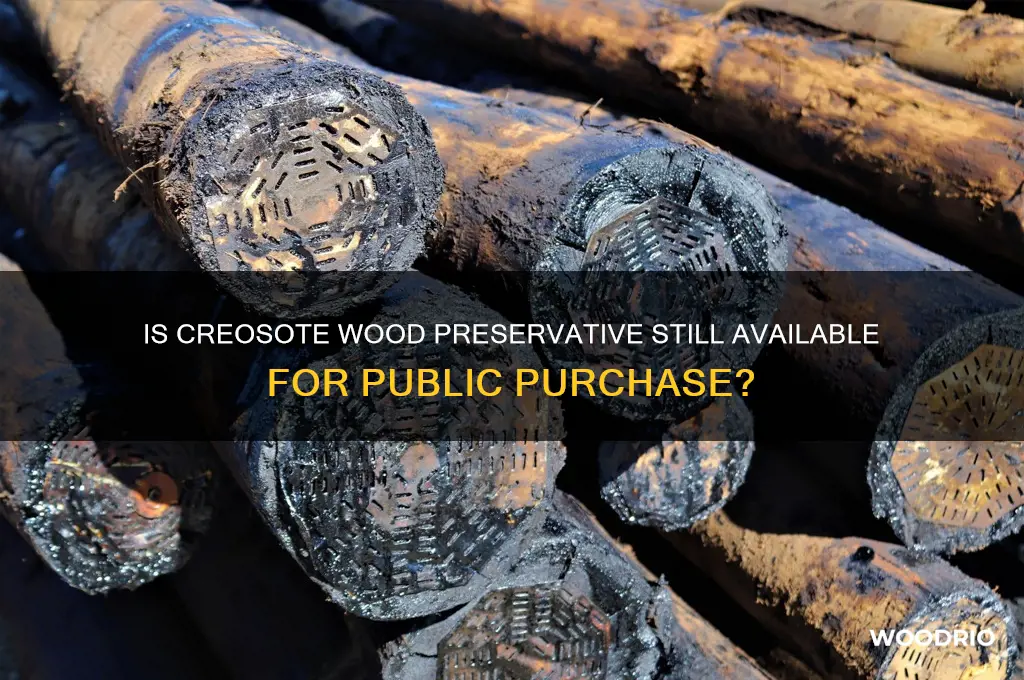

Creosote, a well-known wood preservative, has been widely used for decades to protect wooden structures like railroad ties, utility poles, and marine pilings from decay, insects, and fungi. However, due to growing environmental and health concerns, its availability to the general public has become increasingly restricted. Classified as a hazardous substance by regulatory agencies such as the U.S. Environmental Protection Agency (EPA), creosote is now primarily limited to industrial and commercial applications, with strict regulations governing its use and disposal. As a result, the general public typically cannot purchase creosote for residential or personal projects, and safer alternatives are recommended for wood preservation needs.

| Characteristics | Values |

|---|---|

| Availability to General Public | Restricted; primarily available for industrial or commercial use only. |

| Regulation | Banned or heavily restricted in many countries (e.g., EU, Canada) due to health and environmental concerns. |

| Health Risks | Carcinogenic, skin and respiratory irritant, toxic if ingested. |

| Environmental Impact | Persistent organic pollutant (POP), harmful to aquatic life and soil. |

| Alternatives | Copper azole, ACQ (Alkaline Copper Quaternary), borates, and other eco-friendly preservatives. |

| Current Use | Limited to specific industrial applications, such as railroad ties and utility poles. |

| Legal Status in the U.S. | Restricted for residential use; EPA allows only for certified professionals. |

| Consumer Access | Not readily available at retail stores; requires special permits or licenses. |

| Chemical Composition | Mixture of creosols, phenols, and polycyclic aromatic hydrocarbons (PAHs). |

| Durability | Highly effective in preserving wood against decay, insects, and fungi. |

Explore related products

What You'll Learn

Availability of Creosote for Public Purchase

Creosote, a tar-based wood preservative, has been a staple in outdoor construction for decades, prized for its durability against rot, insects, and weathering. However, its availability to the general public has become increasingly restricted due to environmental and health concerns. In many regions, including the United States and the European Union, creosote is no longer sold for residential use. This shift is primarily driven by regulations such as the U.S. Environmental Protection Agency’s (EPA) restrictions, which limit creosote to industrial and agricultural applications only. For homeowners and DIY enthusiasts, this means traditional creosote is largely off-limits, leaving them to seek alternative wood preservatives.

