When considering the longevity of sheds, the choice between metal and wood is a critical factor. Metal sheds are renowned for their durability, as they are resistant to rot, pests, and weather damage, making them a low-maintenance option that can last 20 years or more with proper care. On the other hand, wood sheds, while aesthetically pleasing and customizable, require regular maintenance to prevent issues like warping, rotting, and insect infestations, typically lasting 15 to 20 years if well-maintained. Ultimately, the lifespan of either type depends on factors such as climate, quality of materials, and upkeep, making it essential to weigh these aspects when deciding which shed material best suits your needs.

| Characteristics | Values |

|---|---|

| Durability | Metal sheds generally last longer than wood sheds due to resistance to rot, pests, and warping. Wood sheds can last as long with proper maintenance but are more susceptible to environmental damage. |

| Lifespan | Metal sheds: 20–30+ years with minimal maintenance. Wood sheds: 10–20 years, but can extend to 30+ years with regular upkeep. |

| Maintenance | Metal: Low maintenance; occasional rust checks and repainting. Wood: Requires regular staining, sealing, and pest control to prevent decay. |

| Weather Resistance | Metal: Better resistance to harsh weather (rain, snow, wind). Wood: Prone to water damage, warping, and cracking unless treated. |

| Pest Resistance | Metal: Naturally resistant to pests like termites. Wood: Susceptible to termites and other wood-boring insects unless treated. |

| Cost | Metal: Generally more expensive upfront. Wood: Often cheaper initially but may require higher long-term maintenance costs. |

| Aesthetics | Metal: Modern, industrial look; limited customization. Wood: Natural, customizable appearance that blends well with outdoor environments. |

| Insulation | Wood: Naturally better insulated, ideal for storing temperature-sensitive items. Metal: Poor insulation unless additional materials are added. |

| Environmental Impact | Wood: Biodegradable and renewable if sourced sustainably. Metal: Longer-lasting but requires more energy to produce. |

| Customization | Wood: Easier to modify, repair, and customize. Metal: Limited customization options due to rigid structure. |

| Resale Value | Metal: Retains value better due to longer lifespan. Wood: Value decreases faster due to wear and tear. |

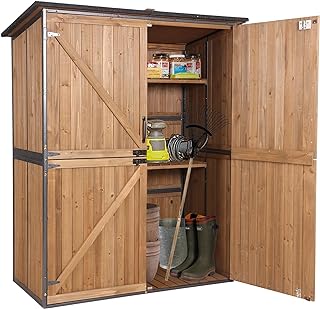

Explore related products

$239.99 $339.99

What You'll Learn

Climate Impact on Durability

In regions with high humidity, such as coastal areas or tropical climates, wood sheds face a formidable adversary: moisture. Prolonged exposure to damp conditions encourages rot, mold, and termite infestations, significantly shortening a wooden structure’s lifespan. Metal sheds, while resistant to these biological threats, are not immune to corrosion, particularly in salty air where rust accelerates. For wood sheds in humid zones, apply a water-repellent sealant annually and ensure proper ventilation. Metal sheds benefit from galvanized coatings or regular rust-inhibiting treatments. In both cases, elevating the shed’s foundation above ground level minimizes moisture contact, a critical step often overlooked in DIY installations.

Extreme temperature fluctuations, common in continental climates, test the resilience of both materials. Wood naturally expands and contracts with temperature shifts, leading to warping or cracking over time. Metal, particularly thin-gauge varieties, can dent or warp under rapid heating and cooling cycles. To mitigate these effects, choose pressure-treated wood for sheds in such climates, as it better withstands dimensional changes. For metal sheds, opt for thicker-gauge steel or aluminum, which offer greater stability. Additionally, installing reflective roofing materials can reduce heat absorption, easing thermal stress on both structures.

Arid climates, characterized by intense sunlight and minimal rainfall, pose unique challenges. UV radiation degrades wood’s surface, causing it to fade, splinter, and become brittle. Metal sheds, while UV-resistant, can become uncomfortably hot, potentially damaging stored items. For wood sheds, apply UV-protective stains every 2–3 years and consider shading solutions like awnings. Metal sheds benefit from light-colored finishes that reflect sunlight, reducing internal temperatures. In both cases, positioning the shed to maximize natural shade or using insulated panels can enhance durability and functionality.

