounted pieces often overlooked by larger buyers. Third, time purchases strategically: end-of-season sales or overstock clearances can yield significant savings. For example, buying pressure-treated lumber in late fall, when demand drops, might save 20–30%. By navigating cost per board foot, bulk discounts, and minimums with these tactics, you can balance quantity and budget effectively.

Best Places to Buy Wood Splits for Smoking Meat & BBQ

You may want to see also

Explore related products

$14.88

Wood Quality and Grades: Understanding grades, defects, and selecting the right quality for projects

Wood grades are not just labels—they are a language that communicates the material’s intended use, defects, and overall quality. Understanding this language is critical when purchasing from a lumber yard, as it directly impacts the structural integrity, appearance, and cost of your project. For instance, Select Structural grades are ideal for load-bearing applications due to their minimal defects, while Standard grades, with more knots and imperfections, are better suited for non-visible or utility purposes. Knowing these distinctions ensures you don’t overpay for wood you don’t need or compromise safety by choosing subpar material.

Defects in wood—such as knots, splits, or warping—are not inherently bad but must be evaluated in context. A small, tight knot in a No. 1 Common grade board might be acceptable for framing, but the same defect in a Clear grade board would render it unsuitable for fine furniture. Inspecting wood for defects involves more than a cursory glance; run your hand along the surface to detect subtle warping, and examine end grains for signs of cracking or decay. Pro tip: Bring a straightedge to the lumber yard to check for bowing or twisting, as even minor deviations can complicate cutting and assembly.

Selecting the right wood quality begins with defining your project’s requirements. For outdoor structures, prioritize pressure-treated lumber with a Premium grade to resist rot and insect damage. For cabinetry, opt for First and Seconds (FAS) hardwoods, which offer wide, clear boards with minimal defects. If budget is a concern, consider No. 2 Common for projects where appearance is secondary, such as subflooring or temporary forms. Always factor in waste—higher-grade woods may reduce scrap, offsetting their higher cost.

Comparing grades across species reveals how quality standards adapt to natural variations. Softwoods like pine are graded for strength and knot size, while hardwoods like oak are evaluated for color consistency and grain pattern. For example, FAS oak boards are nearly defect-free and ideal for high-end furniture, whereas No. 1 Common oak, with its color variations and small knots, is perfect for rustic projects. Understanding these species-specific standards ensures you select wood that aligns with both your aesthetic and functional needs.

Finally, building a relationship with your lumber yard staff can be as valuable as understanding grades. Experienced employees can guide you to the best options for your project, often suggesting alternatives that balance quality and cost. Ask about offcuts or bundles of mixed grades, which can be cost-effective for smaller projects. And remember: wood is a natural material, so embrace minor imperfections as character rather than flaws. With the right knowledge and approach, selecting wood becomes less about avoiding defects and more about finding the perfect match for your vision.

Discover Authentic Real Wood Furniture: Top Retailers and Buying Tips

You may want to see also

Explore related products

Delivery and Pickup Options: In-store pickup, delivery fees, and scheduling for large wood orders

Buying wood from a lumber yard offers flexibility in how you receive your materials, but the logistics of large orders demand careful planning. In-store pickup is often the most cost-effective option, as it eliminates delivery fees entirely. Most lumber yards allow you to select and load your wood on-site, though you’ll need a vehicle capable of handling the size and weight of your order. Pro tip: Call ahead to confirm availability and ensure staff can assist with loading if needed. This option is ideal for smaller projects or if you have immediate access to transportation.

For larger or heavier orders, delivery becomes a practical necessity, but fees can vary widely. Delivery costs are typically calculated based on distance, order size, and whether specialized equipment like cranes or forklifts is required. Some lumber yards offer free delivery for orders exceeding a certain threshold, often $500–$1,000, depending on the supplier. To minimize costs, consolidate your order into a single delivery or coordinate with neighbors on bulk purchases. Always request a detailed quote upfront to avoid surprises, and inquire about any additional charges for weekend or expedited delivery.