For those still seeking creosote, understanding its restricted status is crucial. Industrial-grade creosote, while available, is typically sold in bulk quantities and requires specialized handling due to its toxic nature. It contains polycyclic aromatic hydrocarbons (PAHs), which are known carcinogens, posing risks through skin contact, inhalation, or ingestion. If you work in industries like railroad maintenance or utility pole treatment, you may access creosote through authorized suppliers, but strict safety protocols, including personal protective equipment (PPE) like gloves and respirators, are mandatory. For the average consumer, however, these requirements make it impractical and often unsafe to use.

Alternatives to creosote have emerged to fill the gap for residential projects. Copper azole, ACQ (alkaline copper quaternary), and borate-based treatments are now popular choices, offering comparable protection without the same health risks. These modern preservatives are widely available at hardware stores and online retailers, often in user-friendly formulations suitable for fences, decks, and garden structures. While they may require more frequent reapplication compared to creosote, their ease of use and safety profile make them a preferable option for most homeowners.

If you’re determined to use creosote for a specific project, research local regulations thoroughly. In some countries, such as Canada, creosote remains available for certain applications, though restrictions still apply. Additionally, reclaimed creosote-treated wood can sometimes be sourced from salvage yards, though its use should be limited to non-contact areas due to lingering chemical residues. Always prioritize safety and legality, as improper handling or use of creosote can lead to fines or health complications. For most, the transition to safer alternatives is not just a regulatory requirement but a practical and responsible choice.

Top Places to Purchase High-Quality Wooden Bed Frames Online

You may want to see also

Explore related products

Regulations on Creosote Sales to Consumers

Creosote, a potent wood preservative, is no longer freely available to the general public in many regions due to stringent regulations aimed at protecting human health and the environment. Historically, creosote was widely used for treating wooden structures like fences, poles, and railroad ties because of its effectiveness against decay and pests. However, its toxic components, including polycyclic aromatic hydrocarbons (PAHs), have been linked to skin irritation, respiratory issues, and even cancer. As a result, regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) have imposed strict controls on its sale and use.

In the United States, the EPA classifies creosote as a restricted-use pesticide, meaning it can only be purchased and applied by certified professionals. This restriction, implemented under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), aims to minimize consumer exposure to its harmful chemicals. Similarly, in the European Union, creosote is listed as a substance of very high concern (SVHC) under the REACH regulation, severely limiting its availability to the public. These measures reflect a global trend toward prioritizing safety over convenience, even for products with proven efficacy.

For homeowners and DIY enthusiasts, these regulations mean that traditional creosote is no longer an option for wood preservation projects. Instead, alternatives such as copper azole, alkaline copper quat (ACQ), and borate treatments are recommended. These substitutes are less toxic and equally effective for most applications. However, they may require different application methods, such as pressure treatment or brush-on techniques, and their longevity can vary depending on environmental conditions.

Despite these restrictions, creosote remains in use for industrial and commercial purposes, particularly in applications where its durability is unmatched. For instance, utility poles and marine pilings often rely on creosote treatment due to their exposure to harsh conditions. Certified applicators must follow strict safety protocols, including wearing protective gear and ensuring proper disposal of treated materials, to comply with regulations. This dual approach—restricting consumer access while allowing controlled industrial use—balances the benefits of creosote with its inherent risks.

In summary, while the general public can no longer purchase creosote for personal use, its legacy in industrial applications endures under tight regulatory oversight. Consumers are encouraged to explore safer alternatives and consult professionals for wood preservation needs. By understanding these regulations, individuals can make informed choices that protect both their projects and their health.

