Wood's remarkable durability stems from its unique composition and natural protective mechanisms. Comprised primarily of cellulose, hemicellulose, and lignin, wood's cellular structure provides inherent strength and resistance to decay. Lignin, in particular, acts as a natural adhesive, binding cellulose fibers together and creating a robust framework. Additionally, wood's ability to withstand the test of time is bolstered by its natural defenses against pests and fungi. Many tree species produce resins, tannins, and other chemical compounds that deter insects and microorganisms, further enhancing wood's longevity. When properly treated and maintained, wood can endure for centuries, as evidenced by ancient wooden structures and artifacts that remain intact today.

| Characteristics | Values |

|---|---|

| Natural Durability | Certain wood species possess natural resistance to decay, insects, and fungi due to chemical compounds like tannins, resins, and oils. Examples: Teak, Cedar, Redwood. |

| Density | Denser woods have tighter cell structures, making it harder for moisture and pests to penetrate. Example: Mahogany, Oak. |

| Moisture Resistance | Woods with low moisture absorption rates and natural water-repellent properties last longer in humid environments. Example: Cypress, Cedar. |

| Resin Content | High resin content acts as a natural preservative, protecting wood from decay and insects. Example: Pine, Fir. |

| Tannin Content | Tannins are natural preservatives that deter fungi and insects. Example: Oak, Chestnut. |

| Heartwood vs. Sapwood | Heartwood, the inner part of the tree, is more durable than sapwood due to higher concentrations of protective chemicals. |

| Proper Drying and Treatment | Kiln-drying and pressure-treating wood with preservatives significantly extend its lifespan by reducing moisture content and adding chemical protection. |

| Environmental Conditions | Wood lasts longer in well-ventilated, dry environments with minimal exposure to moisture, sunlight, and extreme temperatures. |

| Maintenance | Regular sealing, staining, or painting protects wood from UV rays, moisture, and pests, prolonging its life. |

| Structural Integrity | Proper construction techniques, such as using stainless steel fasteners and avoiding direct ground contact, prevent premature decay. |

| Sustainability Practices | Responsibly sourced and managed wood from sustainable forests ensures long-term durability and environmental benefits. |

Explore related products

What You'll Learn

- Natural preservatives in wood resist decay and insect damage effectively

- Dense wood types like teak have longer lifespans due to structure

- Proper drying and treatment prevent moisture-related rot and warping

- Historical preservation techniques like charring enhance wood durability significantly

- Environmental conditions like low humidity slow down wood degradation

Natural preservatives in wood resist decay and insect damage effectively

Wood's longevity is not merely a product of its inherent strength but also its natural defenses against decay and insect damage. Certain tree species, such as cedar, redwood, and black locust, contain extractives—chemical compounds like tannins, resins, and oils—that act as built-in preservatives. These substances make the wood unpalatable to insects and resistant to fungal growth, significantly extending its lifespan. For instance, cedar’s high tannin content repels termites and moths, while redwood’s natural resins inhibit rot-causing fungi. Understanding these properties allows us to select wood types strategically for applications requiring durability without synthetic treatments.

To maximize wood’s natural resistance, consider the environment in which it will be used. Wood with high preservative qualities performs best in outdoor settings, such as decking, fencing, or garden beds, where exposure to moisture and pests is common. For example, black locust, known for its robust resistance to decay, is an ideal choice for posts buried in soil. However, even naturally durable wood benefits from proper installation techniques, such as ensuring good drainage and elevating structures to minimize ground contact. Combining these practices amplifies the wood’s innate defenses, reducing the need for chemical treatments.

While natural preservatives are effective, they are not invincible. Over time, weathering and prolonged exposure can diminish wood’s protective compounds. To counteract this, periodic maintenance is key. Applying a protective finish, such as linseed oil or a water-repellent sealant, can enhance resistance to moisture and UV damage. For added protection against insects, consider integrating physical barriers like mesh screens or gravel layers around wooden structures. These measures ensure that the wood’s natural defenses are supplemented, not replaced, preserving its integrity for decades.

