When comparing the longevity of wood and steel, several factors come into play, including environmental conditions, maintenance, and intended use. Steel is generally more durable in harsh environments due to its resistance to rot, pests, and moisture, making it ideal for structural applications like buildings and bridges. However, wood, when properly treated and maintained, can also last for decades or even centuries, as seen in historic wooden structures. Ultimately, the lifespan of either material depends on how well it is cared for and the specific demands of its application, making it essential to consider both materials' strengths and weaknesses in context.

| Characteristics | Values |

|---|---|

| Durability | Steel generally lasts longer than wood due to its resistance to rot, pests, and moisture. Wood can last a long time if properly treated and maintained. |

| Maintenance | Steel requires minimal maintenance, while wood needs regular sealing, staining, or painting to prevent decay. |

| Resistance to Elements | Steel is highly resistant to weather, fire, and pests. Wood is susceptible to rot, termites, and warping unless treated. |

| Lifespan | Steel structures can last 50+ years with minimal maintenance. Treated wood can last 20-30 years, but untreated wood may degrade in 5-10 years. |

| Environmental Impact | Wood is renewable and biodegradable but requires deforestation. Steel is recyclable but has a higher carbon footprint in production. |

| Cost | Steel is generally more expensive upfront but may be cost-effective long-term due to lower maintenance. Wood is cheaper initially but may require more frequent replacement. |

| Aesthetic Appeal | Wood offers natural beauty and warmth, while steel provides a modern, industrial look. |

| Strength-to-Weight Ratio | Steel has a higher strength-to-weight ratio, making it ideal for large structures. Wood is lighter but may require more material for equivalent strength. |

| Corrosion Resistance | Steel can corrode without proper coating, while wood does not corrode but can decay. |

| Sustainability | Wood is more sustainable if sourced responsibly. Steel is sustainable if recycled, but production is energy-intensive. |

Explore related products

What You'll Learn

Environmental Impact on Durability

The durability of wood and steel is not solely determined by their inherent properties but is significantly influenced by environmental factors. Exposure to moisture, temperature fluctuations, and chemical agents can accelerate degradation, making material choice a critical decision in construction and manufacturing. For instance, wood in humid climates is prone to rot and insect damage, while steel in coastal areas corrodes rapidly due to saltwater exposure. Understanding these interactions is essential for maximizing the lifespan of either material.

Consider the role of moisture, a primary environmental factor affecting durability. Wood, being hygroscopic, absorbs and releases water, leading to swelling, warping, and eventual decay if not properly treated. Sealants and preservatives like creosote or copper azole can mitigate this, but regular maintenance is required, especially in wet environments. Steel, on the other hand, rusts when exposed to moisture and oxygen, forming iron oxide that weakens its structure. Galvanization or stainless steel alloys offer protection, but even these solutions have limits, particularly in corrosive atmospheres.

Temperature extremes further complicate the durability equation. Wood expands and contracts with temperature changes, causing cracks and splits over time. This thermal movement is less of an issue for steel, which has a higher coefficient of expansion but is more structurally forgiving in this regard. However, steel’s strength diminishes at high temperatures, making it unsuitable for fire-prone environments without additional protective measures. In cold climates, both materials face challenges: wood becomes brittle, and steel may crack under stress due to reduced ductility.

Chemical exposure is another environmental factor that disproportionately affects these materials. Wood is vulnerable to acids, alkalis, and pollutants, which can break down its cellular structure. Steel, while resistant to many chemicals, corrodes in the presence of acids and salts, common in industrial or marine settings. Coatings and inhibitors can extend steel’s life, but they require precise application and periodic renewal. For wood, choosing naturally resistant species like teak or cedar can reduce chemical susceptibility, though this comes at a higher cost.

Ultimately, the environmental impact on durability underscores the need for context-specific material selection. In dry, temperate climates with minimal chemical exposure, untreated wood may outlast steel. Conversely, in harsh, corrosive environments, steel with appropriate protective treatments will endure longer. The key lies in assessing local conditions and applying preventive measures—whether through material choice, treatment, or design—to counteract environmental stressors. This proactive approach ensures both wood and steel can achieve their maximum potential lifespan.

Metal vs. Wood Sheds: Which Material Offers Greater Durability?

You may want to see also

Explore related products

Maintenance Requirements for Longevity

Wood and steel, when left untreated and exposed to the elements, degrade in vastly different ways. Wood succumbs to rot, warping, and insect damage, while steel corrodes and rusts. However, with proper maintenance, both materials can achieve remarkable longevity. The key lies in understanding their unique vulnerabilities and implementing targeted care routines.

