Buying wood directly from a sawmill can be a cost-effective and sustainable option for those seeking high-quality lumber. By bypassing traditional retailers, customers often gain access to fresher, locally sourced materials at competitive prices. Additionally, purchasing directly from a sawmill allows for greater customization, as buyers can specify dimensions, cuts, and types of wood tailored to their needs. However, it’s important to research local sawmills, understand their processes, and inquire about availability, as not all sawmills sell directly to the public. This approach not only supports local businesses but also reduces the environmental impact associated with long supply chains.

| Characteristics | Values |

|---|---|

| Availability | Yes, you can buy wood directly from sawmills. |

| Benefits |

|

| Types of Wood Available | Varies by sawmill, but typically includes hardwoods (e.g., oak, maple, walnut) and softwoods (e.g., pine, cedar, spruce) |

| Pricing | Generally lower than retail prices, but may require purchasing in larger quantities (e.g., full logs, truckloads, or board feet) |

| Location | Sawmills are often located in rural areas near forests or timber sources; use online directories or local resources to find nearby sawmills |

| Ordering Process |

|

| Payment Methods | Varies by sawmill, but often includes cash, check, or bank transfer; some may accept credit cards |

| Additional Services |

|

| Challenges |

|

| Environmental Impact | Can be more sustainable, as buying locally sourced wood reduces transportation emissions and supports local economies |

| Online Resources |

|

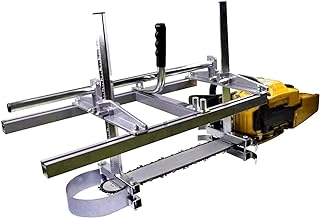

Explore related products

What You'll Learn

- Locating Local Sawmills: Find nearby sawmills through online directories, local forestry offices, or community recommendations

- Types of Wood Available: Sawmills offer various species, grades, and cuts tailored to specific project needs

- Cost Savings: Buying direct often reduces costs by eliminating middlemen and retail markups

- Custom Orders: Sawmills can provide custom dimensions, milling, and drying services for unique projects

- Sustainability Practices: Many sawmills source locally and use eco-friendly methods, ensuring responsible wood procurement

Locating Local Sawmills: Find nearby sawmills through online directories, local forestry offices, or community recommendations

Buying wood directly from a sawmill can offer cost savings, unique lumber options, and a connection to local craftsmanship. But first, you need to find one. Fortunately, locating nearby sawmills is easier than you might think, thanks to a combination of online resources, local expertise, and community networks.

Online Directories: A Digital Shortcut

Start your search with online directories specifically designed to connect buyers with sawmills. Websites like *The Sawmill Database* or *Wood-Mizer’s Sawmill Locator* allow you to filter by location, wood types, and services offered. These platforms often include reviews and contact details, streamlining the process. For instance, if you’re in the Pacific Northwest, a quick search might reveal sawmills specializing in cedar or Douglas fir, complete with pricing estimates and availability.

Local Forestry Offices: Tapping into Expertise

For a more personalized approach, visit or call your local forestry office or extension service. These agencies maintain records of active sawmills in the area and can provide insights into their operations, such as whether they sell directly to the public or specialize in certain wood species. In rural areas, forestry offices often have maps or lists of nearby mills, sometimes even noting which ones are open to small-scale buyers. This method is particularly useful if you’re seeking sustainably sourced or locally harvested wood.

Community Recommendations: The Power of Word-of-Mouth

Don’t underestimate the value of community knowledge. Local woodworking clubs, farmers’ markets, or even social media groups can be goldmines for sawmill recommendations. Ask around at hardware stores or lumberyards—staff often have insider knowledge of nearby mills willing to sell directly. For example, a Facebook group for DIY enthusiasts in your region might reveal a family-owned sawmill just 20 miles away that offers custom milling at competitive prices.

