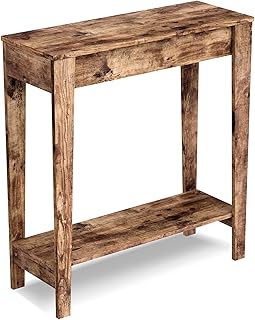

Creating a DIY long reclaimed wood media console is a rewarding project that combines sustainability, craftsmanship, and personalized design. By repurposing reclaimed wood, you not only reduce waste but also add a unique, rustic charm to your living space. This project allows you to tailor the console to your specific needs, whether it’s accommodating a large TV, providing ample storage, or incorporating cable management solutions. With basic woodworking tools and a bit of creativity, you can transform weathered wood into a functional and stylish centerpiece that reflects your individuality while contributing to a more eco-friendly home.

| Characteristics | Values |

|---|---|

| Material | Reclaimed wood (e.g., barn wood, pallet wood, salvaged timber) |

| Length | Typically 60–90 inches (customizable based on space and preference) |

| Height | 20–24 inches (standard for media consoles) |

| Depth | 16–20 inches (to accommodate electronics and storage) |

| Finish | Natural, stained, or sealed (polyurethane, wax, or oil-based finishes) |

| Storage Features | Open shelves, cabinets, drawers, or a combination |

| Legs/Base | Metal hairpin legs, wooden legs, or a solid wood base |

| Hardware | Rustic or modern handles/knobs for drawers and cabinets |

| Cable Management | Pre-drilled holes or channels for cords and cables |

| Cost | $100–$300 (depending on materials and tools) |

| Difficulty Level | Intermediate (basic carpentry skills required) |

| Tools Needed | Saw, drill, sander, screwdriver, measuring tape, clamps |

| Time to Build | 1–3 days (depending on complexity and drying time for finishes) |

| Customization Options | Adjustable shelf heights, added wheels, or decorative accents |

| Sustainability | Eco-friendly due to use of reclaimed materials |

| Aesthetic | Rustic, farmhouse, industrial, or modern depending on design choices |

Explore related products

What You'll Learn

Sourcing Reclaimed Wood

Reclaimed wood carries a story, its weathered grain and unique imperfections adding character to any DIY project, especially a long media console. But where do you find this treasure trove of history? Salvage yards are a goldmine, often brimming with beams, planks, and panels rescued from demolished buildings. Expect to find a variety of species – oak, pine, fir – each with its own distinct personality. Prices vary widely depending on rarity, condition, and size, so be prepared to negotiate and inspect carefully for rot or insect damage.

Some lumberyards now offer reclaimed wood sections, providing a more curated selection. While prices might be higher, the wood is often cleaned, milled, and ready for use, saving you time and effort. Online marketplaces like Craigslist, Facebook Marketplace, and specialized reclaimed wood retailers offer a vast array of options, often with detailed descriptions and photos. However, be cautious about shipping costs and always request close-up images to assess the wood's condition.

Consider the environmental impact of your sourcing. Choosing locally sourced reclaimed wood reduces transportation emissions and supports local businesses. Look for suppliers who prioritize sustainable practices, such as salvaging from responsibly demolished structures. Don't overlook unconventional sources. Old barns, fences, and even shipping pallets can yield beautiful, character-rich wood. With a bit of creativity and elbow grease, you can transform these forgotten pieces into the centerpiece of your media console.

Remember, reclaimed wood is an investment in both your project and the environment. By carefully sourcing and selecting your materials, you'll create a piece that's not only functional and beautiful but also carries a unique story within its grains.

Cedar Wood Durability: How Long It Lasts Outdoors and Why

You may want to see also

Explore related products

Measuring & Cutting Wood

Accurate measurements are the foundation of any successful woodworking project, especially when crafting a long reclaimed wood media console. Begin by determining the desired dimensions of your console, considering factors like room size, TV width, and storage needs. Use a tape measure to record lengths, widths, and heights, double-checking each measurement to avoid costly mistakes. Mark these dimensions clearly on your reclaimed wood with a pencil and a straightedge, ensuring lines are sharp and visible. Remember, reclaimed wood often has irregularities, so measure each piece individually rather than assuming uniformity.