Comparing naturally preservative wood to treated alternatives highlights its advantages. Pressure-treated wood, while durable, relies on chemical additives like copper azole or alkaline copper quaternary (ACQ), which can leach into the environment and pose health risks. In contrast, naturally resistant wood is eco-friendly, sustainable, and safe for use in food gardens or children’s play areas. For instance, a cedar raised bed not only lasts 15–20 years but also avoids the potential toxicity of treated lumber. This makes it a superior choice for those prioritizing health and environmental impact without compromising longevity.

Finally, leveraging wood’s natural preservatives requires thoughtful species selection and care. For high-moisture areas, choose wood with proven water resistance, like teak or cypress. In insect-prone regions, opt for cedar or redwood. Pairing these choices with simple maintenance—such as annual inspections for cracks or splintering—ensures the wood remains resilient. By respecting and enhancing its natural defenses, we can enjoy wood’s beauty and functionality for generations, proving that sometimes the best preservation methods are the ones nature provides.

Metal vs. Wood Box Springs: Which Material Offers Greater Durability?

You may want to see also

Explore related products

$23.71 $24.95

Dense wood types like teak have longer lifespans due to structure

Teak, a dense and highly durable wood, owes its longevity to its intricate cellular structure. Unlike softer woods, teak’s grain is tightly packed with fibers and natural oils, creating a barrier against moisture, insects, and decay. This density reduces the wood’s ability to absorb water, minimizing swelling, warping, and cracking over time. For instance, teak’s natural oil content, primarily composed of tectoquinone, acts as a built-in preservative, repelling pests and fungi that typically degrade wood. This structural advantage is why teak is often used in outdoor furniture, shipbuilding, and flooring, where exposure to harsh conditions is inevitable.

To understand why dense woods like teak outlast others, consider the role of lignin and cellulose in their composition. Lignin, a complex polymer, binds wood fibers together, providing rigidity and strength. In dense woods, lignin is more concentrated, enhancing the wood’s resistance to physical stress and microbial attack. Cellulose, another key component, forms the cell walls and contributes to the wood’s tensile strength. When these elements are tightly packed, as in teak, the wood becomes less permeable to water and less hospitable to organisms that cause rot. This structural integrity is not just a feature but a survival mechanism evolved over centuries.

Practical applications of dense woods like teak highlight their structural superiority. For example, teak’s density makes it ideal for decking on boats, where constant exposure to saltwater and UV radiation would quickly degrade lesser woods. Similarly, in outdoor furniture, teak’s ability to withstand temperature fluctuations and humidity without deteriorating ensures a lifespan of decades, often with minimal maintenance. To maximize the lifespan of teak or similar dense woods, avoid over-sanding or stripping away the natural oils, as this can expose the wood to damage. Instead, periodic cleaning with mild soap and water, followed by the application of teak oil, can help maintain its protective surface.

Comparatively, softer woods like pine or cedar lack the structural density and natural oils of teak, making them more susceptible to environmental damage. While treatments like pressure-treating or staining can extend their lifespan, they rarely match the innate durability of dense woods. For those seeking long-term solutions in construction or craftsmanship, investing in dense wood types is a strategic choice. However, it’s essential to source sustainably, as overharvesting of woods like teak has led to environmental concerns. Opting for certified sustainable teak or alternatives like ipe or cumaru can balance durability with ecological responsibility.

In conclusion, the longevity of dense woods like teak is no accident—it’s a direct result of their structural composition. From the tightly packed fibers to the natural oils, every element works in harmony to resist decay and damage. By understanding and leveraging these properties, individuals can make informed decisions in selecting materials for projects requiring durability. Whether building a deck, crafting furniture, or restoring a boat, dense woods offer a reliable solution that stands the test of time. With proper care and ethical sourcing, their benefits can be enjoyed for generations.

