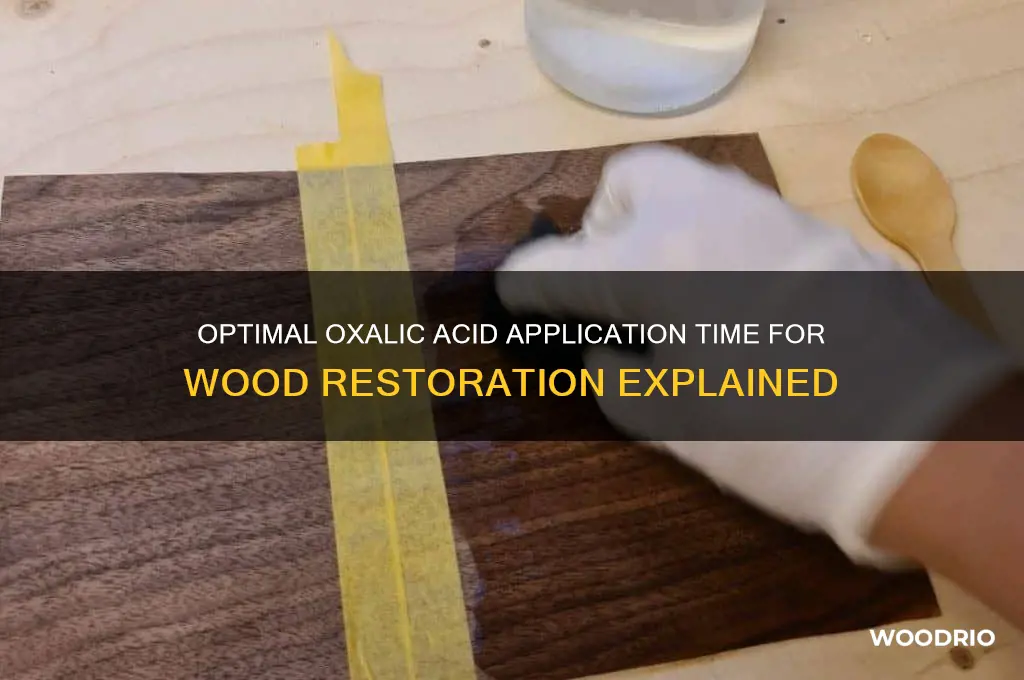

When using oxalic acid to clean or bleach wood, the duration it should be left on the surface depends on the desired outcome and the condition of the wood. Typically, oxalic acid is applied as a solution and left on the wood for 10 to 30 minutes, allowing it to penetrate and neutralize stains or discoloration caused by iron or tannins. However, for more severe stains, the solution may need to sit for up to an hour. It’s crucial to monitor the process, as leaving it on too long can potentially damage the wood fibers. After the recommended time, the wood should be thoroughly rinsed with clean water and allowed to dry completely before further treatment or finishing. Always test a small, inconspicuous area first to ensure compatibility and avoid adverse effects.

| Characteristics | Values |

|---|---|

| Application Time | Typically 10–15 minutes for most wood types |

| Drying Time | Allow wood to dry completely after application (usually 1–2 hours) |

| Rinsing Requirement | Rinse thoroughly with water after application |

| Neutralization | Neutralize with a mild base (e.g., baking soda solution) if necessary |

| Reapplication | Reapply if needed after rinsing and drying (wait 24 hours between coats) |

| Safety Precautions | Wear gloves, goggles, and work in a well-ventilated area |

| Effectiveness | Best for removing tannin stains and brightening wood |

| Concentration | Typically 1–2 tablespoons of oxalic acid per quart of water |

| Wood Compatibility | Safe for most wood types, especially effective on oak and pine |

| Storage of Solution | Discard leftover solution; do not store for future use |

| Environmental Impact | Dispose of solution according to local regulations |

| Post-Treatment Care | Seal or finish the wood after treatment for protection |

Explore related products

What You'll Learn

Application Time for Softwoods

Softwoods, such as pine, cedar, and spruce, react differently to oxalic acid compared to hardwoods due to their lower density and higher resin content. This necessitates a tailored approach to application time to achieve optimal results without damaging the wood. Typically, oxalic acid is used to remove stains, brighten wood, or neutralize tannins, but its dwell time on softwoods should be carefully monitored to avoid oversaturation or surface etching.

Steps for Application: Begin by preparing a solution of oxalic acid, commonly mixed at a ratio of 1 to 2 tablespoons per gallon of warm water. Apply the solution liberally to the softwood surface using a brush, sponge, or spray bottle, ensuring even coverage. For stained or heavily discolored areas, a stronger concentration (up to 4 tablespoons per gallon) may be necessary, but this should be tested on a small, inconspicuous area first. Allow the solution to sit for 10 to 15 minutes, which is generally sufficient for softwoods to react without causing harm.

Cautions: Prolonged exposure to oxalic acid can lead to a bleached or uneven appearance in softwoods, as their porous nature allows deeper penetration. Avoid leaving the solution on for more than 20 minutes, as this increases the risk of wood fiber damage. Additionally, softwoods with existing finishes or sealants may not absorb the acid evenly, so sanding or stripping may be required beforehand for consistent results.