Practical Tips for Success

When reaching out to sawmills, be clear about your needs: specify the type of wood, quantity, and whether you require milling services. Some sawmills may have minimum order requirements or seasonal availability, so plan accordingly. Additionally, inquire about delivery options or prepare to transport the wood yourself—many sawmills offer on-site pickup but may not provide delivery. Finally, build a relationship with the mill owner; repeat business often leads to better pricing and priority service.

By leveraging online directories, local forestry offices, and community networks, you can efficiently locate nearby sawmills and unlock access to high-quality, locally sourced wood. Whether you’re a hobbyist or a professional builder, this approach ensures you get the materials you need while supporting local businesses.

Buying Wooden Stock in Thunder Bluff: A Comprehensive Guide for Players

You may want to see also

Explore related products

$29.99 $32.99

$6790

Types of Wood Available: Sawmills offer various species, grades, and cuts tailored to specific project needs

Sawmills are treasure troves of diversity, offering a wide array of wood species that cater to various project requirements. From the rich, reddish-brown hues of mahogany to the light, creamy tones of maple, each species possesses unique characteristics that make it suitable for specific applications. For instance, oak is renowned for its strength and durability, making it an ideal choice for flooring and furniture, while cedar's natural resistance to decay and insects renders it perfect for outdoor projects like decking and fencing.

When selecting wood from a sawmill, understanding the grading system is crucial. Grades typically range from select (highest quality, minimal defects) to common (more knots and imperfections), with each grade offering a balance between aesthetics and cost. For example, a select grade of pine might be used for high-end cabinetry, where appearance is paramount, whereas a common grade could be suitable for structural framing, where strength takes precedence over visual appeal. This grading system allows buyers to make informed decisions based on their project's specific needs and budget constraints.

The cutting process at sawmills also plays a significant role in determining the wood's final application. Quarter-sawn and rift-sawn cuts, for instance, produce boards with distinctive grain patterns and enhanced stability, making them ideal for fine furniture and cabinetry. In contrast, plain-sawn cuts yield a more traditional, cathedral-grain appearance, often used in general construction and paneling. By offering various cuts, sawmills enable craftsmen and builders to select the most suitable option for their project, ensuring optimal performance and aesthetic appeal.

Consider a scenario where a woodworker is crafting a bespoke dining table. They might opt for a quarter-sawn white oak, prized for its tight, straight grain and exceptional stability, ensuring the table remains flat and true over time. Alternatively, a builder constructing a rustic cabin might choose a plain-sawn cedar, valuing its natural resistance to the elements and the charming, irregular grain patterns that add character to the structure. These examples illustrate how sawmills' diverse offerings empower creators to bring their visions to life with precision and confidence.

To maximize the benefits of buying wood directly from a sawmill, it's essential to communicate your project's specific requirements. Provide details such as the desired species, grade, and cut, as well as any special considerations like moisture content or surface finish. Many sawmills also offer custom milling services, allowing you to request unique dimensions or profiles tailored to your project. By fostering a collaborative relationship with the sawmill, you can ensure that the wood you receive is perfectly suited to your needs, resulting in a more efficient, cost-effective, and satisfying building experience.

Top Places to Purchase High-Quality Wooden Canvas Frames Online

You may want to see also

Explore related products

Cost Savings: Buying direct often reduces costs by eliminating middlemen and retail markups

Buying wood directly from a sawmill can significantly reduce costs by cutting out the middlemen and retail markups that often inflate prices. When you purchase from a retailer, you’re paying not just for the wood but also for the retailer’s overhead, profit margin, and any additional handling or transportation fees. By bypassing these layers, you gain direct access to wholesale pricing, which can save you anywhere from 20% to 50% depending on the type and quantity of wood. For example, a board foot of hardwood that retails for $8 might cost only $5 when bought directly from a sawmill. This price difference becomes especially impactful for large projects like building a deck, framing a house, or crafting custom furniture.