Scheduling is critical for both pickup and delivery, especially for large wood orders. Lumber yards often require 24–48 hours’ notice to prepare your materials, and delivery slots may fill up quickly during peak seasons like spring and summer. For delivery, ensure someone is available to receive the shipment and provide clear instructions for drop-off, including any access restrictions or preferred placement. If you’re picking up, plan your visit during off-peak hours to avoid long waits. Flexibility with timing can often secure you a better deal or faster service.

Comparing delivery and pickup options reveals trade-offs between cost, convenience, and control. While in-store pickup saves money, it requires more effort and resources on your part. Delivery, though pricier, offers convenience and is essential for oversized or unwieldy materials. For example, a full cord of firewood might cost $50–$100 to deliver, but attempting to transport it yourself could risk vehicle damage or multiple trips. Weigh these factors against your project’s scale, timeline, and budget to make the best choice.

Finally, don’t overlook the value of building a relationship with your lumber yard. Regular customers often receive perks like waived fees, priority scheduling, or discounts on future orders. Ask about loyalty programs or bulk purchase incentives, and communicate your needs clearly to ensure smooth transactions. Whether you opt for pickup or delivery, proactive planning and open communication will streamline the process and set your project up for success.

Discover the Best Places to Buy High-Quality Wood for Your Projects

You may want to see also

Explore related products

$32.85 $36.9

$19.45 $20.88

Custom Cutting Services: Availability of cutting, planing, and milling services at lumber yards

Lumber yards are not just repositories of raw timber; they often serve as hubs for custom wood processing. Many yards offer cutting, planing, and milling services, transforming rough lumber into precisely dimensioned pieces ready for your project. This is particularly valuable for DIY enthusiasts and professionals alike, as it saves time and ensures accuracy that might be hard to achieve with home tools. For instance, if you’re building a custom bookshelf, a lumber yard can cut boards to exact lengths, plane them to uniform thickness, and even mill edges for a polished finish.

When considering these services, it’s essential to understand the scope of what’s offered. Cutting services typically include crosscutting (cutting across the grain) and ripping (cutting along the grain). Planing reduces thickness and smooths surfaces, while milling can create custom profiles like tongue-and-groove or decorative edges. Some yards may also offer joinery services, such as cutting dadoes or rabbets. Always inquire about the yard’s capabilities and any limitations, such as minimum or maximum board lengths, to ensure they align with your needs.

Cost is another critical factor. Custom cutting services are usually priced per linear foot or by the complexity of the task. For example, simple crosscuts might cost $0.50 per cut, while intricate milling could run $2–$5 per linear foot. Bulk orders often qualify for discounts, so if you’re working on a large project, ask about pricing tiers. Additionally, some yards charge a setup fee for specialized machinery, so factor this into your budget.

To make the most of these services, come prepared. Bring detailed measurements and a clear plan for your project. If possible, provide a sketch or digital file outlining the cuts and finishes you need. Communicate any specific requirements, such as grain direction or edge treatment, to avoid misunderstandings. Finally, ask about turnaround times, as custom work can take anywhere from a few hours to several days, depending on the yard’s workload and the complexity of your request.

In conclusion, custom cutting, planing, and milling services at lumber yards are a game-changer for woodworking projects. They offer precision, save time, and can elevate the quality of your work. By understanding the services available, budgeting appropriately, and preparing thoroughly, you can leverage these resources to bring your vision to life with professional results. Whether you’re a novice or a seasoned builder, these services are a valuable tool in your woodworking arsenal.

Discover Top Retailers for Whittier Wood Furniture: Your Ultimate Guide

You may want to see also

Frequently asked questions

Yes, most lumber yards sell wood directly to both contractors and individual customers.

No, lumber yards typically serve both professionals and DIY enthusiasts, so anyone can purchase wood.

Lumber yards offer a wide variety of wood types, including hardwoods (e.g., oak, maple), softwoods (e.g., pine, cedar), and specialty woods, depending on the yard.

Many lumber yards offer cutting services for an additional fee, allowing you to get wood cut to your desired dimensions.

Some lumber yards may have minimum purchase requirements, especially for specialty or custom orders, but many allow purchases of any quantity.