Prefinished wood window ledges have become a popular choice for homeowners and builders seeking a blend of aesthetic appeal and convenience. These ready-to-install ledges come pre-sanded, stained, or painted, eliminating the need for additional finishing work on-site. Available in a variety of wood species, colors, and profiles, they offer a polished look that complements both traditional and modern interiors. The question of whether you can buy prefinished wood window ledges is straightforward: yes, they are widely available from specialty lumber suppliers, home improvement stores, and online retailers. Opting for prefinished options not only saves time but also ensures a consistent, professional finish, making them an attractive solution for renovation or new construction projects.

| Characteristics | Values |

|---|---|

| Availability | Yes, prefinished wood window ledges are available for purchase. |

| Materials | Typically made from solid wood species like pine, oak, maple, or mahogany. |

| Finishes | Come in various pre-applied finishes such as stain, paint, or clear coat. |

| Sizes | Available in standard lengths (e.g., 6', 8', 10') and widths (e.g., 4", 6", 8"), with custom sizing options often available. |

| Profiles | Offered in different profiles (e.g., flat, bullnose, chamfered) to match window styles. |

| Durability | Prefinished for enhanced durability and resistance to moisture, scratches, and UV damage. |

| Installation | Easy to install with basic tools; often includes pre-drilled holes or mounting hardware. |

| Maintenance | Low maintenance; occasional cleaning and touch-ups may be required. |

| Cost | Generally more expensive than unfinished wood ledges due to the prefinishing process. |

| Retailers | Available at home improvement stores (e.g., Home Depot, Lowe's), specialty lumberyards, and online retailers (e.g., Amazon, Build.com). |

| Brands | Examples include Metrie, Alexandria Moulding, and Woodgrain Millwork. |

| Customization | Some manufacturers offer custom finishing or sizing options for an additional cost. |

| Eco-Friendly Options | Some brands use sustainably sourced wood and low-VOC finishes. |

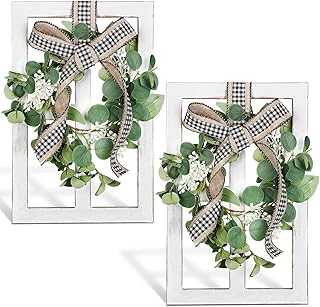

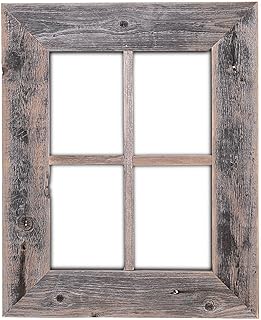

Explore related products

$5200

What You'll Learn

- Prefinished Wood Types: Oak, pine, maple, and mahogany options for window ledges

- Cost Comparison: Prefinished vs. unfinished wood ledge pricing differences

- Installation Process: Steps to install prefinished wood window ledges easily

- Durability Factors: How prefinished ledges withstand moisture and wear over time

- Where to Buy: Top retailers and online stores for prefinished wood ledges?

Prefinished Wood Types: Oak, pine, maple, and mahogany options for window ledges

Prefinished wood window ledges offer a blend of durability and aesthetic appeal, making them a popular choice for homeowners seeking both functionality and style. Among the most sought-after wood types are oak, pine, maple, and mahogany, each bringing unique characteristics to the table. Oak, known for its robust grain patterns and hardness, provides a timeless look that complements both traditional and modern interiors. Pine, on the other hand, is lighter in color and more affordable, making it ideal for those who prefer a rustic or Scandinavian aesthetic. Maple offers a smooth, fine-grained surface that exudes elegance, while mahogany stands out with its rich, deep tones and exceptional durability, perfect for high-end applications.

When selecting a prefinished wood type, consider the specific needs of your space. For high-traffic areas or homes with children and pets, oak and mahogany are excellent choices due to their hardness and resistance to wear. Pine, while softer, can be a great option for less demanding environments or for those who appreciate its natural knots and variations. Maple’s light color and smooth texture make it a versatile choice, though it may require more careful maintenance to preserve its pristine appearance. Prefinished options save time and effort, as they come ready to install with a protective finish that enhances longevity and reduces the need for immediate upkeep.

Installation of prefinished wood window ledges is straightforward but requires attention to detail. Measure the window area precisely, ensuring the ledge fits snugly without gaps. Use a level to guarantee a straight installation, and secure the ledge with appropriate screws or adhesive, depending on the manufacturer’s recommendations. For added protection, apply a bead of silicone caulk along the edges to prevent moisture infiltration, especially in humid environments. Regular cleaning with a soft, damp cloth will maintain the wood’s appearance, while avoiding harsh chemicals or abrasive tools will preserve the prefinished surface.