To maximize these savings, it’s essential to understand the purchasing process. Start by researching local sawmills and comparing their offerings. Many sawmills sell wood in bulk, so be prepared to buy larger quantities to secure the best prices. For instance, purchasing a full cord of lumber (128 cubic feet) can often unlock deeper discounts than buying smaller amounts. Additionally, inquire about delivery options, as some sawmills offer free or reduced-cost delivery for large orders, further enhancing your savings. Keep in mind that the wood may be rough-cut or unfinished, so factor in any additional processing costs if you require sanding, planing, or drying services.

A comparative analysis reveals that the cost savings from buying direct aren’t just theoretical—they’re tangible and measurable. Consider a scenario where a homeowner needs 500 board feet of oak for a renovation project. At a retail lumberyard, this might cost $4,000. In contrast, purchasing the same quantity directly from a sawmill could reduce the cost to $2,500 or less. Over time, these savings can accumulate, especially for contractors, builders, or hobbyists who regularly work with wood. However, it’s important to weigh these savings against potential drawbacks, such as limited selection or the need for additional processing, to ensure the direct purchase aligns with your project needs.

Persuasively, the financial benefits of buying direct extend beyond immediate cost savings. By establishing a relationship with a sawmill, you gain access to fresher, higher-quality wood that hasn’t been sitting in a warehouse or retail space. This can lead to better project outcomes, as fresher wood is less likely to warp, crack, or degrade. Moreover, direct purchasing supports local businesses and reduces the environmental impact associated with long supply chains. For those committed to sustainability and cost-efficiency, buying wood directly from a sawmill isn’t just a smart financial decision—it’s a strategic one that pays dividends in both quality and conscience.

Best Places to Purchase High-Quality Birch Wood for Your Projects

You may want to see also

Explore related products

$23.03 $24.79

Custom Orders: Sawmills can provide custom dimensions, milling, and drying services for unique projects

Buying wood directly from a sawmill opens up a world of possibilities for custom orders, especially for unique projects that demand specific dimensions, milling techniques, or drying processes. Unlike pre-cut lumber from big-box stores, sawmills can tailor their services to meet exact specifications, ensuring the wood fits your project perfectly. For instance, if you’re building a custom furniture piece that requires 2-inch thick walnut boards in 12-foot lengths, a sawmill can source the raw logs, mill them to your dimensions, and even kiln-dry the wood to your desired moisture content, typically around 8-12% for indoor projects. This level of customization is invaluable for artisans, builders, and hobbyists alike.

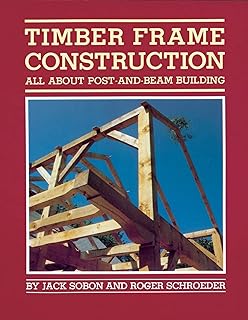

The process begins with a consultation, where you discuss your project’s requirements with the sawmill. Be prepared to provide detailed measurements, wood species preferences, and any specific milling needs, such as live edge slabs, quarter-sawn cuts, or custom molding profiles. For example, a live edge dining table might require a 2-inch thick slab with the natural edge preserved, while a timber-framed cabin could need 4x6 beams with precise joinery cuts. Sawmills often have the equipment to handle these requests, from band sawmills for rough cuts to planers and molders for finishing touches. Clear communication is key to ensuring the final product aligns with your vision.

One of the most significant advantages of custom orders is the ability to control the drying process. Air drying, kiln drying, or a combination of both can be tailored to your project’s timeline and requirements. Kiln drying, for instance, accelerates the process and ensures uniformity, reducing the risk of warping or cracking. However, it’s more expensive and may not be necessary for all projects. For outdoor structures, you might opt for air-dried wood with a moisture content of 15-18%, while fine furniture projects may require kiln-dried wood at 8-10%. Discuss these options with the sawmill to balance cost and quality.

While custom orders offer unparalleled flexibility, they also require careful planning and patience. Lead times can vary from a few weeks to several months, depending on the sawmill’s workload, the availability of the wood species, and the complexity of your request. Additionally, custom milling and drying services come at a premium, so budget accordingly. To maximize value, consider ordering in bulk or coordinating with other buyers to share costs. Finally, inspect the wood upon delivery to ensure it meets your specifications, as mistakes in custom orders can be costly to rectify.