In areas prone to heavy snowfall, the weight and moisture of snow accumulation threaten both shed types. Wood structures may sag or collapse under prolonged pressure, while metal roofs can dent or buckle. To combat this, ensure wood sheds have reinforced trusses and a roof pitch of at least 10 degrees to shed snow efficiently. Metal sheds should feature robust framing and a smooth roof design to prevent snow buildup. Regularly removing snow with a roof rake (avoiding sharp tools that could damage surfaces) is essential for both materials, especially after storms exceeding 6 inches of accumulation.

Finally, in regions with frequent storms or high winds, the structural integrity of sheds becomes paramount. Wood sheds, when properly anchored, can flex slightly under wind stress, but poorly constructed ones may splinter or topple. Metal sheds, while generally sturdier, require secure anchoring to prevent uplift. For both, embed anchor bolts in concrete footings and use hurricane ties or straps to reinforce connections. In tornado-prone areas, consider adding shear panels to wood sheds or opting for metal sheds with reinforced walls, as these measures significantly enhance resilience against extreme weather events.

DIY Reclaimed Wood Media Console: Craft Your Rustic Living Room Focal Point

You may want to see also

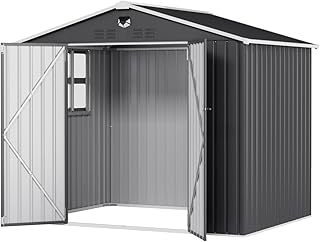

Explore related products

Maintenance Requirements Comparison

Metal sheds demand minimal upkeep, making them a low-maintenance choice for busy homeowners. Unlike wood, metal doesn’t rot, warp, or attract pests, eliminating the need for annual treatments like staining or sealing. A simple rinse with a hose twice a year removes dirt and debris, while occasional touch-ups with rust-resistant paint can address minor scratches. This hands-off approach saves time and money, particularly for those who prefer not to invest in regular maintenance routines.

Wood sheds, however, require a more proactive care regimen to ensure longevity. At a minimum, wood should be treated with a water-repellent sealant or stain every 2–3 years to protect against moisture, UV damage, and insect infestations. Pressure-washing once a year helps remove mold, mildew, and grime, but caution is needed to avoid damaging the wood fibers. Additionally, inspect wooden sheds annually for signs of rot, splintering, or pest activity, addressing issues promptly to prevent structural deterioration.

The tools and materials needed for maintenance differ significantly between the two materials. For metal sheds, a garden hose, mild detergent, and rust-inhibiting spray paint are sufficient for most tasks. Wood sheds, on the other hand, require a broader toolkit: a pressure washer, sandpaper, sealant or stain, and possibly insecticides. While metal’s maintenance is straightforward, wood’s upkeep involves more steps and specialized products, increasing both effort and expense over time.

Climate plays a critical role in determining maintenance demands. In humid or rainy regions, metal sheds may require more frequent inspections for rust, especially if the protective coating is compromised. Wood sheds in such areas are prone to rot and mold, necessitating more vigilant care. Conversely, in dry, sunny climates, wood sheds may fade or crack without regular sealing, while metal sheds remain largely unaffected. Tailoring maintenance to local conditions ensures both types of sheds perform optimally.

Ultimately, the choice between metal and wood sheds hinges on your willingness to commit to maintenance. Metal offers convenience and durability with minimal effort, ideal for those seeking a set-it-and-forget-it solution. Wood, while more labor-intensive, provides a natural aesthetic and can last just as long with proper care. Assess your lifestyle, budget, and climate before deciding—the right shed is one that aligns with your ability and desire to maintain it.