Practical Tips: After the recommended dwell time, neutralize the acid by rinsing the wood thoroughly with clean water. This prevents residual acid from continuing to react with the wood. For best results, work in a well-ventilated area and wear protective gear, including gloves and goggles, to avoid skin and eye irritation. If the desired effect is not achieved after the first application, wait 24 hours before reapplying to allow the wood to dry completely.

Durability of Wood Fences: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

$12.45

Duration for Hardwoods

Hardwoods, with their dense grain and natural resilience, demand a tailored approach when using oxalic acid for bleaching or stain removal. Unlike softer woods, which may absorb solutions quickly, hardwoods require a longer dwell time to achieve the desired effect. Typically, oxalic acid should be left on hardwoods for 30 to 60 minutes, depending on the severity of the stain and the wood’s density. For deeper stains or darker woods like walnut or mahogany, extending the duration to 90 minutes can yield better results. Always test a small, inconspicuous area first to gauge the wood’s reaction and avoid over-bleaching.

The concentration of the oxalic acid solution plays a critical role in determining the appropriate duration. A standard mixture of 100 grams of oxalic acid per liter of warm water is effective for most hardwoods. However, for stubborn stains, increasing the concentration slightly (up to 150 grams per liter) can enhance penetration, but this should be done cautiously to prevent damage. After applying the solution, allow it to sit undisturbed, ensuring even coverage. If the wood begins to dry out during the process, lightly mist the surface with water to keep the acid active.

One practical tip for hardwoods is to monitor the wood’s appearance during the treatment. As the oxalic acid works, you’ll notice the stain lifting or the wood lightening. If the desired effect is achieved before the full 60 minutes, rinse the surface immediately with clean water to halt the chemical reaction. Conversely, if the stain persists after an hour, reapply the solution and extend the dwell time in 15-minute increments. Always wear protective gloves and work in a well-ventilated area, as oxalic acid can irritate skin and eyes.

Comparing hardwoods to softer woods highlights the need for patience and precision. While pine or cedar may only require 15 to 30 minutes of exposure, hardwoods’ tighter grain structure necessitates a longer process. This extended duration ensures the acid penetrates deeply enough to address stains or discoloration effectively. Additionally, hardwoods are less prone to warping or damage from prolonged exposure, making them ideal candidates for this method. However, always prioritize observation over strict timing to avoid over-treatment.

In conclusion, treating hardwoods with oxalic acid is a balance of time, concentration, and vigilance. By adhering to the recommended 30 to 60-minute dwell time, using an appropriate solution strength, and monitoring progress, you can achieve optimal results without compromising the wood’s integrity. Whether restoring an antique table or revitalizing a hardwood floor, this approach ensures both effectiveness and preservation of the wood’s natural beauty.

Seasoning Wood: Optimal Time for Perfectly Dried Firewood Explained

You may want to see also

Explore related products

Weather Impact on Drying

Humidity and temperature wield significant control over how long oxalic acid remains effective on wood. In dry climates with low humidity (below 40%), the solution evaporates rapidly, often within 15-30 minutes, leaving insufficient time for the acid to penetrate and brighten the wood fibers. Conversely, in humid environments (above 60%), drying slows dramatically, extending the dwell time to 2-4 hours. This prolonged exposure can lead to uneven bleaching or over-saturation if not monitored carefully.

Consider the application process in varying weather conditions. On a hot, sunny day (temperatures above 80°F), the oxalic acid solution dries so quickly that a second application is often necessary to achieve uniform results. In cooler temperatures (50-65°F), the drying process is more gradual, allowing the acid to work effectively with a single application. For optimal results, aim to apply oxalic acid during mild weather (60-75°F) with moderate humidity (40-50%).

Wind is another factor that accelerates evaporation, particularly in outdoor settings. If applying oxalic acid to exterior wood, shield the treated area from direct wind using tarps or natural barriers. Alternatively, work in the early morning or late afternoon when wind speeds are typically lower. Indoor applications are less affected by wind but still require proper ventilation to avoid inhaling fumes, especially in humid conditions where the solution lingers longer in the air.

For precise control, use a hygrometer to measure humidity and adjust your approach accordingly. In high-humidity scenarios, dilute the oxalic acid solution slightly (10-15% more water) to prevent over-saturation. In dry conditions, apply the solution more generously and consider misting the wood periodically to slow evaporation. Always test a small area first to gauge how the weather impacts drying time and adjust your technique as needed.

Ultimately, understanding weather’s role in drying oxalic acid allows for more predictable and effective wood treatment. By tailoring your approach to humidity, temperature, and wind, you can achieve consistent results regardless of environmental challenges. Remember, patience and observation are key—let the weather guide your process, not dictate it.