Wood, for instance, requires regular sealing or staining to repel moisture and UV rays. This should be done every 2-3 years, depending on climate and exposure. For example, a wooden deck in a humid coastal region will need more frequent treatment than one in a dry desert climate. Steel, on the other hand, benefits from coatings like paint or galvanization, which act as barriers against corrosive elements. These coatings typically last 10-15 years before requiring reapplication.

Wood Chips vs. Mulch: Which Lasts Longer in Your Garden?

You may want to see also

Explore related products

Resistance to Weather Conditions

Steel's resistance to weather conditions is a testament to its durability, particularly in environments where moisture and temperature fluctuations are constant threats. Unlike wood, which can warp, crack, or rot when exposed to prolonged dampness, steel maintains its structural integrity. For instance, galvanized steel, treated with a zinc coating, offers exceptional corrosion resistance, making it ideal for outdoor structures like bridges and fences. This treatment can extend steel's lifespan by decades, even in coastal areas where saltwater accelerates material degradation. The key takeaway? Steel’s ability to withstand harsh weather without compromising strength positions it as a superior choice for long-term outdoor applications.

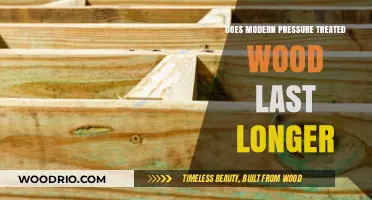

Consider the maintenance required to preserve wood in adverse weather conditions. Regular sealing, staining, or painting is essential to prevent water infiltration, which can lead to fungal growth or insect damage. In contrast, steel demands minimal upkeep once properly treated. For wood structures, annual inspections and treatments are recommended, especially in regions with high humidity or frequent rainfall. A practical tip: use pressure-treated wood for ground contact to delay decay, but even this measure pales in comparison to steel’s innate resilience. The labor and cost associated with wood maintenance underscore steel’s advantage in weather resistance.

A comparative analysis reveals steel’s edge in extreme temperatures as well. Wood expands and contracts with heat and cold, leading to structural stress and eventual failure. Steel, however, has a higher thermal stability, maintaining its shape and strength across a broader temperature range. For example, in regions prone to wildfires, steel structures are less likely to ignite or warp under intense heat. Similarly, in freezing climates, steel does not become brittle like some wood types, ensuring safety and longevity. This thermal resistance makes steel a more reliable choice for environments with unpredictable weather patterns.

Persuasively, steel’s weather resistance translates to cost-effectiveness over time. While the initial investment for steel may be higher than wood, its longevity reduces the need for frequent replacements or repairs. A case study of outdoor furniture illustrates this: steel pieces, though pricier upfront, outlast wooden counterparts by 2-3 times, even in rainy climates. For homeowners and builders, this means fewer disruptions and lower long-term expenses. By prioritizing steel in weather-exposed projects, one can achieve both durability and economic efficiency.

Descriptively, imagine a seaside pier—a structure constantly battered by salt spray, wind, and sun. Steel pilings and beams endure these conditions with minimal wear, while wooden components would require regular replacement. The pier’s steel framework remains steadfast, a silent guardian against the elements. This vivid example highlights steel’s unparalleled resistance to weather, making it the material of choice for projects where durability cannot be compromised. In the battle against nature’s forces, steel stands as the clear victor.

Mastering Wood Chip Soaking: Optimal Time for Perfect Smoking Results

You may want to see also

Explore related products

Corrosion vs. Rotting Factors

Steel's longevity hinges on its susceptibility to corrosion, a relentless process where metal oxidizes and degrades. This electrochemical reaction, accelerated by moisture, salt, and pollutants, eats away at steel structures, compromising their integrity. For instance, coastal bridges face higher corrosion rates due to saltwater exposure, requiring frequent maintenance. To combat this, engineers apply protective coatings like zinc galvanization or use corrosion-resistant alloys, which can extend steel's lifespan by decades. However, even with these measures, steel’s durability is a constant battle against environmental factors.

Wood, on the other hand, faces its own nemesis: rotting. This biological process occurs when fungi, bacteria, and insects break down cellulose and lignin, the primary components of wood. Moisture is the catalyst here, as it creates an ideal environment for these organisms to thrive. For example, untreated wooden fence posts buried in soil can rot within 5–10 years due to constant dampness. Preventive measures include pressure-treating wood with preservatives like chromated copper arsenate (CCA), which can double or triple its lifespan. Proper ventilation and regular inspections are also crucial to keep wood dry and intact.

