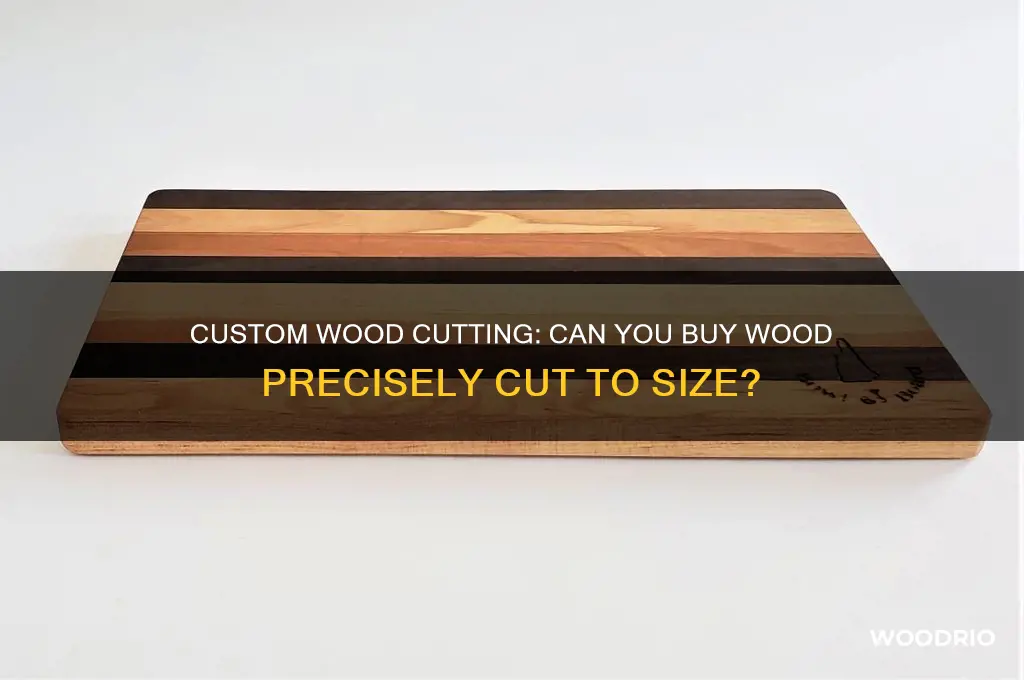

When embarking on a woodworking project or home improvement task, many individuals wonder if they can purchase wood cut to their specific size requirements, saving time and effort. The good news is that numerous hardware stores, lumberyards, and online retailers offer custom wood cutting services, allowing customers to obtain precisely measured and shaped wooden pieces. This convenient option eliminates the need for specialized tools and expertise, making it an attractive choice for both DIY enthusiasts and professionals alike. By providing detailed dimensions and specifications, customers can ensure they receive the exact wood pieces needed for their projects, whether it's for furniture, cabinetry, or construction purposes. This service not only streamlines the building process but also minimizes waste, as the wood is cut to the required size, reducing the need for additional trimming and adjustments.

| Characteristics | Values |

|---|---|

| Availability | Widely available at hardware stores, lumberyards, and online retailers |

| Materials | Various wood types (pine, oak, maple, MDF, plywood, etc.) |

| Thickness | Typically ranges from 1/4" to 2" or more, depending on supplier |

| Width | Customizable, usually up to 48" or more, depending on supplier |

| Length | Customizable, usually up to 96" or more, depending on supplier |

| Cutting Methods | Precision cutting using saws, CNC machines, or laser cutters |

| Tolerance | Usually within ±1/16" to ±1/8", depending on supplier and method |

| Cost | Varies based on wood type, size, and complexity of cut; additional fees for custom cuts |

| Lead Time | Same-day to several days, depending on supplier and order complexity |

| Minimum Order | Some suppliers may require a minimum order size or fee for small cuts |

| Edge Finishing | Options may include raw, sanded, or routed edges |

| Delivery/Pickup | Available for pickup or delivery, depending on supplier |

| Popular Suppliers | Home Depot, Lowe's, Menards, local lumberyards, and online platforms like BuildDirect or Woodworkers Source |

| Applications | Furniture, shelving, cabinetry, DIY projects, and more |

| Environmental Impact | Depends on wood source; look for FSC-certified or sustainably harvested options |

| Customization | Complex shapes and designs possible with CNC or laser cutting |

