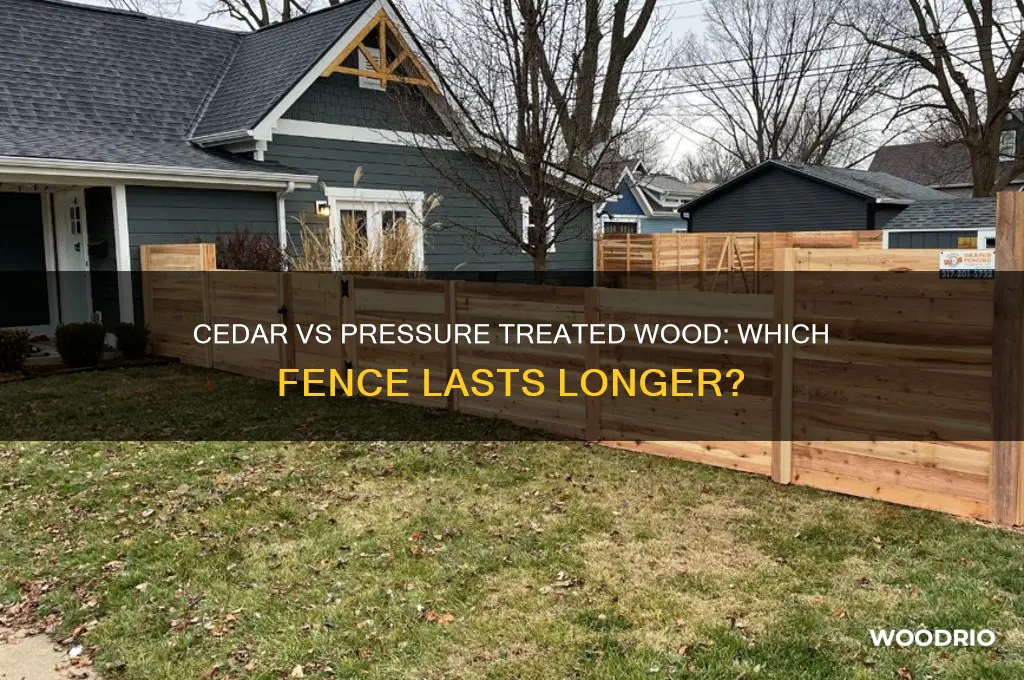

When comparing the longevity of cedar fencing to pressure-treated wood, several factors come into play, including natural resistance to decay, insect damage, and environmental conditions. Cedar is inherently durable due to its natural oils and tannins, which repel pests and resist rot, making it a popular choice for outdoor structures. Pressure-treated wood, on the other hand, is chemically treated to enhance its durability, providing protection against moisture, fungi, and insects. While both materials offer significant advantages, cedar typically lasts longer in its natural state, often enduring 15 to 30 years or more with proper maintenance, whereas pressure-treated wood can last 20 to 40 years, depending on the quality of treatment and care. Ultimately, the choice between the two depends on specific needs, budget, and aesthetic preferences.

Explore related products

What You'll Learn

Cedar's natural durability and resistance to decay

Cedar wood's natural durability stems from its unique cellular structure and chemical composition. Unlike many other softwoods, cedar contains natural oils and tannins that act as built-in preservatives. These compounds are toxic to fungi, insects, and bacteria, the primary culprits behind wood decay. For instance, the heartwood of Western Red Cedar, a popular choice for fencing, has a natural resistance to rot and insect damage, making it a superior option for outdoor applications.

Consider the process of decay in wood: it typically begins with moisture absorption, leading to fungal growth and structural breakdown. Cedar, however, has a low moisture absorption rate due to its dense grain pattern. This inherent property significantly slows down the decay process, ensuring that cedar fences remain structurally sound for decades. In contrast, pressure-treated wood relies on chemical treatments to achieve similar results, which can leach out over time, leaving the wood vulnerable.

To maximize cedar’s longevity, proper installation and maintenance are key. Ensure the wood is sealed or stained to protect it from UV rays, which can cause surface degradation over time. Additionally, avoid ground contact by using concrete or gravel bases, as direct soil contact can accelerate moisture absorption. When comparing cedar to pressure-treated wood, cedar’s natural resistance means it often requires less frequent treatment and maintenance, saving time and resources in the long run.

A practical example illustrates cedar’s durability: a well-maintained cedar fence can last 20–30 years or more, whereas pressure-treated wood typically lasts 15–20 years under similar conditions. This extended lifespan is not just a matter of aesthetics but also of structural integrity. Cedar’s resistance to warping, splitting, and cracking ensures that the fence remains functional and secure, even in harsh weather conditions. For homeowners seeking a long-term, low-maintenance solution, cedar’s natural properties offer a compelling advantage.