Comparing the two, corrosion in steel is a chemical process, while rotting in wood is biological. Steel’s corrosion is often uniform and predictable, allowing for targeted interventions like cathodic protection or sacrificial anodes. Wood’s rotting, however, can be localized and unpredictable, as pests and fungi attack specific areas. This makes wood’s degradation harder to monitor and control. For outdoor applications, steel may outperform wood in arid climates, but in humid or wet environments, treated wood can hold its own, especially when elevated off the ground.

A practical takeaway is to match the material to the environment. For structures exposed to water, like boat hulls or waterfront piers, stainless steel or treated wood with a high preservative dosage (e.g., 0.6% CCA retention) is ideal. In dry, indoor settings, untreated wood or mild steel with a paint coating suffices. Regular maintenance, such as reapplying coatings every 5–7 years for steel or inspecting wood for cracks annually, ensures both materials reach their maximum lifespan. Understanding these factors allows for informed decisions that balance cost, durability, and environmental conditions.

Morning Wood Duration: How Long Does It Typically Last?

You may want to see also

Explore related products

$265 $265

Cost-Effectiveness Over Time Comparison

Initial maintenance costs often tip the scale in favor of wood, which is generally cheaper to install than steel. For instance, a wooden fence might cost $10–$30 per linear foot, while a steel one can range from $20–$50. However, this upfront savings comes with a trade-off: wood requires more frequent upkeep. Stain or paint must be reapplied every 2–3 years to prevent rot and insect damage, adding $200–$500 per application for a typical backyard fence. Steel, on the other hand, may need only occasional rust treatment or repainting every 5–10 years, costing roughly $300–$800 per session. Over two decades, wood maintenance could total $2,000–$5,000, while steel might stay under $2,000.

Consider the lifespan-to-cost ratio for a clearer picture. Wood structures typically last 15–20 years with proper care, whereas steel can endure 40–70 years. For a 50-foot fence, wood’s total 20-year cost (installation + maintenance) might be $2,500–$4,500, while steel’s 50-year cost could be $3,000–$6,000. Here, steel’s longevity makes it more cost-effective in the long run, despite higher initial expenses. This principle applies to larger projects too: a wooden deck replaced every 20 years versus a steel one that lasts a lifetime can save thousands over decades.

Environmental factors play a critical role in cost-effectiveness. In humid climates, wood’s susceptibility to mold and decay accelerates maintenance needs, potentially doubling upkeep costs. Steel, while prone to rust in coastal areas, can be mitigated with galvanized coatings or stainless alloys, adding 10–20% to initial costs but reducing long-term repairs. For example, a galvanized steel fence in Florida might cost $25–$60 per linear foot but require minimal intervention over 50 years, outperforming wood in both durability and cumulative expenses.

Finally, resale value and adaptability should factor into cost analysis. Steel structures often retain 70–80% of their value over time, while wood depreciates faster due to wear. Additionally, steel’s modularity allows for easier modifications—a steel beam can be repurposed or adjusted, whereas damaged wood often requires complete replacement. For commercial projects, this flexibility reduces future costs, making steel a smarter investment despite its premium price. In residential settings, however, wood’s lower initial cost might align better with short-term budgets, provided maintenance is diligently managed.

To maximize cost-effectiveness, assess your timeline and environment. For projects under 20 years in dry climates, wood may suffice with vigilant upkeep. For long-term or harsh-condition use, steel’s higher upfront cost pays dividends through reduced maintenance and extended lifespan. Always factor in local material prices, labor rates, and climate-specific treatments to tailor your choice. Ultimately, the “cheaper” option isn’t always the most economical over time—steel’s durability often justifies its premium, while wood demands consistent investment to remain viable.

Discovering the Lifespan of Wood Ducks: How Long Do They Live?

You may want to see also

Frequently asked questions

Steel generally lasts longer in outdoor environments due to its resistance to rot, pests, and moisture, though it can rust without proper treatment.

Steel is more durable in high-moisture areas as it doesn’t absorb water, while wood is prone to warping, rotting, and mold without proper sealing.

Steel typically has a longer lifespan in construction due to its strength, durability, and resistance to environmental factors, whereas wood requires more maintenance.

Steel lasts longer with minimal maintenance, as it doesn’t need regular treatments like staining or sealing, unlike wood, which requires ongoing care to prevent deterioration.

Steel maintains its structural integrity longer than wood, as it doesn’t degrade from pests, rot, or weathering, making it a more reliable long-term choice.

![Second International Conference on Durability of Building Materials and Components, September 14-16, 1981 : preprints. 1981 [Leather Bound]](https://m.media-amazon.com/images/I/81nNKsF6dYL._AC_UY218_.jpg)