Explore related products

What You'll Learn

- Local Hardware Stores: Many offer custom wood cutting services for various projects

- Online Retailers: Websites like Home Depot or Lowe’s provide cut-to-size options

- Specialty Lumber Yards: Focus on precise cuts for unique woodworking needs

- DIY Cutting Tips: Tools and techniques for cutting wood at home

- Cost Considerations: Factors affecting pricing for custom wood cutting services

Local Hardware Stores: Many offer custom wood cutting services for various projects

Local hardware stores often serve as unsung heroes for DIY enthusiasts and professionals alike, offering a service that can save both time and effort: custom wood cutting. Whether you’re building a bookshelf, framing a window, or crafting a custom table, these stores provide precision cuts tailored to your project’s exact dimensions. This service eliminates the need for owning or renting expensive tools like table saws or miter saws, making it accessible for those with limited resources or space. By leveraging this offering, you can focus on assembly and finishing rather than wrestling with measurements and cutting techniques.

The process is straightforward but varies slightly by store. Typically, you’ll bring in your raw wood or select from the store’s inventory, then provide detailed measurements or a sketch of your project. Staff will guide you on the feasibility of your request, ensuring the cuts align with the wood’s grain and structural integrity. Some stores charge a small fee per cut, while others include it as a complimentary service for customers purchasing materials. Always call ahead to confirm availability, as not all locations offer this service, and some may have restrictions on wood types or project complexity.

One of the standout advantages of using local hardware stores for custom cutting is the personalized expertise you gain. Unlike big-box retailers, where staff may be less specialized, local stores often employ craftsmen with hands-on experience. They can offer advice on the best wood species for your project, suggest alternative cutting methods, or even recommend additional tools for finishing touches. This human touch can turn a potentially frustrating task into a collaborative, educational experience, especially for beginners.

However, there are a few caveats to keep in mind. Precision is generally high, but it’s not infallible—always double-check measurements before leaving the store. Some stores may have longer turnaround times during peak seasons, so plan your project timeline accordingly. Additionally, while custom cutting saves time, it doesn’t replace the need for sanding or additional prep work. Bring your own sandpaper or finishing tools, or inquire if the store offers these services as well.

In conclusion, local hardware stores offering custom wood cutting services are a valuable resource for anyone tackling woodworking projects. They bridge the gap between raw materials and finished pieces, providing accessibility, expertise, and convenience. By understanding the process, preparing your materials, and communicating clearly, you can maximize this service to bring your vision to life efficiently and affordably. Next time you’re planning a project, consider starting with a visit to your local hardware store—it might just be the key to unlocking your creativity.

Where to Buy Straight Edge Wood for Perfect DIY Projects

You may want to see also

Explore related products

Online Retailers: Websites like Home Depot or Lowe’s provide cut-to-size options

Major home improvement retailers like Home Depot and Lowe's have recognized the growing demand for customized building materials, offering online platforms where customers can specify exact dimensions for wood cuts. This service is particularly beneficial for DIY enthusiasts and professionals who require precise measurements but lack the tools or expertise to make cuts themselves. By inputting length, width, and thickness requirements directly on the website, users can order pre-cut wood that arrives ready for assembly, saving time and reducing waste.

The process is straightforward: after selecting the desired wood type (e.g., pine, oak, or plywood), customers navigate to the customization section, where they input measurements in inches or feet, often with decimal precision. Some platforms even provide visual aids or templates to ensure accuracy. For instance, Home Depot’s "Custom Cut Lumber" tool allows users to specify cuts down to 1/16th of an inch, while Lowe's offers a similar feature with additional options for edge treatments, such as sanding or rounding.