Comparing the cost and longevity of these wood types reveals distinct advantages. Oak and mahogany are pricier but offer superior durability, making them a long-term investment. Pine is budget-friendly and ideal for temporary or low-impact applications, though it may require more frequent replacement. Maple strikes a balance between cost and quality, providing a premium look without the high price tag of mahogany. Regardless of the choice, prefinished wood window ledges are a practical solution for those seeking to enhance their windows with minimal hassle and maximum impact.

Finally, the aesthetic versatility of these wood types allows for creative customization. Oak’s bold grain pairs well with earthy tones and natural decor, while pine’s softness complements light, airy spaces. Maple’s neutrality makes it a perfect backdrop for vibrant accents, and mahogany’s richness adds a touch of luxury to any room. By choosing the right prefinished wood type, homeowners can achieve a cohesive look that elevates their interior design while enjoying the convenience of a ready-to-install product.

Where to Buy Veneer Wood: Top Retailers and Online Sources

You may want to see also

Explore related products

Cost Comparison: Prefinished vs. unfinished wood ledge pricing differences

Prefinished wood window ledges typically cost 20–40% more upfront than their unfinished counterparts due to the added labor and materials involved in factory finishing. For example, a 6-foot unfinished oak ledge might retail for $50–$70, while the prefinished version could range from $75 to $100. This price gap widens with higher-end wood species like mahogany or walnut, where prefinished options can exceed $150 for the same length. The initial investment reflects the convenience of a ready-to-install product, eliminating the need for sanding, staining, or sealing on-site.

However, the total cost of unfinished ledges extends beyond the purchase price. DIY finishing requires additional materials—such as wood conditioner, stain, sealant, and brushes—which can add $30–$60 per project. Labor time is another factor; sanding and applying multiple coats of finish can take 4–6 hours, depending on skill level. For those hiring professionals, labor costs for finishing can range from $100 to $200, effectively closing the price gap with prefinished options. Thus, the apparent savings of unfinished wood often diminish when accounting for these hidden expenses.

From a long-term perspective, prefinished ledges may offer better value due to their durability. Factory finishes are typically applied under controlled conditions, ensuring even coverage and deeper penetration into the wood grain. This results in a harder, more scratch-resistant surface compared to DIY finishes, which may wear unevenly over time. For high-traffic areas or exterior applications, the extended lifespan of prefinished ledges can offset their higher initial cost, making them a more economical choice over 10–15 years.

For budget-conscious buyers, unfinished ledges remain a viable option, especially when paired with cost-saving strategies. Purchasing finishing supplies in bulk or opting for water-based stains (which dry faster and require fewer coats) can reduce material costs. Additionally, tackling the finishing process during milder seasons minimizes the need for climate-controlled workspaces. While this route demands more effort, it allows for customization in color and sheen, providing a tailored aesthetic that prefinished options may not offer.

Ultimately, the decision between prefinished and unfinished wood window ledges hinges on balancing budget, time, and desired quality. Prefinished ledges streamline installation and offer superior durability, justifying their premium for those prioritizing convenience and longevity. Unfinished ledges, meanwhile, cater to DIY enthusiasts willing to invest sweat equity for potential savings or customization. By weighing these factors against specific project needs, homeowners can make an informed choice that aligns with both financial constraints and aesthetic goals.

Best Places to Buy Quality Lumber for Furniture Projects

You may want to see also

Explore related products

Installation Process: Steps to install prefinished wood window ledges easily

Prefinished wood window ledges offer a blend of aesthetic appeal and durability, making them a popular choice for homeowners seeking to enhance their interior spaces. Once you’ve sourced the perfect prefinished ledge, the installation process is straightforward, requiring minimal tools and time. Here’s a step-by-step guide to ensure a seamless installation.

Step 1: Measure and Prepare the Window Area

Begin by measuring the width of your window to determine the length of the ledge needed. Most prefinished wood ledges come in standard sizes, but customization may be required for unique window dimensions. Clean the window sill thoroughly, removing any dust, debris, or old paint. Ensure the surface is level and smooth; use a putty knife to scrape away any imperfections and sand lightly if necessary. A clean, even surface is crucial for proper adhesion and a professional finish.