Discover Top Spots to Buy Fresh Hen of the Woods Mushrooms

You may want to see also

Explore related products

Alternatives to Creosote for Wood Preservation

Creosote, a traditional wood preservative, has faced restrictions due to its environmental and health concerns, limiting public access. As a result, the search for safer and more sustainable alternatives has intensified. One prominent alternative is copper-based preservatives, such as ACQ (Alkaline Copper Quaternary) and CA-B (Copper Azole). These treatments are widely available to the general public and are known for their effectiveness against decay, fungi, and insects. ACQ, for instance, is applied at a retention level of 0.4 to 0.6 pounds per cubic foot of wood, depending on the intended use, and requires proper ventilation during application. While copper-based preservatives are more expensive than creosote, their low toxicity and long-lasting protection make them a preferred choice for residential and commercial projects.

Another eco-friendly option gaining popularity is borate-based preservatives, which penetrate wood deeply and act as a barrier against pests and fungi. Products like Disodium Octaborate Tetrahydrate (DOT) are applied through spraying, dipping, or pressure treatment. A typical solution concentration is 10% borate in water, and the wood should be allowed to dry thoroughly after treatment. Borates are particularly effective in indoor applications, such as flooring or framing, due to their low leaching rate in dry conditions. However, they are less suitable for outdoor use in humid climates, as moisture can cause the borates to leach out, reducing their efficacy.

For those seeking natural alternatives, linseed oil and natural resins offer a non-toxic solution. Linseed oil, derived from flax seeds, penetrates wood fibers, providing a protective barrier against moisture and UV damage. When combined with pine resin or other natural additives, it enhances durability. Application involves brushing or spraying multiple thin coats, allowing each layer to dry before adding the next. While this method is labor-intensive and less durable than chemical treatments, it is ideal for small-scale projects like garden furniture or interior woodwork, where a chemical-free approach is desired.

A comparative analysis reveals that heat treatment is another innovative alternative, though less accessible to the general public. This process involves heating wood to temperatures between 190°C and 212°C (374°F to 414°F) to kill fungi, insects, and their eggs. The result is dimensionally stable, durable wood with a darker, weathered appearance. While professional equipment is required, some DIY enthusiasts use homemade kilns for smaller projects. Heat-treated wood is particularly popular in Europe and is gaining traction in North America for its chemical-free, eco-friendly appeal.

In conclusion, the shift away from creosote has spurred the development of diverse wood preservation methods. From copper-based treatments to natural oils and advanced techniques like heat treatment, each alternative offers unique advantages and limitations. The choice depends on factors such as intended use, environmental impact, and budget. By exploring these options, the general public can make informed decisions to protect wood effectively while minimizing harm to health and the environment.

Best Places to Purchase Butternut Wood for Carving Projects

You may want to see also

Explore related products

Health and Safety Concerns of Creosote Use

Creosote, a tar-based wood preservative, has been widely used for decades to protect wooden structures like fences, railroad ties, and telephone poles from decay and insect damage. However, its availability to the general public has become increasingly restricted due to significant health and safety concerns. While industrial-grade creosote remains in use for specific applications, consumer-grade products containing creosote have largely been phased out in many regions, including the United States and the European Union. This shift is primarily driven by the substance’s toxicity and environmental impact, prompting regulatory bodies to limit its accessibility and recommend safer alternatives.

One of the most pressing health concerns associated with creosote is its classification as a probable human carcinogen by the International Agency for Research on Cancer (IARC). Prolonged or repeated exposure to creosote, whether through skin contact, inhalation, or ingestion, can lead to severe health issues. For instance, workers in industries like railroad maintenance or construction, who handle creosote-treated wood regularly, face higher risks of skin disorders, respiratory problems, and even certain types of cancer. The general public, particularly children and pets, can also be at risk if they come into contact with creosote-treated surfaces, as the substance can leach into soil and water over time.

To mitigate these risks, regulatory agencies have implemented strict guidelines for creosote use. In the U.S., the Environmental Protection Agency (EPA) restricts the sale of creosote-based wood preservatives to certified professionals only, effectively banning its use by consumers. Similarly, the European Chemicals Agency (ECHA) has classified creosote as a substance of very high concern (SVHC), limiting its application to industrial settings with controlled exposure. These measures aim to protect both workers and the general public from the harmful effects of creosote while minimizing its environmental footprint.