One notable advantage of these services is the ability to handle bulk orders efficiently. Contractors or hobbyists working on large projects can upload spreadsheets or lists of multiple cut dimensions, streamlining the ordering process. However, it’s essential to double-check measurements before finalizing the order, as custom cuts are typically non-refundable. Additionally, delivery times may vary, with some retailers offering expedited shipping for an additional fee.

While the convenience of online cut-to-size services is undeniable, there are limitations to consider. Complex shapes or intricate designs often exceed the capabilities of standard cutting tools used by these retailers, requiring specialized services elsewhere. Moreover, the cost per cut can add up, especially for small projects, so it’s advisable to compare prices with local hardware stores or lumberyards. Despite these caveats, the accessibility and precision of online retailers make them a go-to resource for many woodworkers.

For those new to this service, start with a small test order to verify accuracy and quality. Familiarize yourself with the website’s interface and measurement tools to avoid errors. By leveraging the cut-to-size options from retailers like Home Depot or Lowe's, even novice builders can tackle projects with confidence, knowing their materials will fit perfectly from the start.

Best Places to Buy High-Quality Guitar Wood for Luthiers

You may want to see also

Explore related products

Specialty Lumber Yards: Focus on precise cuts for unique woodworking needs

For woodworkers seeking precision and customization, specialty lumber yards are a treasure trove. Unlike big-box stores, these niche suppliers cater to projects demanding exact dimensions and unique specifications. Imagine crafting a bespoke dining table with legs requiring 3.25-inch square cuts or a custom bookshelf needing 1/16-inch tolerances for dovetail joints. Specialty yards invest in industrial-grade saws and skilled operators to deliver such precision, often offering cuts within ±1/32 inch—a level of accuracy unattainable with standard hardware store services. This capability transforms raw lumber into project-ready components, saving hours of workshop labor.

The process typically begins with a consultation. Bring detailed plans or digital files (DXF or PDF formats work best) to ensure clarity. Most yards charge per cut or by linear foot, with prices ranging from $0.50 to $2.00 per cut depending on complexity. Exotic hardwoods or intricate angles may incur premiums, but the cost often offsets the expense of specialized tools or time spent on trial-and-error cuts. Pro tip: Order slightly oversized pieces to account for fine-tuning during assembly, as wood can shift during transport or acclimate to new environments.

While convenient, relying on specialty cuts requires careful planning. Cross-check measurements twice, as errors in your specifications become the yard’s blueprint. Some yards offer edge sanding or planing services for an additional fee, ensuring surfaces are ready for finishing. For intricate projects, inquire about their machinery—CNC routers, for instance, excel at repetitive patterns but may be overkill for simple rip cuts. Understanding their capabilities ensures you’re not overpaying for services you don’t need.

Specialty lumber yards also serve as knowledge hubs. Staff often have decades of experience and can advise on grain orientation, moisture content, or species suitability for specific applications. For example, they might recommend quarter-sawn white oak for stability in humid environments or suggest kerf adjustments to compensate for wood movement. This expertise bridges the gap between raw material and finished piece, making them invaluable partners for both hobbyists and professionals.

In a world of mass-produced components, specialty lumber yards preserve the art of tailored craftsmanship. Their precise cuts enable woodworkers to focus on design and assembly rather than laborious prep work. Whether building a heirloom-quality cabinet or a one-off sculpture, these yards provide the foundation for projects that stand out. Just remember: precision is a partnership. Clear communication and thoughtful planning ensure the wood arrives exactly as envisioned, ready to bring your creative vision to life.

Where to Buy Cedar Wood: Top Sources and Tips for Quality Purchases

You may want to see also

Explore related products

DIY Cutting Tips: Tools and techniques for cutting wood at home

Woodworkers and DIY enthusiasts often face the dilemma of cutting wood to precise dimensions, especially when store-bought options fall short. While many hardware stores offer custom cutting services, mastering the art of cutting wood at home empowers you to tackle projects with greater flexibility and precision. Here’s how to get started.