Understanding Rick of Wood: Size, Measurement, and Practical Uses

You may want to see also

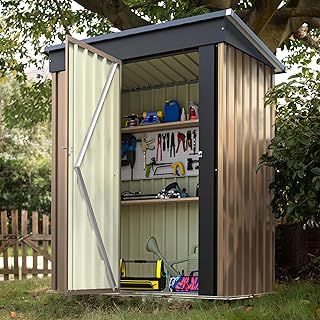

Explore related products

Resistance to Pests & Rot

Termites, carpenter ants, and wood-boring beetles pose a significant threat to wooden sheds, often leading to structural damage that shortens their lifespan. Metal sheds, by contrast, are impervious to these pests, as their material composition offers no nutritional value or habitat for wood-destroying organisms. This inherent resistance eliminates the need for chemical treatments like termiticides, which typically require professional application every 5–10 years and can cost between $500 and $1,500 per treatment. For homeowners in regions with high pest activity, such as the southeastern United States, this makes metal sheds a more cost-effective and low-maintenance option.

Rot, caused by fungi that thrive in damp conditions, is another critical factor in shed longevity. Wooden sheds, especially those made from untreated or low-quality lumber, are highly susceptible to moisture absorption, which accelerates decay. Metal sheds, however, are naturally resistant to rot due to their non-porous surface. To enhance wood’s resistance, pressure-treated lumber infused with preservatives like chromated copper arsenate (CCA) can be used, but this adds to the initial cost and may not be eco-friendly. Alternatively, applying a waterproof sealant annually to wooden sheds can mitigate rot, though this requires consistent upkeep and adds to long-term expenses.

Ventilation plays a pivotal role in preventing the conditions that foster pests and rot. Metal sheds often come with built-in ventilation systems, such as ridge vents or gable louvers, which reduce humidity and discourage fungal growth. For wooden sheds, installing vents and ensuring proper airflow is essential but may require additional DIY work or professional installation. Poorly ventilated wooden sheds in humid climates, like the Pacific Northwest, can deteriorate within 5–7 years, whereas metal sheds in similar conditions can last 20 years or more with minimal maintenance.

For those considering a wooden shed, strategic placement can reduce pest and rot risks. Elevating the shed on a concrete foundation or gravel base improves drainage, while positioning it away from dense vegetation minimizes pest access. Metal sheds, however, offer flexibility in placement due to their inherent resistance, making them suitable for damp or wooded areas where wooden structures would quickly degrade. Ultimately, while wooden sheds can be treated and maintained to resist pests and rot, metal sheds provide a hassle-free, long-term solution that requires no additional interventions.

Treated Wood Lifespan: Factors Affecting Durability and Longevity Explained

You may want to see also

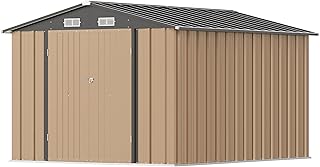

Explore related products

Cost vs. Lifespan Analysis

Metal sheds typically offer a lower upfront cost compared to wood, with prices starting around $300 for basic models, while wooden sheds often begin at $800 or more. However, this initial savings must be weighed against long-term durability. Metal sheds, constructed from galvanized steel or aluminum, resist rust and pests but can dent or warp under extreme weather. Wood, while more expensive, provides natural insulation and aesthetic appeal but requires regular maintenance to prevent rot, warping, or insect damage. For those prioritizing immediate budget constraints, metal may seem the obvious choice, but the frequency of repairs or replacements over time can erode its cost advantage.

Consider the lifespan of each material to gauge true value. Metal sheds generally last 15–20 years with minimal upkeep, whereas well-maintained wooden sheds can endure 20–30 years or more. For instance, a $500 metal shed replaced every 15 years would cost $2,000 over 45 years, while a $1,200 wooden shed maintained to last 30 years would cost $2,400 over the same period. However, these figures shift when factoring in maintenance: wood requires annual treatments (staining, sealing) at $50–$100 per year, adding $1,500–$3,000 to its lifetime cost. Metal, though lower-maintenance, may incur costs for rust repair or panel replacement. This analysis highlights how a higher initial investment in wood could yield longer-term savings if properly cared for.