Step 2: Apply Adhesive and Position the Ledge

Choose a high-quality construction adhesive suitable for wood and apply a generous bead along the back edge of the prefinished ledge. For added stability, apply adhesive in a zigzag pattern across the entire surface that will contact the window sill. Carefully position the ledge onto the sill, pressing firmly to ensure full contact. Use a level to confirm the ledge is straight and adjust as needed. Wipe away any excess adhesive immediately with a damp cloth to avoid staining the prefinished surface.

Step 3: Secure with Finishing Nails (Optional)

While adhesive often suffices, securing the ledge with finishing nails can provide extra stability, especially in high-traffic areas. Use a nail gun or hammer to drive 1.5-inch finishing nails through the prefinished ledge and into the window sill at a slight angle. Space nails every 12–16 inches along the length of the ledge. Countersink the nails slightly below the surface and fill the holes with wood putty to maintain the ledge’s pristine appearance.

Step 4: Seal and Inspect

Once the ledge is securely installed, inspect the edges and seams for any gaps. Apply a bead of paintable caulk along the junction between the ledge and the wall to create a watertight seal and enhance the finished look. Smooth the caulk with a damp finger or caulking tool for a clean finish. Allow the adhesive and caulk to dry completely according to the manufacturer’s instructions, typically 24 hours.

By following these steps, installing prefinished wood window ledges becomes a manageable DIY project that adds both functionality and elegance to your windows. With proper preparation and attention to detail, the result is a durable, visually appealing addition to your home.

Discover Top Places to Buy Quality Wooden Boxes Online & Locally

You may want to see also

Explore related products

$63.98 $83.99

$55.98 $61.99

Durability Factors: How prefinished ledges withstand moisture and wear over time

Prefinished wood window ledges are engineered to resist the elements, particularly moisture, which is a primary threat to wood’s longevity. Manufacturers apply factory-grade finishes that penetrate deeper than traditional on-site coatings, creating a robust barrier against water infiltration. These finishes often include multiple layers of moisture-resistant sealants, such as polyurethane or acrylic, which bond to the wood fibers and prevent swelling, warping, or rot. For instance, prefinished ledges treated with UV-resistant coatings can withstand up to 500 hours of accelerated weathering tests, equivalent to years of outdoor exposure. This level of protection ensures the ledge remains structurally sound even in humid climates or rainy regions.

The durability of prefinished ledges also hinges on the wood species selected. Hardwoods like oak, maple, or teak naturally resist moisture better than softwoods, but even softwoods can be enhanced through pressure treatment or lamination. Prefinished ledges often incorporate engineered wood composites, such as MDF or plywood, which are less prone to moisture absorption than solid wood. These materials are then sealed with moisture-curing polyurethanes that expand in damp conditions, further tightening the protective layer. Homeowners in coastal areas, where salt air accelerates wood degradation, should opt for ledges with marine-grade finishes, which provide an additional 30–40% resistance to corrosion and moisture penetration.

Wear resistance is another critical factor, as window ledges are subject to frequent contact and environmental abrasion. Prefinished ledges are typically coated with abrasion-resistant finishes, such as catalyzed lacquers or conversion varnishes, which harden into a durable shell. These finishes are tested to withstand up to 10,000 taber abrasion cycles, ensuring they retain their luster even in high-traffic areas. For added protection, some manufacturers embed ceramic particles or aluminum oxide into the finish, increasing scratch resistance by 50%. Regular maintenance, such as wiping the ledge with a pH-neutral cleaner every 3–4 months, can extend the finish’s lifespan by preventing dirt buildup that accelerates wear.

Comparing prefinished ledges to their unfinished counterparts highlights their superior durability. Unfinished wood requires multiple coats of sealant applied on-site, a process prone to human error, such as uneven application or missed spots. Prefinished ledges, however, are treated in controlled environments, ensuring consistent coverage and curing. Additionally, factory finishes often include additives like mildewcides or fungicides, which unfinished wood lacks. A study by the Forest Products Laboratory found that prefinished wood retains 80% of its structural integrity after 10 years, compared to 50% for unfinished wood under the same conditions. This makes prefinished ledges a more reliable choice for long-term performance.

To maximize the durability of prefinished wood window ledges, homeowners should follow specific care guidelines. Avoid placing potted plants directly on the ledge without a waterproof tray, as prolonged moisture exposure can compromise even the best finishes. In regions with extreme temperature fluctuations, inspect the ledge annually for cracks or peeling, and reapply a compatible sealant if necessary. For ledges exposed to direct sunlight, consider installing UV-filtering blinds or curtains to minimize fading. By combining high-quality prefinished products with proactive maintenance, homeowners can ensure their window ledges remain both functional and aesthetically pleasing for decades.