In conclusion, custom orders from sawmills are a game-changer for unique projects, offering precision, quality, and personalization that off-the-shelf lumber can’t match. By understanding the process, communicating clearly, and planning ahead, you can leverage sawmill services to bring your vision to life. Whether you’re crafting a one-of-a-kind piece or building a bespoke structure, the investment in custom milling and drying pays off in the final result.

Best Bulk Wood Chip Suppliers: Where to Buy in Large Quantities

You may want to see also

Explore related products

$7.97

Sustainability Practices: Many sawmills source locally and use eco-friendly methods, ensuring responsible wood procurement

Buying wood directly from a sawmill isn’t just about cost savings—it’s an opportunity to support sustainable practices that benefit both the environment and local economies. Many sawmills prioritize sourcing timber from nearby forests, reducing the carbon footprint associated with long-distance transportation. For instance, a sawmill in the Pacific Northwest might exclusively use trees harvested within a 50-mile radius, ensuring that the wood you purchase has traveled minimal distance from forest to mill to your project. This localized approach not only lowers emissions but also supports regional forestry management, which often includes selective harvesting to maintain ecosystem health.

Eco-friendly methods are another cornerstone of responsible wood procurement at sawmills. Techniques like kiln drying with renewable energy, recycling sawdust for biomass fuel, and minimizing waste through precise cutting are increasingly common. Some mills even use water-based finishes instead of chemical-heavy alternatives, reducing pollution and creating safer products for end users. For example, a sawmill in Vermont might employ solar-powered kilns and donate wood scraps to local artisans, showcasing how sustainability can be woven into every step of the process. These practices not only preserve natural resources but also align with consumer demand for ethically produced materials.

Transparency is key when evaluating a sawmill’s sustainability claims. Look for certifications like FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative), which verify that the wood is harvested responsibly. Additionally, inquire about the mill’s sourcing policies and whether they partner with local landowners or forestry programs. A sawmill in Oregon, for instance, might collaborate with state-run reforestation initiatives, ensuring that every tree cut is replaced. By choosing mills with such credentials, you’re not just buying wood—you’re investing in a system that prioritizes long-term environmental health.

For DIY enthusiasts and builders, buying directly from a sustainable sawmill offers practical benefits beyond ethics. Locally sourced wood is often fresher, reducing the risk of warping or cracking compared to wood that’s been shipped across continents. Plus, you can request custom cuts or finishes tailored to your project, minimizing waste on your end. Pro tip: Visit the sawmill in person if possible to inspect the wood and discuss your needs—many mills are happy to educate customers about their sustainable practices and offer advice on material selection. This hands-on approach ensures you get exactly what you need while supporting a greener supply chain.

Finally, purchasing wood directly from a sustainable sawmill is a tangible way to contribute to a circular economy. By supporting local businesses that prioritize eco-friendly methods, you’re helping to create a market for responsibly sourced materials. This, in turn, encourages more sawmills to adopt sustainable practices, creating a ripple effect across the industry. For example, a small sawmill in Michigan might inspire neighboring businesses to follow suit by showcasing how profitability and sustainability can coexist. In this way, your choice to buy direct becomes a vote for a more responsible future—one project at a time.

Discover the Best Places to Buy Authentic Olive Wood Products

You may want to see also

Frequently asked questions

Yes, you can buy wood directly from a sawmill. Many sawmills offer lumber for sale to both individual customers and businesses, often at competitive prices compared to retail suppliers.

Buying directly from a sawmill often provides access to fresher, higher-quality wood at lower prices. You may also have more customization options, such as specific dimensions or wood species, and you can support local businesses.

It depends on the sawmill. Some sawmills cater to small orders, while others may require minimum purchase quantities. It’s best to contact the sawmill directly to inquire about their policies.

You can find sawmills through online searches, local business directories, or by asking at lumberyards or woodworking communities. Visiting local sawmills or contacting them via phone or email can help you determine their offerings and availability.