Climate plays a critical role in this cost-lifespan equation. In humid or rainy regions, wood sheds demand more frequent treatments to combat moisture-related decay, potentially doubling maintenance costs. Metal sheds, while resistant to rot, may corrode faster in coastal areas due to salt exposure. Conversely, in dry climates, both materials perform well, but metal’s reflective surface can make it uncomfortably hot for storage. For example, a homeowner in the Pacific Northwest might find the added maintenance of a wooden shed justified by its longevity, while a desert-dwelling counterpart could prefer metal’s heat resistance despite its shorter lifespan.

To maximize value, align your choice with intended use and effort tolerance. If storing valuable tools or temperature-sensitive items, wood’s insulation properties may justify its higher cost and maintenance. For temporary or low-stakes storage, metal’s affordability and ease of assembly make it practical. A pro tip: invest in a metal shed with a reinforced roof for snow loads if in colder regions, or opt for cedar wood for its natural rot resistance. Ultimately, the "better" choice depends on balancing upfront cost, maintenance commitment, and environmental factors to ensure the shed’s lifespan aligns with your needs.

Citristrip on Wood: Optimal Time for Effective Paint Removal

You may want to see also

Explore related products

Weatherproofing Effectiveness Over Time

Metal sheds inherently resist rot, rust, and pests, but their weatherproofing effectiveness hinges on material quality and maintenance. High-grade galvanized steel or aluminum sheds with powder-coated finishes can endure decades with minimal degradation. However, cheaper models may develop rust or corrosion within 5–10 years, especially in coastal or humid climates. Regular inspections for scratches or chips in the coating are critical; untreated damage accelerates deterioration. Unlike wood, metal doesn’t warp or crack, but its thin walls may dent under heavy hail or debris, compromising structural integrity. For longevity, choose sheds with thicker gauges (12–14 gauge steel) and apply rust-inhibiting sprays biannually.

Wood sheds, while naturally insulating, require vigilant weatherproofing to rival metal’s durability. Pressure-treated lumber or cedar resists decay, but untreated pine sheds can rot within 5 years without proper care. Staining or sealing every 2–3 years is non-negotiable, particularly in regions with extreme temperature swings or heavy rainfall. Waterproofing treatments like silicone-based sealants or epoxy coatings enhance resistance, but their efficacy diminutes over time. For example, a single coat of sealant may last 18 months in arid areas but only 12 months in wetter zones. Pairing these treatments with a gravel foundation and roof overhangs minimizes ground moisture exposure, a common culprit in wood shed deterioration.

Comparing the two, metal sheds maintain their weatherproofing longer with less effort, but wood sheds offer repairable surfaces. A metal shed’s rusted panel often requires replacement, whereas a rotted wooden plank can be sanded, treated, and re-sealed. However, wood’s susceptibility to UV degradation means its protective coatings break down faster than metal’s factory finishes. In regions with intense sunlight, wood sheds may need annual touch-ups, while metal sheds can go 3–5 years between inspections. Both materials benefit from elevated foundations, but wood sheds particularly require ventilation to prevent moisture buildup, which metal sheds naturally resist.

To maximize weatherproofing effectiveness, prioritize proactive measures tailored to your shed’s material. For metal, focus on preventing surface damage and treating corrosion early. For wood, establish a strict staining schedule and monitor for mold or mildew. Installing gutter systems on both types diverts rainwater, reducing erosion and moisture-related issues. Ultimately, while metal sheds offer longer-lasting weatherproofing out of the gate, wood sheds can compete with diligent maintenance and high-quality treatments. The choice depends on your climate, budget, and willingness to invest time in upkeep.

Wood Glue Drying Time: When Can You Start Sanding?

You may want to see also

Frequently asked questions

Metal sheds generally last longer than wood sheds due to their resistance to rot, pests, and weather damage. However, with proper maintenance, wood sheds can also have a long lifespan.

For metal sheds, factors like rust prevention and quality of materials determine longevity. For wood sheds, regular staining, sealing, and protection from moisture are crucial to extending their lifespan.

Metal sheds are often more cost-effective in the long run due to lower maintenance needs and longer durability. Wood sheds may require more upkeep, but they can be more affordable upfront depending on the design and materials used.