Where to Buy Permaseal Wood Deck Products: A Comprehensive Guide

You may want to see also

Explore related products

Where to Buy: Top retailers and online stores for prefinished wood ledges

Prefinished wood window ledges are a sought-after solution for homeowners and builders looking to combine aesthetics with convenience. While custom carpentry remains an option, the demand for ready-to-install products has spurred a growing market. Below, we explore where to find these ledges, focusing on top retailers and online stores that cater to diverse needs and preferences.

Home Improvement Giants: A One-Stop Shop

Major retailers like Home Depot and Lowe’s dominate the market with their extensive selections of prefinished wood window ledges. Home Depot offers brands such as Fypon and Royal Mouldings, featuring pine and oak options in various finishes, including stain-grade and paint-ready surfaces. Lowe’s counters with its exclusive line of prefinished ledges, often bundled with installation guides and matching trim pieces. Both stores provide in-store pickup and delivery, making them ideal for last-minute project needs. Pro tip: Check their websites for bulk discounts or seasonal promotions, which can reduce costs by up to 20%.

Specialty Wood Retailers: Quality Meets Craftsmanship

For those prioritizing premium materials and unique finishes, specialty wood retailers like Woodworkers Source and Hearne Hardwoods are go-to destinations. Woodworkers Source offers prefinished ledges in exotic woods like teak and mahogany, treated with marine-grade finishes for durability. Hearne Hardwoods, known for its sustainable sourcing, provides custom-milled ledges with low-VOC finishes, perfect for eco-conscious buyers. While prices are higher—starting at $50 per linear foot—the investment ensures longevity and distinctive character. Caution: Lead times can be longer, so plan purchases well in advance.

Online Marketplaces: Convenience and Variety

E-commerce platforms like Amazon and Wayfair have revolutionized access to prefinished wood ledges, offering thousands of options from global suppliers. Amazon’s advantage lies in its filtering tools, allowing users to sort by material, finish, and customer ratings. Wayfair excels in curated collections, such as farmhouse or modern styles, with detailed product descriptions and 3D visualizations. Both platforms offer free shipping on qualifying orders, but beware of inconsistent quality from third-party sellers. Always read reviews and verify return policies before purchasing.

Direct-to-Consumer Brands: Cutting Out the Middleman

Emerging brands like Craftwood Co. and TimberEdge specialize exclusively in prefinished wood products, selling directly to consumers via their websites. Craftwood Co. stands out for its customizable ledges, where buyers can select wood type, finish, and dimensions. TimberEdge focuses on pre-assembled kits, complete with adhesive and installation hardware, ideal for DIY enthusiasts. These brands often offer competitive pricing—up to 30% less than traditional retailers—and prioritize customer service. However, limited physical showrooms mean you’ll rely on digital samples and swatches.

Local Lumber Yards: Hidden Gems for Personalized Service

Don’t overlook local lumber yards, which often stock prefinished wood ledges tailored to regional preferences. Establishments like 84 Lumber or family-owned suppliers frequently partner with regional mills, offering unique species like cedar or cypress. The advantage here is personalized advice: staff can recommend finishes suited to your climate or provide tips for maintaining wood in humid or dry conditions. While selection may be smaller, the expertise gained is invaluable. Call ahead to confirm availability, as inventory varies by location.

By exploring these avenues, buyers can find prefinished wood window ledges that align with their budget, style, and project timeline. Whether opting for the convenience of big-box stores or the craftsmanship of specialty retailers, the key is to balance quality with practicality.

Best Places to Buy Quality Wood for Woodworking Projects

You may want to see also

Frequently asked questions

Yes, prefinished wood window ledges are widely available from home improvement stores, specialty woodworking suppliers, and online retailers.

Prefinished wood window ledges save time and effort since they come ready to install, eliminating the need for sanding, staining, or painting on-site.

Yes, prefinished wood window ledges are treated with durable finishes that enhance their resistance to moisture, scratches, and wear, ensuring longevity.

Many suppliers offer prefinished wood window ledges in various wood species, colors, and finishes, allowing you to choose one that complements your interior design.

Installation typically involves measuring the window area, cutting the ledge to fit (if needed), and securing it with adhesive, nails, or screws, following the manufacturer’s instructions.