Durability of Wood Siding: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

Reapplication Waiting Period

The reapplication waiting period for oxalic acid on wood is a critical factor in achieving optimal results, particularly when addressing stubborn stains like iron or rust. After the initial application, wood typically requires at least 24 hours to fully react with the acid and neutralize the discoloration. This waiting period allows the oxalic acid to penetrate the wood fibers and break down the iron compounds causing the stain. Rushing this process by reapplying too soon can lead to uneven results or insufficient stain removal. For deeper stains, a second application may be necessary, but patience is key—wait the full 24 hours before reassessing the wood’s condition.

Instructively, the waiting period also depends on the concentration of the oxalic acid solution. A 10% solution, commonly used for wood restoration, generally requires the full 24-hour window for maximum effectiveness. However, if using a weaker solution (e.g., 5%), the waiting period may extend to 48 hours to ensure complete reaction. Always test a small, inconspicuous area first to gauge the wood’s response and adjust the waiting period accordingly. After reapplication, allow another 24 hours before sanding or sealing the wood to avoid disrupting the chemical process.

Comparatively, the reapplication waiting period for oxalic acid differs from other wood treatments, such as bleach or vinegar. While bleach acts quickly and can be reapplied within hours, oxalic acid’s chemical reaction is slower and more deliberate. Unlike vinegar, which may require multiple applications in quick succession, oxalic acid’s potency means reapplication should be spaced out to prevent oversaturation or damage to the wood. This distinction highlights the importance of adhering to the recommended waiting period for each specific treatment.

Practically, environmental factors can influence the reapplication waiting period. High humidity or low temperatures can slow the drying and reaction process, potentially extending the waiting time beyond 24 hours. In such conditions, ensure the wood is in a well-ventilated area and consider using a fan to expedite drying. Conversely, in dry, warm environments, the wood may dry faster, but avoid reapplying sooner than 24 hours to maintain consistency. Always monitor the wood’s appearance during the waiting period to determine if additional treatment is needed.

Finally, the reapplication waiting period is not just about stain removal—it’s also about preserving the wood’s integrity. Overlapping applications without sufficient waiting time can lead to excessive moisture buildup, causing warping or cracking. For older or delicate wood, extend the waiting period to 36–48 hours to minimize stress on the material. After the final application, allow the wood to dry completely before finishing with a sealant or stain. This careful approach ensures both aesthetic and structural longevity, making the waiting period a cornerstone of successful wood restoration.

Wood Wick Candles: Do They Burn Longer Than Traditional Wicks?

You may want to see also

Explore related products

$15.99

Safety Precautions During Exposure

Oxalic acid, a potent bleaching agent for wood, demands meticulous safety precautions during application. Its corrosive nature poses risks to skin, eyes, and respiratory health, necessitating a proactive approach to protection.

Before handling, ensure adequate ventilation by working outdoors or in a well-ventilated area. If indoors, use fans or open windows to disperse fumes, and consider a respirator with acid vapor cartridges for prolonged exposure.

Protective Gear is Non-Negotiable: Treat oxalic acid with the respect it warrants. Wear chemical-resistant gloves (nitrile or neoprene) that extend beyond the wrist to prevent skin contact. Safety goggles are essential to shield eyes from splashes, and long sleeves and pants minimize exposed skin. For added protection, consider a chemical-resistant apron, especially when working with larger quantities.

Remember, even diluted solutions can cause irritation, so avoid touching your face or eyes during application and wash hands thoroughly after handling.

Dilution and Application Techniques Matter: Oxalic acid is typically diluted with water before application. Common ratios range from 1:10 to 1:20 (acid to water), but always follow manufacturer instructions for specific concentrations. Apply the solution with a brush, spray bottle, or sponge, avoiding excessive saturation. Allow the solution to dwell on the wood for the recommended time, typically 10-30 minutes, depending on the wood type and desired effect.

Rinse the wood thoroughly with clean water after the dwell time to neutralize the acid and prevent residue.

Spill Response and Disposal: Accidents happen. If oxalic acid spills on skin, immediately flush the area with running water for at least 15 minutes. For eye contact, rinse with water for 20 minutes and seek medical attention. Neutralize spills on surfaces with baking soda or a mild base solution, then dispose of the neutralized material according to local regulations. Never pour oxalic acid down drains; it can corrode pipes and harm the environment.

Wood Rot Timeline: Factors Affecting Decay and Prevention Tips

You may want to see also

Frequently asked questions

Oxalic acid should typically be left on wood for 10 to 30 minutes, depending on the severity of the stains and the desired results. Always test a small area first.

No, leaving oxalic acid on wood overnight is not recommended, as it can cause damage or over-bleaching. Follow the recommended application time for best results.

Oxalic acid can remove black stains within 10 to 20 minutes, but stubborn stains may require a second application after rinsing and drying the wood.

Oxalic acid should be rinsed off thoroughly with water after the recommended application time (10–30 minutes) to prevent residue and ensure proper neutralization.

Wood typically dries within 1 to 2 hours after rinsing off oxalic acid, depending on humidity and ventilation. Ensure it is completely dry before applying any finish.

![Oxalic Acid [C2H2O4] 99.8% ACS Grade Powder 8 Oz in a Space-Saver Bottle](https://m.media-amazon.com/images/I/81MyjE5ttkL._AC_UY218_.jpg)