Drying Wood: Understanding the Timeframe for Perfectly Seasoned Lumber

You may want to see also

Explore related products

Proper drying and treatment prevent moisture-related rot and warping

Wood's longevity is often attributed to its natural resilience, but this durability is not inherent in all wood types or conditions. Proper drying and treatment are critical to preventing moisture-related rot and warping, ensuring wood structures and artifacts endure for decades, even centuries. Without these measures, wood becomes susceptible to fungal decay, insect damage, and structural instability, drastically reducing its lifespan.

The Science of Drying: Moisture Content Matters

Freshly cut timber contains up to 50% moisture, which must be reduced to 12–15% for optimal durability. Air drying, kiln drying, or solar drying are common methods, each suited to different wood types and applications. For instance, oak requires slower drying to prevent cracking, while pine can tolerate faster kiln drying. Improper drying leads to internal stresses, causing warping or splitting as moisture unevenly escapes. Kiln drying, though energy-intensive, offers precise control, reducing moisture content to desired levels within days to weeks, depending on thickness.

Treatment Techniques: Chemical and Natural Solutions

Once dried, wood benefits from treatments that repel moisture and deter pests. Pressure treatment with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) is widely used for outdoor structures. For eco-conscious applications, natural oils such as linseed or tung oil penetrate wood fibers, enhancing water resistance without toxicity. Heat treatment, such as thermomodification, alters wood’s cellular structure, reducing moisture absorption and improving dimensional stability. Each method has trade-offs—CCA is effective but contains arsenic, while natural oils require more frequent reapplication.

Practical Tips for Longevity

For DIY projects, seal all wood surfaces with a moisture-resistant finish, especially end grains, which absorb water most readily. Store wood in a dry, well-ventilated area during acclimatization to prevent mold. When using treated wood, wear protective gear to avoid chemical exposure, and dispose of scraps responsibly. Regularly inspect wood structures for signs of moisture intrusion, such as discoloration or soft spots, and reapply treatments every 2–3 years for outdoor use.

Comparative Analysis: Treated vs. Untreated Wood

Untreated wood in humid environments can rot within 5–10 years, while properly treated and dried wood can last 40+ years. For example, the historic Japanese temple Horyuji, built in the 7th century, showcases the longevity of naturally durable wood combined with traditional preservation techniques. In contrast, modern pressure-treated lumber in decking applications demonstrates how chemical treatments extend lifespan in harsh conditions. The key takeaway? Drying and treatment are not optional—they are essential investments in wood’s future.

Wood Sealer Drying Time: Factors Affecting Cure and Dry Time

You may want to see also

Explore related products

Historical preservation techniques like charring enhance wood durability significantly

Wood's longevity is a testament to its inherent resilience, but historical preservation techniques have unlocked its true potential. Among these, charring stands out as a transformative method that significantly enhances wood's durability. By exposing the surface to controlled heat, charring creates a carbonized layer that acts as a protective barrier against moisture, insects, and decay. This ancient practice, known as "Shou Sugi Ban" in Japan and "Yakisugi" in other cultures, has been used for centuries to preserve wooden structures, from temples to fences. The process not only extends the wood's lifespan but also imparts a distinctive aesthetic, blending functionality with artistry.

To achieve optimal results, the charring process requires precision. The wood is typically heated to temperatures between 200°C and 300°C (392°F to 572°F) for a duration that depends on the wood species and desired depth of charring. For example, softer woods like cedar may only need a few minutes, while harder woods like oak might require longer exposure. After charring, the wood is cooled and then brushed to remove loose particles, revealing a smooth, durable surface. This technique is particularly effective in humid climates, where moisture-related decay is a primary concern. By sealing the wood’s pores, charring minimizes water absorption, reducing the risk of rot and fungal growth.

One of the most compelling aspects of charring is its sustainability. Unlike chemical treatments that rely on preservatives with environmental drawbacks, charring uses only heat, making it an eco-friendly option. Additionally, the process can be applied to reclaimed or locally sourced wood, further reducing its environmental footprint. Historical examples, such as the charred wooden structures in Japan that have endured for centuries, demonstrate the technique’s effectiveness. Modern applications, including exterior cladding and furniture, continue to showcase its versatility and durability.