Choosing the Right Tools for the Job

The foundation of successful wood cutting lies in selecting the appropriate tools. For straight cuts, a circular saw paired with a guide rail is ideal for beginners, offering accuracy and control. If you’re working on smaller pieces or intricate designs, a jigsaw provides maneuverability, though it may sacrifice precision. For those seeking professional-grade results, a table saw is unmatched but requires careful handling due to its power. Hand tools like a miter box and backsaw are excellent for occasional use, though they demand more effort and time. Always prioritize tools that align with your project’s complexity and your skill level.

Techniques to Ensure Precision

Accuracy is non-negotiable when cutting wood. Start by measuring twice and marking once with a sharp pencil and a straightedge. Use clamps to secure the wood firmly, preventing movement during the cut. For long cuts, a guide rail or straightedge attached to your saw ensures a straight line. When using a jigsaw, maintain a steady hand and follow the marked line closely. For angled cuts, a miter saw or miter box is essential, allowing you to achieve precise angles consistently. Practice on scrap wood to refine your technique before tackling your main project.

Safety First: Essential Precautions

Cutting wood at home carries inherent risks, but proper safety measures minimize accidents. Always wear safety goggles to protect your eyes from flying debris. Ear protection is crucial when using power tools, as prolonged exposure to loud noise can damage hearing. Dust masks or respirators are essential to avoid inhaling wood particles. Ensure your workspace is well-lit and free of clutter to prevent trips and falls. Keep your tools sharp and in good condition, as dull blades can cause kickback or uneven cuts. Never rush the process; patience and focus are key to safe and successful cutting.

Maximizing Efficiency and Minimizing Waste

Efficient wood cutting not only saves time but also reduces material waste. Plan your cuts in advance by laying out the pieces on the wood to optimize space. Use a cutting list to keep track of dimensions and quantities. When working with expensive or rare wood, consider dry-fitting pieces before making final cuts to ensure accuracy. For repetitive cuts, invest in a stop block or jig to maintain consistency. Finally, repurpose offcuts for smaller projects or kindling to minimize waste. With thoughtful planning and execution, cutting wood at home becomes a rewarding and sustainable practice.

Discover the Best Sources to Buy Authentic Brazilian Wood Today

You may want to see also

Explore related products

Cost Considerations: Factors affecting pricing for custom wood cutting services

Custom wood cutting services offer convenience, but understanding the cost factors ensures you get the best value. The primary driver is wood type and quality. Exotic hardwoods like mahogany or walnut command higher prices than pine or plywood due to scarcity and processing difficulty. For instance, a 4x8 sheet of birch plywood might cost $50, while the same size in teak could exceed $200. Always balance aesthetic desires with budget constraints.

Next, cut complexity significantly impacts pricing. Simple straight cuts are cheaper, while intricate designs or angled cuts require more time and precision, often doubling or tripling the cost. For example, a basic 2x4 cut to 36 inches might cost $2, whereas a custom-angled bracket could run $10 or more. Provide detailed plans or templates to avoid additional design fees, which can add $20–$50 per project.

Quantity and batch size also play a role. Ordering in bulk reduces the per-unit cost, as setup fees are distributed across more pieces. A single custom-cut board might cost $15, but ordering 10 identical pieces could lower the price to $8 each. Conversely, small orders often incur a minimum charge, typically $25–$50, to cover machine setup and labor.

Finally, additional services like sanding, edging, or finishing can inflate costs. A rough-cut board might cost $5, but adding a smooth finish could add $10–$20. If you’re skilled, consider handling these steps yourself to save money. Always request a detailed quote to understand how each service contributes to the total price. By prioritizing needs and negotiating where possible, you can optimize costs without sacrificing quality.

Cathie Wood's Latest Buys: Uncovering Her Top Investment Picks

You may want to see also

Frequently asked questions

Yes, many hardware stores and lumberyards offer wood cutting services, allowing you to purchase wood cut to your specific dimensions.

Some stores charge a small fee for cutting wood to size, while others may offer the service for free, depending on the store policy and the size of the order.

Most common types of wood, including plywood, MDF, hardwoods, and softwoods, can be cut to size, though availability may vary by store.

Yes, you can provide your own measurements, but ensure they are accurate and clear, as mistakes may result in additional costs or delays.