Finally, cedar’s eco-friendly profile adds another layer to its appeal. Unlike pressure-treated wood, which often contains chemicals like arsenic or copper compounds, cedar is a sustainable and non-toxic choice. Its natural durability reduces the need for chemical treatments, making it safer for both the environment and those in contact with it. By choosing cedar, homeowners invest in a material that not only lasts longer but also aligns with sustainable building practices.

Longhorn Beetles and Wood: Exploring Their Borrowing Habits

You may want to see also

Explore related products

Pressure-treated wood's chemical treatment lifespan

The lifespan of pressure-treated wood hinges on the chemicals used in its treatment. Modern pressure-treated wood typically contains copper azole (CA-B) or alkaline copper quaternary (ACQ), which are less toxic than the now-banned chromated copper arsenate (CCA). These chemicals protect the wood from rot, decay, and insect damage, but their effectiveness varies. Copper azole, for instance, is known for its resistance to fungal decay and termites, while ACQ is more water-repellent. The concentration of these preservatives is crucial—typically, treatment levels range from 0.15 to 0.25 pounds of chemical per cubic foot of wood, depending on the intended use. Higher concentrations generally extend the wood’s lifespan but can increase costs and environmental concerns.

Understanding the chemical treatment process is key to maximizing the lifespan of pressure-treated wood. During treatment, the wood is placed in a pressurized chamber where the preservative is forced into its fibers. This ensures deeper penetration compared to surface treatments like painting or staining. However, not all pressure-treated wood is created equal. Wood treated for ground contact, for example, receives a higher dosage of preservatives than wood intended for above-ground use. Ground-contact treated wood can last 20 to 40 years, while above-ground treated wood typically lasts 15 to 20 years. Proper installation, such as ensuring the wood is not in direct contact with soil or moisture, can further extend its life.

Despite its durability, pressure-treated wood is not maintenance-free. Over time, the chemical treatment can leach out, especially in harsh weather conditions. To mitigate this, apply a water-repellent sealant every 2 to 3 years. Avoid using paints or stains that contain oil, as they can trap moisture and accelerate decay. Regularly inspect the wood for cracks, splinters, or signs of insect activity, and address issues promptly. For fences, ensure posts are set in concrete with proper drainage to prevent water accumulation. These steps can help maintain the wood’s structural integrity and preserve the effectiveness of the chemical treatment.

Comparing pressure-treated wood to cedar highlights the trade-offs between chemical treatment and natural resistance. Cedar contains natural oils that repel insects and resist decay, but it lacks the heavy-duty protection of chemically treated wood. Pressure-treated wood, with its engineered lifespan, is often more cost-effective for high-moisture applications like fence posts or decking. However, cedar’s aesthetic appeal and lower environmental impact make it a preferred choice for visible structures. Ultimately, the choice depends on the specific needs of the project, balancing longevity, maintenance, and environmental considerations.

Do Roaches Thrive in Long Island's Woodland Habitats?

You may want to see also

Explore related products

Maintenance requirements for both materials

Cedar fences naturally resist rot and insects, reducing maintenance needs compared to pressure-treated wood. Left untreated, cedar weathers to a silvery gray over 1-2 years, a look some homeowners prefer. To maintain its original color, apply a UV-protective sealant every 2-3 years. Pressure-treated wood, while durable, requires more vigilance. Inspect annually for splinters, warping, or mold, especially in humid climates. Both materials benefit from regular cleaning with a mild detergent and water to remove dirt and mildew.

For pressure-treated wood, staining or painting every 3-5 years is essential to prevent moisture absorption and extend lifespan. Use a semi-transparent stain to allow the wood’s natural grain to show while adding protection. Cedar, though more forgiving, can crack or warp if exposed to extreme moisture. Ensure proper drainage around the fence and trim vegetation to prevent water pooling. For both materials, repair or replace damaged boards promptly to avoid structural issues.

A key difference lies in chemical treatment. Pressure-treated wood contains preservatives that leach out over time, requiring reapplication of protective coatings more frequently. Cedar’s natural oils make it inherently resistant, but these oils diminish with age, necessitating sealant application to compensate. In high-traffic areas, consider adding a protective barrier, like gravel or mulch, to reduce soil-to-wood contact and minimize decay.

Ultimately, cedar’s low-maintenance appeal comes from its natural properties, but it still requires periodic care to maximize longevity. Pressure-treated wood demands more proactive maintenance but offers robust durability when properly tended. Choose based on your willingness to invest time and effort, balancing aesthetics and practicality for your specific needs.

Wood Glue Curing Time: How Long for Full Strength and Durability?