However, charring is not without its challenges. Over-charring can compromise the wood’s structural integrity, while under-charring may fail to provide adequate protection. Practitioners must balance heat exposure and timing to achieve the desired outcome. For DIY enthusiasts, investing in a propane torch or specialized charring tools can provide greater control over the process. It’s also essential to wear protective gear, including heat-resistant gloves and a respirator, to ensure safety during application.

In conclusion, charring is a time-tested technique that bridges tradition and innovation in wood preservation. Its ability to enhance durability while maintaining aesthetic appeal makes it a valuable tool for both historical restoration and contemporary design. By understanding and applying this method, we can ensure that wooden structures not only last longer but also retain their beauty and character for generations to come.

Drying Time for Pressure Treated Wood: What to Expect

You may want to see also

Explore related products

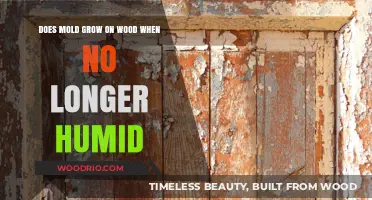

Environmental conditions like low humidity slow down wood degradation

Wood's longevity is significantly influenced by its environment, particularly humidity levels. In regions with low humidity, wood can endure for centuries, as seen in ancient Egyptian artifacts and Viking longships. The key lies in the reduced presence of moisture, which is essential for the growth of fungi and bacteria—the primary culprits in wood degradation. When humidity is low, these microorganisms struggle to thrive, slowing down the decay process. For instance, wood stored in arid desert conditions or within climate-controlled environments can maintain its structural integrity far longer than wood exposed to damp, humid climates.

To maximize wood preservation, consider the following practical steps: store wood in areas with relative humidity below 50%, use dehumidifiers in enclosed spaces, and ensure proper ventilation to prevent moisture accumulation. For outdoor applications, treat wood with moisture-resistant coatings or sealants, and elevate structures to minimize ground contact. These measures create an environment hostile to decay agents, effectively extending the wood's lifespan.

A comparative analysis highlights the stark difference between humid and dry environments. In tropical regions with high humidity, untreated wood can deteriorate within a decade due to relentless fungal and insect activity. Conversely, in arid climates like the Atacama Desert, wood remains virtually unchanged for millennia. This contrast underscores the critical role of humidity in wood preservation, offering a clear takeaway: controlling moisture is paramount for longevity.

From a persuasive standpoint, investing in humidity control is not just a preservation tactic—it’s a cost-effective strategy. The expense of dehumidifiers or sealants pales in comparison to the cost of replacing degraded wood structures. Additionally, preserving wood reduces the demand for new timber, contributing to sustainable forestry practices. By prioritizing low-humidity conditions, individuals and industries alike can safeguard wood resources for future generations.

Finally, a descriptive exploration reveals the science behind this phenomenon. Low humidity deprives decay-causing organisms of the water they need for metabolic processes, effectively stalling their activity. Simultaneously, dry conditions minimize the swelling and shrinking of wood fibers, reducing structural stress and cracking. This dual action—inhibiting biological decay and preventing physical damage—explains why wood in low-humidity environments remains robust and durable over time.

Into the Woods Musical Duration: A Comprehensive Guide to Its Length

You may want to see also

Frequently asked questions

Wood can last a long time in environments where it is protected from moisture, insects, and fungi. When wood is kept dry and well-ventilated, it is less susceptible to decay, allowing it to endure for centuries, as seen in ancient wooden structures and artifacts.

Wood preservation techniques, such as pressure-treating with chemicals, using natural oils, or applying sealants, protect it from rot, pests, and weathering. These methods create a barrier that slows down degradation, significantly extending the wood's longevity.

In oxygen-free environments like bogs, the lack of oxygen prevents bacteria and fungi from breaking down the wood. This anaerobic condition acts as a natural preservative, allowing wood to remain intact for millennia.

Yes, the type of wood plays a crucial role in its durability. Hardwoods like oak and teak are naturally more resistant to decay due to their dense structure and natural oils, while softwoods like pine may require additional treatment to last as long.