Cutting reclaimed wood requires both precision and respect for the material’s unique character. Use a sharp circular saw or table saw for straight cuts, guiding the blade along your marked lines with steady pressure. For curved or intricate cuts, a jigsaw offers greater flexibility. Always wear safety gear, including goggles and ear protection, and secure the wood firmly to prevent slipping. When cutting, let the blade do the work—forcing it can lead to splintering or uneven edges. If your reclaimed wood has nails or screws, remove them beforehand or use a metal detector to locate hidden hardware.

One common challenge with reclaimed wood is its tendency to warp or crack during cutting. To minimize this, acclimate the wood to your workspace’s humidity and temperature for at least 48 hours before beginning. For particularly stubborn pieces, pre-cut slightly larger than your measurements and sand down to the exact size afterward. Additionally, consider using a fine-toothed blade to reduce tear-out, especially on weathered surfaces. If you’re new to woodworking, practice cutting on scrap pieces first to get a feel for the wood’s behavior.

Finally, organization is key when measuring and cutting multiple pieces for a media console. Label each cut piece with its intended location (e.g., “left side panel,” “bottom shelf”) to avoid confusion during assembly. Keep a detailed cut list nearby, noting dimensions and quantities for each component. This not only streamlines the process but also ensures consistency across your project. By approaching measuring and cutting with patience and precision, you’ll transform raw reclaimed wood into a polished, functional centerpiece for your space.

Durability of Wood: Factors Affecting Longevity and Preservation Techniques

You may want to see also

Explore related products

Assembling the Frame

The foundation of any sturdy media console lies in its frame, and assembling it from reclaimed wood requires precision and care. Begin by selecting straight, structurally sound planks for the vertical supports and horizontal braces. Measure twice, cut once—accuracy here prevents misalignment later. Use a miter saw for clean, straight cuts, ensuring each piece fits snugly. Pre-drill holes to prevent splitting, especially in aged wood, which can be more brittle. Secure the joints with wood screws and reinforce with wood glue for added stability.

Consider the design’s load-bearing needs. A long media console will span several feet, so incorporate additional braces or legs to distribute weight evenly. For example, a 72-inch console might require three legs or braces spaced evenly along the length. If using reclaimed barnwood, inspect for hidden nails or hardware that could interfere with assembly. Sand rough edges to ensure smooth joints and prevent splintering during handling.

A persuasive argument for pocket hole joinery emerges here. This method creates strong, hidden connections ideal for reclaimed wood’s rustic aesthetic. Invest in a Kreg Jig to simplify the process, drilling angled holes at precise depths. Pair pocket screws with wood glue for joints that rival traditional mortise-and-tenon techniques in strength. This approach not only enhances durability but also maintains the console’s clean, uncluttered appearance.

Finally, test the frame’s stability before proceeding. Place it on a flat surface and check for wobbling or uneven weight distribution. Adjust as needed by tightening screws or adding shims beneath legs. Remember, the frame is the skeleton of your console—a well-assembled structure ensures longevity and safety, especially when supporting heavy electronics. Take the time to get it right; the finished piece will reflect your attention to detail.

Plastic Wood Drying Time: Factors Affecting Cure and Dry Speed

You may want to see also

Explore related products

Adding Shelves & Doors

Reclaimed wood media consoles often lack built-in storage, making shelves and doors essential for functionality. Open shelves provide easy access to frequently used items like remotes and gaming consoles, while doors conceal clutter and protect less-used components from dust. This balance between accessibility and concealment is key to a polished, practical design.

Analyzing Shelf Placement:

Position shelves at ergonomic heights to maximize usability. For example, place the top shelf 12–18 inches above the console surface to accommodate soundbars or decor without obstructing the TV. Include a middle shelf 8–10 inches below for cable boxes or game systems, ensuring adequate ventilation. Avoid overcrowding by limiting shelves to 2–3 levels, maintaining a clean aesthetic.