You may want to see also

Explore related products

$20.89 $21.99

Cost comparison over time

Cedar and pressure-treated wood are both popular choices for fencing, but their long-term costs differ significantly due to durability, maintenance, and lifespan. Initially, cedar is more expensive, often costing 20-30% more than pressure-treated wood. However, this upfront investment can pay off over time because cedar naturally resists rot, decay, and insect damage, reducing the need for frequent repairs or replacements. Pressure-treated wood, while cheaper at the outset, may require more maintenance and could need replacement sooner, especially in humid or wet climates.

Analyzing maintenance costs reveals another layer of the comparison. Cedar fences typically require staining or sealing every 2-3 years to maintain their appearance and structural integrity, with each treatment costing around $100-$200 for a standard 150-foot fence. Pressure-treated wood, on the other hand, may need more frequent treatments, including stain, sealant, and potential repairs for warping or splitting, which can add up to $150-$300 every 1-2 years. Over a 20-year period, these maintenance costs for pressure-treated wood can surpass the initial savings, making cedar the more cost-effective option in the long run.

A persuasive argument for cedar lies in its lifespan. A well-maintained cedar fence can last 20-30 years, while pressure-treated wood typically lasts 15-20 years. Replacing a fence is a significant expense, often costing $2,000-$4,000 for materials and labor. By choosing cedar, homeowners can delay this expense by 5-10 years, effectively spreading out the cost over a longer period. This extended lifespan not only saves money but also reduces the hassle and disruption of frequent fence replacements.

For a practical comparison, consider a scenario where a homeowner installs a 150-foot fence. The initial cost for cedar might be $3,000, while pressure-treated wood could be $2,250. Over 20 years, cedar maintenance could total $1,000-$1,500, whereas pressure-treated wood might reach $2,000-$3,000. Additionally, if the pressure-treated fence needs replacement after 15 years, adding another $3,000, the total cost could reach $7,250-$8,250. In contrast, the cedar fence, lasting 20-30 years, would cost $4,000-$4,500 in the same timeframe. This example highlights how cedar’s higher initial cost is offset by lower long-term expenses.

In conclusion, while pressure-treated wood offers a lower upfront cost, cedar’s durability and longer lifespan make it a more cost-effective choice over time. Homeowners should weigh the initial investment against future maintenance and replacement costs to determine the best option for their budget and needs. By prioritizing long-term savings, cedar often emerges as the smarter financial decision for fencing projects.

Understanding Morning Wood Duration: What's Normal and When to Worry

You may want to see also

Explore related products

Environmental impact and sustainability differences

Cedar fencing boasts a natural resistance to decay and insects, reducing the need for chemical treatments over its lifespan. Pressure-treated wood, on the other hand, relies on preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), which leach into the soil over time. While modern treatments are less toxic than older CCA formulations, they still pose environmental risks, particularly in gardens or areas frequented by children and pets.

Consider the lifecycle of these materials. Cedar, a renewable resource when harvested responsibly, sequesters carbon during its growth. Its durability minimizes replacement needs, lowering overall resource consumption. Pressure-treated wood, while extending the life of less durable species, carries the environmental footprint of chemical production and application. Disposal of treated wood is also problematic, as it cannot be burned or composted safely due to its chemical content.

For homeowners prioritizing sustainability, cedar offers a clearer advantage. Its longevity reduces waste, and its end-of-life disposal is less harmful. However, sourcing matters: opt for cedar certified by the Forest Stewardship Council (FSC) to ensure sustainable harvesting practices. Pressure-treated wood, while more affordable upfront, requires careful consideration of its chemical impact on surrounding ecosystems, especially in water-sensitive areas.

Practical steps can mitigate the environmental impact of either choice. For pressure-treated wood, install a geotextile barrier beneath the fence to minimize soil contamination. Regularly inspect and maintain both types to maximize lifespan. When replacing sections, recycle or repurpose old materials where possible. Ultimately, cedar’s natural durability aligns better with long-term environmental goals, but informed choices and responsible practices can lessen the ecological footprint of either option.

How Long Do Essential Oils Scent Wood Surfaces?

You may want to see also

Frequently asked questions

Yes, cedar generally lasts longer than pressure treated wood due to its natural resistance to rot, decay, and insects.

Cedar contains natural oils and tannins that repel pests and resist moisture, while pressure treated wood relies on chemical treatments that can wear off over time.

A cedar fence can last 15–30 years or more with proper maintenance, whereas pressure treated wood typically lasts 10–20 years.

Yes, cedar is usually more expensive upfront, but its longer lifespan and lower maintenance needs can make it a cost-effective choice over time.

Cedar requires minimal maintenance, such as occasional sealing or staining, while pressure treated wood may need more frequent treatments to maintain its durability.

![[Pack of 4] 2-7/8" Chain Link Fence Post Cap, Galvanized Steel Fence Terminal Post Caps for 2-7/8" OD Post/Pipe.](https://m.media-amazon.com/images/I/61Wf3EYK0kL._AC_UL320_.jpg)