For those who still encounter creosote-treated wood, practical precautions are essential. If handling treated materials, wear protective clothing, gloves, and a respirator to minimize skin and respiratory exposure. Avoid burning creosote-treated wood, as this releases toxic fumes into the air. Instead, dispose of it through approved hazardous waste programs. For homeowners, consider replacing old creosote-treated structures with safer alternatives like copper azole or borate-treated wood, which offer similar durability without the health risks.

In conclusion, while creosote remains a potent wood preservative in industrial applications, its health and safety risks have led to severe restrictions on public access. Understanding these concerns and adopting safer practices can help protect individuals and the environment from the harmful effects of this once-common chemical. As regulations continue to evolve, staying informed about alternatives and best practices is crucial for anyone working with or around treated wood.

Discover Authentic Real Wood Furniture: Top Retailers and Buying Tips

You may want to see also

Explore related products

$423

Environmental Impact of Creosote Application

Creosote, a tar-based wood preservative, has been widely used for decades to protect wooden structures like railroad ties, utility poles, and marine pilings from decay and insect damage. However, its environmental impact is a growing concern, particularly as regulations tighten and public awareness increases. The primary issue lies in creosote’s composition: a mixture of polycyclic aromatic hydrocarbons (PAHs), some of which are classified as probable human carcinogens by the EPA. When applied, creosote can leach into soil and water, posing risks to aquatic life and potentially contaminating groundwater. For instance, studies have shown that PAHs from creosote-treated wood can accumulate in sediments, affecting organisms like fish and invertebrates, which in turn disrupts entire ecosystems.

To mitigate these risks, it’s essential to follow best practices during application. First, ensure the wood is treated in a controlled environment to minimize runoff. Use drip trays or containment systems to capture excess creosote, and dispose of it as hazardous waste. Second, avoid using creosote near water bodies or in areas with high water tables. For residential projects, consider safer alternatives like copper azole or borate-based preservatives, which are less toxic and equally effective for most applications. If creosote must be used, apply it in thin, even coats to reduce excess product while maintaining efficacy—typically, 1 gallon of creosote covers 200–300 square feet of wood surface.

Comparatively, the environmental footprint of creosote is stark when contrasted with newer preservatives. For example, while creosote has a lifespan of 10–20 years, alternatives like alkaline copper quaternary (ACQ) offer similar durability with significantly lower environmental risk. ACQ’s copper content is less likely to leach into the environment, and its biodegradable carriers minimize long-term ecological harm. This comparison underscores why regulatory bodies like the EPA have restricted creosote’s use in residential settings since 2003, limiting it primarily to industrial applications.

Despite its effectiveness, the persistence of creosote in the environment raises long-term concerns. PAHs can remain in soil for decades, binding to organic matter and resisting breakdown. In urban areas, creosote-treated wood in playgrounds or fences can expose children and pets to harmful chemicals through direct contact or ingestion of contaminated soil. To address this, regularly inspect treated structures for wear and tear, and seal any exposed areas with a non-toxic sealant. When disposing of creosote-treated wood, follow local hazardous waste guidelines—never burn it, as this releases toxic fumes into the air.

In conclusion, while creosote remains a viable option for industrial applications, its environmental impact demands careful consideration. By adopting safer alternatives, following strict application protocols, and prioritizing proper disposal, individuals and industries can minimize harm to ecosystems and public health. As regulations continue to evolve, staying informed and proactive is key to balancing preservation needs with environmental stewardship.

Where to Buy Cedar Wood: Top Sources and Tips for Quality Purchases

You may want to see also

Frequently asked questions

No, the general public cannot buy creosote for most uses. Its sale and use are heavily restricted due to health and environmental concerns.

Creosote is restricted because it contains toxic chemicals, including polycyclic aromatic hydrocarbons (PAHs), which pose serious health risks, such as cancer, and harm the environment.

In some regions, creosote may still be used for specific industrial or agricultural applications, but it is generally prohibited for residential or consumer use.

Safer alternatives include water-based preservatives, copper-based treatments, and eco-friendly options like borates or linseed oil, which are widely available and approved for consumer use.