Incorporating Doors: Hinges vs. Sliders

Hinged doors offer a classic look but require clearance for swing space, making them ideal for larger rooms. Use soft-close hinges (e.g., Blum or Hafele brands) to prevent slamming and extend door life. Alternatively, sliding doors save space and work well in tight areas. Opt for barn-door hardware for a rustic touch or aluminum tracks for a modern feel. Ensure doors align flush with the frame to maintain the reclaimed wood’s natural charm.

Material & Construction Tips

Match shelf and door materials to the console’s reclaimed wood for cohesion. If using contrasting wood, stain or seal both elements to unify the look. Secure shelves with metal brackets or wooden supports, ensuring they bear weight without sagging. For doors, reinforce corners with L-brackets or dowels to prevent warping over time. Pre-drill holes to avoid splitting the reclaimed wood, which can be brittle from age.

Practical Takeaways

Shelves and doors transform a basic media console into a versatile storage solution. Prioritize functionality by tailoring shelf heights to your devices and choosing door styles that suit your space. Invest in quality hardware to ensure durability, and always measure twice to align components seamlessly. With careful planning, these additions enhance both the utility and rustic appeal of your reclaimed wood console.

Optimal Oxalic Acid Application Time for Wood Restoration Explained

You may want to see also

Explore related products

Finishing & Staining Tips

Reclaimed wood brings character to any project, but its aged surface demands careful finishing to enhance, not obscure, its natural beauty. Before applying any stain or sealant, assess the wood’s condition. Fill deep cracks or voids with epoxy resin or wood filler to stabilize the structure while preserving texture. Sanding is critical but should be minimal—start with 80-grit to remove splinters, then progress to 120- or 150-grit for a smoother finish. Over-sanding erases the patina that makes reclaimed wood unique. Always sand with the grain to avoid scratches that catch light and detract from the rustic aesthetic.

Staining reclaimed wood requires a light touch to avoid overwhelming its natural variations. Water-based stains are ideal for their low odor and quick drying time, but oil-based options penetrate deeper, enriching the wood’s color without obscuring grain details. Apply stain with a brush or rag in thin, even coats, wiping off excess immediately to prevent pooling in uneven areas. For a more subtle effect, dilute the stain with water or mineral spirits, testing on a scrap piece first. If the wood has existing finishes or stains, strip them with a chemical remover or sand lightly to ensure new stain adheres evenly.

Sealing is non-negotiable for durability, but the choice of finish depends on the desired look and use. Polyurethane provides a hard, protective surface but can yellow over time, altering the wood’s tone. For a more natural appearance, opt for tung oil or wax, which penetrate the wood and enhance its texture without adding gloss. Apply sealants in multiple thin coats, allowing each to dry fully before sanding lightly (220-grit) between applications. This builds a smooth, protective layer without obscuring the wood’s character. Avoid over-applying, as thick finishes can crack or peel, especially on reclaimed wood with inherent movement.

One often-overlooked technique is using reactive wood finishes like iron acetate (vinegar and steel wool solution) to deepen the wood’s color without traditional stain. This method reacts with tannins in the wood, creating a weathered gray or rich brown tone that mimics aged patina. Apply the solution evenly, let it dry, then seal with a clear finish. For added depth, layer stains or glazes, but always test combinations on scrap wood to avoid unintended colors. Remember, reclaimed wood is unpredictable—embrace imperfections as part of its story, and let the finish highlight, not hide, its history.

Mastering Wood Glue Clamping: Optimal Time for Strong, Durable Joints

You may want to see also

Frequently asked questions

Essential tools include a circular saw or table saw, drill, sander, measuring tape, clamps, screwdriver, and a Kreg Jig for pocket holes. Additionally, safety gear like gloves and goggles is crucial.

Reclaimed wood can be sourced from salvage yards, demolition sites, antique stores, or online marketplaces. Ensure the wood is clean, dry, and free of pests before use.

A clear polyurethane or wax finish works well to protect the wood while preserving its natural look. For a more rustic appearance, consider using a stain or oil-based finish before sealing.